A device such as a heating element was invented in America at the end of the 19th century. The electric heater was patented in 1896. The very first such devices were a spiral, which was insulated with a ceramic material and inserted into a metal tube. This invention was practical, but not safe. Such a device entered mass production 50 years after it was invented. From that moment on, it began to be widely used and it became one of the most popular heating devices operating from the network. Over time, electric heaters have changed and improved greatly. If we compare their improved analogues, they will differ markedly from their predecessors. Only the operating principle of such devices remains the same.

heating element

Today, tubular electric heaters for heating, which consist of one or more nichrome spirals, are in great demand. These spirals are located in a metal shell. In order to differentiate between the shell and the spiral, a material such as periclast, which has good insulating properties, is laid.

General characteristics and operating principle

A radiator heating element is a device that can be used as an additional or main heating device. The device consists of a cylindrical metal body. A copper spiral or steel wire is mounted in the middle of it. Internal parts have an insulating coating.

The heating element intended for radiators is equipped with a thermostat. Thanks to this, the device can be used both for heating and for temperature control.

The operating principle of such electrical appliances is quite simple:

- a tubular electric heater is installed in the battery;

- the heating element is connected to the electrical network;

- The coils are heated, causing heat to flow to the coolant.

What does a heating element for a radiator look like?

Setting the required temperature is allowed if there is a regulator in the device. When the level of the specified mode is reached, the electrical circuit opens and the heating element turns off. When the temperature drops below the set upper limit, automatic heating occurs. You can connect the heating element to almost any battery.

Radiator electric heating at home

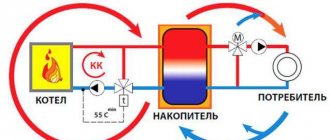

Installation diagram of the heating element in the radiator

Before installing a heating element into the heating system, you need radiator parameters. The main one is the diameter of the connecting pipe. Currently, manufacturers produce products in two sizes - 1/2 and 3/4 inches. Then a comparative analysis of the heating parameters is carried out before and after installing the heating element.

Connecting the heating element to the existing heating

If it will be used as an additional method of heating water, you need to take into account the change in hydraulic pressure when passing through the radiator. Since the flow diameter of the system this month will be smaller, it is recommended to install a pump of higher power.

When connecting a radiator to the system, installing a heating element for heating the house will not be possible. To do this, you must either change the connection diagram to the top, or install a heating element on the top of the battery, which is not recommended by experts.

They are often installed in old cast iron batteries. Before performing work, you must first check the direction of the thread of the pipe (right or left) and also measure its diameter. Then you should follow this scheme:

- Coolant drain. It is prohibited to install a heating element into a heating radiator if there is water in it;

- Checking the battery level. Even at a slight angle of inclination, the likelihood of air pockets significantly increases;

- Installing the heating element into the pipe. To seal the holes, you must use the gaskets supplied with the heating element or make them yourself;

- Installation of a unit with a thermostat, if included.

An example of installing a heating element in a cast iron radiator

After this, you need to fill the system with water. Using the installed Mayevsky crane, possible air pockets are removed. Before switching on, to ensure safety, a tester is used to check any possible heating coil-battery circuit. If there is one, you need to dismantle the heating element and install it again, improving the sealing.

Radiator electric heating

When organizing heating using heating elements made by yourself, installation of a pipeline is not necessary. A heating element must be installed on each radiator. At the same time, it is possible to install models of different power depending on the thermal conditions in a specific room of the house. The advantages of such a system are as follows:

- Saving on the purchase of materials and reducing the labor intensity of installation work;

- If you use a heating element with a thermostat for heating and a temperature sensor connected to it, the degree of heating of the room will be adjusted automatically;

- Minimum system heating inertia.

But all these positive qualities can be offset by the total cost of service. Therefore, before heating with electric heaters, you need to calculate not only the cost of purchasing materials and components, but also the subsequent costs of electricity. Only after this should a heating system of this type be introduced.

It is recommended to purchase factory radiators with installed heating elements. Their operating efficiency is higher than that of homemade ones, since special oil is used as a coolant. Even when the heating element is turned off, it will give off heat to the room for some time.

Types of heating elements

You can find various models of tubular electric heaters on sale. They differ in the structure of the body and the material of manufacture. Devices are also divided according to power and purpose:

- from 2.5 to 4 kilowatts - household;

- from 4 to 6 kilowatts - industrial.

