Between November and April, in much of our country, the cost of heating a home often exceeds other utility bills. Therefore, even at the stage of designing a home, it is necessary to determine the most economical method of heating a private house. The choice may vary depending on the availability of connection to centralized gas and electricity supply networks, as well as energy prices.

When calculating the total cost of heating, take into account:

- network connection costs;

- the cost of equipment, materials and installation of the heating system;

- energy price;

- depreciation expenses.

Indirect costs, for example, for the construction of a firewood or coal storage facility are included in the cost of utility premises.

Return on investment in reducing heat loss

All consumed heat leaves the house through building structures: floors, walls, ceilings, roofing and windows (doors).

A visual representation of heat loss in a private home.

You can understand how effective thermal insulation is by using heat loss calculators.

Example. A one-story house 6x6 m with a wall height of 3 meters made of expanded clay concrete blocks 40 cm thick, covered with a 20 cm concrete slab. The wall area will be 72 m2, the ceiling area will be 36 m2. The difference between the outside and room temperature is 40 °C (outdoors -20, indoors +20).

Without taking into account windows and doors, heat loss through building structures will be approximately 20 kW (8.7 through the walls and 12.2 through the ceiling).

If you insulate the walls with 100 mm thick polystyrene foam and the ceiling with 50 mm polystyrene foam, then the losses will be reduced to 3 kW (1.4 through the walls and 1.6 through the ceiling).

Even the most approximate calculations show that insulation with modern materials can reduce energy costs by more than 5-7 times.

Replacing one window with an area of 2 m2 with a wooden frame with a two-chamber one made of plastic gives an annual fuel saving of about 350 rubles. On average, it is believed that plastic windows pay for themselves in 8-10 years of operation. Already at the design stage, they plan the placement of rooms, windows and doors, taking into account the cardinal directions.

Conclusion: insulating a house reduces current heating costs several times. The insulation lasts up to 50 years, and the investment pays off in 2-4 years, which is much more effective than saving on the heating system.

Boiler installation instructions

Strict requirements are put forward only for the installation of gas-powered heaters. But we recommend following these rules when installing any heat generators:

- Equipment with a power of up to 60 kW can be placed in a kitchen with ceilings of 2.5 m (minimum). More powerful units are moved to a technical room - internal, attached or free-standing.

- The requirement for furnace ventilation is threefold air exchange, that is, the amount of supply and exhaust air is equal to three volumes of the room in 1 hour. The kitchen window is equipped with a window.

- When placing a floor-standing boiler, observe the minimum technological passages - 1.25 m in front, 60 cm on the side, 250 mm in the back from the nearest building structure, as shown in the photo.

- The distances from the wall-mounted heat generator to the walls or cabinets are 20 cm on the side, 45 cm on the top, 300 mm on the bottom. Before hanging, a protective sheet of roofing steel is laid on the wooden wall.

- The height of the chimney is 5 m, calculated from the grate or gas burner, not from the ground. The head of the pipe should not fall into the wind support zone of the roof.

- The maximum number of turns of the chimney is 3, the distance from the chimney to combustible structures is 0.5 m.

Clarification. Double-walled sandwich-type chimneys can be placed at a distance of 38 cm from wooden walls and ceilings.

The heat generator piping depends on the fuel consumed. High efficiency boilers - gas, diesel - are connected to the system directly through shut-off valves. Floor-standing versions are additionally equipped with an external expansion tank and pump.

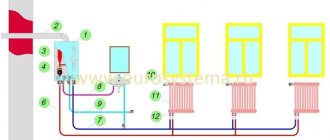

Typical wiring diagram for a double-circuit wall-mounted heat generator

Solid fuel units must be protected from cold return flow and condensation; accordingly, a small boiler circuit with a three-way mixing valve is provided. Please note: the pump is always installed inside the circuit, on the supply or return line - it makes no difference. Detailed wiring diagrams are shown in the instructions for connecting TT boilers.

