Plastic window structures are considered reliable and airtight. But over time, they also begin to let in cold air. This is especially unpleasant in winter, when precious heat is literally blown out of the apartment. Changing the situation doesn't always require installing a new system. In most cases, it is enough to properly insulate plastic windows. Let's figure out how to do it right.

No. 1. Where does the insulation of wooden windows begin?

Insulation of old wooden windows begins with examining the structure to detect cold bridges , i.e. the main routes of cold air entering the apartment. It is important to find all the weak points in order to carry out comprehensive insulation . The main cold bridges in wooden windows include:

- the junction of the window frame and sash;

- wood from which the frame is made;

- glass;

- slopes, window sills and ebb.

It is better to insulate the slopes, ebb and window sill from the outside, the remaining elements require insulation from the inside, so you will have to work hard to turn an old wooden window into an airtight one that meets current comfort requirements.

If the window inspection and its insulation are carried out efficiently, you can count on an increase in the temperature in the apartment by 3-40C if you are connected to centralized heating, or on significant cost savings if individual heating is used. In addition, it will be possible to get rid of drafts. The other side of the coin is the cessation of natural air circulation. This problem is also typical for sealed plastic windows. Its solution is periodic ventilation or installation of special valves that allow you to regulate the amount of fresh air entering the apartment.

Be prepared for the fact that for effective insulation you will have to use several of the methods described below. Let's start with the technologies that are used for internal insulation.

Causes of drafts

You should also have basic information about the causes of drafts. Having basic knowledge, you can avoid such unpleasant situations in the future.

- Making mistakes during window installation. One of the most common problems associated with the low qualifications of the installer. If a draft occurs immediately after installation, then you need to contact this installation company again and demand that the defects be corrected. If you install plastic windows yourself, you need to check the correct installation and correct any errors.

- Shrinkage of the soil under the house and, as a result, skewing of windows. A rare problem that occurs among residents of new houses.

- Poor quality materials and manufacturing defects. An attempt to save on the price of double-glazed windows can cause poor window sealing, but even owners of expensive windows are not insured against defective parts. If the terms of purchase allow, take advantage of the opportunity to return the entire set or only the defective parts.

- Physical wear and tear on the locking parts of the window and seal. A very common problem for window owners who have been using them for a long time without replacing them.

- Violation of the rules of use and care. Over time, the sealant may lose its properties. To prevent this from happening prematurely, it is necessary to wash it and treat it with emollients. For example, glycerin.

If you evaluate in detail all the causes of drafts and heat leaks, you can divide them into two categories based on the possibility of eliminating them - with the help of window installation specialists and solving problems yourself.

It is best to use the services of professionals to solve the following problems:

- If problems with the window are identified during the warranty period. At this time, the installer company bears full responsibility for its operation. Independent intervention in the design features may result in denial of further warranty service.

- External work at height is required. In such conditions, the likelihood of injury greatly increases, and it is better to entrust such work to professional workers.

- Detection of manufacturing defects during the warranty period.

- Replacement of some structural parts, requiring certain tools and skills to work with them.

If the work is done from the inside, then most of it can be done independently.

No. 2. Insulation of windows with paper

The most ancient, simple and inexpensive way . Today it is rarely used, but it is suitable if the budget is very limited. There are several variations of this insulation method:

- newspapers, wallpaper, paper are torn into pieces, twisted into ropes, which clog the cracks between the sash and the window; to simplify the task, use a ruler, knife, screwdriver or other sharp tools. Some people advise pre-wetting the flagella in water;

- paper waste is shredded, soaked in water and wrung out. To the resulting mass add 1 part clay or 2 parts crushed chalk. The result is a plastic putty that penetrates well even into the smallest cracks.

The classic old-fashioned recipe involves sealing paper insulation with strips of fabric or paper . In order for them to stick well, they were moistened with a solution of laundry soap or a homemade paste was used. The latter can be obtained by mixing water and flour in equal proportions, stirring well and bringing the resulting mixture to a boil.

