Efficient heating systems for a one-story or multi-story building can be organized with forced or natural circulation, using a single-pipe or two-pipe principle. The second option is the most common. A number of convincing and important factors determine the feasibility and relevance of using a two-pipe heating system. In addition, the work can be done with your own hands.

A two-pipe heating system is one of the best options for providing heat to your home.

Construction of two-pipe heating systems

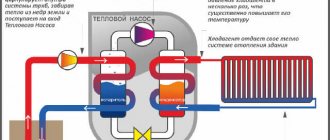

A design feature of a two-pipe heating distribution is the presence of a supply and return line. The coolant is heated in the boiler, and then transported and distributed along one of the pipeline branches to registers and devices. The other removes and returns the cooled liquid back to the heat generator.

Note! A two-pipe heating system for a private house (or multi-story building) ensures that heat is supplied to all heating devices at the same temperature. With a single-pipe circuit, heated water sequentially passes a chain of radiators and pipes, losing heating characteristics when approaching the last of them.

Water can be supplied to such a system directly from the water supply. It requires an expansion tank. It can be with water circulation or simple. The latter consists of a container and 2 pipes: one of them is a riser that supplies water, the other is for draining excess liquid.

Two-pipe heating systems for a single-story house (or multi-story building) can operate using a pump to provide forced circulation.

A heating scheme with forced circulation of working fluid involves installing a special pump in close proximity to the boiler

In practice, dead-end elements and elements with a passing flow (direct flow) are distinguished. With the first method, the movement of heated water is opposite to the direction of cooled water. In the second case, the directions of movement of the return and direct coolant coincide.

Modern control for single-pipe systems

The boiler is usually controlled by a single thermostat, which provides poor control, especially in townhouses. The thermostat will only take into account the temperature of the floor or room in which it is located.

For example, if the thermostat is located on the ground floor next to the boiler, then it will read the temperature of that floor.

The steam will reach the radiators first, quickly heating the floor. This means that the thermostat will turn off the boiler before the steam can fully heat the radiators on the floors furthest from the boiler, resulting in lower temperatures on those floors.

To eliminate this problem, it is proposed to place temperature sensors on several floors with an averaging thermostat.

This ensures more even heat distribution.

Larger single-pipe steam heating systems may require the use of a thermal timer control.

Heating system elements

The design diagram of a two-pipe heating system for a private house assumes the presence of the following materials:

- boiler (or other means for heating water);

- safety valve;

- expansion tank;

- reagents to ensure cleaning;

- pump (connected to water circulation);

- radiators;

- air venting mechanism;

- pressure gauge (determines pressure);

- additional accessories;

- pipes.

To install a two-pipe heating system in a private house, you may need various tools: a hammer, a welding machine, a drill, a gas and adjustable wrench, a tape measure, a plumb line and level, a screwdriver.

Two pipes are installed in all radiators; taps are installed in front of each of them, with the help of which you can, if necessary, disconnect any heating element from heat transfer.

The main pipe extends upward from the boiler (or from the furnace), which supplies hot coolant. It is connected to a compensatory tank that has a drain and a signal pipe.

Each heating radiator in the house is connected to two pipes equipped with taps to turn off the heat supply

A pipeline is led from the tank to the top line, from which communications are routed to all radiators included in the system. A pump is mounted at the outlet or inlet of the boiler installation with a two-pipe heating system with forced circulation. The return line is drawn parallel to the laid main line, connected to the radiators, brought in and cut into the lower part of the boiler.

Thermal energy consumption is controlled using thermostats.

Steam traps

To control the flow of steam and condensate, the two liquids must be separated. The usual method is to install a steam trap at the outlet of each radiator. This device allows air and water to exist in the radiator, but not vapor. If the traps do not work, the system cannot be monitored.

The interior of a failed trap can be easily replaced by a plumber. Of course, if your traps don't work, then it's reasonable to assume that all the traps in the building should be checked.

If the system is old, it would be wise to replace all radiator thermostatic traps.

Now that the steam and water are separated, we can move on to controlling the radiators. A thermostatic radiator valve (TRV) is used to control temperature in two-pipe steam systems. The expansion valves monitor the temperature near the radiator and are attached to the steam supply pipe.

You can then manually set the temperature: the settings are usually displayed numerically, with a temperature range corresponding to each element of the system. When the desired temperature is reached, the valve will close the steam supply to the separate radiator. If the radiator is installed in a housing, then it is necessary to use the capillary tube model.

