Previously, when the heating system was a stove, there were no problems getting rid of soot. And such a profession as a chimney sweep was held in high esteem. Now many people use boilers as a heating system. But in order to ensure uninterrupted operation, you need to observe simple conditions and clean them on time, as well as carry out preventive inspection of the equipment.

How to clean the fire tube heat exchanger of a single-circuit boiler

Cleaning floor-standing boilers with a fire tube heat exchanger differs from the same procedure for mounted equipment.

Here, to carry out the procedure, the heat exchanger is not removed, but only access to it is provided. To complete the work you will need the following tools:

- open-end wrenches;

- metal brush;

- hand brush for metal;

- screwdriver;

- natural bristle brush or nylon brush.

The first mandatory action is to turn off the gas supply valve. Next, you need to complete three stages of work - providing access to the heat exchanger, cleaning parts, and assembling the boiler. The disassembly/assembly steps depend on the specific model. How to clean boilers of the MAYAK-12 KS model can be seen in detail in the video.

Boiler cleaning

When the chimney becomes dirty, as a rule, automatic control systems are activated, notifying residents of problems with smoke removal and the need to clean the system. This is not provided inside the boiler, and you must monitor its contamination yourself so that poisoning from combustion products does not occur and the device continues to function normally.

Before cleaning the boiler, you must turn off the gas and power supply, wait until the boiler has completely cooled down, and then carefully disassemble it. Cleaning can be carried out in two ways - chemical and mechanical.

Chemical cleaning

The first option is less dusty and faster. Sulfamic and adipic acids, as well as special gels, are used. But chemicals corrode not only the soot itself, but also the metal of the boiler. This harmful effect can be reduced by diluting cleaning products, but it will not be possible to make them completely safe for metal. This is how it is recommended to clean only small stains that do not require prolonged exposure to the metal.

If, nevertheless, it is decided to use the chemical method for large accumulations of soot, then neat grooves are left on their surface with a brush or scraper, which will help the solvents to better penetrate the soot. The acids are diluted in water and pumped under pressure into the boiler container, then they are washed out with a large amount of water.

Mechanical cleaning

This cleaning method involves physical separation of soot from the surface.

It is also imperfect - it is a long process, and if handled carelessly, it is also harmful to the boiler. Trying to remove soot, its walls can be severely scratched, which will lead to accelerated corrosion of the metal

To prevent this, choose items for cleaning that do not have sharp corners. Tools for mechanical cleaning of the boiler are often included with it - these are scrapers, wire brushes, and pipe cleaners.

They clean the boiler either simply with brushes, or use various abrasive substances with them. For a thin layer of soot of 1-2 mm, ordinary soda is also suitable.

In addition to soot, cleaning will also remove salts that have settled from the water - scale. This scale must also be removed from time to time by cleaning the boiler heat exchanger, mechanically or chemically. During mechanical cleaning, it is regularly washed with running water, and during chemical cleaning, acids are pre-mixed with water and heated. Gel chemicals do not need to be diluted but are added directly to the cooled heat exchanger. They are slightly less effective, but at the same time less aggressive towards metal.

Filling the boiler with water, boiling it and then draining it will help to significantly reduce the amount of soot. Many boilers also provide air cleaning - there are holes for supplying air under pressure.

Why does soot form in the chimney?

When fuel burns, it releases products that are carried away by the flow of furnace gases. Sometimes they do not evaporate completely, settling on the walls, clogging the passage.

The reason may be:

- Burning damp wood. Due to increased humidity, active evaporation occurs. The vapor moves through the chimney and mixes with the cooled air flows. As a result, condensation settles on the walls. Due to the acid content in the vapor, carbon deposits form. It can be difficult to get rid of it.

- Use of unsuitable fuel. Waste consisting of wood and binding fillers, such as plywood, is not suitable for combustion. They release a lot of resins, which settle in large quantities on the walls of the chimney.

- Use for burning household waste. Such fuel always contains polyethylene or plastic packaging. When burned, garbage releases many harmful chemicals that quickly clog the chimney.

- The chimney is cold. It was noted that a certain temperature can trigger the formation of condensation. As a result, a layer of soot appears on the walls inside the structure.

- Horizontal pipe sections. A large amount of soot is formed in the bends of the structure. Therefore, when installing the pipe, the horizontal installation method should be avoided. But if there is no other way out, cleanouts are installed in the fold areas. They will allow you to open the knee and remove soot.