A more modern option is to use masking tape or special window tape . In this case, the task is simplified, but costs still remain. Windows insulated with paper cannot be opened for ventilation if it suddenly gets warmer in the middle of winter. In the spring you will have to remove the strips of paper/fabric/adhesive tape and take out the insulation. Visible marks remain on the window frames, sometimes even some of the paint is removed, so, unfortunately, you cannot do without updating the decorative coating. However, fabric and self-adhesive paper are the easiest to remove and leave minimal marks.

What would be better - choosing double-glazed windows or repairing old frames?

If problems with frames arise, the homeowner will have to make a choice which technology is more preferable for him.

In one case, the result is a well-repaired window that closes perfectly, with seals in place, and, of course, painted. Another case is a simple turnkey plastic window. Of course, you choose the option that is closest to you yourself. Despite the fact that the cost of both windows is almost the same, not everyone prefers double-glazed windows. There can be many reasons for this: from the personal preferences of homeowners to the reluctance to have plastic in the house. Meanwhile, reviews of Swedish technology are the most favorable.

Important! When choosing insulation for wooden windows, you should check that the frames are not rotten - replacing these elements will cost a tidy sum. First, you need to pay attention to the lower part of the sashes and window frames, where the water drains from the glass. If these elements are too rotten, restoration and subsequent thermal insulation of the window is almost pointless.

No. 5. Insulation of a wooden window with foam rubber and sealant

A much more modern, reliable and effective method of insulation is the use of foam tape and sealing cords.

Foam tape is inexpensive, but its service life is only about 2 years. This method of insulation is optimal when sufficiently large gaps have formed between the sashes and the frame. The installation process itself is simple, but labor-intensive, since everything needs to be accurately measured and carefully glued so that the window is well insulated, but at the same time does not stop closing normally. The main advantage of this method is the ability to open the window.

The process of insulation with foam tape comes down to the following:

- measuring the required length and width of the tape. The length should correspond to the perimeter of the valves, and the compressed width should correspond to the width of the voids;

- the places on the doors where the tape will be glued must first be cleaned of dust and degreased with alcohol or acetone;

- foam rubber tapes are produced, as a rule, with a self-adhesive base, so the task is simplified and comes down to only removing the protective layer and carefully gluing the foam rubber to the designated places;

- Some experts advise additionally sealing the window with paper tape, but this loses the main advantage of the method - the ability to open the window whenever you want. An alternative solution is to glue foam rubber in several rows.

Insulation made using sealing cords . They are made from different materials:

- rubber;

- polyvinyl chloride;

- polyethylene foam;

- polyurethane.

The main advantage of a rubber seal is its price, but when the temperature drops, it can harden and break. In addition, rubber is highly wear-resistant, so it is best chosen for windows that constantly open and close. Although other types of cords are more expensive, they perform much better in terms of operation.

Sealing cords are made in different shapes - the choice depends on the size of the cracks in the window structure:

- a seal whose profile resembles the letter P is suitable for windows with medium-sized cracks;

- seal with a D-shaped profile - for sealing fairly large gaps;

- seal type E - for windows with small gaps.

Tubular seals allow you to achieve a fairly high level of sealing, do not interfere with the free opening of the window, can be left in the summer and serve for several seasons in a row. The seal may have a self-adhesive base and then its installation will be identical to the installation of foam rubber tapes described above. If you take such a seal, pay attention to the shelf life of the glue: if it comes to an end, the cord may either not stick at all or quickly peel off.

The safest thing to do is to take a separate sealant and separate glue for it, which can be used as silicone sealant. In this case, the durability of the insulation reaches 5 years.

There is one more nuance. All work with tubular profiles is carried out at temperatures above +100C, so it is better not to delay it until cold weather. The seal must be glued very carefully so as not to disrupt the opening system of the sashes.

Average price for services

The cost of various types of insulation depends on the material, as well as the complexity of the work (for example, high-rise).

Average prices for some types of work:

- replacement of seal – 150 rubles/linear meter (l.m);

- sealing seams with silicone – 250 r/m;

- adjustment of fittings – 150 RUR/window;

- external insulation with polystyrene foam – 400 rubles/meter.

