Choosing the right fireplace model for your home is very important. But to obtain a high-quality and safe fireplace, it is necessary to correctly install the fireplace.

It is important to understand that a wooden house is a fire hazard, so many owners are afraid to install a fireplace in them. However, having the knowledge of how to properly install a fireplace, observing all fire safety standards, you can nullify all such fears.

Types of fireplaces for a wooden house

When choosing a stove for a wooden house, it is important to choose a model that is not only efficient, but also fireproof:

- The Russian stove takes up a lot of space, so it is ideal for a large house. In addition to reliable heating, it makes it possible to cook; all you need to do is install a hob and oven.

*

- A fireplace stove, as the name suggests, contains both a fireplace and a stove. This is a fairly safe and effective type of fireplace. Its design allows you to quickly and effectively warm up the room, which is very important in winter, especially if there are interruptions in gas or electricity supply. Such structures can be cast iron or steel.

- The bio-fireplace is easy to install and operate and greatly enhances the interior of the home. Environmentally friendly bioethanol in liquid form is used as fuel.

- An electric fireplace is also easy to install, convenient to use, safe, but depends on the supply of electricity.

- A gas fireplace has good heat transfer, easy ignition and the absence of soot and soot, but requires a gas pipeline.

By location they can be:

- Frontal, installed along the walls;

- Corner, they fill the corner of the room and take up relatively little space;

- Island, installed away from the walls.

Fireproof glass

Typically, materials that provide various types of protection are subject to the most severe tests from external factors. Their high technical performance inversely affects the aesthetic appearance. But modern technologies make it possible to achieve a level at which the use of heavy-duty materials is possible not only in technical terms, but also as decorative elements.

Heat-resistant floor glasses have the described characteristics; they are not subject to damage in the form of scratches and retain their integrity when subjected to impact. The maximum permissible pressure is tens of times higher than real conditions. Therefore, they place such glass under the fireplace, directly on a prepared, flat floor surface. It not only supports the weight of the fireplace, but is also resistant to damage from firewood temporarily placed next to the fireplace.

The variety of designs allows you to choose the right glass size for wall-mounted or corner fireplace models. The glass platforms are only 6 mm thick. Thanks to this, there is no need to finish the level transition from the stand to the floor.

Fireplace in a wooden house

*

Recently, a country house is gradually turning into a full-fledged year-round home. In any home, the main issue is heating. Owners of wooden buildings often prefer to use a fireplace with natural fire as a heater.

However, when choosing this heating method, it is very important to remember safety rules, because the main material of the constructed home is easily combustible.

A classic wood-burning fireplace has a closed firebox and a chimney pipe. Such a stove is usually finished with natural stone or other heat-resistant materials.

Important! Installation of a fireplace in a wooden house should be carried out no earlier than 3 years after the construction of the house itself; this time is necessary for the shrinkage of wooden structures.

What fuel to use

The main fuel for metal fireplaces is wood. The wood of deciduous trees (birch and ash) will quickly heat up the fireplace and the room where it is installed. And coniferous firewood (spruce or pine) will fill the room with the specific aroma of pine resin. However, it is not recommended to often burn a fireplace with pine wood, since the released resins quickly pollute the chimney and fireplace grate.

Sometimes peat pellets can be used in wood-burning fireplaces. But coal cannot be used as fuel. In addition to increased contamination of the room, it greatly heats up the working elements of the fireplace, which can lead to their deformation and damage to the fireplace.

In some cases, by modifying the design of the fireplace, natural gas can be used as a fuel source. But it must be remembered that the installation of gas equipment is possible only subject to prior approval of the project with gas services.

Basic rules for installing a fireplace

*

How to install a fireplace in a wooden house? To answer this question, we highlight the mandatory requirements:

- At the design stage of the building, the presence of a fireplace is provided. When building a house, it is necessary to insulate the inside of the fireplace wall using a metal sheet.

- The heating device should not be tied to the walls of the house.

- A separate independent base for the stove must be created.

- The floor around the fireplace is insulated to prevent fire; for this, ceramic tiles, iron sheets, roofing felt, etc. are used.

- The ceiling should be protected from the effects of elevated temperatures using plasterboard partitions and metal gratings.

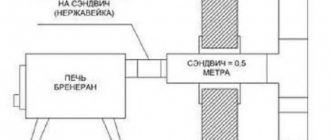

- When constructing a chimney, fire-resistant sandwich panels are used.

- If there are several floors in the house, heating structures must be provided separately for each level. Planning the installation of a fireplace at the design stage of a wooden house makes it possible to foresee all fire safety measures in advance.