- Roughness of wall surfaces. If the channel was not mopped when laying the structure, this will cause unevenness in the chimney, where soot will clog.

The first three points apply only to wood-burning stove heating.

Disassembly and soot removal

For efficient operation of the equipment, it is necessary to clean the gas water heater. The deposits formed on the walls can disrupt the uninterrupted operation of the device, so there is no need to wait for the equipment to completely fail; preventive cleaning should be carried out periodically.

Before dismantling, it is necessary to block access to gas and water. Do-it-yourself cleaning of a gas water heater begins with removing the boiler doors and disconnecting the auto-ignition wire. Then the thermocouple, piezoelectric element and burner tube are removed

Carefully remove the nozzle and the burner itself

The thermometer sleeve, boiler lid, and flue are removed. Cleaning the geyser is done using a brush and brushes, which clean all internal and external elements. The nozzle hole is cleaned with a needle with a smaller diameter to avoid enlarging the hole and disrupting the combustion mode. The internal channels of the heat exchanger are blown out with a vacuum cleaner and wiped with a damp cloth.

At the same time, you can carry out minor repairs to the heat exchanger yourself: replace the gasket under the pilot burner, check the thermocouple, which is prone to breakdowns due to the specifics of its operation, and so on. Such work does not require large investments, but maintains the boiler’s performance at a high level, and the thermocouple device is quite simple, and replacing the element will not be difficult.

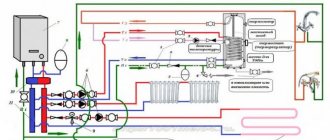

Structure of a gas boiler

Assembly is carried out in reverse order. When connecting the piezoelectric element, it is recommended not to use a tool to avoid damaging the ceramic base; it is better to tighten it by hand.

When installing, you need to check the thermocouple on the gas boiler; you need to know that the end of the conductors must be at the level of the place where the flame appears.

Where to begin

Before you start cleaning a gas boiler, it is worth understanding how this equipment is equipped. It contains the following components that require periodic cleaning:

- burner with nozzles;

- igniter;

- heat exchanger;

- gas filter;

- firebox;

- chimney.

To clean the equipment, you will need to prepare all the necessary tools:

- plastic or metal brush for cleaning the chimney;

- scrapers;

- steel rope;

- special hooks;

- holders for brushes of various lengths.

The cleaning process itself will be reduced to the following steps:

- Closing the gas supply valve.

- I dismantle the boiler door, nozzles, and burner tube.

- Removing the top cover of the equipment.

- Removing the insulation sheet.

- Carrying out the dismantling of the chimney.

- Choosing a metal brush.

- Carefully clean the heat exchanger from soot.

- To clean the heat exchanger channels, use a vacuum cleaner.

- Cleaning the walls of the boiler with a scraper and brush and wiping with a rag.

- We clean the chimney using a brush with a long handle.

- Reassemble all boiler components in reverse order.

Attention: when disassembling gas equipment, carefully remember the location of all parts and components.

How to clean individual units of the unit

Let's look at how to clean individual components of the unit if they become clogged and stop working properly.

When the igniter is in normal condition, the flame will have a blue tint. If, during operation of the heating equipment, the flame turns yellow, it’s time to clean the igniter. The procedure for cleaning the igniter boils down to:

- Blocking the flow of gas to the equipment.

- Unscrewing the igniter.

- Thoroughly clean the igniter from soot and dirt with a wire brush.

- Blowing out the igniter.

- Installing it in its original place.

If you need to clean the burner with nozzles, you will need:

- Shut off the gas supply.

- Remove the burner.

- Carefully remember the location of the injectors and carefully unscrew them.

- Clean the injectors with a brush.

- Clean the burner with a brush.

- Blow out the burner hole with pumping equipment.

- Insert the injectors into place.

- Install the burner.

Important : the burner with nozzles must be cleaned at least once a year, before the start of the heating season. The gas filter cleans the gas from impurities and contaminants and must be cleaned regularly.

The heat exchanger can become clogged both inside and outside. Its outer part becomes dirty with soot, and its cleaning is carried out mechanically. To effectively clean the heat exchanger, you will need to stock up on the following tools:

- scraper;

- wire brush;

- ruffs of various shapes;

- power tools and cleaning attachments.

The cleaning procedure boils down to:

- Disconnecting the boiler from electricity and gas supply.

- Removing the heat exchanger.

- Clean it with previously prepared tools.

- Installing the unit in its original place.

