The potbelly stove is very popular for heating small spaces. It is an excellent option for a summer residence, and is very economical and easy to use. The appearance of this stove is a small rectangular box on four legs; it has a door and a compartment for storing fuel, as well as an ash drawer, which must be cleaned regularly. Each stove has a pipe onto which an exhaust pipe is installed; its length must be at least 5 meters. The longer the pipe, the better the traction and, accordingly, the power of the stove. This type of heating device can be made of cast iron or steel.

Potbelly stoves were very popular in the second half of the 19th and first half of the 20th centuries; they appeared in Russia. At that time, this device was considered an excellent solution for heating small houses and even city apartments. The stove consumes wood as fuel, but produces enough heat to heat a room of up to 60-70 square meters. Now such stoves are used for secondary heating, for example, in a country house. potbelly stoves in our time . It allows you to warm the room at the right time, and does not require any financial costs. To operate such a stove, you only need firewood, a chimney and good ventilation in the room.

Functional parameters of a potbelly stove

Nowadays, these stoves are created in various styles, so they can not only heat a room, but also decorate it . The potbelly stove can operate on wood, no more than 25 cm long, and other solid fuels, its main functions:

- Heating of the room;

- Possibility of cooking;

- Interior element, decoration.

The potbelly stove heating stove competes with fireplaces or brick stoves, but it has an advantage over them - very small dimensions. The potbelly stove is easy to connect, assemble and move to another place, take it outside for cooking in the fresh air, and so on.

If there is a need to constantly transport the stove, then a collapsible potbelly stove . It provides for the removal of the top cover, which can be a hob, collapsible legs and a chimney; it can also be divided into several sections. Thus, the potbelly stove does not take up much space, is a very mobile stove and is easy to transport. The use of this heating device eliminates the risk of carbon monoxide poisoning, since it all comes out through the chimney. The main thing is to carry out correct installation , this will allow the stove to operate at full capacity, which directly depends on the draft.

Possible difficulties during construction

The gas cylinder valve is screwed on very tightly. It's not easy to remove. Unscrewing will require a good adjustable wrench and a lot of physical effort. To make the process go faster, it is recommended to fix the cylinder.

Attention! Do not start cutting the cylinder without first filling it with water, as residual propane can lead to an explosion. Cutting metal, cutting sheet steel with a grinder is a labor-intensive process

The work will be speeded up by a plasma cutter, which can be rented from specialized companies.

Cutting metal and cutting sheet steel with a grinder is a labor-intensive process. The work will be speeded up by a plasma cutter, which can be rented from specialized companies.

A finished potbelly stove placed on a base may wobble. This happens if the heater legs are of different lengths. Trim them using a grinder.

Safety Recommendations

For such stoves it is recommended to use dry firewood and logs . To light a potbelly stove, you need to open the firebox door, load in the required amount of fuel and set it on fire. After the fuel has ignited, its power can be adjusted by opening the ash drawer. The unit can be cleaned of ash only in a cold state; the ash drawer is removed and all its contents are poured into the trash. When the stove is lit for the first time, there may be a smell of burning paint, but this will not happen again with subsequent uses.

What must be observed for safe operation of the potbelly stove:

- The stove must be installed on a non-combustible base ;

- All objects and flammable surfaces must be no closer than 70-80 cm from the stove;

- more than three kilograms of fuel into the potbelly stove at one time ;

- The firebox door should always be closed, except when loading firewood;

- It is prohibited to operate the stove if there is a problem with the exhaust pipe ;

- Do not leave the oven running unattended for a long time or in the presence of small children;

- It is forbidden to touch the oven body while it is running or immediately after the flame in it has gone out; the entire surface heats up to a very high temperature ;

- Do not leave or keep flammable objects or materials near a working stove.

If all the rules are followed, the potbelly stove will heat the room for a long time.

General rules

The art of properly heating a Russian bathhouse is not available to every steam room owner. Everything matters here: temperature, burning time of raw materials. You also need to be able to light wood in the stove. However, it all starts with careful preparation of the premises. All objects that are not directly related to the process of steaming and washing are removed from its space.

First, dry and then wet cleaning of the room is carried out. The shelves, walls, and ceiling are washed with a brush and an antiseptic solution. Upon completion of this procedure, doors and windows are opened and thorough ventilation is performed. This is necessary so that when the temperature rises in the bathhouse space, a favorable environment does not arise for the spread of pathogenic microflora.

