Owners of private houses strive in every possible way to save on heating, which requires considerable costs from year to year. In order to create economical heating systems in residential, industrial, and public premises, various schemes for generating profitable thermal energy are being developed and put into practice. A cavitation heat generator is suitable for these purposes.

To save on thermal energy - this heat generator will help you with this

Design features and operating principle

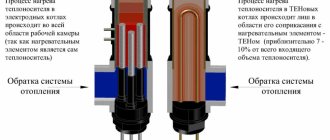

Based on a cavitation heat generator, the mechanical energy of the movement of water (working fluid) is converted into heat, which is used to heat premises for any purpose. Cavitation involves the formation of bubbles in a liquid, the destruction of which produces thermal energy.

Operating principle of the cavitator:

- the working flow moves through a device in which pressure is provided by a pump,

- further, with increasing speed, a local decrease in the pressure of the substance occurs,

- Free spaces are formed in the liquid and filled with bubbles.

Subsequently, the flows mix in the center of the chamber, and the process of cavitation occurs: the bubbles collapse, as a result of which mechanical energy is converted into thermal potential. This is explained by the fact that during the formation of a vortex flow, cavitation ruptures lead to heating of the liquid medium.

Common devices

Let's look at the most frequently advertised vortex pumps on the Internet.

The NTG-5.5 pump produced by NPP EcoEnergoMash has the following characteristics:

- Electric motor power: 5.5 kW

- Heating capacity: 6.6 kW/h

Here the first question arises for the manufacturer: how, bypassing the law of conservation of energy, does this device produce more thermal energy than it consumes electrical energy? Exactly the same excess of heat generation over energy consumption is promised for other products from this company.

Possible applications

Cavitation devices are in demand in various industries, and they are mainly used as an alternative type of heating systems for the home. The equipment is also used in other areas:

- heating and purification of water in swimming pools,

- cleaning deposits inside heat exchangers,

- in industry.

In the latter case, for example, in the production of concrete with high performance characteristics.

Heating

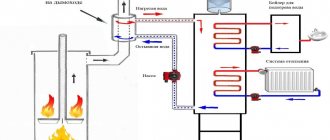

A cavitation device helps convert the mechanical energy of moving water into thermal potential, which is used to heat buildings of various purposes and sizes, including private households and industrial complexes.

Cavitation heat generator can be used for heating

Autonomous heating of water for domestic needs

The cavitation heat generator is capable of fully providing the household with hot water, which is supplied to the kitchen, bathroom, and bathhouse. The equipment is also used in water preparation in swimming pools, laundries and saunas, and is used in autonomous water supply systems.

Application of heat cavitation in production

The devices are relevant when it is necessary to qualitatively mix substances with different density parameters and are used in laboratories, production shops and other industrial facilities.

Installing the pump

Next we must choose the “right” water pump. The range of these tools today is so wide that you can find a model of any strength and size. We only need to pay attention to two things:

- Will the engine be able to spin this pump;

- Is it (the pump) centrifugal?

Next, the pump is installed in the same frame; if necessary, additional fasteners are attached.

The body of a vortex generator is a cylinder, closed on both sides. There should be through holes on the sides through which the device will be connected to the heating system. But the main feature of the design is inside the body: a nozzle is located immediately near the inlet. The nozzle hole must be selected purely individually.

Note! It is desirable that the nozzle hole be half as large as 1/4 of the total diameter of the cylinder. If the hole is smaller, then water will not be able to pass through it in the required quantity and the pump will begin to heat up. Moreover, internal elements will begin to be destroyed by cavitation.

To make the case we will need the following tools:

- Iron pipe with thick walls with a diameter of about 10 cm;

- Couplings for connection;

- Welding;

- Several electrodes;

- Impeller;

- A pair of pipes with threads;

- Electric drill;

- Drill;

- Adjustable wrench.

Now - directly to the manufacturing process.

- To begin with, we cut off a piece of pipe about 50-60 cm long and make an external groove on its surface about half the thickness, 2-2.5 cm. We cut the thread.

- We take two more pieces of the same pipe, each 5 cm long, and make a couple of rings from them.

- Then we take a metal sheet with the same thickness as the pipe, cut out original covers from it, and weld them where the thread was not made.

- We make two holes in the center of the covers - one of them around the circumference of the pipe, the second around the circumference of the nozzle. Inside the cover next to the jet we drill a chamfer so that we get a nozzle.

