A gas boiler is an effective individual heating system. To avoid the penetration of carbon monoxide into the home, it is necessary to properly organize the outflow of air from the room.

The ventilation requirements for a boiler with a closed combustion chamber depend on its power, but are always less stringent than for an appliance with an open burner.

Types of ventilation

There are only two main types of ventilation: forced and natural, and in some cases combined ventilation is used, which is sometimes classified as a separate category.

As the names indicate, the first type of ventilation uses forced air supply, for which air pumps or fans are used. In the second case, the air flow occurs due to the difference in its temperature and pressure - inside and outside the room. To ensure air exchange, it is enough to position the ventilation holes correctly. Also, some of the air can enter the room through natural openings - for example, cracks under doors.

If there is such a possibility, then it is most profitable to use a combined system - while natural ventilation copes with air exchange, forced ventilation is in standby mode.

Natural ventilation

If the air volume changes three times per hour, then in a standard six-meter (in height) room you can get by with natural air exchange.

When the ceiling is lowered by every meter, you will have to increase the air circulation by at least 25%. Plus, in any case, you should design the air exchange with some margin.

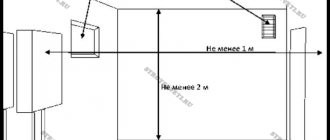

Scheme of operation of the ventilation system in the boiler room of a private houseSource pew.ledikycora.ru.net

The scheme is extremely simple - opposite the boiler, in the door or wall, there is a ventilation inlet (the diameter depends on the power of the boiler), which is located no higher than its working area. The second, the exhaust hole is arranged above the boiler; usually an air duct with a check valve is attached to it (so that the hood only works in one direction) and an “umbrella” on the outside (so that the pipe does not flood).

The distance between the “input” and “exit” of air in the room should be as large as possible to ensure better draft.

Disadvantages of natural ventilation:

- Dependence on weather conditions. It is necessary to protect air ducts from external environmental influences.

- Difficulty in accurately calculating air conditioning. Depending on the direction and strength of the wind, different volumes of air can enter the room.

- It is very difficult to design one ventilation system for several rooms - so that one pipe passes through all the rooms. Mostly, the exit from each room is made directly to the street.

Forced ventilation system or, more simply put, an exhaust hood for a boiler in a private houseSource m.yukle.mobi

Forced ventilation

Forced air supply is carried out by so-called “mechanical devices”, that is, fans. This type of air exchange arrangement is convenient for two reasons:

- It becomes possible to install climate control equipment, with heaters and filters, which will clean and heat the incoming air;

- It also becomes possible to turn on the system only at the necessary moments, which will save energy by turning it on, for example, only when the boiler is operating.

The disadvantages of forced ventilation are as follows:

Cost - first of all, such a system will cost more than natural ventilation; In some cases, noise – for example, when installing climate control equipment with air conditioning;

Choosing equipment without proper preparation can be fraught with a safety violation: in particular, for gas boiler houses it is important to have fire-resistant equipment.

The heating system is a rather complex set of equipment, so its selection and adjustment should be carried out by professionals. Source stroimdom.com.ua

How to choose material for the hood

The hood can be constructed from various materials. Below is a list of the main ones.

- Brick – used for exhaust hood in solid fuel boiler houses. It is quite difficult to clean, but it lasts a long time in the case of solid fuel boilers. For gas and other boilers, this type will not be a good choice, because they have a lower temperature - condensation forms in the pipe, and the surface of the brick quickly collapses;

Brick air duct Source en.yenni.biz

- Ceramics can be different; for solid fuel boilers, ceramics are used that can withstand temperatures of more than 650°C. It is also necessary to ensure that soot does not ignite in the chimney. For liquid fuel (and gas) you can use a ceramic hood using a lower temperature range, but with condensate removal. Insulation of the pipe should be provided (most often it is insulated with mineral wool);

- Steel is a good choice for solid fuel heaters, and if ventilation is used in a boiler room with a gas boiler. In the case of a higher temperature (solid fuel), you should simply choose a thicker pipe, up to 1 mm, in others - 0.6 mm. The steel must be heat resistant. The only negative is that such pipes cannot be called cheap, and their service life is shorter than, for example, brick.

The choice of a specific material depends on the combination of corrosion resistance parameters and resistance to soot (its accumulation). In addition, the hood is selected according to the draft pressure (forced ventilation implies excess pressure), according to the degree of condensation formation from the fuel, and according to the smoke temperature. It is worth knowing that the hood can be reconstructed - for example, the hood for a gas boiler in a private house, if there is already a brick pipe, is organized by inserting a steel pipe into a brick chimney, subject to other conditions.

Calculation of the ventilation system

According to building standards, the entire air space of the boiler room must be replaced with new one every 20 minutes. To ensure the appropriate air circulation, you will have to arm yourself with a calculator and formulas.