Once the rooms have been properly ventilated, it’s time for kindling. Here are general recommendations that are relevant for all types of ovens. In general, the procedure includes several traditional points.

Preparing the oven. The grate and ash pan are cleaned using a special metal scoop with a long handle. You need to unload unburnt coals into any convenient container. Then the ash is used for its intended purpose as fertilizer or disposed of in any convenient way.

Preparing firewood. They need to be brought into the bathhouse and placed at a sufficient distance from the firebox to avoid accidental sparks.

Preparing the stones. With a closed type of heater, only rinsing the surface from settled soot is possible. When open, the stones are washed before each new use. You should take warm water.

Checking the water tank (if equipped)

It is important to make sure there is enough liquid inside. If the boiler is empty, the metal will simply burst under intense heating

For washing and rinsing in bathhouses without a plumbing system, a supply of water is prepared in a separate clean container.

Preparing for kindling. The steam room is closed, the valves, the doors of the smoke window, the blower and the firebox are pulled out and swung open. Next, using a lit match, you need to check the presence of draft - the flame should follow the air flow. If this does not happen, the chimney is clogged and needs cleaning. You need to use a special wire brush to remove carbon deposits.

Start of kindling. 2 thin logs are placed in the firebox on top of the grates, between them - crumpled newsprint, on top of it - thinly planed birch bark, wood chips or shavings. To secure it, a few more logs are added on top diagonally to the resulting structure, with a small gap. You should get a kind of “well” with dry and light filler inside.

Lighting the fire. If you lack experience, you should use long fireplace matches. They are lit and brought to the paper inside the firebox. It is strictly forbidden to use any chemical liquids for ignition in sauna stoves. If the firewood is damp, it is permissible to put a tablet of dry alcohol inside the kindling “well”. After the paper ignites, you need to wait a little and then close the firebox door.

If everything is done correctly, after a few minutes the fire will engulf the wood. Combustion will be accompanied by a characteristic measured hum. If the flame goes out, the steps will have to be repeated. After the flame flares up, the firebox door should be half-open, providing air flow. Then, if the structure has a water tank, its view opens and closes in the flood pipe - this is necessary so that the contents of the tank are heated.

5-10 minutes after kindling, the ignited firewood and coals are leveled, firewood is laid on top, filling no more than 2/3 of the firebox.

When the fuel burns completely, the coals become red, covered with gray ash, there are no blue tongues left in the flame (signs of the presence of carbon monoxide in the chamber), you can complete the procedure. It is worth making sure that the desired temperature has been reached in the steam room and that the stones in the oven are hot. After this, you can open the valves, simultaneously blocking the access of air through the blower. The firebox remains closed.

Upon completion of all combustion processes, you need to thoroughly ventilate the bathhouse from dampness by opening the doors and windows. The stones are rinsed with water from a ladle. This is necessary to remove traces of soot. Then the windows and doors are closed, except for the window in the steam room. After 1-2 hours you can start using the bath.

Advantages and disadvantages of a potbelly stove

A potbelly stove has a lot of advantages, the most important of which is efficiency , no fuel costs are required. The stove works great with any wood, sawdust, or wood chips, as long as they are dry enough to catch fire. This unit can be easily transported and food can be cooked on it without any problems if the potbelly stove model includes a hob on the top surface. This is an excellent option for a summer house that does not need to be heated every day; this unit can also be found at construction sites, in garages and other small spaces.

If you choose a stove in any style, it will also become a wonderful decoration and interior detail. A potbelly stove made of stainless steel quickly heats up and cools down after use, this allows you to clear it of ash as soon as possible after extinguishing the fire. This stove is durable and reliable; the materials from which it is made can easily withstand high temperatures and are not subject to destruction.

The disadvantages of this stove include the fact that it can provide a favorable environment only in a small room. Using it in a cottage or large building will not bring good results. A cast iron unit tends to cool down for a long time after operation. During operation of the stove, the natural smell of burning wood . It is necessary to constantly monitor the operation of the stove and after it, until the potbelly stove has completely cooled down.

Installing a stove in a country house

Before starting installation, you need to choose a suitable location for the stove. It must be remembered that it must be kept away from all foreign surfaces and objects. At the same time, her work must always be monitored, which means she must be in sight.

The legs of the potbelly stove are also made of metal and, accordingly, heat up to a high temperature. It is necessary to install the stove on a non-flammable base, such as: concrete, ceramic tiles, brickwork, tin covering. You cannot place a potbelly stove on linoleum, laminate, soft coverings, plank floors, parquet, or plastic.