- We connect the generator to the heating system. We connect the pipe near the nozzle to the pump, but only to the hole from which water flows under pressure. We connect the second pipe to the entrance to the heating system, but the output must be connected to the pump inlet.

The pump will create pressure, which, acting on the water, will force it to pass through the nozzle of our design. In a special chamber, the water will overheat due to active mixing, after which it is supplied directly to the heating circuit. In order to be able to regulate the temperature, the vortex heat generator must be equipped with a special locking device located next to the pipe. If you slightly cover the constipation, the structure will take longer to move water through the chamber, therefore, the temperature will rise because of this. This is how this kind of heater works.

Read about other alternative heating methods here

Varieties

Cavitation devices are divided into the following types:

- rotary - a vortex cavitation heat generator includes a modified centrifugal pump, the body of which is a stator with an inlet and outlet pipe. The main working part of the device is a chamber with a movable rotor that rotates like a wheel,

- static - the device has no rotating parts; for cavitation, a nozzle design with a powerful centrifugal pump is used,

- tubular - the design includes longitudinally arranged tubes. The efficiency of tubular cavitation heat generators is high,

- ultrasonic – the cavitation effect is achieved using ultrasonic waves.

Vortex cavitation heat generator

The efficiency of ultrasonic equipment is incredibly high.

Operating principle of rotary generators

Perhaps the most productive models include the Griggs design, in which a disk-shaped rotor has a surface with numerous blind holes of a certain diameter and depth. The stator is presented in the form of a cylinder with sealed ends in which the rotor rotates. There is a gap of about 1.5 mm between the rotor disk and the stator walls. In the cells of the device, turbulence is generated to form cavitation cavities. The number of cells is determined by the rotor speed.

As experts note, for the efficiency of the device, a rotor with a transverse size of 30 cm and a rotation speed of 3,000 rpm is used. With a smaller diameter, it is necessary to increase the speed parameters.

Features of rotary heat generators of cavitation action:

- there is a significant noise level,

- The efficiency of the device is not impressive,

- short service life,

- performance indicators are 25% higher than static models.

When operating a rotary unit, it is necessary to work out the precise operation of all elements, including balancing the cylinder. It is also necessary to promptly replace insulating materials for the shaft seal that have exhausted their potential.

Operating principle of a static heat generator

Cavitation involves a high speed of movement of the working fluid using a powerful centrifugal motor. Since d of the nozzle exit is significantly less than the parameters of the opposite end, the speed of movement of the substance increases, and cavitation effects occur.

Static cavitation devices have many advantages:

- no balancing or precise fitting of parts is required,

- the seals wear out less than in the rotary model, since there are no moving parts,

- The service life of the static cavitator is about 5 years, which is significantly longer than that of the previous version of the device.

If necessary, the nozzle is replaced, which requires a relatively small expenditure of time and effort, whereas in the case of a rotary device it will be necessary to recreate it again if the equipment fails.

Tubular heat generators: design and principle of operation

In this model, cavitation heat is generated due to the longitudinal arrangement of the tubes:

- the pump helps to build up pressure into the incoming chamber, and the working substance is directed through the tubes. In this case, bubbles form at the inlet,

- When entering the second chamber, where high pressure is established, the bubbles are destroyed, creating a thermal potential in the process.

Tubular heat generator

The energy generated in this way is sent along with the steam to heat the house. According to manufacturers of tubular cavitation heat generators, as well as experts in the field of climate control equipment, this model is characterized by high efficiency indicators.

Features of ultrasonic cavitation generators

The installation creates ultrasonic waves, which generate cavitation heat. For this purpose, a quartz plate is used; on its basis, sound vibrations are created under the influence of electric current. They are directed to the entrance, subsequently creating vibration. During the reverse phase of sound waves, areas of rarefaction appear and the effect of cavitation is observed. The operating principle of the ultrasonic cavitator assumes minimal energy losses and virtually no friction. All this determines the exceptionally high efficiency of ultrasonic equipment.

Types of heaters

A cavitation heating boiler is one of the most common types of heaters. The most popular of them:

- Rotary installations, among which the Griggs device deserves special attention. The essence of its action is based on a rotary centrifugal pump. Externally, the described design resembles a disk with several holes. Each such niche is called a Griggs cell; their number and functional parameters are interdependent with the drive speed and the type of generating set used. The working fluid is heated in the space between the rotor and stator due to its rapid movement along the disk surface.