Horizontal and vertical systems

The division of the heating system into vertical and horizontal determines the placement of pipes that connect all devices into a single whole.

Note! Both types of heating circuits are characterized by excellent hydraulic and thermal stability.

A two-pipe horizontal heating system is more typical for a one-story building of considerable length. In such buildings, it makes more sense to connect radiators to a pipeline laid horizontally. This method of organizing heating is convenient for panel-frame buildings, housing, where the wiring is carried out from risers located in the corridor or on the staircase.

Two-pipe heating systems for multi-storey buildings are predominantly of a vertical type. Such organization is more expensive, but air locks will not interfere with effective operation. In this case, all devices are connected to a vertical riser, and each floor is connected separately.

If the house is multi-story, you need to use a vertical heating system, and in a one-story building, the horizontal option will be optimal

How does dual-circuit heating work?

In two-pipe thermal structures, unlike single-pipe ones, radiators are connected to two mains. The inlet pipes are connected to the supply line, through which hot liquid flows, and the outlet pipes are attached to the return line - through it the cooled medium flows out for reheating. The heating devices are independent, so you can set a comfortable temperature in each room.

Wiring of a two-pipe heating network

According to the construction method, heating system circuits are divided into networks with upper and lower wiring.

The method with bottom wiring involves laying a hot water line in the underground space, basement or basement. The pipeline that returns the cooled water back to the boiler is located even lower. With lower wiring, it is necessary to include an upper line in the circuit, which is responsible for removing excess air from the system.

To ensure uniform transport of heat to all appliances, the boiler must be buried, and the batteries must be located above it.

The upper distribution is characterized by the upper laying of the distribution pipeline. The expansion tank is installed at the highest point of the heating circuit. It is usually located in an insulated attic. Thus, for a one-story house with a flat roof, a two-pipe heating system with overhead wiring is not suitable.

Double-circuit heating: how to calculate the diameter of the pipes

For a house with an area of up to 250 square meters, heated via dead-end and collector wiring, you do not need to make a detailed hydraulic calculation. It is enough to use the table, which shows the total power of radiators that can be connected to a line of a certain diameter.

To calculate, you need to find out the power of each heating device. To do this, the indicators of one section are multiplied by the quantity. In places where connections are made to several heating devices, the power is summed up. To connect to the boiler, elements measuring 32 or 25 mm are used - boilers for a double-circuit circuit often have pipes of these dimensions.

For ring or gravity distribution, the diameter of the line must be calculated. As an example, let’s calculate the diameter of pipes for heating a room of 50 square meters. m. Calculations are rounded up only

First you need to calculate the coolant flow using the formula:

G = 0.86 x Q/∆t

- G – coolant flow (kg/h).

- Q is the amount of heat required to heat the room. Take an average of 100 W/sq. m. Therefore, for an area of 50 sq. m. m will need 5000 W.

- ∆t – temperature difference in the supply and return lines. For ease of calculation, the indicator is assumed to be 20 degrees.

We make the calculation:

0.86 x 5000/20 = 215 kg/h - this volume of coolant should be passed by the branch that goes to our rooms.

Now let's calculate the cross-section of the pipeline:

F = V/3600u

- F is the required section.

- V is the volumetric flow rate of hot water, in our case it is 215 kg/h or 0.215 cubic hour.

- u is the coolant flow rate. In pressure circuits it is 0.3–0.7 m/s, in gravity circuits it is 0.1–0.3 m/s. Let’s take the indicator 0.3 m/s for calculation

The cross-sectional area is: 0.215/(3600x0.3) = 0.000150 sq. m

We calculate the diameter of the circle based on its area. We get D = 0.014 m or 14 mm. The size you need is 16 mm.

Features of the use of upper and lower wiring

Both types of wiring are applicable for horizontal or vertical do-it-yourself organization of two-pipe heating of a private house (one- or multi-story).

Both the lower and upper wiring have their own subtleties, and in order to avoid mistakes, you need to carefully study the diagram of both systems

For multi-storey buildings, which are of the vertical type, it is more typical to install a two-pipe heating system with bottom wiring. This is explained by too much pressure created by the difference in the temperatures of the treatment and the heated coolant, which increases with the subsequent floor.

Note! Additional pressure during the lower distribution helps the coolant move through the pipeline. If, for structural reasons, it is impossible to carry out the lower distribution, the construction of the upper supply line is carried out.

A pump can be connected to a network with natural circulation at any time, the launch of which will, if necessary, allow the room to be evenly and quickly heated.