There are both single heating elements and devices with two heating coils. Such devices are also made with right-hand or left-hand threads. Many models are equipped with additional options:

- Antifreeze. The function protects the heating system from possible defrosting at low temperatures. At the same time, the permissible minimum temperature is automatically maintained. During this operating mode, a completely insignificant amount of electrical energy is consumed.

- Turbo heating. This option will allow you to maximize the temperature in the room. For turbo heating to work, a thermostat is required, which makes it possible to change the heating mode.

Heating elements for radiators are produced in various lengths and with distinctive design characteristics.

How not to make a mistake in choosing

Radiators for heating elements are quite simple to choose, since they do not require a special variety of designs and technical characteristics. Please consider the following points before purchasing.

Electric heating element power calculation

In order to correctly determine the required power of the device, it is advisable to know the thermal standards in force in the given area. As a last resort, you can use the average indicator, which can be used in central Russia and make some adjustments if necessary.

Based on this, for 10 sq. meters of heated area, provided that the heating element will be used as the main heating, 1 kW of its power is required.

If heating elements for radiators are chosen as the main heating for the home, it is highly advisable to purchase models with a thermostat. In this way, it will be possible to regulate the power of the device and thereby reduce energy costs

If the device is used as additional heating, the required power will be 3-4 times lower. In addition, when choosing a device, you should take into account the specifics of the radiator heating element.

Due to its design features, it will be able to operate uninterruptedly only at 75% of the heat transfer from the radiator. With higher power, the device will overheat and it will constantly turn off.

Based on this, the power of the device is calculated. The exact heat transfer values of a particular radiator can be found in its technical documentation. However, on average, one section of an aluminum battery has a heat output of 180 W, and a cast iron battery has a heat output of 140 W.

Let us calculate, as an example, which heating element is suitable for a 10-section radiator. We multiply the data by 10 and we get that for an aluminum battery it is worth taking a heating element with a power of up to 1.35 kW, for a cast iron battery - up to 1 kW.

Design features of the device

For each radiator, you should select a heating element that is suitable for it in size and thread direction. The equipment has different shaft lengths, which may affect its performance.

If the length of the heating element is insufficient, the equipment is not able to provide a sufficiently high circulation rate of the coolant, as a result of which the heating of the radiator will be uneven and insufficient.

The length of the device is perhaps one of its most important characteristics, which directly affects its efficiency. Before purchasing, you should measure the radiator and calculate the required length of the built-in heating element

The optimal option is when the heating element rod does not reach the inner wall of the opposite edge of the radiator by 60-100 mm

It is also important to choose the right body shape and diameter of the device.

The material of the plug may vary between models. To make the right choice, you should study the manufacturer’s recommendations, where he describes the types of heating devices suitable for using a particular heating element.

Availability of automatic control

Devices are available for sale with or without built-in automatic control. The first variation is as convenient as possible and does not require the purchase of additional equipment. In this case, a thermostat with a sensor that measures the temperature of the coolant is built into the lower part of the heating element housing.

If there is no built-in automation, the electrical appliance does not have a thermostat. In this case, it is advisable to connect using a detector that measures the air temperature in the room.

It must be admitted that this equipment is not so popular and in demand for large European companies to start producing it.

In stores you can find radiator heating elements made by Turkish, Polish and Ukrainian brands. In terms of quality and functionality, they are approximately similar.

It is difficult to say which company's products should be preferred. But you need to be wary of Chinese heating elements, since you can often get a low-quality product.

Criterias of choice

When selecting a heating element for a radiator, you should take into account its technical characteristics, as well as the parameters of the battery. The main factors influencing the choice of device are:

- Power. In rooms with good thermal insulation properties, heaters from 2 to 3 kilowatts can be installed. In older buildings, it is best to use heating elements with higher power.

- Length of the electric heating tube. It is recommended to purchase heating elements ten centimeters shorter than the battery. Correct selection of the length of the heating device allows you to evenly heat all sections of the radiator.

- Battery Type. In order for the heating element to optimally fit the radiator, you should carefully study its technical data sheet. It specifies which types of batteries the product should be used with.

- Automatic control. Not all models have this option. For ease of use, it is best to purchase heating elements with automation, which are equipped with a thermostat.

The heating element should be ten centimeters shorter than the radiator.

The diameter of the electric heater is also taken into account in accordance with the cross-section of the plug on the radiator. It is important to correctly determine the placement of the thread.

It is necessary to purchase only high-quality heating elements from trusted manufacturers. Before purchasing an electrical appliance, you should check its integrity and serviceability.