Important! In a closed system operating under pressure, there is always a safety group - a pressure gauge, an automatic air vent and a safety valve. The installation point is the supply pipe at the boiler outlet. To prevent dirt and sand from getting inside the heat exchanger, a filter - a mud filter - is placed on the return line in front of the heater.

Other ways to improve heating efficiency and economy

If you are only interested in the type of fuel, scroll here. But we think it's good to start with the basics. The fight for efficiency is possible not only through reducing losses, but also in other ways:

- correct choice of type and type of heating;

- compliance with equipment installation rules;

- the use of temperature sensors associated with heating equipment;

- installation of shut-off and control valves;

- installation of energy efficient appliances;

- timely maintenance.

Completing each item can save from 2 to 5% of energy resources, and in total reduce costs by up to 20%.

Types and types of heating systems

A properly selected system allows you to use the selected fuel with the greatest benefit.

A pictorial diagram of a typical single-pipe heating system.

Single-pipe wiring is optimal for small houses with 3-4 radiators in the circuit. A small number of pipes minimizes inefficient heat transfer through their walls.

Diagram of a typical two-pipe heating system in a private house.

Two-pipe wiring ensures uniform heating of all radiators. There is no need to increase the boiler power and energy consumption, since in the farthest room the temperature is maintained at the desired level.

Houses with up to 2 floors and an area of up to 150 m2 can be effectively equipped with a non-volatile gravity-type system that does not require circulation pumps and expensive expansion tanks.

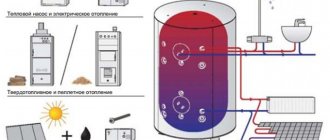

In regions with electricity tariffs that depend on the time of day, it is beneficial to install high-capacity hydraulic accumulators. At night, the boiler heats the water, and after connecting to the daytime tariff, heating occurs for about 2-3 hours due to the circulation of coolant from the hydraulic accumulator.

Rules for installing radiators

Proper placement of radiators allows you to avoid a decrease in heat transfer:

- leave 50-70 mm to the floor;

- to the outer wall from 30 mm;

- to the window sill at least 80 mm.

Exact recommendations are indicated in the device data sheets. Approximate heat transfer losses for various placement options are shown in the figure below.

Changes in the thermal power of the radiator depending on the placement and presence of a screen.

The decrease in temperature is compensated by installing radiators with a large number of sections. The volume of circulating coolant increases, which will require additional fuel to heat up.

Diagonal connection method.

Side connection method.

Bottom connection.

You can increase the efficiency of heat transfer by using diagonal connections of radiators. Side connection reduces heat transfer, but is best suited for gravity systems. Radiators with bottom connections are least effective - this can be considered a “payment” for invisible pipes hidden in the floor or wall.

Temperature sensors

The control units of gas and electric boilers react to the temperature of the coolant, which does not allow timely adjustment of the intensity of work when weather conditions change. Modern boilers allow the connection of remote air temperature sensors in the room, which more objectively reflects the need to increase or decrease the power of the equipment.

A boiler with connected sensors and timers maintains the required temperature at night and when the owners are absent, which also reduces heating costs.

How to choose a room thermostat and save up to 30% per month on heating

Adjustment fittings

With any type of pipe layout and radiator connection, it is possible to change the heat transfer of the device.

Install manual or automatic regulators. This allows some rooms to maintain a lower temperature, which affects energy savings.

Radiator efficiency

Modern radiators have a power of one section from 100 to 210 W. When purchasing, pay attention to this parameter indicated in the device passport. Additional sections are filled with coolant, which will have to be heated and moved through pipes using a more powerful circulation pump, which increases costs.

Heat transfer from heating radiators Comparison of indicators and calculation methods

Maintenance

The formation of calcium deposits on the internal walls of the heat exchanger and radiators reduces the efficiency of the equipment.

It is important to use clean, soft water or antifreeze recommended by the heating equipment manufacturer. It is necessary to monitor the condition of the coarse and fine coolant filters, as well as the purity of the water (antifreeze).

How to choose a water softener for a gas boiler and extend the life of the heat exchanger

Radiators or water convectors, which is better?