Plumber tips

Finally, some simple practical tips, one way or another related to the operation of one- and two-pipe heating systems.

- In a one-story house, you shouldn’t complicate your life by using complex schemes. It is better to use a simple one-pipe system with a circulation pump and the possibility of natural circulation.

- A simple solution to the problem of air risers during lower filling is to not reset the heating system for the summer. Actually, this is prescribed by housing maintenance standards: steel pipes filled with water are more slowly destroyed by corrosion.

- If all heating devices are connected to one of the risers connected on the upper floor, install a valve on the second riser instead of a plug. It will be possible to bypass it and expel the air lock from the basement.

- For a cottage with a floor area of up to 150 m2 and forced circulation, DN25 mm pipes are used. Radiators are cut into them with a pipe of smaller diameter.

Attention: do not confuse the internal cross-section of the pipe with its external diameter.

- In small houses in a two-pipe system, balancing of heating devices with chokes is mandatory. The ones closest to the boiler are pressed so that the flow of water through them does not dampen the difference in the distant ones.

- In apartment buildings, balancing is achieved in another way: by the difference in permeability between bottlings and risers. If the bottling has a cross-section of 80 millimeters, and the risers are 20, those closest to the elevator unit will not absorb the difference at those farther away.

Properties of forced and natural circulation

There are two-pipe systems with natural and forced circulation of the working fluid. With natural heating, the coolant expands from heating in the boiler, creates pressure in the network and moves along the circuit, gradually cooling in the existing radiators. This type of heating does not require electricity to function properly. For two-pipe heating systems with natural circulation, correct angles of inclination of communications during installation and accurate selection of pipe sizes are important.

The total length of the contour should not be more than 30 meters. Natural circulation networks are used for low-power boilers and small houses. The efficiency of this method of heating a room is lower than that of systems with forced circulation.

The circulation pump accelerates the movement of coolant through the system and promotes its uniform distribution throughout all heating devices (radiators)

A network with forced circulation assumes the presence of a circulation pump mounted in the return pipe. This installation eliminates its contact with high-temperature coolant and extends its service life. Several pumps or one instance can be used. It all depends on the size of the house, the number and length of wiring circuits.

A system with forced circulation is characterized by independence from the temperature conditions of the coolant, an increase in the length of the circuits, a variety of circuit solutions for heating design, the ability to adjust operating modes and dependence on power supply.

Heating standards for apartment buildings heated centrally

These norms are the most “ancient”.

They were calculated at a time when they did not save on fuel for heating the coolant, the batteries were hot. But houses were built mainly from materials that were “cold” in terms of heat-saving qualities, that is, from concrete panels. Times have changed, but the norms remain the same. According to the current GOST R 52617-2000, the air temperature in residential premises should not be lower than 18°C (for corner rooms - at least 20°C). At the same time, the organization that supplies thermal energy has the right to reduce the air temperature at night (0-5 hours) by no more than 3°C. Heating standards are set separately for different rooms of the apartment: for example, in the bathroom it should be at least 25°C, and in the corridor - at least 16°C.

Society has been fighting for a long time, and at times not unsuccessfully, to change the procedure for determining heating standards, tying them not to the air temperature in the premises, but to the average temperature of the coolant. This indicator is much more objective for consumers, although it is unprofitable for the heat energy supplier. Judge for yourself: the temperature in residential premises often depends not only on the operating system, but on the nature of a person’s life activity and living conditions.

For example, the thermal conductivity of brick is much lower than that of concrete, so in a brick house at the same temperature you will have to spend less thermal energy. In rooms such as the kitchen, the process of cooking food does not generate much less heat than from radiators.

Much also depends on the design features of the heating devices themselves. For example, panel heating systems will have a higher heat transfer rate than cast iron radiators at the same air temperature. Thus, heating standards tied to air temperature are not entirely fair. This method takes into account the outside air temperature below 8°C. If such a value is recorded for three days in a row, the heat generating organization must unconditionally supply heat to consumers.

For the middle zone, the calculated values of the coolant temperature depending on the external air temperature have the following values (for the convenience of using these values using household thermometers, temperature indicators are rounded):

Outside air temperature, °C

Temperature of network water in the supply pipeline, °C

Using the table above, you can easily determine the water temperature in a panel heating system (or any other) by using a regular thermometer at the time of draining part of the coolant from the system. For the forward branch, use the data in columns 5 and 6, and for the return branch, use the data in column 7. Note that the first three columns establish the release temperature of the water, that is, without taking into account losses in the transmission main pipelines.