- Static heaters. The boilers do not have any moving parts; cavitation in them is ensured by special Laval elements. A pump installed in the heating system sets the required water pressure, which begins to move quickly and heat up. Due to the narrow holes in the nozzles, the liquid moves at an accelerated rate. Due to its rapid expansion, the cavitation necessary for heating is achieved.

The choice of a particular heater depends on the needs of the person. It should be taken into account that the rotary cavitator is more productive, and it is also smaller in size.

The peculiarity of the static unit is the absence of rotating parts, which determines its long service life. Duration of operation without maintenance reaches 5 years. If the nozzle breaks, it can be easily replaced, which costs much less than purchasing a new working element for a rotary installation.

Advantages and disadvantages

The main advantage of a cavitation heat generator is the economical operation of the heating device. The following factors are also noted among the advantages:

- high level of device performance,

- possibility of independent production and installation,

- equipment can be installed without permits.

Among the disadvantages are:

- it is necessary to arrange a separate room for the boiler room,

- Quite a high noise level during operation of the device.

We must not forget that equipment takes up a lot of space.

Vortex damper

Yes, we will make a device with such a mysterious name - a vortex damper. It will consist of plates arranged lengthwise, placed inside both rings.

Let's see what we need for the job.

- Welding.

- Turbinka.

- Sheet of steel.

- Pipe with thick walls.

The pipe should be smaller than the heat generator. We make two rings out of it, about 5 cm each. We cut several strips of the same size from the sheet. Their length should be 1/4 of the length of the device body, and their width should be such that after assembly there is free space inside.

- We insert the plate into the vice, hang metal rings on one end of it and weld them to the plate.

- We take the plate out of the clamp and turn it the other way. We take the second plate and place it in the rings so that both plates are placed parallel. We fasten all the remaining plates in the same way.

- We assemble the vortex generator with our own hands, and install the resulting structure opposite the nozzle.

Note that the scope for improving the device is almost limitless. For example, instead of the above plates, we can use steel wire, first twisting it into a ball. In addition, we can make holes in plates of various sizes. Of course, none of this is mentioned anywhere, but who says you can't use these improvements?

And as a conclusion, here are some practical tips. Firstly, it is advisable to protect all surfaces by painting. Secondly, all internal parts should be made of thick materials, since it (the parts) will constantly be in a fairly aggressive environment. And thirdly, take care of several spare caps that have different hole sizes. In the future, you will select the required diameter in order to achieve maximum performance of the device.

The cavitation heat generator is characterized by good efficiency and compactness. It is rare that an owner does not try to save on heating or the consumption of other benefits, which become more and more expensive every year. To make the heating system of a residential or industrial premises economical, many people resort to various schemes and methods for generating thermal energy. One of the devices suitable for these purposes is a cavitation heat generator.

Criterias of choice

When choosing a cavitation device, consider the following points:

- It is important to select a design in accordance with operating conditions. It is necessary to take into account the scale of the heated space, the possibility of thermal insulation of the premises, and the climatic features of the area in the off-season and in winter.

- It is worth addressing configuration issues when purchasing standard equipment. In this case, it is desirable that the product be equipped with protection sensors and heat monitoring devices. The best option is to purchase equipment with an automatic monitoring and control unit; it is also worth ordering.

- If you purchase equipment individually, you must clearly know all the features of each component of the system.

If you plan to make it yourself, it is important to carefully study the diagrams and arm yourself with the recommendations of specialists, then proceed to choosing a model.

We insulate the VTP

First of all, we put on the casing. To do this, take a sheet of aluminum or stainless steel and cut out a couple of rectangles. It is better to bend them along a pipe that has a larger diameter, so that a cylinder is eventually formed. Next we follow the instructions.

- We fasten the halves together using a special lock used to connect water pipes.

- We make a couple of covers for the casing, but do not forget that there should be holes in them for connection.

- We wrap the device with thermal insulating material.

- Place the generator in the housing and close both covers tightly.

There is another way to increase productivity, but for this you need to know how exactly Popov’s miracle device works, the efficiency of which can exceed (not proven and not explained) 100%. You and I already know how it works, so we can proceed directly to improving the generator.

Popular models

Domestic manufacturers offer models of hydraulic shock and electrohydraulic shock cavitators. The line includes low-power units.

VTG-2.2

The equipment is a low-power device that is suitable for heating buildings with a volume of up to 90 m³. The cost of products varies between 32-35 thousand rubles.