Convectors are based on the principle of heating a room through air flow. It heats up as it passes through the body of the heating installation. In turn, radiators heat the room by radiating heat from the surface body.

Radiators have gained great popularity. Their operating principle can be compared to the operation of a Russian stove.

Convectors are heating panels; they heat a space using the movement of cold and warm air masses. The convector includes a pipe in which the coolant is located. The pipe is framed by ribs, plates that heat the surrounding space. The plates are often made of copper or steel. Convectors are divided into external and built-in. The first type of convectors is mounted on the wall, the second can be mounted along the floor or wall. Convectors also include warm baseboards. This device is an excellent solution for people who do not want to depend on public heating systems.

Convectors are used as additional and main heating; they are especially indispensable in places where standard radiators are not used. For example, built-in convectors in the floor are also located along sliding doors and glass walls. Convectors heat a room much faster and cool it down faster. The devices are durable in use.

If it is better for you when heating a private house when the room warms up faster and more evenly, then install convectors. The most common options are steel radiators (60% convection) or copper-aluminum (90% convection). If these points are not important, then install regular radiators.

Common heating system options

Traditional types of fuel are:

- wood: firewood, pallets, sawdust and chips;

- coal of various types;

- natural gas (from a centralized pipeline);

- liquefied gas in cylinders or gas tank storage;

- electricity.

Table. Calorific value of various types of fuel.

| Fuel | Unit | Specific heat, kcal | Released thermal power, kW | Compliance with 1m3 of natural gas | Cost of fuel to produce 1 kW of energy, rub. |

| Electricity | 1 kW/h | 864 | 1,0 | 0,11 | 2,8–5,6 |

| Natural gas | 1 m3 | 8000 | 9,3 | — | 0,8 |

| Liquefied gas | 1 kg | 10800 | 12,5 | 1,35 | 2,3 |

| Coals: hard, anthracite, charcoal | 1 kg | About 6500 | 7,5 | 0,8 | 1,4 |

| Brown coal | 1 kg | 3100 | 3,5 | 0,4 | 1,8 |

| Peat | 1 kg | 2500–4200 | 3,0–4,9 | 0,3–0,5 | 1,8–2,5 |

| Firewood | 1 | 1800–4000 | 2,2–4,8 | 0,25–0,6 | 1,3–1,8 |

| Pallets, granules | 1 kg | 3400–4300 | 3,7–5,0 | 0,4–0,6 | 1,5–1,9 |

The cost may vary depending on the tariffs in force in the region and the price of fuel purchased from private suppliers, as well as the efficiency of a specific boiler model.

The cheapest fuel is mains gas, the most inefficient from an economic point of view is electricity.

The most economical heating method remains a gas boiler

Modern wall-mounted models can also be placed in a kitchen cabinet, completely hiding it from view.

High calorific value and low price make main gas an optimal fuel.

The advantage of installing gas boilers will only increase if the Presidential Order on free gas pipeline installation to individual areas is implemented.

Table. Advantages and disadvantages of gas boilers.

| Advantages | Flaws |

| Low price | Strict requirements for the combustion room |

| Possibility of connecting different heating schemes: gravity and forced, vertical and horizontal, one- and two-pipe | Mandatory paid technical maintenance in a specialized organization |

| Availability of electrically independent models | Difficulties in ensuring the removal of combustion products and the supply of combustion air |

| Interchangeability, availability of spare parts | |

| Wide range of models: floor-mounted or wall-mounted, single- or double-circuit with heating of sanitary water, various powers, with a closed or open combustion chamber, convection and condenser | |

| Presence of Gazprom operating organizations in every locality |

Gas boilers with a capacity of 24 kW cost from 35 thousand rubles. Such equipment heats and supplies houses with an area of up to 150-180 m2, which are in demand by families of 3-4 people.

In areas without a centralized gas pipeline, an individual or group gas tank is installed. Equipment and installation will cost about 70 thousand rubles per 1 m3 of storage. Heating an insulated house of 150 m2 will require consumption of about 4.5 tons of fuel per year. Refueling is usually carried out 2 times a year, so choose a capacity of 2.5-3 m3.