If the actual coolant temperature does not correspond to the standard temperature, this is the basis for a proportional reduction in the payment for the central heating services provided.

There is also an option to install heat meters, but it only works when all apartments in the building are served by a centralized heating system. In addition, such meters are subject to annual mandatory inspection.

Features of heating a one-story and two-story building

For a one-story house, the most successful is vertical wiring, the main advantage of which is the ability to install pipes of equal diameter and high pressure values due to the difference in supply and return levels. When planning horizontal distribution and natural circulation, the slope of the main line should be directed towards the boiler. This, in turn, allows you to create an optimal temperature regime and evenly distribute heat in the house.

For a two-story house, the increase in efficiency of such a scheme is explained by increased circulation, which is possible by increasing the difference in heights of the boiler and radiators of the second tier. The hot coolant enters the distribution tank on the second floor or attic, and then is directed to the heating devices along an inclined line. Organizing a system with natural circulation involves installing a supply pipe at an angle of 5 mm every 2 meters. A two-pipe heating system for a two-story house can be combined with a single-pipe one.

In order for a system with natural circulation of coolant to function normally, when installing the network, the required level of pipe slope must be observed

Note ! The quality of heating in a house is related to the circulation of the coolant, which depends on the diameter of the pipes used for distribution, their material, the number and radii of turns, the presence and type of shut-off valves.

The disadvantage of two-pipe heating, both using natural and forced circulation, is the high consumption of pipes. In this regard, it is worth deciding in advance which pipes to use - polypropylene, metal-plastic or copper. The latter will cost more than the first two types.

Question answer

What is the difference between a 2-pipe system and a 1-pipe system?

A 1-pipe system operates using a complete ring of piping with flow and return from the boiler. The disadvantages of this system tend to outweigh the advantages, so they are used less and less.

The 2-pipe system has become popular since the 1970s, and is still the most common method of feeding radiator circuits. Water circulates here both through the circuit and through the radiators, which, in turn, increases the heating rate of the radiators.

What advantages does such a system have?

It is more practical and affordable for autonomous heating of housing.

What should you pay attention to when choosing a heating system?

In everyday life you can come across various heating schemes, but note that the choice is influenced by several factors. Preference is given to one or another scheme, based on the availability of funds from the homeowners, the expected effect and the design features of the residential building. The 2-pipe version is more often used in practice due to its high efficiency, reliability and ease of setup.

What is the operating principle of 2-pipe heating?

The principle of operation is quite simple: the coolant circulates from the boiler to the radiators through two circuits. The first pipe directly supplies heat from the boiler to the radiators, while the second is designed to transport the cooled coolant back.

Of course, this option has some technical difficulties associated with installation, but reliability, ergonomics and efficiency have made the 2-pipe heating principle the most popular for decades. But still, when choosing a system, pay attention to the characteristics of the living space, its square footage, as well as your own selection criteria and financial capabilities.

Installation rules

When installing a two-pipe heating system in a private house with your own hands, you must follow some technological rules. The circuit should consist of two pipes: the upper one with hot water and the lower one with cooled water. The slope to the last battery included in the system should be at least half a percent (preferably 1%).

If the network has 2 mirrored wings, then the end radiators must be installed at the same level. The lower line must be parallel and symmetrical to the upper one. For maintenance and repair, radiators and technological units are equipped with taps. Insulation of the supply pipe will help prevent temperature loss when transporting coolant by wiring.

The sizes of valves, fittings and taps must correspond to the parameters of the pipes. Properly organized wiring eliminates the presence of overlaps, which cause the formation of air pockets, and 90-degree angles, which create resistance. Do-it-yourself fastening of the steel pipeline is carried out in increments of 1.2 meters.

The two-pipe heating system of a private house (multi-story or one-story building) is a closed loop that allows you to effectively maintain the required temperature. Such a network can be launched and installed with your own hands, but for this it is advisable to have a project and specialized education.

Pressure drop

In order for the heating system to perform its functions normally, the pressure drop, which is the difference between its values at the supply and return, must be of a certain and constant value. In numerical terms, it should be in the range from 0.1 to 0.2 MPa.

A downward deviation of the parameter indicates a failure in the circulation of the coolant through the pipes. A fluctuation in the direction of increasing the indicator indicates airing of the heating system.

In any case, you need to look for the reason for the change, otherwise individual elements may fail.

If the pressure has dropped, then check for leaks: turn off the pump and observe changes in static pressure. If it continues to decrease, then they look for the location of the damage by sequentially removing different sections from the diagram.