Block heaters

Block options are several tubular-type heaters that are combined into one block and usually have one fastening element

When choosing a particular block heater, you should pay attention to the power ratings and the ability of the boiler equipment and pump to provide effective heat removal

It is recommended to give preference to these types if:

- you need to use a device with high power and heating rate of the environment;

- there is no way to quickly transfer heat energy from the working coil to the medium due to the small area of the heating element shell on the outside.

The advantage of the block solution is the ability to reduce the load on each tube, which simultaneously increases the uniformity of heating of the medium and causes little wear on the heating elements located inside these tubes.

View products

As for power, models can provide from 5 to 10 kilowatts. So, during the installation of equipment with block heating elements, you will have to take care of laying an additional electrical cable.

Advantages and disadvantages

Tubular electric heaters contribute to uniform and complete heating of the heating system. Installing such devices has many advantages:

- safety of use;

- ease of installation;

- economical use;

- the ability to install additional options;

- reliability;

- long service life;

- relatively low price for the product.

Along with their advantages, heating elements for radiators have their disadvantages:

- When connecting a heating element, the high speed of liquid circulation in the radiator does not allow increasing the level of heat transfer. Thus, the operation of the heating system prevents uniform heating of the device.

- When using a heating element as the main heating device, the cost of electrical energy increases significantly.

Among the advantages of heating elements for radiators is their low cost.

The cost of the heating element itself is low, but when purchasing the necessary additional equipment to automate the work process, costs increase significantly. The complete set has a price several times higher than a convector operating on electricity.

Rules for choosing a heating element with a thermostat

The diversity on the market makes it difficult for the buyer to choose, so you need to decide in advance on the characteristics, appearance, and connection method.

A few features of the devices that you should pay attention to when purchasing:

- The diameter of a specialized hole in the radiator. Not every model will fit the heating device. This parameter needs to be known in advance;

- Thermostat quality. Ideally, a small control device should have a turbo mode for emergency heating and an economy mode, which prevents the system from defrosting. But a simple sensor with a temperature scale will do the job just fine;

- Heating element power. It is a generally accepted fact that 1 kilowatt is required per 10 square meters of room. If oil or antifreeze is used as a coolant, then a coefficient of 1.5 is applied, that is, for the same size of heated space, the heating element must have a power of at least 1.5 kilowatts;

- Metal tube. Titanium is an ideal and durable option, but extremely expensive. Regular or stainless steel is most often used. It’s not worth purchasing a Chinese heating element, because the thickness of the metal will cause it to burn out in a short time;

- Type. Based on the required power and heating method, you need to decide on the variety. The features of each are described above;

- Additional options. Shutting off when overheating will avoid many troubles. After all, even in a radiator filled with liquid, there are air pockets that cause the tube to heat up much faster.

How are they used for heating radiators?

The main function of tubular-type electric heaters for radiators is to heat liquid in an autonomous or centralized heating system. The device is used as a secondary or main heat source.

As an autonomous system and the only coolant heater, heating elements are used in the following cases:

- The need to heat rooms where there is no other type of heating. This could be a workshop, garage or agricultural building. The main condition for installing a radiator electric heater is the small size of the building. It is more effective to fill batteries with oil of low viscosity, since it has a fairly low freezing point.

- Subject to periodic heating of the room. Most often, such structures are dachas with no main heating system. At the same time, the number of installed heating elements, their power must correspond to the volume of the room.

As an additional device to the main heating, a tubular electric heater can be installed:

- In multi-storey buildings. Heating elements are installed in radiators in apartments if the main heating is not particularly efficient. The device helps create and maintain the necessary indoor microclimate. But its installation requires limiting the access of water that circulates through the heating system of the entire house. In this case, the use of a heating element is completely impractical, since you end up paying twice for heating - for the operation of the electric heater and to the housing office for the use of the coolant.

- In private homes. A heating element is installed if it is not possible to regularly add firewood to a solid fuel boiler. In such a situation, the tubular heater does not allow the coolant to cool completely and the required temperature is constantly maintained in the room.

A heating element for a radiator is installed in both private and apartment buildings.

Using a heating element for gas boilers does not make sense, since such units cope well with heating due to an automated system.

Scope of application of heating elements for heating

Electric heating elements have gained popularity due to their versatility and high efficiency. All the electricity they consume is used for its intended purpose - heating the surrounding space.

The main heating devices where heating elements are used are:

- Portable and stationary oil electric heaters.

- Water heating radiators.

- Bathroom heated towel rails.

- Electric fireplaces.

- Electric convectors.

- Electric boilers.