The price of a complete set of equipment will be about 150 thousand rubles, and installation costs from 100 thousand rubles.

For natural or liquefied gas, the same boiler models are used, only the types of nozzles are replaced.

Efficient gas boilers

In areas with frequent power outages, preference is given to non-volatile boilers. The automation unit is built on the basis of a thermocouple. While the wick is burning, the gas supply valve to the burners is open. If the gas is turned off, the wick will go out, the valve will shut off the supply, and the boiler will turn off. Restarting is only possible in manual mode.

The main part of the front panel of an electrically independent gas boiler.

Attention! Non-volatile boilers are used only in gravity systems or in case of reliable backup of the power supply to the circulation pump.

Boilers with an electronic control circuit turn off when there is a loss of gas or electricity in the network and automatically turn on when the power supply is restored, they are safe, and the heating circuit can be constructed by any means.

The efficiency of most gas boilers is in the range of 80-94%. Considering the same schemes for constructing automatic boilers, we should talk not about efficiency, but about the price/quality ratio - how long the equipment will last and how expensive repairs will be.

The most famous manufacturers of high-quality gas boilers:

- Vaillant;

- Bosch;

- Protherm;

- BAXI;

- Viessmann;

- Buderus;

- Siberia;

- Lemax.

The equipment is built according to a single functional scheme and often uses the same components - heat exchangers, circulation pumps, gas valves. When choosing, pay attention to the possibility of warranty service and repairs near your place of residence.

In recent years, marketers and manufacturers have been focusing on advertising condensing boilers, which are 2.5-3 times more expensive than conventional convection boilers.

Differences and selection criteria for condensing gas boilers. Details about operating conditions, requirements for CO and chimney

For your information! Convection boilers are conventional gas boilers in which the heat exchanger is located above the burner, and according to the laws of physics, the flame rises upward, heating the coolant flow.

The statement that the efficiency of a condensing boiler is more than 100% is nothing more than an advertising ploy. The operating principle is based on the fact that combustion products are returned to the heat exchanger by means of a fan, where condensation occurs.

The results of the measurements indicate that the efficiency of the boiler due to condensation can be increased by no more than 3-5%. Considering the difference in price by one and a half, the payback period for boilers with a power below 30 kW should be expected in 7-10 years. At this point it is time to replace the boiler. Units with a power above 40 kW pay for themselves in 4-5 years, in this case such a purchase is profitable.

Tips for installing a home heating system

The heating installation begins with the installation of radiators in pre-prepared places under windows or on corner external walls. The devices are hung on special hooks attached to the structure itself or the plasterboard finish. The unused lower outlet of the radiator is closed with a plug, and a Mayevsky valve is screwed in from above.

The pipeline network is installed according to the assembly technology of certain plastic pipes. To protect you from mistakes, here are some general recommendations:

- When installing polypropylene, take into account the thermal elongation of pipes. When turning, the knee should not rest against the wall, otherwise, after starting the heating, the line will bend like a saber.

- It is better to lay the wiring in an open way (excluding collector circuits). Try not to hide the joints behind the sheathing or embed them in the screed; use them to secure pipes.

- Mains and connections located inside the cement screed must be protected with a layer of thermal insulation.

- If for any reason a loop has formed in the pipeline, facing upward, install an automatic air vent on it.

- It is advisable to install horizontal sections with a slight slope (1-2 mm per linear meter) for better emptying and removal of air bubbles. Gravity flow schemes provide for slopes from 3 to 10 mm per 1 m.p.

- Place the membrane expansion tank on the return line near the boiler. Provide a valve to shut off the container in the event of a malfunction.

Installation trick. Do not fill the TP screed until you fill the circuits with water and warm up the system. The goal is to increase the pressure in plastic pipes and force them to lengthen, that is, to put them into operating mode. Then the material will not bend under the weight of the monolith and will not float up if the solution turns out to be liquid.

Solid fuel

Coal.

Solid fuels include:

- wood;

- different types of coal;

- waste from wood processing and agricultural enterprises.