Attention : when cleaning the heat exchanger, it is recommended to use a tool without sharp edges. If the unit is damaged, it will lead to corrosion.

The cause of internal clogging of the heat exchanger is most often scale and will require dry cleaning using:

- adipic acid;

- sulfamic acid solution;

- special gel.

Attention : it is necessary to select chemicals depending on the degree of contamination of the heat exchanger.

As for cleaning the firebox and chimney, the collection of soot on their walls reduces the functioning of the boiler, so it is recommended to clean the chimney soot regularly.

How often should the boiler be cleaned?

The technical documentation for the boiler indicates how often it needs to be serviced. For closed circuits with the addition of reagents (single-circuit heating boilers), cleaning is required less frequently. It can be performed once every 2-3 years. The bithermic and secondary heat exchanger must be washed every year, and under difficult operating conditions (“poor” water composition) – twice a year.

Signs that the boiler urgently needs cleaning:

- the boiler slowly gains temperature;

- insufficient traction;

- the burner does not ignite or burns poorly;

- with the same gas consumption, the heat transfer is less;

- traces of soot or partially burnt paint in the area of the viewing window.

You should not neglect preventive measures, because this can result not only in broken equipment, but also a threat to the safety of all residents of the house. Clogged smoke exhaust ducts and pipes with build-up inside can cause serious accidents.

The nuances of cleaning a gas boiler

When starting cleansing you need to know that:

Boilers should be flushed when they are completely disconnected from electricity, gas and water. When dismantling the heat exchanger, you must try not to damage the sealing elements; failure to seal will lead to leaks and breakdown of the unit. Care must be taken when cleaning the heat exchanger; the thin tubes on the inner surface may be damaged. A control check for the tightness of connections can be carried out by coating the joints with a soap solution. When washing, it is recommended to add stabilizers to aggressive solutions. reducing the acidic effect on the metal and forming a protective film on the surface of the element.. It is best to rinse the heat exchanger of a gas boiler with special reagents that will be gentle on the material of the unit and qualitatively remove all contaminants

It is best to rinse the heat exchanger of a gas boiler with special reagents that will be gentle on the material of the unit and efficiently remove all contaminants.

Master Boiler Power - the product removes iron oxide and calcium carbonate deposits, does not affect gaskets and seals, the process is accompanied by active foaming, works at a temperature of 20 - 40 ° C. Cleaning is considered complete when foaming stops.

Zinconex Powder - removes almost all deposits, contains a color indicator that allows you to control the degree of washing. Compatible with aluminum, galvanized, copper, steel and cast iron surfaces.

Fauch 200, Fauch 610 – spray (aerosol) designed to remove soot from the walls of boilers and heat exchangers.

Effective soot remover HANSA - is a mixture of crystals that burn in the firebox when ignited. It is designed to clean boiler and chimney elements from soot and resinous deposits; it reacts with them, destroying the structure of deposits.

Periodically washing the heat exchanger of a gas boiler with your own hands will save costs on electricity, fuel and replacement of expensive parts, and will also extend the life of the unit.

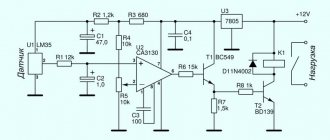

Do-it-yourself booster for washing heat exchangers

clean the gas water heater

heat exchanger for gas boiler

What is the difference between chemical cleaning and mechanical cleaning?

Gas equipment can be cleaned in the following ways:

- mechanical;

- chemical;

- electric discharge;

- hydrodynamic.

Mechanical cleaning is carried out using various brushes and scrapers using physical force.

The process is quite lengthy and must be carried out with care so as not to damage equipment parts. As a rule, tools for mechanical reading of the unit come with it.

These include: wire brushes, brushes and scrapers.

Mechanical cleaning of the boiler is carried out with brushes and abrasives. If the soot layer is small and is no more than 1-2 mm, you can use simple soda

Please note that when cleaning the boiler, it is necessary to remove not only soot, but also scale from the water. You can clean scale from the heat exchanger mechanically or chemically

Mechanical cleaning involves regular washing of the heat exchanger with running water, and chemical cleaning involves the use of acid mixed with water.

Experts recommend using dry cleaning only for heavily soiled areas - chemicals corrode not only soot, but also metal. Although diluting chemicals with water reduces the harmful effects on the metal, it is impossible to make them completely safe.

Heat exchanger flushing methods

When choosing a washing method, they usually rely on their own capabilities and knowledge. Let's look at three generally accepted methods.