If the ceilings are located at a height of 6 meters, then without special devices the air in the room is renewed three times per hour. Six-meter ceilings are a luxury for a private home. The reduction in ceilings is compensated for in calculations in the following proportion - for each meter lower, air exchange increases by 25%.

Suppose there is a boiler room with dimensions: length - 3 m, width - 4 m, height - 3.5 m. To solve this problem, you need to perform a number of actions.

Step 1. Find out the volume of air space. We use the formula v = b * l * h, where b is the width, l is the length, h is the height of the ceiling. In our example, the volume will be 3 m * 4 m * 3.5 m = 42 m3.

Step 2. Let's make an adjustment for the low ceiling using the formula: k = (6 - h) * 0.25 + 3, where h is the height of the room. In our boiler room the correction turned out to be: (6 m – 3.5 m) * 0.25 + 3 ≈ 3.6.

Step 3. Calculate the air exchange provided by natural ventilation. Formula: V = k * v, where v is the volume of air in the room, k is the correction for lowering the ceiling height. We got a volume equal to 151.2 m3 (3.6 * 42 m3 = 151.2 m3).

Step 4. It remains to obtain the cross-sectional area of the exhaust pipe: S = V / (w * t), where V is the air exchange calculated above, w is the air flow speed (in these calculations taken as 1 m/s) and t is the time in seconds. We get: 151.2 m3 / (1 m/s * 3600 s) = 0.042 m2 = 4.2 cm2.

The dimensions of the channel also depend on the area of the internal surface of the boiler. This number is indicated by the manufacturer in the technical documentation of the device. If this number is not indicated, calculate it yourself based on the volume of the device. Then compare the area with the radius of the section according to the inequality:

2πR*L > S, where

R – internal radius of the chimney pipe section,

L – its length,

S is the area of the internal surface of the boiler.

If for some reason such a calculation is difficult, you can use the table.

| Boiler power, kW | Chimney pipe diameter, mm |

| 24 | 120 |

| 30 | 130 |

| 40 | 170 |

| 60 | 190 |

| 80 | 220 |

The last stage of the calculation is the height of the weather vane relative to the roof ridge. The need for this is due to the creation of additional draft by the wind, which increases the efficiency of the entire exhaust structure. At this stage, we are guided by the following principles:

- the height of the weather vane above a flat roof, or at a distance of up to 1.5 meters from its ridge, must be at least 0.5 meters;

- at a distance from 1.5 to 3 meters - not lower than the ridge of the roof;

- at a distance of more than 3 meters - not lower than a conventional line drawn from the roof ridge at an angle of 10˚;

- the weather vane should be 0.5 meters higher than the building, which is attached to the heated room;

- if the roof is made of flammable materials, the chimney must be raised 1-1.5 meters above the roof ridge.

Calculation of the height of the chimney relative to the roof

Natural and forced ventilation of the boiler room

According to the method of updating the air space, natural and artificial (or forced) ventilation are distinguished.

Natural ventilation operates without the use of fans; its effectiveness is determined solely by natural draft, and, consequently, weather conditions. The draft force is influenced by two aspects: the height of the exhaust column and the temperature difference between the room and the street. In this case, the air temperature outside must be lower than that indoors. If this condition is not met, reverse draft occurs and ventilation of the boiler room is not ensured.

Forced ventilation involves the installation of additional exhaust fans.

Usually these types are combined into one boiler room exhaust system. When calculating it, it is important to take into account that the volume of air drawn outside must be equal to that pumped into the room. To ensure this condition is met, check valves are installed.

Installation features according to SNIP

In the absence of specific recommendations in the documents attached to the boiler, it is worth using SNIP standards, according to which:

- Installation of gas boilers is only possible on walls made of non-combustible materials. The distance from the gas boiler to the wall must exceed 2 cm.

- If the walls are still subject to combustion, they must be protected with fireproof material. The most common options are a layer of asbestos with a metal sheet, plaster over 3 cm thick, ceramic tiles or mineral wool cardboard.

- On the sides, the distance from the boiler to the wall must be at least 10 cm. If the walls are made of flammable materials, this distance increases to 25 cm.

- A gas boiler can only be installed on a substrate made of non-combustible material. In the case of wooden coverings, special supports are made from tiles or bricks, which provide the necessary fire resistance. The base for floor-standing devices must be at least 10 cm wider than the dimensions of the boiler itself.