The specified equipment can be used as a main or additional heating source. It is inexpensive, easy to install and does not require special skills to operate.

You can connect the heating element to a cast iron central heating radiator after disconnecting the common riser. This device can be used for main and additional heating

How big is the benefit from heating elements?

If you have an old battery, then why not use a heating element to turn it into a heating system for a small utility room - a chicken coop, a workshop, a garage.

There are even myths that heating with heaters is beneficial. But “dreams are shattered by harsh reality” - heating with electricity is the most expensive. Since the most expensive energy carrier is used.

It doesn’t matter whether there is a proprietary programmable electric boiler, or a barrel with a heating element lowered into it on a wire, the efficiency of such electric heaters is about 97%. And then we pay according to the meter...

Installation of heating elements

Before installing the device, it is necessary to make power calculations taking into account the type of battery and the average thermal characteristics that are the norm in the given area.

Making calculations

When determining the power indicator, you can use the average value of thermal data in the Russian Federation. Thus, when installing a tubular-type electric heater as the main heating device on 10 square meters, a power of 1 kilowatt is sufficient.

For radiator heating elements that are supposed to be installed as an addition to the main heating system, it is recommended to use a power rating three times lower.

The rated power of an electric heating device can be calculated according to the formula:

Q = 0.0011*M (T1-T2)/t

In this case, M is the mass of the energy carrier, T1 is the temperature indicator after heating, T2 is the temperature value before heating and t is the time required for the maximum increase in temperature.

An important factor is the technical characteristics of the electric heater itself, as well as the heat transfer of the battery. All necessary data about the device can be read in the passport attached to it. The heat output of one section of a cast iron radiator is on average 1.40 watts, and that of aluminum is 180 watts. Therefore, the power of the heating element for the same volume of batteries made of different materials will be slightly different.

Installation

Installation of a tubular electric heater is not difficult. To do this you need:

- unscrew the battery plug on one side;

- install using threaded fasteners and rubber gaskets.

The process of connecting a tubular electric heater has some features:

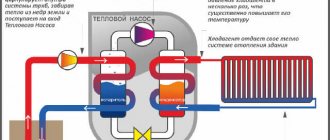

- When the coolant heats up, it increases the pressure in the battery. In this regard, the installation of a small expansion tank is required. You can also equip the radiator with a valve that regulates pressure in a closed system.

- The fastening connections of the heating element are quite fragile. Therefore, when installing the device, it should be done carefully, without additional effort.

To ensure maximum efficiency of the electric heater, it is best to connect it to the bottom of the battery. This is due to the fact that the coolant, when cooling, descends, and when heated, rises to the top.

Power calculations

To choose the optimal heating element for a cast iron battery, you will have to make some calculations.

- The power of the device is determined by the amount of heat that the room needs. So, to heat 1 m2 you will need 100 W, which means that for a room of 20 m2 you need 2000 W. Since cast iron batteries are used as heaters, the required amount of heat must be divided by the thermal power of one section of the battery, for example, 180 W. It turns out that this room will require 11 cast iron sections. The length of the heating element and its power must correspond to the size and needs of the radiator.

- Another parameter that should be calculated is the volume of coolant in the structure. This is important, since even a powerful device will not be effective if there is not enough liquid in the battery. Therefore, when purchasing a heating element, it is so important to consider what type of battery it is needed for. The volume of aluminum radiators is only 0.2 l, while in a cast iron battery it can be from 0.6 to 1.5 l, depending on the model and manufacturer.

Approximately 1 kW of heating element power per 15 liters of coolant is taken. Based on this and taking into account the number of radiator sections, it is easy to determine what power the device needs and how many of them should be in the heater.

Safety precautions and operational points

A heating element is a mains-powered heater. When using the device, it is quite important to follow some rules that will ensure safe use and significantly extend its service life:

- In order for the device to operate for a long time with full heat transfer, the scale that forms on its surface should be cleaned once every three months. If a large layer of white deposits forms, it can damage the device. The intensity of scale formation can be reduced by using distilled water as a coolant.

- Do not allow the electric heater to overheat. The temperature of the radiator in the place where the electric heater is installed should not reach seventy degrees above zero. Therefore, it is quite important to choose the correct power of the heating element.

- The heater can only be turned on in a battery filled with coolant. If water enters an already heated electrical appliance, it can lead to a thermal explosion. As a result, not only the radiator, but the entire heating system may be damaged.

- If static electricity appears on the surface of a tubular device, it must be immediately turned off and all connections and the device itself checked for leaks.