Choosing a fireplace location

After choosing a model, it is important to decide on its location in a wooden house. This factor is one of the determining factors for ensuring safety.

- The stove should not be placed opposite windows and doors to avoid drafts, as this may subsequently lead to smoke.

- It is not advisable to install it in small rooms, since optimal combustion requires a large supply of oxygen. If it is necessary to heat a large area, it is recommended to use air ducts.

- The floor near the fireplace should be lined with non-combustible materials such as metal, stone, porcelain stoneware. This measure will help prevent a fire if coal or sparks fall out.

The ideal option in a wooden house is a free-standing structure, not attached to the walls of the building.

When located next to a wall, its surface must be protected with brick or metal.

See also the article: types and photographs of gazebos with a fireplace!

Preparing the premises

The most important stage in installing a metal furnace is preparing the site for its placement. There are several reasons for this. Firstly, you need to take into account the location of windows and doors so that the thermal radiation emitted by the walls of the stove is correctly distributed throughout the room. Secondly, it is necessary to provide space for fuel storage. It should be positioned so that you can easily transport it to your destination.

Thirdly, it is extremely important to ensure fire safety. This is perhaps the most basic thing that needs to be done, so let’s look at this in more detail.

Protection of the premises from fire is ensured in several stages:

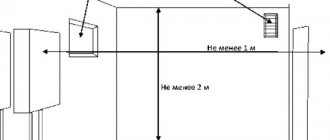

- it is necessary to maintain a minimum distance from the stove to the walls and furnishings. It must be at least 50 centimeters. Remember that the metal body produces rather harsh and powerful thermal radiation, and wooden walls easily catch fire even with the protection that will be discussed below. Also, ensure a free approach to the combustion chamber - keep in mind that you will need a place where you can easily move, bend over, when laying firewood or other fuel. According to the standard, 130 centimeters is enough for this;

- the surface of the floor and walls that are in the immediate vicinity of the stove must be insulated using fire-resistant materials. In the first case, the role of such can be successfully played by a concrete screed, ceramic tiles or metal sheet. The floor should be protected not only under the stove, but also around it at a distance of 50 to 70 cm. As for the walls, they can be covered with asbestos sheets. Superisol is also a good choice. If you equip such high-quality protection, then the distance from the stove to the wall can be made less than indicated above - 20 centimeters will be enough. If the stove is placed in such a way that the furnishings are too close to it, then it is necessary to protect them with the same asbestos sheets;

- The distance to the ceiling should also be maintained taking into account safety requirements. it must be at least 120 centimeters;

- the design of some stoves provides for the installation of not only a chimney, but also special channels running inside the walls. This is done to heat neighboring rooms. The walls of these channels must also be made of high-quality materials that are resistant to high temperatures;

- the last point concerns general safety not related to fire. During operation of the furnace, its walls become heated, their temperature ranges from 500 to 600 degrees. Touching them at this moment is fraught with very serious burns. Therefore, if there are animals or small children in the house, it is necessary to fence the structure with some kind of fence. Naturally, it is absolutely forbidden to install such a stove in a children's room.

As for the process of laying tiles, there are also several rules:

If the floor is made of concrete, then you can lay ceramics directly on it. If it is wooden, then between the surface and the tile it is necessary to make a layer of plywood or plasterboard. A glass-magnesite sheet is also suitable for this purpose. The layer must be firmly fixed to the floor using self-tapping screws, primed and wait for the composition to dry completely. Only after this can you begin further work; For installation you will need a tile adhesive composition, as well as a building level. The level must be used in order to achieve the ideal appearance of the finish. This point is especially important when laying the first row of tiles - if unevenness occurs at this stage, this will lead to distortion of the entire coating

Tile adhesive must be applied using a notched trowel - it will give the necessary evenness to the adhesive layer, which is also important for installation; don’t be too lazy to use special crosses that are placed at the joints of the tiles. This will help make the seams even.

The crosses are removed two days after installation is completed. Then the seams are filled with decorative grout. However, the last stage is optional; The tiles are attached to the wall using a special heat-resistant mastic. As with the floor, do not forget to use a building level during the installation process to check the levelness.

Fireplace base structure

*

Depending on the dimensions and material used, the weight of the firebox can be more than 100 kg, and taking into account the lining, sometimes over 500 kg. Plus the weight of the brick partition protecting the wooden wall of the house. This is almost 1000 kg. Let's add the weight of the chimney. This design requires a heat-resistant, durable base.

Therefore, before laying the fireplace, the floor layer is dismantled and a pit is dug. A layer of crushed stone is placed on its bottom, compacted and filled with a solution of a mixture of sand and cement in a ratio of 3:1.