Requirements for ventilation in a private house with a gas boiler

For private homes, gas boilers of low power are most often used - up to 30 kilowatts. Their installation does not require separate boiler rooms. Such equipment can even be placed in kitchens that meet the following requirements:

- room area more than 15 m²;

- ceiling height of at least 2.2 m;

- the area of window openings is more than 3 cm² per 1 m³ of room volume. The window must open completely or be equipped with a window;

- the presence of fresh air ventilation through holes at the bottom of the door (4-5 holes with a diameter of at least 20 mm);

- the distance from the wall made of non-combustible material to the boiler is at least 10 cm. It is allowed to install an additional cement bonded particle board or metal sheet to cover the section of the wall next to the boiler.

The wall next to which the boiler is located must be finished with non-combustible material

In addition to the ventilation device, there are some special requirements for the boiler installation site. Boiler rooms are allowed to be installed:

- in premises attached to a residential building;

- in separate buildings;

- in attics;

- in separate rooms in the house.

Boiler rooms are often installed in the basement or basement of a building. This does not apply to devices running on liquefied gas. Its density is higher than that of air and, if a leak occurs, it can accumulate near the floor, being initially invisible at human height. This creates an explosive situation.

Selection and installation of equipment

The selection of equipment will depend primarily on the following factors :

- area ;

- Permissible distance to combustible devices;

- Type of room (separate room, free-standing room or existing one - for example, a kitchen or attic);

- Budget (for example, monoblock ventilation is significantly quieter than other types, but it will cost more)

The boilers themselves are:

- Gas;

- Solid fuel;

- Pellet (pellet-based, essentially solid fuel boilers);

- Diesel;

- Electrical;

- Combined (using several methods).

Combination boilers are an excellent option in a home where there are interruptions in electricity or gas supply Source brjansk.buyreklama.com

Currently, gas boilers are most often used in private homes, and we are talking about low-power boilers. This is due to the relatively low price of gas in gasified areas, and the convenience of using this heating method (the combustion temperature is lower, which allows the use of cheaper materials in production). To install it you will need permits. In addition, the boiler can be installed simultaneously with water heating (with a boiler) only for rooms up to 200 m2.

How to choose a ventilation system

The boiler room and ventilation scheme are designed at the stage of construction of a private house. Three types of air exchange systems are used:

- natural ventilation, but for a home it can work intermittently, especially if PVC windows are installed or in the summer when there is no temperature difference;

- flow ventilation, suitable for a house up to 300 square meters;

- supply and exhaust, used for large houses.

Natural ventilation can be done with your own hands with a minimum set of tools. To do this, a hole with a diameter of about 20 centimeters is made in the wall. , valve and mesh. Also, the room must have a window and a vent. This system can be made in addition to the main one, as an additional one.

Ventilation for a gas boiler in the house can be installed with your own hands, following the instructions or by relevant specialists. In the latter case, it is necessary to conclude an agreement and check the admission of specialists.

To install exhaust ventilation, you will need a grille to prevent dirt from entering, a fan with a check valve to prevent gas from entering the house, and an air duct. The pipe must match the diameter of the fan. Installation is quite simple, the chimney is vented through the roof and connected to the boiler.

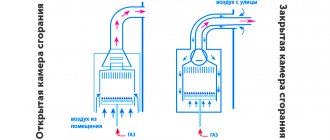

Ventilation for a gas boiler with a closed combustion chamber differs from the ventilation system for a boiler with an open combustion chamber.

Boilers with an open combustion chamber should only be installed in a well-ventilated and ventilated area

.

Boiler rooms are mainly used to install such heating equipment. Mandatory conditions for installing boilers with an open combustion chamber are windows, vents and a door with openings. Boilers with a closed combustion chamber use a chimney with air intake from the street and from neighboring rooms. Thus, boilers with a closed chamber can be installed in any room. Now it is allowed to install units with a closed chamber in basements and basements; the requirements for the installation of such equipment have been simplified.

Which system is better: natural or forced?

Even if natural ventilation works well, it is always better to use forced exhaust. Drilling a hole into the street and inserting a fan there will cost 5-10 thousand rubles.

A forced system is much safer than a fanless system for the following reasons:

- the operation of natural ventilation depends on the weather: the stronger the wind, the better the hood works, and vice versa (if there is no wind, air exchange may stop altogether);

- the frequency of air exchange is unknown, is not regulated and is not maintained at the required level;

- natural ventilation will not provide much air exchange (relevant if the boiler room is large, and if a powerful boiler is used - for a large country house).

The fan will do a better job of removing air if an emergency occurs (gas leakage). If the ventilation is natural, then if a gas leaks, it may not be completely removed and may accumulate in the room, which can lead to poisoning or an explosion.

Boiler room in a private house in a separate room (built-in or attached)

Separate boiler rooms for the installation of gas boilers with a power of up to 200 kW must be separated from other rooms by a non-combustible wall with a fire resistance rating of at least 0.75 hours. Brick, cinder block, concrete (light and heavy) meet these requirements. The requirements for separate combustion chambers in a built-in or attached room are as follows:

- The minimum volume is 15 cubic meters.