Chimney pipes must be installed without connections within the same room. If such work cannot be carried out, then the connection should be as tight as possible, the lower part of the pipe should “fit” into the upper. If pipes require passage through walls, then you need to equip a ceramic or brick thermal barrier . The fuel storage location should be at a safe distance from the stove.

Criterias of choice

To choose the appropriate option, use the following recommendations:

- Select the maximum possible cost limit for the potbelly stove;

- Firebox volume (check the maximum load rate);

- Chimney diameter;

- Efficiency indicator;

- The presence of additional layers to improve efficiency;

- Composition of the material (metal or cast iron);

- Quality of finish, if any;

- Size and weight of the structure.

You can find a potbelly stove with a hob on sale. This will help reduce resource costs and save space - you can cook on the equipped surface of the oven.

Combined potbelly stoves

People often use such stoves not only for heating their homes; a potbelly stove with a cast-iron stove can also be used for cooking. Stoves with a water tank, which in appearance resemble a samovar, are very popular. A cast iron potbelly stove with one burner can perfectly replace a gas stove if it is used by one or two people. Ovens with a continuous cooking surface or several burners are also provided; there can be no more than four of them.

A potbelly stove has a low price, and no costs are required during operation, therefore it is the cheapest option for heating a country house or other small room.

Conclusion

For a country house, a potbelly stove is chosen to provide heating, cooking, and achieve certain aesthetic parameters. The options are different. Devices are divided by type of material into two categories - cast iron and steel (metal).

A cast iron potbelly stove for a wood-burning cottage is a heavy, reliable device that gives off heat for a long time. Steel equipment heats up faster and takes longer to cool down. Most models are equipped with a hob. When choosing, it is recommended to take into account the pipe performance, loading volume, burning duration, as well as how many square meters the device is designed to heat.

Where is the best place to put a stove in a wooden house?

The installation location of the stove in a wooden house is determined as follows:

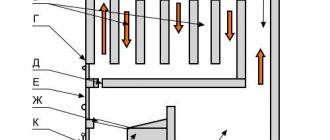

Principle of operation :- Air-heating furnaces, operating like the Russian “Burzhuika” or the Canadian “Buleryan”, are installed in a place where convection currents move unhindered. If it is planned to heat adjacent rooms, the structure is built into the interior partition, or air ducts are connected.

- A stove with a built-in water heat exchanger is installed so that the circuit in the stove is the lowest point of the heating system. The location is not critical and is determined only by fire safety requirements.

- Connecting a chimney - installation of a heating stove and chimney in a wooden house are closely interconnected. The stove is located where it will be easier to connect the chimney in compliance with fire safety requirements.

- Ease of maintenance - to fire and clean the stove, you will need a sufficient distance towards the opening of the combustion chamber door. Furnace equipment with panoramic glass provides the opportunity to admire a live flame; this feature is also taken into account when choosing a location

- Fire breaks - from the heating surfaces of the stove body to the walls made of combustible materials, leave a distance of 110-125 cm. In the direction of the opening fire door, at least 125 cm.

A rational installation is important, taking into account the optimal location of the furnace, ensuring better heat transfer, safety and ease of use.

Types of foundations for a stove in a wooden house

There are several types of foundations used for furnace equipment, each of which has its own characteristics, design and operation features.

When choosing a suitable foundation, consider the following:

- Installation cost – the price of building materials, installation and preparatory work is taken into account.

- Characteristics of the foundation and soil characteristics - the choice is based on the total weight of the structure, the type of soil (clayey, sandy, black soil, stone).

- Dimensions of the foundation for the stove in the house - depending on the area occupied by the stove equipment, the total weight of the structure, the required type of foundation is calculated.

Additionally, several other factors are taken into account. The choice of foundation is influenced by the time of manufacture of the foundation (in an already finished building or simultaneously with the construction of the house), the qualifications of the craftsman, weather conditions, speed of work, etc.

All existing foundations are usually classified into several groups:

- On stilts and pillars.

- Concrete bases.

The stove, subject to certain conditions, can be installed directly on the floor.

Foundations on piles and pillars

The base is made in three ways:

- Screw piles are a method that requires material investments. The advantage of using screw piles is the speed of installation. During installation, a worker drives a steel screw into the ground. The steel pillar will be the basis of the future foundation. The piles are tied together, after which a concrete pad is poured on top. The work only takes 1-2 days. You can even put a heavy cast-iron stove lined with brick on a screw foundation. The only drawback is the limited service life. The steel base rots after 50-60 years of use.