Method #1 - manual cleaning

To perform this, it is necessary to carefully remove the heat exchanger from the boiler, otherwise there will be no free access to contaminated surfaces. Next, we choose either mechanical cleaning or washing with solutions. To remove deposits mechanically, you will need a scraper, brush and vacuum cleaner. For flushing, which is good for double-circuit boilers, use a salt-dissolving liquid.

When cleaning manually, all actions must be careful and careful. When installing the heat exchanger in place, you should carefully check the tightness of the connections.

After removing the heat exchanger from the boiler body, you will understand that the inner surface of its main part - the curved pipe - needs to be cleaned, and it will be extremely problematic to carry out complete cleaning manually

Method #2 - chemical solution through a booster

It involves the use of special equipment - a booster, with which an acidic washing solution is pumped into the heat exchanger. It is passed through the pipes several times over a long period of time; as a result, the deposit dissolves and is removed along with the flushing liquid. As a result, throughput and thermal conductivity indicators increase. Even the most persistent contaminants - salt deposits of carbonate and deposits of ferric iron - can be treated with an acidic solution. The remaining acid in the pipes is neutralized with a special solution, which is finally released into the heat exchanger.

Method #3 - hydrodynamic flushing

Does not require equipment disassembly. It consists of pumping in water (in some cases with an abrasive filler) and then pumping up pressure. The movement of fluid at increased speed causes the destruction of deposits, which are eventually discharged. There is a danger of exceeding critical pressure levels, which could result in pipe rupture.

It is not recommended to clean the heat exchanger yourself. The best solution is to contact professionals who are certified to work with gas equipment. Knowing the cleaning methods and sequence, you will be able to control the work of specialists.

Prevention and repair of gas equipment by specialists guarantees that high-quality equipment, proven materials, safe technologies will be used - and all this in compliance with standards

Negative effects of deposits and cleaning frequency

If you do not regularly clean the boiler, negative consequences cannot be avoided. First of all, heat transfer rates decrease. The room will warm up slowly and the heat will spread unevenly. The next disadvantage is that you will need to use more fuel, and costs will increase accordingly.

A solid fuel boiler that is not promptly cleaned of ash, soot and tar will not last very long, since its main elements responsible for high-quality heating will quickly fail.

By regularly cleaning the pyrolysis boiler, you will ensure not only its efficient operation, but also increase its service life.

The frequency of cleaning procedures for a solid fuel boiler depends on the quality of the fuel used.

If you use high-quality firewood, coal, etc., then it will be enough to clean the unit once every 30-40 days. If you use low quality fuel with high humidity, then the boiler must be cleaned at least once every two weeks.

https://youtube.com/watch?v=AzjiVKtEHCY

https://youtube.com/watch?v=AzjiVKtEHCY

You can read about the features of pellet boilers here.

How to clean a burner with nozzles

The burner is the most important part; it must be perfectly clean, otherwise there will be no fuel savings. This applies to any type of boiler: wall-mounted or floor-mounted.

- the gas supply must be shut off;

- the burner is removed from the boiler;

- unscrew the nozzle (it’s convenient to take a photo before doing this so you know how to put the nozzle back);

- The nozzle is carefully cleaned with a soft brush;

- The burner is cleaned with a brush;

- The burner holes are purged with any pump (regular bicycle or car);

- the nozzle is inserted back into the burner (do not confuse its location);

- The burner and nozzle are put in place.

Mechanical cleaning of plate heat exchangers

You can clean the boiler from soot without removing the heat exchanger. To do this, just remove the cover, arm yourself with a stiff nylon brush and close the gas injectors so that dirt does not get in there. The whole process is clearly shown in the video:

If soot has stuck to the surface and is not removed by mechanical treatment with a brush, then the heat exchanger is removed and soaked in special cleaning solutions for several hours. Such products are available for sale in a wide range, examples include Fauch and MAZBIT+ products. But you can also use household chemicals - gels for cleaning grills and ovens.

Before disassembling the boiler, you need to disconnect it from gas and the igniter from electricity. In addition, it is necessary to drain the water from both circuits and the expansion tank. The secondary heat exchanger is removed first; it is located immediately behind the boiler lid. The primary (main) one is more problematic to remove, since you will have to disassemble the combustion chamber.

Subtleties of cleaning a stainless steel chimney

Stainless steel structures have a good internal surface quality. The characteristics of the chimney allow the condensate to drain into a special collection tank. It is necessary to periodically empty it and dispose of the liquid. This helps prevent soot from appearing. But this does not prevent stainless steel models from developing carbon deposits.