No. 6. Insulation of wooden windows using Swedish technology

This is the most progressive, modern and effective way . Windows insulated using Swedish technology are actually equivalent in terms of tightness to modern plastic windows. This method also involves the use of a seal, only for it special grooves are prepared in the window sashes.

Swedish insulation technology involves the following procedure:

- dismantling the sashes;

- cutting thin grooves around the perimeter of the valves, which is carried out with a special cutter; the size of the groove must correspond to the size of the selected seal;

- installation in the grooves of the seal (polyurethane, PVC, polyethylene foam, less often foam rubber is used). No glue is used in this case - the seal holds well due to the thickenings existing in its design;

- applying silicone sealant to the junction of the sash and glass;

- if necessary, fittings and glass are replaced;

- installation of the sashes in place.

The durability of such insulation is 15-20 years , so the labor intensity and high price of the method are fully justified. It’s worth doing such work yourself only if you have at least a little experience in carpentry, otherwise you can only make things worse. The easiest way, of course, is to entrust all the work to specialists.

Windows insulated using Swedish technology can be opened at any time of the year, their appearance does not deteriorate, and sound insulation can be considered an additional bonus.

Foam rubber

Foam rubber insulation for windows (foam rubber tapes) was used to seal windows for the winter long before the production of insulation was put into production.

The advantages of this material are known to everyone: it is easily compressed (and, as a result, installed), does not injure the surface of the frame, this method is cheap and simple.

There are also disadvantages: foam rubber for insulating windows is not the best choice; even with very good compression, air still leaks through the pores, and it is also not very durable - foam rubber comes off relatively easily.

The second problem can be partly solved by modern rubber-based adhesives. To solve the first part of the cracks (especially in hard-to-reach places), it is advisable to fill them with silicone or acrylic sealant before installing the insulation.

No. 7. Insulating a wooden window with sealant

This method is aimed at thermal insulation of the junction of glass and sash . It can be done with your own hands, but will require a high degree of care and precision. The procedure is as follows :

- removing glazing beads, thin slats that hold the glass around the perimeter. During dismantling, almost all glazing beads break, so it is better to buy new ones in advance, and with a reserve. Removal begins with the lower bead, then the side ones are removed, and only then the top one; for this it is convenient to use a small knife or screwdriver;

- the seat inside the sash is thoroughly cleaned of dirt and dust;

- applying silicone sealant and installing the glass in place. All work on dismantling and installing glass is carried out wearing thick gloves;

- installation of new glazing beads.

Instead of caulk, you can use window putty . The procedure remains the same, only after installing the glass, excess putty must be immediately removed with a knife. In terms of aesthetics, this method is no worse, since subsequently the joint will still be covered with a new bead.

No. 8. Insulating a wooden window with polyurethane foam

Polyurethane foam is used for internal and external insulation ; it fills large cracks well and is used to seal the joints between the frame and the slope, between the slope and the window sill, under the window sill, and between the frame and the top beam.

Working with polyurethane foam is not difficult, but you should know some nuances:

- filling is best done from the bottom up;

- As the foam hardens, it increases in volume, so filling the cracks costs about 1/3;

- work is carried out at air temperatures not lower than +5 and not higher than +300C;

- Polyurethane foam is destroyed under the influence of sunlight, so it must be covered with a layer of finishing material. However, it is unlikely that anyone will leave this material unfinished - it does not look very good.

Instead of polyurethane foam, you can use homemade putty . It is prepared from chalk and gypsum, which are mixed in a 1:2 ratio, and then water is added until a solution of a viscous consistency is obtained. This mixture easily fills all the cracks, and outwardly it looks much more aesthetically pleasing than polyurethane foam.

Is it possible to replace insulation in PVC structures?

Replacing old insulation on plastic windows may be necessary when the old one wears out. In some cases, replacement may be difficult or impossible:

- external insulation on slopes, walls and under drains can be replaced independently in buildings that have no more than 2 floors, since the work will require specialized equipment or specialists in high-rise work;

- Replacing insulation at temperatures below 0 is most often not possible, since the fastening mixtures will freeze and not dry.