Next, roofing felt is laid for waterproofing.

A sheet of metal is laid on the wooden floor in front of the fireplace.

To build wall-mounted fireplaces, the adjacent building wall is insulated using heat-resistant materials, such as brick.

When laying its base, red brick is used, and when creating the firebox, fire-resistant brick is used. When constructing a chimney, sheets of metal are used.

Assembly stages

If you decide to assemble a fireplace with your own rivers, you will need to acquire: standard and fireclay bricks, a grate, a door with a glass window, and dampers.

To assemble the main structure we will need solid bricks, while to assemble the chimney and firebox opening we will only need fireclay bricks. The solution must also contain a certain percentage of clay.

A minimum distance of 200-300 millimeters must be maintained from the wall to the heating unit. For assembly, a pre-prepared order is used.

The chimney system can be installed on the roof of the house through the façade or interior. If the pipes will pass indoors, they must be multi-layered, insulated and placed in a special box, which will be located with a small gap of 150-200 millimeters. External installation implies the presence of fasteners, indentation, followed by sealing.

The floor surface in the room with the fireplace is also insulated and sealed with heat-resistant materials

Furniture and textiles are located at a safe distance from the fireplace

When passing a chimney through ceilings or the roof of a wooden house, it is important to follow fire safety rules

At the final stage, we isolate the space in front of the combustion chamber. You can lay out the indentation with porcelain stoneware, ceramic tiles, or stone.

Fireplace insert

When building a firebox, it is very important to ensure that it is perfectly horizontal.

The firebox for open fireplaces is placed using refractory bricks, while for closed fireplaces it is made of metal.

For metal fireboxes, a window made of fire-resistant glass is provided. Fireplaces with closed fireboxes are more efficient and convenient to use, and allow you to control the combustion process.

Important rule! When installing a fireplace in a wooden house, it is advisable to strictly follow the prepared masonry scheme.

This affects not only the efficiency of the heating structure, but also its safety.

Masonry must be carried out at positive temperatures to ensure the reliability and strength of the structure.

The first row should be perfectly straight. The outcome of the work directly depends on this.

Advantages and disadvantages

A fireplace in a country house is a decorative element that creates a unique design of the room and an attractive design. Another advantage is that it provides an additional source of heating for the home. Disadvantages are usually due to the arrangement of the firebox:

- Difficulties associated with the installation and arrangement of the fireplace area. The construction of an open fireplace is possible only if this possibility was provided for at the initial stage of construction of the house and a separate foundation was poured for the structure. It is necessary to follow the order of installation, including the stage-by-stage delivery of the structure for acceptance by the registration authorities.

- An inspection of the combustion chamber and chimney duct by an employee of the Ministry of Emergency Situations, carried out before connecting the chimney. Work on completing all the paperwork may take more than one year.

- Features of wooden structures - complete shrinkage of the house can occur no earlier than after 6-7 years. Construction of the fireplace can only be done after this time has been completed.

- Limitations related to the size of the room. The dimensions of the portal increase taking into account the selected material. A home can be built in a room no smaller than 25 m².

Facing

*

To give the fireplace a decent look and style, its firebox is lined with tiles or asbestos-based plaster.

When constructing fireplaces with a closed firebox, cladding is a necessary condition. For this, brick, tile, marble, wood and other materials are used.

Plastering the surface of fireplaces is often used.

This method is very common due to its accessibility and simplicity. Important!!! Plastering is carried out in two passes, the thickness of the final layer of plaster should not exceed 50 mm.

After drying, the plaster is covered with a layer of paint. Heat-resistant plasterboard or ceramic tiles are also used for cladding fireplaces.

Chimney installation

When installing a chimney in a wooden house, non-flammable building materials are used and foil wool is laid on the inside. Above the fireplace, at a height of at least 0.3 m, a casing is created to protect the wooden ceiling.

When installing ventilation ducts, two options are possible:

- ventilated, this is a more rational way to cool a chimney pipe due to the movement of cooled air;

- unventilated, when all the cracks in the chimney pipe are carefully insulated.

If the construction of a fireplace is planned at the house design stage, it is possible to think through the main points right away:

- choose a convenient space for the future chimney, taking into account the proximity of beams and rafters;

- strengthen the foundation of the house in the future location of the fireplace.

The safest and most durable option in this case for a wooden structure is a three-layer main chimney. It has a huge weight, up to 100 kg.

When erecting a chimney in an already built house, an inconvenience arises due to the lack of free space when choosing its location. In this case, a double-circuit stainless steel chimney is a good option.