VGT-30

Medium power unit, designed for heating buildings with a volume of up to 1400 m³. A control cabinet is required. The price of the product is about 150,000 rubles.

ITPO

The products of Izhevsk manufacturers, as claimed by cavitator suppliers, have an efficiency of up to 150%. Despite the high cost range, the model attracts the attention of a wide audience of consumers.

How to make cavitation heat generators with your own hands?

The equipment is a simple device, which allows you to independently manufacture the structure if necessary.

Required tools and materials:

- pressure gauges – to control inlet/outlet pressure,

- thermometers – for measuring the temperature of the working fluid at the inlet/outlet,

- thermometer sleeves.

You also need pipes with taps - inlet and outlet.

Features of pump selection

The pump parameters must meet specific requirements. So, you need a unit with the ability to work with high-temperature substances. The ability of the device to create the required operating pressure is also taken into account - at the entrance of the liquid, a pressure of 4 atmospheres is sufficient; to increase the heating rate, an indicator of up to 12 atmospheres is required.

Manufacturing of a cavitation chamber

Homemade cavitation devices most often provide an option in the form of a Laval nozzle. When choosing the cross-sectional size of the passage channel, it is worth considering that it is necessary to ensure the maximum pressure drop of the working substance. To do this, select a model with the smallest diameter; the result is a fairly active cavitation process. D9-16 mm is considered acceptable; with a smaller cross-section, the intensity of the water flow decreases, which leads to mixing of liquid with cold masses. The use of a nozzle with a small hole is also fraught with the following consequences:

- the number of air bubbles increases. As a result, there is an increase in noise during equipment operation,

- there is a risk of bubbles forming already in the pump chamber, which can cause its rapid failure.

Depending on the installation parameters, cylindrical, rounded or conical nozzles are selected. The main thing is that it is necessary to ensure the formation of a vortex process already at the initial stage of the working substance entering the nozzle.

Features of manufacturing a water circuit

When designing a device yourself, first perform a diagram: determine the length of the contour, clarify the features of the model, and transfer all this with chalk to the floor.

The design is a curved pipe that is connected to the chamber outlet, then the working medium is again supplied to the input. The substance enters the circuit in a counterclockwise direction. The circuit is equipped with two pressure gauges and a pair of sleeves with thermometers. The model is complemented by a valve for collecting air. To regulate pressure, a valve is installed between the inlet and outlet.

Generator test

After installing the equipment and connecting the radiators to the heating system, the pumping device is plugged in and the engine is started. When the structure is working properly, the required amount of water is supplied. The reading of the pressure gauges of the liquid medium is adjusted using a valve, taking into account that a difference in the range of 8-12 atmospheres is required. After starting the working fluid, observe the temperature parameters: heating of 3-5°C/10 minutes is considered correct. Taking into account that the system and pump are powered by 15 liters of water, the heating will reach 60°C in a short period of time. This is a good result for the efficient operation of heating equipment.

Cavitation-type heating equipment is an economical device that can heat a room in a short period of time. Manufacturers offer various models of the device; if necessary, it is easy to make the structures yourself, taking into account the characteristics of the area being developed.

Physical Basics

Cavitation is the formation of steam in a mass of water with a slow decrease in pressure and high speed.

Vapor bubbles can arise under the influence of a sound wave of a certain frequency or radiation from a coherent light source.

In the process of mixing steam voids with water under pressure, it leads to the spontaneous collapse of bubbles and the occurrence of water movement of impact force (it is written about the calculation of hydraulic shock in pipelines).

Under such conditions, molecules of dissolved gases are released into the resulting cavities.

As the cavitation process progresses, the temperature inside the bubbles rises to 1200 degrees.

This negatively affects the materials of water tanks, since oxygen at such temperatures begins to intensively oxidize the material.

Experiments have shown that under such conditions even alloys of precious metals are subject to destruction.

Making a cavitation generator yourself is quite simple. The well-studied technology has been embodied in materials and used for space heating for several years.

In Russia, the first device was patented in 2013.

The generator was a closed container through which water was supplied under pressure. Vapor bubbles are formed under the influence of an alternating electromagnetic field.

What do you know about polypropylene pipes for cold and hot water supply? In this useful article, read about how they differ, as well as the advantages of some and the disadvantages of others.

Read reviews of dishwasher detergents on this page.