In another case, you can change the old insulation yourself:

- to replace insulation on slopes (internal and external), you must first remove the top protective layer;

- after this, clean the surface of the walls and use the instructions indicated above;

- to change the insulation on the windowsill you need to carefully remove it;

- then clean the area from old foam, glue and insulation, and then carry out the insulation process again;

- replacing film on glass can cause difficulties, since with heat shrinkage or a large amount of adhesive, it sticks strongly to the window;

- to remove it you need to carefully pry up one edge and then try to peel off the film;

- if it is tight, then the edges that are adjacent to the glass can be slightly soaked with soapy water.

No. 9. Heat-saving film for wooden windows

This method is aimed at increasing the thermal insulation qualities of glass , but today heat-saving film is also glued to a wooden frame. It works like energy-saving double-glazed windows, i.e. allows daylight into the apartment, but does not release heat. This film is made on the basis of polyester, and it receives unique properties to reflect thermal radiation thanks to metal coating. This is a transparent material that does not violate the optical properties of window glass, withstands the effects of detergents, is highly durable and makes the window safe, because if the glass is damaged, all the pieces will remain on the film.

The process of installing the film is simple, but it requires care, because it is important to stick it evenly, without bubbles, with the metallized side facing out. It is best to work with gloves so as not to leave greasy marks on the surface.

Thermal insulation film can make a window “warmer”, but cannot be used as an independent insulation material.

Requirements for materials used for thermal insulation

Exactly what requirements the insulation must meet largely depends on its type. The most important rules are the following :

- sealant, putty and other similar products must maintain their original geometric parameters throughout their entire service life;

- tape, self-adhesive seals must have high adhesiveness and strength;

- cotton wool and foam rubber must meet the recommended values of vapor permeability and moisture absorption.

Also, when choosing a material, you need to take into account the design of the windows:

- for wooden frames, it is primarily important that the product is not flammable;

- another important point for such windows is that the material must be environmentally friendly;

- In the case of plastic windows, the “density” parameter must be taken into account.

Additionally, it is important to take into account the climatic conditions that the selected material will have to withstand. For example, paper tape will not cope with strong winds and frosts.

No. 10. We eliminate gaps in the sashes and frames

It is not enough to seal the gaps between the frame and the sashes, and between the sashes and the glass - the window will still let in cold air if there are cracks in the wooden elements . They certainly appear on wood as a result of temperature changes. It is not difficult to eliminate them; the following materials are used for this:

- paraffin. It is heated in a water bath to a temperature of about 700C, drawn up with a syringe without a needle and filled into all the cracks. Within an hour it will harden and turn into a serious barrier to drafts;

- special wood putty;

- sealant, and you can choose the material to match the color of the wood;

- homemade putty made from plaster and chalk, the recipe for which was described above.

Naturally, such thermal insulation measures will be most effective if you first remove the old decorative coating, then fill the cracks, and after that apply a new layer of finishing. Keep in mind that paint adheres worse to paraffin and sealant, so it is better to carefully remove their excess.

Self-adhesive tape

Insulating window structures is a very important process that must be approached very carefully.

Uninsulated windows often cause drafts, which as a result negatively affect the health of residents.

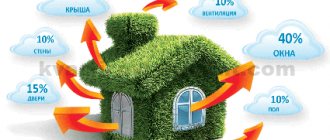

In addition, window openings become the main bridge of cold, which leads to the loss of a large amount of thermal energy.

Today, the market offers a large selection of modern insulating materials that can reduce heat loss through window units.

All these materials are highly effective and very easy to install. Among all the options, it is worth highlighting self-adhesive tape.

It is made on the basis of foam rubber, polyethylene and polyvinyl chloride. On one side, the material is coated with a sticky compound, which allows it to be fixed in a specific place.

Advantages of self-adhesive insulation

This self-adhesive window insulation has certain advantages.

These include:

- Ability to close cracks, the thickness of which can reach 7 mm;

- High resistance to changes in temperature and air humidity;

- Various colors, which allows you to optimally aesthetically fit the tape into the appearance of the window;

- Relatively low cost;

- Possibility to open the doors.