It is important to properly prepare the chimney pipe shaft. Wooden materials in contact with the pipe must be replaced with brick. It is also necessary to take into account the possibility of the influence of shrinkage in these places. Therefore, the distance between the chimney and the ceiling is larger.

Installation and use of a fireplace in a wooden house must be carried out strictly in compliance with building codes and fire safety requirements. It is not recommended to install it yourself, without special knowledge.

Important! When operating a fireplace, it is imperative to annually check the safety of thermal insulation materials in the spaces around the chimney.

To remove accumulated carbon deposits, you should periodically invite a specialist.

To protect against flying sparks, you can install a door with heat-resistant glass. If you want to watch the flames of the fire, you can open it slightly.

When installing a fireplace and chimney, it is important to achieve maximum evenness of the surface, otherwise the turbulence of smoke flows arising from the curvature will lead to smoke.

Brick chimneys have a rectangular cross-section; this itself leads to the appearance of turbulence in its corners, which reduces draft. In this regard, pipes with a round cross-section, for example, pipes made of stainless steel, have the best performance.

When the chimney cools down, moisture and condensation occur. It gets into microcracks in the chimney, which when frozen leads to its destruction.

To solve problems with turbulence and moisture formation in brick chimneys, you can use a stainless steel insert.

Operating a fireplace in a wooden house

A fireplace is, first of all, a source of fire, so when using it it is important to minimize all possible fire risks.

Before use, make sure that there are no flammable objects such as curtains, books, etc. nearby.

Important! Houses equipped with fireplaces must have fire extinguishing equipment and fire extinguishers.

In addition, all residents of the house must have basic knowledge of the rules of behavior in case of fire and fire safety rules.

Copper Sheet Platform

Quite often, for fire safety purposes, the floor is finished with a simple sheet of metal. Copper is usually used as a suitable material. Copper has certain advantages over other metals. It has a characteristic shade similar to the color of a flame, which harmoniously fits the platform into the cozy atmosphere of the room.

The sheet serves as a screen from which radiation is reflected. This increases the proportion of energy entering the room and reduces the proportion transferred to the floor. Copper perfectly resists corrosion and is environmentally friendly.

In addition, due to the fact that the metal can be processed, various patterns can be engraved on it even at home. Being in close proximity to the fireplace, the copper sheet does not lose its physical properties, and the ability to reflect radiation ensures the platform glows in the dark.

Installing a fireplace in a wooden house

Despite the increased popularity of brick fireplaces, they have one serious drawback - the inability to efficiently warm up the entire house.

In addition, some of the heat escapes through the pipe. A more rational solution for a wooden house is to install a fireplace stove. This design makes it possible not only to heat the room, but also to cook food.

They are also easy to install and safer to use. If you need to heat a house with several floors, it is enough to connect a water heating circuit to the stove.

Modern fireplace stoves do not require design or professional installation; just choose the model you like and carry out a simple installation.

The main advantages of modern fireplaces:

- economical;

- equipped with systems for regulating combustion parameters;

- do not involve installing a solid foundation and creating protective walls in the house;

- have increased heat transfer;

- equipped with a closing firebox with heat-resistant self-cleaning glass;

- have a detachable ash pan;

- are able to heat the entire area of the house evenly.

Structurally, there are two types of such installations:

- with air heating system;

- with water heating system.

If the house has few interior partitions and is used as a summer house in which people live intermittently, an air heating system is quite suitable. For permanent residence, as well as in a multi-room or multi-story building, it is rational to use a water heating system. To do this, a water circuit is connected to the radiator.

Furnace piping

In rare cases, a room is heated by a stove due to convection currents. The very status of the device implies the most efficient use of released energy. Therefore, the heating system is supplied with a coolant, which can be water circulating through pipes or air moving under the influence of forced convection. Connecting the coolant channels to the furnace is called piping.

Some problems associated with the installation of a fireplace stove are concentrated in the incorrect installation of the main line. With water heating, circulation is provided by a pump or it is carried out due to natural convection

In the second case, it is important to maintain a certain slope of the line, since a reverse slope will lead to stagnation of liquid. In a closed heating system (case 1), the slope does not matter, but the system has strict requirements for tightness

Even a small amount of trapped air will stop circulation.

Heating circuit connection diagram

Piping the air duct is not difficult, but laying the line under the panels or covering it with plasterboard is a labor-intensive process. A furnace that uses air as a coolant is equipped with a fan system that drives air through the main line. By adjusting the supply dampers, you can direct heat selectively to different rooms.