Blockage in the chimney

If you find it, it is recommended to remove it. For this:

- You will need a brush on a flexible round shaft. It must be placed in the pipe through the hole in the tee. The tool must be rotated using an electric drill. You must act carefully. As you move forward, the drive shaft must increase in length. This will allow you to completely clean the entire pipe.

- If the soot has formed quite stable, it is recommended to use burning. To do this, use a blowtorch. The chimney is first dismantled. Then burning is used. It is enough to set the temperature to 800-900 degrees.

It is recommended to check the quality of the stainless steel construction before starting cleaning. It is important to correctly define the class. This affects the ability to use different cleaning methods. High-quality stainless steel will not be magnetic. This can be cleaned using the specified means and not worry about its safety.

If sandwich pipes are used, there is rarely a need to clean them. This is due to a working condensate removal system. But if the need arises, then the tool you should use is a long cylinder-shaped brush equipped with a flexible drive cable. It should rotate using an electric motor, which will allow the structure to be thoroughly cleaned.

Another suitable cleaning option is to dismantle the chimney. Then it is enough to process each part separately.

How to clean interior surfaces

Washing the inner surface of a plate, fire tube or bithermal heat exchanger is possible only with the help of special equipment.

- High pressure pump – hydrodynamic flushing. Used to remove small deposits. Advantages are the speed of the procedure and the ability to clean without removing the heat exchanger.

- Booster (acid-resistant pump) – acid (chemical) flushing. Removes even old scale. Advantages – removes scale that cannot be removed by other methods. Disadvantages - if the reagents (acids and neutralizers) are selected incorrectly, it reduces the service life of the heat exchanger.

- Complex "Streamer" for electric discharge cleaning. Used to remove scale of any strength. Advantages - the metal of the heat exchanger is not destroyed, a high degree of cleaning is ensured. Disadvantages: noise and duration of the procedure.

Of all the methods listed above, only chemical cleaning is possible at home, since the factory booster can be replaced with a low-pressure pump. The rest of the equipment is both expensive and voluminous, so such boiler washing can only be carried out by service centers.

Boiler cleaning prices

We offer professional cleaning and chemical flushing services for industrial and domestic boilers. The cost of services consists of the price of reagents, transportation costs, as well as the cost of the team’s work to prepare the equipment and wash it. A transparent estimate is drawn up, which reflects the prices of all stages of work on the service.

The RusWater company has an SRO Certificate and has the right to conduct chemical flushing of boilers. Our specialists will assist in the development of a project for acid washing of boilers; upon completion of the work, a report on the chemical conduct will be drawn up. boiler flushing. We use modern equipment and have the most effective reagents at our disposal. All work is carried out efficiently, on time and with a guarantee of safety.

How to clean a gas boiler: procedure for each unit and do-it-yourself cleaning video

An indispensable attribute of any heating system is a boiler, which acts as a heat generator for heating the home.

The modern heating equipment market is saturated with a very wide range of boiler units of various types. But gas boilers occupy a special place in this range. which are gaining more and more popularity every day.

This trend is due to the fact that units of this type are very effective and economical devices for heating a country house or even an apartment. In order for a gas boiler to function smoothly and stably, it is necessary to properly care for it.

One type of such maintenance is cleaning the gas boiler from soot and other contaminants. Let's talk in more detail about why to clean a gas unit, as well as in what ways this can be done.

An effective way to descale

To carry out the highest quality cleaning of equipment, you can use a modern device - a booster. It will effectively solve the problem of how to flush a gas boiler from limescale.

What does the booster include:

- circulation pump;

- container for loading reagents;

- electric heating part.

The booster functions as follows:

- the reagent is heated in a special container (in order to increase its cleaning properties);

- the circulation pump pumps the heated reagent into the coil;

- chemicals circulate through the heat exchanger and clean the walls;

- the spent reagent with dirt pours out.

Advice. The booster will also help out in cases where you need to clean not only the heat exchanger, but also the pipes of the entire system, or heating radiators.

The heat exchanger must be cleaned regularly, at least once a year. However, this procedure can be repeated more often if the quality of the coolant is very low. If ordinary tap water is poured into the system, then it is very simple to determine this: observe how quickly scale forms on the kettle. Hard water “suffers” from this deficiency.

Boilers of any model can suffer from scale. How to clean a Baxi boiler at home if there is no way to understand its structure? In this case, the best solution is to contact gas boiler specialists.