In many individual houses with autonomous or main water supply and supply of only cold water, in communal housing, where for some reason there is no hot water supply (DHW), the task of heating water resources with water heaters is urgent. When installing equipment yourself, you should know how to properly connect the boiler to the water supply.

The task is complicated by the fact that there are several types of water heaters, differing in operating principle, installation and connection technology. Almost any user can connect a boiler to a water supply with their own hands by studying the appropriate diagrams and methods for connecting water heaters, taking into account the fact that installation operations do not require special or expensive plumbing tools.

Rice. 1 Floor and wall boilers

Types of water heaters

In individual houses, in the absence of a central water supply, water is obtained from wells or borehole sources, pumping it into the household water supply using submersible or surface electric pumps (pumping stations). At the same time, for a comfortable stay, the consumer needs hot water, which can be obtained in various ways. A popular option for a water heating unit is a gas water heater, which is installed if the house is connected to a centralized gas supply main.

If there is no gas in an individual house or apartment, the only convenient option for heating water remains (there is no point in considering a heating boiler due to the technological difficulties of obtaining consumable hot water in it) - the use of various types of electric water heaters (boilers).

Another method of heating cold water for homes without electricity and gas is wood-burning (solid fuel) heaters with the common popular name Titan.

Rice. 2 How to connect Titan - piping and design of a solid fuel dispenser

According to the principle of operation and design, all water heaters are divided into two large groups:

Flow-through. They are a tubular electric heating element (TEH) in the form of a non-insulated spiral, placed in a pipeline through which water flows, and is turned on only when water is consumed.

To ensure through heating of a large volume of water to a high temperature, you will need significant electrical power of the device, about 10 kW (it is still not enough to heat the volumes of water required to simultaneously fill a bathtub, take a shower and wash dishes). Not every wiring in a private house can withstand this power (for a comfortable supply of hot water, you will need 20 kW of heater power), and even more so in an apartment.

To supply electricity to the water heater, you will have to run a separate line using a large cross-section wire from the electrical panel, which is not always acceptable and leads to significant financial costs. Therefore, a flow-through heater is a device for small volumes of hot water consumption.

Rice. 3 Main components of an instantaneous boiler water heater

Cumulative. The design of this type of boiler consists of a container of various volumes, inside of which a heating element is placed. The water in the storage tanks is in a constantly heated state; when water is consumed, the tank is emptied and filled at the same time - this allows you to immediately use large volumes of water, which increases the comfort of living. Also, storage water heaters do not require a lot of power to operate, and tanks of any volume have a heat-insulating outer shell to reduce heat loss and protect against burns when touched.

Video description

In the video about how the water heater is installed:

When connecting a storage type water heater, the technician installs the connecting parts in this order (in the direction from the inlet fitting):

- tee-clip;

- ball valve, connected to the side branch of the holder and used to drain liquid;

- safety valve with drainage outlet;

- shut-off valves (valve) used to turn off/on water;

- pipe.

If connection conditions require, the wizard can supplement the diagram:

- Gearbox . The device is used to reduce the incoming pressure to that set by the manufacturer for a specific water heater model.

- Filter . Installed when tap water does not meet the requirements that ensure normal functioning of the boiler. The presence of an excessive amount of salts and insoluble substances in water causes the formation of deposits on the inner surface of the storage tank and heating element.

Connecting a water heater using a polyphosphate filter Source www.stroyportal.ru

Upon completion of installation, the master connects a pipe that supplies flammable water to consumers to the supply pipeline. A shut-off valve is installed on the required branch pipe of the device, ensuring quick shutdown. To transfer heated water, the tap is connected to a flexible hose.

Storage water heater is ready for use Source smartremstroy.ru

What is a boiler and how it works

A boiler (from the English boiler) is a water heating unit in a hot water supply system, which is a container with a built-in heating element. Tubular electric heaters (TEHs) or coils through which hot coolant passes are most often used as a device for heating water.

To supply water from the broiler to plumbing fixtures and household appliances, it is necessary that it be in a container under a certain pressure.

Rice. 4 Structural design of a standard wall-mounted storage boiler

There are two main types of boilers based on the type of water heating:

Electric with heating elements. An electric heating element is placed inside the unit, which heats the water masses through direct contact.

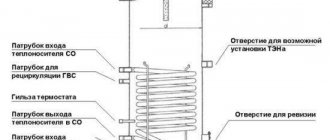

Indirect heating. This type of equipment does not require electricity to function; inside the tank there is a coil that is connected to the heating main. Water is heated when it comes into contact with the surface of a coil connected to the boiler through indirect heating, hence the name of the boiler.

Rice. 5 Main components of an indirect heating boiler

Security

To connect powerful models of storage-type water heaters to the electrical network, craftsmen use a reinforced cable with three cores, which is laid directly from the distribution board. Installation of a double circuit breaker or RCD and grounding are required.