Solid fuel is burned to produce heat. Direct heating does not imply the use of an intermediate coolant; in the case of installing solid fuel boilers, heating systems with radiators are installed.

Stoves, fireplaces, potbelly stoves

It is advisable to consider stoves as the main heating system when building rarely visited country houses or bathhouses.

| Advantages | Flaws |

| Minimum equipment price | Rapid fuel burnout |

| Instant heat release from steel stoves and fireplaces after ignition | High cost of stone stoves |

| Long heating of brick or stone walls | |

| Low efficiency: 30% for potbelly stoves, 60% for the best stove models | |

| The need to arrange fuel storage areas | |

| Fire hazard of stoves and woodburners | |

| Danger of carbon monoxide poisoning | |

| Heating no more than 2-3 rooms |

The best options for heating stoves are of the bell-type type, when hot air passes several times through the smoke channels and is collected under a kind of hood.

Bell type furnace.

Steel stoves are chosen based on the same criteria: the gases must burn completely after passing through several smoke channels.

Solid fuel boilers with manual operation

Cutaway view of a modern Teplodar Kupper coal boiler.

The use of wood or coal boilers is recommended in areas where it is impossible to connect to a centralized gas supply or where it is not possible to equip a gas holder.

Table. Advantages and disadvantages of heating with wood and coal boilers.

| Advantages | Flaws |

| Fuel of any quality is suitable | Instability of calorific value - depends on the moisture content of the fuel, type of coal, type of wood, difficulty in calculating the fuel required for the season |

| Complete independence from power supply when installing a gravity system | Requires constant monitoring and maintenance - loading fuel, removing ash |

| Low price of 1 kW of energy | Low average efficiency |

| Possibility to use free or cheap wood processing waste (often wane can be removed for free, paying only for transport services) | Cooling of radiators with high hot water consumption (in double-circuit boilers) |

| Availability of automated boilers with adjustable combustion speed and supply of pallets or granules | Fire hazard in fuel storage areas |

| Difficulties in organizing a “warm floor” system |

The price of the most popular boilers with a capacity of 14-20 kW ranges from 25 to 70 thousand rubles.

Advice! To maintain the temperature of the coolant at night and during the day, when the owners are absent, they purchase boilers with built-in electric heating elements, which turn on when the fuel burns out and the temperature drops.

Justification for the purchase of high-tech solid fuel boilers

In an effort to increase efficiency, manufacturers resort to various technical solutions:

- create conditions for complete combustion of fuel;

- air charging fans are built into the design to ensure fast or slow combustion;

- install automatic dampers that reduce the air supply when the coolant is overheated.

This is what a pre-installed air charge fan looks like.

Automatic damper on a TT boiler.

Pyrolysis is the separation from fuel by heating it of gases that burn at high temperatures. The process requires precise stabilization of the operating mode.

The operating principle of pyrolysis coal boilers using the Geyser VP model as an example.

It is technologically difficult to achieve the effect in boilers less than 50 kW, but this power is enough to heat a house up to 500 m2.

The offered boilers up to 50 kW can only conditionally be called pyrolysis. Usually these are two-chamber devices. In the first chamber, direct combustion of wood (coal) occurs, and the second is an afterburning chamber, where the remaining organic substances are burned.

The price of such boilers is 2-3 times higher than usual, so part of the profit received by the manufacturer can be used for advertising.

Important! The purchase of so-called “pyrolysis” boilers of low power (up to 40 kW) allows you to increase the efficiency of installations by 5-20%, but you will have to pay 2.5-3 times the cost for the equipment.

In order to talk about the payback of high-tech pyrolysis boilers relative to conventional ones (direct combustion), it is necessary to calculate the costs incurred.

Example. To heat the house, a 25 kW boiler is required. A direct combustion device costs about 35 thousand rubles, a “pyrolysis” device costs about 90 thousand.