- The heater power should not be higher than the thermal rated power of the battery. A load of no more than 3.5 kilowatts is allowed in one outlet.

The temperature of the heating element for the radiator must not reach 70 degrees.

Installation of the heating element in the heating radiator is carried out only using grounding. To avoid voltage drops, it is best to connect the electric heater to the network through a stabilizing device.

How to install and use heating element correctly

The key parameter for any electrical appliance is its rated power. Therefore, in order to correctly install such a device in the heating system, this value must be calculated. After this, you need to study the rules for installing electric heating elements and only then get to work.

The outer shell of the structure must be located in water so that the heat from the coil is compensated by the low temperature of the water, and the heating element does not overheat. For this purpose, it must be installed at the lowest point of the radiators so that it does not enter the area of air pockets.

Water should be distilled because it contains a minimum of impurities. Such additives can form a layer of scale on the protective shell, which, in turn, can cause corrosion.

When installing a heating element in a heating system, check the instructions for how to seal the end joints in this case. If we are talking about additional sealing, this must be done, otherwise if water gets on the heating coil, there may be a danger for the occupants of the room.

Sealing joints

When installing the heater into the heating system, you must first read the instructions from the manufacturer. If it states that the end joints of the electrodes must be additionally sealed, this must be done. Otherwise, if water gets on the surface of the heating coil, the danger for those living in the house increases. After familiarizing yourself with these rules, you can begin installing a heating element.

Not every heating element is suitable for a heating radiator. Only special models with the appropriate mounting diameter should be selected.

Efficiency mark

A heating element for a radiator is not a heating device that can be constantly used to heat a large area. One kilowatt of electrical appliance power is converted into one kilowatt of thermal energy, which is completely used to heat the room.

When using cast iron batteries, a heating element equipped with a thermostat with a heating power of 100 Watt/m² can heat no more than 25 m² of space. Electrical energy consumption for twenty-four hours will be 36 kW/h, which approximately corresponds to 167 rubles. This takes into account the average power consumption of 1.5 kW. If the heating system is well organized, installing a tubular type electric heater does not make sense.

A heating element for a radiator is most effectively used as an emergency device. If the heating system is unstable, such a device will allow you to maintain the required level of heat in the room even in severe frosts. Installing a tubular heater makes sense if its power is correctly selected and all safety rules are observed.

Installation features

Installation is not difficult at all. The heating element is mounted in heating radiators as follows:

- the equipment is turned on outside the radiator for a short time to check its functionality;

- water is drained from the system;

- a hole opens for the heating element, it is placed there and secured;

- the system is filled with water, after which voltage is applied to the tubular heater.

It is worth paying attention to the following nuances:

- If the product documents indicate the need for grounding, then this is necessary for long-term operation. Otherwise, the service life will be significantly shorter;

- You cannot wet a heated heating element with water; an explosion and destruction of the outer shell are practically guaranteed. Therefore, the water level must be monitored before power is supplied.

The air convector and other devices are simply connected to a grounded network. The only limitation is the wire of the required cross-section.

A hole for the heating element opens and it is placed there and secured.

Types of tubular heaters for radiators

Despite the simplicity of the design, you can find various variations of radiator heating elements on sale. First of all, the power of heating devices varies. Models with a minimum power “produce” about 0.3 kW, with a maximum – 6 kW.

The devices differ in the design of the housing. Considering that the configuration and location of radiators can be different, there are heating elements with left-hand or right-hand threads.

The diameter of the device may also vary. This is due to the cross-section of the radiator plug plug, in the place of which the device is mounted. Standard size is 40 mm.

There is no fundamental difference between devices intended for installation in radiators made of different materials. Their design is similar, only the diameter may differ. You can find single and double heating elements on sale.

Double heating elements are more convenient to use. They allow you to significantly increase the rate of heating of the coolant, but at the same time they differ from single analogs at a higher price

The latter is more convenient to use. At the moment of switching on, both elements are activated at once, due to which the coolant heats up as quickly as possible. After this, one of the elements is turned off, which allows you to save energy resources. Some models are equipped with additional functionality.

The manufacturer uses only two functions:

- Turbo heating. Makes it possible to maximize the increase in temperature in the room. A thermostat is necessarily built into the device, which allows you to change the heating intensity.

- Antifreeze. This mode allows you to prevent possible defrosting of the entire system when the temperature drops to negative values. The heating element automatically maintains the minimum permissible temperature, while consuming a small amount of electricity.

In addition, radiator heaters vary in length and the presence or absence of a thermostat.