Thanks to these advantages, this material has gained high popularity and demand among the population.

Disadvantages of the material

Unfortunately, duct tape also has some disadvantages. First of all, it is worth noting its fragility. Most often, it lasts no more than one season.

This means that the insulation needs to be updated annually. Of course, if the doors are rarely opened, then the tape can last two or more seasons.

Despite the fact that such material tolerates temperature changes very well, severe frosts can negatively affect its performance properties.

As a result of exposure to too low temperatures, the adhesive composition may lose its adhesiveness. As a result, this leads to the tape peeling off.

The main disadvantage of such insulation is that it cannot be used on modern window structures. This is due to the fact that it can cause significant harm to the performance characteristics of plastic windows.

No. 11. How to insulate wooden windows from the outside?

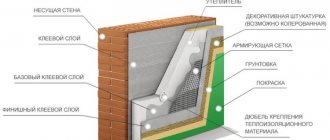

Internal insulation is sometimes not enough. Slopes often need additional thermal insulation . Work on their insulation begins with the dismantling of the old finish, after which the surface is primed. The cracks can be filled with polyurethane foam; another option is to cover the slopes with polystyrene foam. After hardening, excess foam is cut off and the surface is treated with plaster. A polymer mesh is attached to the foam on top, perforated tape is placed in the corners, after which plaster is performed. All that remains is to prime and paint the slopes.

The window sill area is also sealed with polyurethane foam. A mandatory requirement is the installation of a special strip for drainage of rainwater. It should be inclined and have rolled edges so that moisture does not get on the walls or through the window. It is advisable to seal the joints between the plank and frame or slope with sealant.

It is better to insulate the area under the window sill with polystyrene foam from the outside, because in a third of cases the most heat flows away through this area.

The final touch of external thermal insulation is updating the paintwork. The old peeling layer of paint can be removed using a spatula and a hair dryer, and fresh paint or varnish can be applied instead.

Preparatory stage

First, you need to assess the situation, that is, find out where the draft is coming from - from the frames or from under the window sill? The reason may be an old seal or defective slopes.

To determine the area from which the cold is blowing, just run your palm over the surface of the window frame. If you cannot identify the cause, you can hold a lighted candle near the window block. The flame of a fire is most sensitive to drafts.

- Possible gaps and cracks can be indicated by moisture after the previous rain, which is concentrated in a certain place. When water accumulates in the corner of a window opening, most likely the reason lies in the joints.

- Drafts can occur due to poor sealing. You can do an experiment. A piece of paper is placed in an open window and the frame is closed. If the sheet is easily pulled out, then the seal is weakly pressed against the window frame.

When choosing a method of insulation, you need to clearly understand the purpose for which this is being done? Sometimes, in pursuit of cheapness, a window loses its attractive appearance and the approach to the window is blocked.

It is important to consider the price of materials. Some of them are quite affordable (the sealant costs no more than 200 rubles per can). More durable methods will cost more, but may be a worthy investment in the future.

No. 12. Insulation of wooden windows in a wooden house

A wooden house places increased demands on the aesthetics of all work carried out. In principle, you can use any insulation technology, but be extremely careful. It is best to use a transparent sealant for thermal insulation of the junction of glass and frame, heat-saving films, fill large cracks with polyurethane foam and then seal them with casing. An excellent way to additionally insulate windows in a wooden house is to install shutters .

Which ones are better?

The means for insulating windows from those described above in terms of efficiency and availability are ranked in the top as follows:

| Place | Means | Manufacturer | Price |

| 1. | Self-adhesive seal | Novotex | 260 |

| 2. | Self-adhesive foam | PEAK | 190 |

| 3. | Construction putty | Der Master | 100 |

| 4. | Masking tape | Polyal | 110 |

| 5. | Heat-saving film | LLumar | 500 |

| 6. | Silicone based sealant | Makroflex | 700 |

| 7. | Paraffin | Promexport | 60 |

| 8. | Paper tape/paper/newspaper | Knauf | 50 |