If the static pressure does not change, the reason lies in equipment malfunction.

The stability of the operating pressure drop initially depends on the designers, on the hydraulic calculations they performed, and then on the correct installation of the line. The heating of a high-rise building functions normally, the installation of which takes into account the following points:

- The supply pipeline, with rare exceptions, is located at the top, the return pipeline at the bottom.

- Spills are made of pipes with a cross-section from 50 to 80 mm, and risers and inlets to batteries - from 20 to 25 mm.

- In the heating system, regulators are built into the bypass line of the pump or the jumper connecting the supply and return, ensuring that even with sudden changes in pressure, airing will not occur.

- The heat supply circuit contains shut-off valves.

There are no ideal operating conditions for a heating system. There are always losses that reduce pressure indicators, but still they should not go beyond the limits regulated by the Construction Norms and Rules of the Russian Federation SNiP 41-01-2003.

The concept of heating standards can be completely different for two situations: when the apartment is heated centrally, and when autonomous heating is installed and functioning in the house.

Central heating in the apartment

Advantages and disadvantages

A centralized heating system has both advantages and disadvantages.

Among the advantages are:

- reliability and quality of service due to constant monitoring of the system by technical services;

- relatively inexpensive fuel;

- environmentally friendly equipment;

- ease of use.

As for the disadvantages, they are as follows:

- pressure drops in the heating system;

- dependence of the work schedule on the seasons of the year;

- expensive equipment;

- inability to independently regulate the temperature on heating devices;

- colossal heat losses during its transportation through pipes and units.

Actions of an individual to stop paying for central heating

Having received permission from the relevant organizations to disconnect the apartment from central heating, and having completed all the work to re-equip the system, it is necessary to submit a package of documents to the heating networks so that the subscriber is excluded from the register of central heating users. Otherwise, you will have to pay for heating during operation.

The package of documents must include the following:

- A copy of the design documentation for the renovation of the apartment.

- A copy of the act of the relevant commission confirming the acceptance of the heating system.

You should also take into account additional regulations that each region may put forward on an individual basis.

Disadvantages of autonomous heating

Like any other heating system, an individual one also has its drawbacks. The most serious ones are:

user negligence. Any system in the house, be it heating or sewer, requires periodic preventive inspection and maintenance. And often the reason for a significant decrease in the efficiency of the system is precisely the prolonged lack of service repairs. As a rule, the system should be inspected by a specialist at least once a year. But many users simply forget about this, or simply do not want to spend money again. In fact, a preventive inspection of the system carried out by a specialist is inexpensive, but it can save you from a major breakdown in the future. the need to create a high-quality ventilation system and the negative impact on the environment

It should be noted that today the problem is less relevant than 10 years ago. Projects and rules for creating ventilation systems are approved by law, and quite a lot of attention is paid to this issue when planning a house.

Ventilation system of an apartment building

reduction in system efficiency due to unheated neighboring rooms. Unfortunately, this problem is very relevant. It especially affects those who, having purchased an apartment with individual heating in a new building, have no neighbors. In empty apartments, due to the absence of tenants, the autonomous heating of the houses does not work. That is, common walls always remain cold. As a result, this significantly reduces the heating level in occupied apartments. However, many owners of apartment buildings were able to solve this problem. A modern heating system is installed in each individual apartment, which allows you to automatically maintain a minimum heating level without requiring constant monitoring.

Every year more and more houses are put into operation, in which each individual apartment has its own heating system. The systems are regularly updated, which makes their implementation and use as efficient as possible and increasingly accessible.

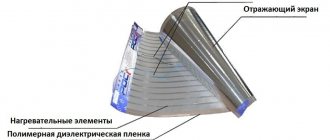

Automatic collector-beam system

The supply of coolant to radiators connected via radial wiring can be made automatically adjustable. In this case, instead of a plastic manual control cover (position 4 in the figure “Complete manifold block”), a small-sized electromechanical servo drive is installed on the thermal valves of the return manifold (position 2 in the figure “Complete manifold block”), connected by a cable to an analog thermostat or controller. Radiators are connected to heating pipes without any fittings at all (ball valves can be installed).

Dimensions of the thermal valve servo drive.

Such a scheme has increased capital costs, while simultaneously providing an increased level of comfort. The user-desired air temperature can be set from the control panel of the room thermostat, the signals of which are processed by servo drives on the thermal valves of the return manifold. The system can be controlled by a so-called chronothermostat, which provides the user with the ability to set a temperature control program for a week, differentiated by day of the week and time of day.