Connection to the electrical network Source otopleniesam.ru

Types of domestic boilers

When installing a storage boiler connected to the water supply in an apartment or individual house, two types of its placement are used, which is also reflected in the design of water heaters:

Wall-mounted. Typically, small-volume tanks are hung on the walls in apartments where there is not enough free space. Traditional locations for heating boilers are the kitchen or bathroom. Also, wall-mounted units can be located on the wall surface in a vertical or horizontal position.

Floor-standing. Large-volume units are usually placed on the floor, designed to heat water in individual cottage-type houses, which have much more free space than city apartments.

Storage boilers differ in tank volume, which is selected based on the following considerations:

- To use hot water in one technical appliance, washbasin or kitchen sink, a tank capacity of 10 - 15 liters is sufficient.

- A 50-liter tank allows you to take a shower; usually this volume is used for a family of one or two people.

- A 100-liter tank should be enough to take a bath or supply water to several points at the same time - shower, kitchen sink, bathroom sink. The 100-liter volume is designed to comfortably accommodate a family of three to four people.

Choosing a chandelier for the suspended ceiling in the bedroom

When choosing a ceiling lamp for a rest and sleep room, you need to focus not so much on the illumination of the device, but on its design.

A few secrets on how to choose the right chandelier for a bedroom with suspended ceiling structures:

- Ceiling lamps mounted around the perimeter of the room, the rays of which are directed at the suspended ceiling, will help to visually raise the ceiling;

- Lamps located along the wall will help expand the bedroom space;

- for chandeliers with shades, an important point is the distance from the horn to the tension fabric (it should not be less than 30 cm);

- The ideal option for a bedroom with a suspended ceiling fabric is a fabric lampshade with soft diffused light or a ceiling lamp with matte shades looking down.

Connection diagrams for various types of boilers

Any boiler is equipped with an automatic system with temperature control due to a built-in thermostat; when a given heating threshold is reached, the electronic circuit turns off the power from the heating elements. However, in order to avoid unforeseen emergency situations in the event of failure of parts responsible for turning off the electric heater when the water overheats, the diagram for connecting the boiler to the water supply must contain elements that ensure the safety of using the equipment.

The main device for performing this function is the pressure relief valve. When deciding how to connect a boiler to a water supply system, they consider its design and, in accordance with this, choose the following piping methods:

- For electrical units, the correct connection diagram for a water heater to the water supply includes a special pressure relief valve, usually a flag type, and a ball drain valve. The two specified elements of plumbing fittings are connected to the cold water inlet pipe of the boiler - first, a drain valve is installed through the tee, and then a safety valve. The shut-off ball valve is designed to drain water from the water heater during its repair or maintenance work. The emergency valve has a small diameter outlet fitting designed to drain water when the pressure inside the boiler increases. A flexible line of the appropriate diameter is connected to the fitting and lowered into the sewer outlet so that the water does not drain or drip onto the floor.

- Ball valves are installed in the cold and hot water pipelines leading to the boiler, which shut off the water flow when dismantling the device.

- If the pressure in the system exceeds 6 bar, which is unacceptable for many types of boilers, a pressure-reducing reducer is installed in the pipeline.

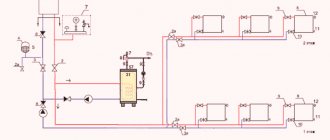

Rice. 7 Installation diagram of an indirect exchange water heater

When determining how to connect an indirect heating water heater to the water supply, two options are considered:

- The first is similar to installing a boiler with an electric heater - an outlet ball valve and an emergency pressure relief valve are connected to the cold water inlet pipe.

- The second way to properly connect a boiler to a water supply system is to use a safety group on the inlet pipeline. The device is a brass part with an inlet pipe and a tee, to which a pressure release valve, an air vent and a control pressure gauge are connected.

- Sometimes, to supply water to individual houses, large storage tanks installed in the attic of the building are used; when connecting a boiler to them, they are guided by the following rules:

- If the distance from the boiler to the storage tank is less than 2 meters, a ball valve and a pressure relief flag valve are connected in series to the cold water pipe.

- When placing the boiler at a distance of more than 2 meters from the storage tank, the flag pressure relief valve need not be installed.

Rice. 8 Connecting the boiler to the water supply in a house with a storage tank

Step-by-step installation instructions

To correctly carry out the process of connecting the water heater to the water supply, follow the instructions:

Measure the height of the water heater, mark the lowest point where the bottom of the boiler will be located. Start taking measurements from the bottom mark.

Measure the distance from the bottom of the water heater to the mounting strip.

Measure the resulting distance on the wall and mark it.

Using a level and a marker, draw a horizontal line. Measure the distance between the hooks. Make notes on the wall.

Prepare hooks for fastening. Check its dimensions. Make sure that the hooks you have prepared can support the hanging tank.

Drill holes at the marked points and drive in dowels and screw in the hooks.

This completes the process of installing an electric water heater; now you can approach the procedure for connecting the water supply.