Bored piles - in this case, holes of sufficient depth and diameter are drilled with a drill. The resulting cavity is reinforced with a mesh to prevent soil from falling out. Knit a reinforcing structure. After reinforcement, the pillars are filled with concrete mixture.

Columnar piles - the process of installing the foundation is the same as in the case of using bored structures. The difference is that ready-made concrete or wooden pillars are used. Massive structures with a large weight load are installed on a columnar foundation. This is the design that is used in the construction of multi-storey buildings.

If you want to make a foundation for a stove in a wooden house with your own hands, without involving outside help, it is better to choose a pile structure, which is easy to install and does not require (with the exception of a screw device) serious material investments.

Concrete bases

The most common type of foundation used for furnace installations is a monolithic foundation made of concrete with mandatory reinforcement.

Concrete foundations are made in two ways:

- Strip foundation - a trench is dug along the perimeter of the structure below the freezing point. A metal frame made of reinforcement is installed. The structure is poured with concrete. The strip foundation of the stove cannot be connected to the foundation of the house. The foundation of the building is squeezed out of the ground in winter. The intensity of the “walking” of the walls, the rise from the ground varies, reaching 20-30 cm. If you make a common foundation, this will lead to the destruction of the brick cladding, and often to the deformation of a steel stove decorated like a brick. In any case, SNiP imposes a strict ban on making a common foundation for a stove and a residential building.

Concrete slab is another popular solution. The slab is poured with a thickness of 15-20 cm. If installed correctly, the result is a monolithic base that can withstand almost any load. To level and evenly distribute the weight, you will need to make a gravel-sand cushion under the foundation. The layer is thoroughly compacted with plenty of water. After filling, a layer of waterproofing is laid, beacons are placed, along which a concrete screed is poured. To prevent the slab from cracking, freshly poured concrete is covered with oilcloth. The base is watered for 2 weeks.

Installing a chimney in a wooden house

The combustion temperature inside the firebox of a solid fuel stove is at the level of 450-550°C. The surface of the chimney heats up to 300°C. When soot ignites, short-term heating to 800-1000°C is possible. Due to high temperatures, fire breaks must be provided when installing metal chimney pipes.

Existing PPB rules stipulate compliance with the following conditions:

- Chimney type - it is recommended to install a sandwich pipe made of stainless steel and ceramics with thermal insulation.

Breaks and thermal insulation materials - in places where they adjoin the walls, the pipe is removed from the surface by 25 cm. The walls are covered with basalt cardboard, followed by sheathing with stainless or galvanized steel.

Installation of ceiling cutting - when passing through the floor slabs, leave a distance of 25 cm on each side between the surface of the pipe and the combustible material. The gap is filled with basalt insulation. The use of factory ceiling trim is allowed.

The chimney is discharged inside and along the outer wall of the building. In the first case, care is taken to ensure sufficient insulation of the pipe when passing through the floors and roof. In the second, it becomes necessary to ensure that the chimney is fixed to the walls of the building to overcome the wind load.

Ceiling passage

To allow the sandwich to pass through the ceiling, a rectangular hole was cut to the size of the stainless ceiling cutout. An SML slab 8 mm thick and 60x60 cm in size was laid for cutting. This entire structure was screwed with self-tapping screws to the bars in the ceiling between the floors. In the ceiling around the pipe, insulation with foil two layers thick was laid, the foil was laid towards the sandwich. I taped all the seams with aluminum self-adhesive tape and covered the top with the same LSU sheet measuring 60x60 cm. The roof passage has not yet been laid in any way, because it is planned to redo the roof next year. Masterflash was placed on top and sealed with sealant.

How to protect a country house from fire when installing a stove

Fire regulations require protection of walls and floors made of combustible materials when using solid fuel heating equipment. Fire prevention measures include:

- Use of thermal insulation materials with a high degree of fire resistance to protect walls and ceilings at the installation site.

- Application of fire protection: impregnations and mastics.

Safe installation of the furnace and the use of fire prevention products are a mandatory requirement for the operation of furnace equipment.