For example, the consumption of firewood in a regular boiler per season will be about 20,000, in a “pyrolysis” boiler it is 5-10% less, i.e. 18–18.6 thousand rubles. The savings will be 1.4–2.0 thousand rubles. Boilers up to 25 kW must be equipped with a fan with a power of 50 W or more, which will consume 800–900 rubles worth of electricity per season. Thus, the net benefit from installing a long-burning boiler will be no more than 1000 rubles per season; we can talk about payback in 30-40 years.

Payback of truly pyrolysis boilers within 10-15 years of operation is possible with equipment power of 40 kW; in such devices, combustion efficiency can be increased by 20%.

Efficiency and selection criteria for modern pyrolysis solid fuel boilers

The best manufacturers of solid fuel boilers

Solid fuel boilers are produced by many brands. Based on the number of sales and user reviews, the following companies' products stand out:

- Teplodar;

- Rommer;

- TMF;

- Zota;

- Heiztechnik;

- Thermocraft.

The choice is made according to the required power and available fuel.

Electricity for heating the house

The most expensive and cost-ineffective heating method is the use of electricity to directly heat the air or using an electric boiler.

Classic heating element electric boilers are compact in size and can be installed in any room. They already contain in their housing all the necessary elements of the heating system (circulation pump, expansion tank, safety group), which greatly simplifies installation.

Table. Advantages and disadvantages of electric heating.

| Advantages | Flaws |

| Does not require approval or a service contract; it is enough to obtain permission for the required power of electrical installations | Not suitable for houses with an area of more than 120-150 m2 - the energy supply organization does not approve power above 15 kW |

| Easy installation, inexpensive components | The highest cost of 1 kW of heat (up to 10 times more than gas systems) |

| High efficiency - up to 99% of energy is released as heat | |

| Variety of designs - convectors (oil, quartz), infrared emitters, halogen heaters, fan heaters, electric boilers with a water heating circuit | |

| Easy to maintain the selected temperature throughout the day and for several days | |

| Long service life - up to 50 years for convectors |

In an effort to increase the efficiency of electric heating, manufacturers have developed heating methods and methods for saving energy that are considered innovative for our country.

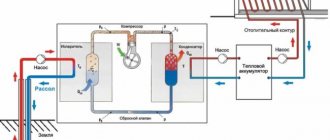

Geothermal pumps

You can learn more about the operating principle of a geothermal pump in a separate article.

The method uses heating of the coolant from the ground or water, due to which the heat transfer is 200-500% of the used compressor power. This makes monthly costs comparable to heating with wood and only slightly higher than using gas.

The advantage of this method is low energy costs. The main drawback that limits its use is the high initial costs for components and installation, reaching from 300 thousand to 1.5 million rubles.

The efficiency of geothermal pumps in frosts from 25 ° C sharply decreases, falling below 90%. In this case, to maintain a comfortable temperature, electric heating is turned on using boilers, convectors or infrared emitters.

Pipes for connecting radiators and heated floors

For homeowners without installation experience, we recommend the following options:

- If you want to save on materials, take reinforced polypropylene pipes (PP-R) with fittings. In addition, buy an inexpensive Chinese soldering iron - it will definitely be enough to assemble 1 system.

- Without special tools, you can install heating pipes from metal-plastic pipes on compression fittings, tightened with open-end wrenches. The disadvantage is the high cost of parts.

- The best solution is to assemble the system from cross-linked polyethylene or metal-plastic with press fittings. You will have to rent special pliers.

The structure of the polypropylene pipe - to prevent thermal elongation, aluminum reinforcement is laid between the layers of plastic

Important note. Polypropylene is not suitable for installing heated floors due to the thick walls and joints that fall inside the screed. Use metal-plastic or polyethylene PE-X, PE-RT.

Polypropylene pipelines are welded according to technology, the main thing is to accurately maintain the heating time. It is strictly not recommended to wall PP-R joints in floors and walls to avoid the consequences of leakage.

Beginners should not use copper, stainless or galvanized pipes. High-quality installation will require certain skills - welding, proper cutting, crimping. Metal is reliable, but inferior to plastic in price.

On the left in the photo are pipes made of metal-plastic, on the right - cross-linked polyethylene