Connecting an instantaneous water heater

In a flow-type boiler, water passes through its shell, and the heating element turns on only when the water flow moves in the body of the device. Therefore, overheating in this system is practically impossible and a pressure release valve is not installed in the heater.

A shut-off ball valve and necessarily coarse sand filters are placed in the cold water supply pipeline of a flow-through water heater - the absence of filter elements is a gross violation of operating rules and may cause the service organization to refuse to fulfill its warranty obligations.

Rice. 9 Examples of installation of instantaneous water heaters

Features of operation, troubleshooting

The walls of a properly functioning boiler are at room temperature, the device does not make noise, does not consume electricity beyond what is specified in the passport, and warms up in 20–30 minutes.

Prolonged heating indicates that scale or debris has accumulated in the tank. The problem is solved by mechanical or chemical cleaning. Both require draining the water and dismantling the tank.

For the first, the boiler is disassembled, the walls and heating elements are cleaned manually. No disassembly is required for dry cleaning.

The removed storage tank is turned over, a solution of citric acid or anti-scale agent is poured into the cold water inlet pipe, and the boiler is left in this form for several hours. Then the cleaning liquid is drained, the container is mounted in place and washed with water.

A hot boiler body indicates depressurization of the container due to microcracks. It is impossible to fix the problem yourself; repair or replacement of the device is required.

Connecting a boiler to a water supply system made of different materials

Often the consumer is faced with the task of how to properly connect a boiler to a water supply system made of various materials. It is too expensive to call plumbing specialists for these purposes; in many situations, the problem can be dealt with on your own.

If the pipeline is equipped with water sockets (fittings with internal threads), then the easiest way to connect to it is with a flexible liner; if the diameters do not match, adapter couplings (fittings) are used. Flexible hoses can be rubber with metal braid, bellows made of corrugated stainless steel, polymer made of various types of plastics. When it is necessary to insert into a pipeline made of various materials, the following technologies are used.

Rice. 10 Examples of inserting into a metal pipeline

Insertion into a metal pipeline

To supply hot or cold water, in some places a steel pipeline is still used, sometimes it is mounted from copper, and the following tapping technologies are used to connect a boiler to them:

Overhead clamps. A typical clamp is a part consisting of two halves, one of which is equipped with a side threaded outlet designed to connect an adapter coupling and any type of threaded pipe. When installing the clamp, a hole is drilled in the pipe casing with a metal drill, an elastic gasket is placed on the pipe and it is compressed by the two halves of the part using four bolts at the edges.

Tees. Often, a small section is cut out of a steel pipe, threads are cut at the ends of the broken pipes, and a tee with a side threaded outlet is screwed into the gap (sometimes it is welded). Next, a flexible liner or pipeline of any type is connected to the threaded pipe of the tee.

Compression couplings . The retail chain sells compression couplings for connecting metal pipes with a threaded outlet, which have the commercial name Gebo. To install the Gebo coupling, a pipe fragment is cut out of the pipeline, one of the sections is bent and the coupling is put on it, after which the ends of the pipes are aligned and the coupling is pulled onto the second section. Next, tighten the union nuts of the coupling, securely fixing it on two pipe sections made of steel or copper.

Strapping stages

First, an installation diagram is drawn taking into account the dimensions of the room and the selected locations for all devices. After this, holes for the heating boiler and boiler are marked and drilled. If the devices are floor-mounted, then it is advisable to make a small foundation for them according to the size of the buildings.

Next, propylene pipes are cut according to size and connected to each other with tees using a soldering iron. Pumps, taps, filters are installed and everything is combined into one system. If you have additional circuits, for example, on a hot floor, then a collector is installed that evenly distributes the coolant flows.

Connection diagram for a double-circuit boiler

An expansion tank and a safety complex are mandatory. When installing a safety group, you should take into account that if it works, water will flow out of it. Excess coolant goes into the expansion tank during expansion.

After all connections, water is introduced into the system and all connections are checked. If there are no leaks, then the boiler starts and the heating rate of the batteries is checked.

Recommendations from the pros!

Accessories for a bath Do-it-yourself gazebo Concrete fence Do-it-yourself potbelly stove Do-it-yourself veranda Screw foundation Do-it-yourself country toilet Decorative brick Stone fence Pouring a foundation How to make a fence Wicket from corrugated sheets Do-it-yourself fireplace Brick fence Do-it-yourself flower beds Forged gates Do-it-yourself porch Pool for a bathhouse Chicken coop do it yourself DIY staircase Metal gates Installation of lining Installation of polycarbonate Pump for a summer house Arrangement of a garage Fences for flower beds Do-it-yourself blind area Steam room in a bathhouse Railings for stairs Do-it-yourself cellar Painting walls Press with your own hands Grilles on windows Rolling gates Do-it-yourself barn Alarm system for a summer residence Benches for a summer residence Fence posts Floor screed Solid fuel boilers DIY greenhouse Fence installation House insulation Attic insulation Foundation insulation