How to cover the walls and ceiling when installing an iron stove

The part of the ceiling located above the stove and at the point where the chimney passes, as well as the adjacent walls, experience severe thermal stress. The following fire safety conditions and measures are considered mandatory:

- The ceiling is made of non-combustible materials. The use of wooden and plastic panels is not allowed. It is optimal to use gypsum fiber boards treated with gypsum putty for painting.

- The walls are protected with basalt cardboard followed by sheathing with steel sheets. For convenience, we use ready-made protective decorative wall screens made of stainless steel, which have a beautiful appearance and provide a high degree of safety. The walls are protected with plaster with a thickness of at least 3 cm, as well as brickwork.

Fire safety requirements for installing a metal stove in a wooden house are described in detail in SNiP 31-05-2003 and SP 118.13330.2012.

Fire retardant treatment of wooden structures

Where the stove is installed, wooden walls are protected using fire retardants: mastics and impregnations. Load-bearing structures and beams must be processed. Fire retardants are applied to the walls and floors where the furnace equipment is installed.

Mastics and impregnations have been developed for protection. The former provide better fire protection, the latter are almost colorless.

The order of installation regarding fire safety measures specified by the manufacturer is specified in the technical documentation. Fire protection work is carried out by representatives of the Ministry of Emergency Situations. You can take measures to prevent fire yourself, but before putting the stove into operation, you will need to obtain a certificate from the inspector of the Ministry of Emergency Situations about the fulfillment of all requirements of the safety regulations.

Detailed parameters for installing a solid fuel heating country stove are described in the technical documentation attached to the heaters of leading European and Russian factories. Compliance with the described rules is mandatory.

A potbelly stove can quickly heat a small room. A potbelly stove is popular for heating small rooms. A potbelly stove can often be found at dachas, as it is economical and easy to use. It is presented in the form of a box with doors. It has 2 doors, one for storing fuel, and the second for removing ash. Each of these stoves has a pipe for installing a chimney. The chimney must be at least 5 meters. And the larger the exhaust pipe, the better organized it will be, and as a result, the more powerful the heating. It can be made of steel or cast iron.

Wood processing

The most common protective agents include special impregnations (fire retardants) and transparent mastics. They usually process the following elements of wooden structures:

- ceiling beams;

- floorboards in the stove installation area;

- walls adjacent to it.

Additional Information! When choosing products, it should be taken into account that putty has a higher fire protection rating than colorless impregnation.

Fire retardant treatment of wooden elements can be carried out not only by representatives of the Ministry of Emergency Situations, but also by the owners of the house. In the second case, they will need to obtain a special certificate confirming the correct installation of the oven.

Potbelly stove for a summer residence: main functions

Today, such stoves are made in different styles and therefore they serve not only for heating the room, but also perfectly decorate it. The potbelly stove can be operated using solid fuel and wood of no more than 25 cm.

The main functions of a potbelly stove are:

- Warming up the rooms;

- You can cook food on it;

- And an element of room decoration.

Among the advantages of a potbelly stove for a summer residence, it is worth noting its compactness and excellent aesthetic properties

A potbelly stove competes with fireplaces and stoves, but it has an advantage over them. The advantage of a potbelly stove is its small size. Also, such a stove is easy to install and assemble for transportation. If you need to constantly transport it, then a collapsible potbelly stove would be the best option. From such a potbelly stove you can remove the top cover, hob, legs, pipe, which can also be disassembled into several parts.

And with this feature, this oven does not take up much space, is mobile and easy to transport. When using this unit, the danger of carbon monoxide poisoning is completely eliminated; it is completely released through the chimney. It is important to install the stove correctly. This will allow the stove to work at full power, and the power depends entirely on the draft of the stove.

Potbelly stove for a summer residence: safety recommendations

It is recommended to use only dry firewood or logs for a potbelly stove. To light a potbelly stove, you need to open the firebox door, put wood in there and light it. After the fuel has ignited, the power can be adjusted using the ash door. It is necessary to clean the ash pan only when the oven has completely cooled down. And this is done in this way: the ash box is taken out and all the contents are poured into the trash. If the stove is lit for the first time, a paint smell may appear; the second time it is used, this will no longer be the case.

The potbelly stove should be checked regularly for cracks.

To ensure safe use, the following requirements must be met:

- The potbelly stove must be installed on non-combustible foundations;

- Objects and surfaces that easily catch fire should not be located at a distance closer than 1 m;

- You cannot put more than 3 kg of fuel into the firebox of a potbelly stove at a time;

- The firebox must be constantly closed with the door, except when adding fuel;

- You cannot use a potbelly stove if the exhaust pipe is not working;

- Do not touch a burning potbelly stove with your hands under any circumstances, since the entire outer part is heated to the maximum;

- Do not place flammable objects close to the stove.

Compliance with these rules will allow your stove to serve you for the longest time possible.

Installing a stove in a country house with your own hands

To begin installation, you need to determine the place where the potbelly stove will be located. Moreover, it is important not to forget that the stove should not be located close to all other objects. You also need to keep an eye on the potbelly stove during operation, which means that it should be visible to you.

You must adhere to the following rules:

- Since the legs are metal, they also heat up to a high temperature. The stove must be installed on a non-combustible base, it can be concrete, tile, brick or tin. Under no circumstances should you place it on a soft surface, on a wooden floor, on parquet, etc.

- The chimney should not have connections within the room. If this cannot be avoided, then the connections must be as tight as possible and the lower part of the pipe must fit into the pipe. If the pipe is to pass through the wall, then in this case it is necessary to make a brick or ceramic thermal barrier.

In addition, be sure to monitor fuel storage. It should not be near the stove.

How to install a potbelly stove in the country

It is very easy to install the oven correctly with your own hands. It is ideal for a private home and will look great on a wooden floor, of course, if you take all safety measures. A modern stove of this type will look beautiful in an apartment with a European renovation, and in any interior this beautiful installation will please the eye. And you can choose it on the well-known alx, where you will see a photo and select the desired design. To install a potbelly stove, you first need to familiarize yourself with the requirements.

The potbelly stove must be installed in such a way that it does not come into contact with flammable materials

The requirements for installing a potbelly stove are:

- You cannot install a potbelly stove in a garage or house if there are lubricants and flammable materials in these rooms;

- The room where the potbelly stove is installed must be well ventilated;

- It is necessary to organize the movement of heat flow so that the heat transfer of the furnace is not too large;

- It is necessary to provide components that will prevent sparks from entering the room and ensure safety of use.

When installing the stove, you must not forget that the body also gets very hot to a high temperature. Ovens made of stainless steel heat up less and cool down faster. Potbelly stoves made of cast iron retain heat longer and for this reason it is necessary to install such stoves in places where you can see them.

When installing a potbelly stove on metal legs, you need to remember that the legs of the structure will also heat up to a high temperature. The temperature of the legs is of course lower than the temperature of the case, but the difference is not great. The installation of a potbelly stove in a country house must be done on a fireproof coating.

For installation as a base you can use:

- Tin base;

- Concrete floors or structures;

- Tile bases;

- Brick laying.

Grounds that are fire hazardous for installing a stove:

- Made from any type of plastic base;

- Parquet or wooden floor;

- Laminate or linoleum flooring.

Also, under no circumstances should the stove be installed on soft surfaces such as carpet.

If your house has wooden walls or panels, the stove should be installed at least 1 meter away from them. The chimney pipe in the room should not have joints, it should be solid. If this is not possible, then it is necessary to make the most airtight connections possible. In this case, the lower part of the pipe must fit into the upper part.

A little history

Potbelly stove Mr. Heath Where did this design come from, and why does its popularity continue unabated these days?

The history of the appearance of the potbelly stove begins at the end of the 18th century. Essentially, it is a cheap alternative to expensive fireplaces and stoves. The device gained particular popularity during the October Revolution, when all the norms and foundations of life were turned upside down. Heating residential and non-residential premises became problematic, so this simple unit quickly spread throughout the country. After all, everything solid that could burn was used as fuel here. And this is firewood, coal, peat, furniture, wooden windows and doors. Potbelly stoves gained a second round of popularity during the Great Patriotic War. In many cities, centralized heating networks did not work, and the country saved energy by sending it to the front. The population had no choice but to use the old proven method - install potbelly stoves in their own apartments.

This stove saved a large number of people from freezing. It worked flawlessly, although it consumed a lot of fuel. And this is its big disadvantage. But this is the simplest and cheapest device that you can make with your own hands, and it is easy to operate.

Currently, potbelly stoves have found their application in country houses, garages, bathhouses and other outbuildings. In modern apartments they were practically not used, if only as a decorative element, creating an antique style. But recently the fashion for them has returned.

True, consumers began to impose more stringent requirements on potbelly stoves:

- Reducing fire danger.

- Presentable appearance.

- Economical fuel consumption.

Let's look at these requirements separately and reveal the secrets of new popularity.