- Ceiling height: with power from 30 kW - 2.5 m;

- up to 30 kW - from 2.2 m.

There must be a window with a transom or window, the glass area is at least 0.03 square meters for each cubic meter of volume. Ventilation should provide at least three air exchanges in one hour.

If the boiler room is located in the basement or basement, the minimum size of the boiler room will be larger: 0.2 m2 is added to the required 15 cubic meters for each kilowatt of power used for heating. A requirement is also added for walls and ceilings adjacent to other rooms: they must be vapor-gas-tight. And one more feature: the furnace room in the basement or ground floor, when installing equipment with a power of 150 kW to 350 kW, must have a separate exit to the street. Exit to the corridor leading to the street is allowed.

It is not the area of the boiler room that is standardized, but its volume; the minimum ceiling height is also set

In general, it is advisable to choose the size of a boiler room in a private house based on ease of maintenance, which usually far exceeds the standards.

Special requirements for attached boiler rooms

There aren't very many of them. Three new requirements are added to the points stated above:

- The extension should be located on a solid section of the wall, the distance to the nearest windows or doors should be at least 1 meter.

- It must be made of non-flammable material with a fire resistance limit of at least 0.75 hours (concrete, brick, cinder block).

- The walls of the extension should not be connected to the walls of the main building.

This means that the foundation must be made separate, incoherent, and not three walls must be built, but all four. The extension is made of non-combustible building material

Things to keep in mind. If you are planning to install a boiler room in a private house, but there is no room of suitable volume or the ceiling height is slightly lower than the requirements, they may meet you and demand that the glazing area be increased in return. If you are planning to build a house, then you must meet all the requirements, otherwise the project will never be approved for you. They also take a strict approach to the construction of attached boiler houses: everything must comply with the standards and nothing else.

For boilers with an open combustion chamber

For gas boilers with an atmospheric burner, a smoke channel is required that provides good draft - the removal of combustion products occurs due to the movement of air through the pipe. Therefore, it is made as straight as possible, preferably with smooth walls. There are two options:

- Bring it horizontally through the wall, then along the outer wall up to the required height. This option is also called an external chimney.

- Lead the pipe up from the boiler, go through all the floors, the roof, and lead it above the roofing material. If necessary, you can move the pipe further away from the wall by making two 45° elbows. It is better not to make 90° bends with this design.

Which option is better? An external chimney is easier to implement - with an outlet through the wall

It is only important to pass through the wall correctly (maintain a fire gap if the walls are flammable). But this option requires good insulation and high-quality fastening to the walls

And even under such conditions there is usually a lot of condensation. Therefore, the installation of a tee and a condensate collector at the outlet is mandatory.

Option for passing through the ceiling and insulation

In the case of a chimney outlet through the roof, there are at least two difficult points - passage through the first floor ceiling and through the roof. In these places, special passage units are installed. They provide the proper degree of fire safety.

Features of metal pipe assembly

If sandwich pipes or single-wall metal pipes are used, then the external chimney for a gas boiler is collected “by condensate”. That is, inserting the upper pipe inside the lower one. This is possible due to the presence of a corrugated edge on one side.

When assembling a chimney inside a building, the structure is assembled “according to the smoke.” In this case, it is more important that gases do not enter the room. Therefore, they unfold the pipes so that the upper element fits onto the already installed one.

Types of chimney assembly made of metal and sandwich pipes

There is a third option - to assemble two circuits in different ways: the external one for smoke, the internal one for condensate. For such an assembly, it is imperative to use sandwiches, since they are the only ones with two circuits. This is the best option, since the protection is complete, but the assembly is complicated.

Smoke pipes in the shaft (box)

To prevent communications from spoiling the interior, they are often “packed” into a shaft - a specially constructed box. Inside there are, as a rule, a chimney (or chimneys, if several devices are working), ventilation ducts, and there may be risers for water supply, heating, and sewerage. In any case, it is better to cover the chimney pipe with thermal insulation. If insulation can still not be used in a heated room, then in the attic (especially if it is cold), insulation must be mandatory. Use basalt wool with an operating temperature of at least 300°C.

The chimney can be hidden in the shaft

Insulation will have a positive effect on the temperature inside the chimneys, which will increase draft and reduce the amount of condensate. But do not forget that we are talking specifically about gas boilers, and their combustion products have a low temperature.

Principle of operation

The principle of operation of ducted supply ventilation

The equipment is an installation of exhaust or supply ventilation for processing air flows and supplying it to the boiler room. The device is a component of the heating system and is often connected to a central pipe. The air comes directly from the street or through the air ducts. A complex system consists of metal boxes or pipes, between which functional devices are mounted. External elements are protected from atmospheric action.

Working elements of the system:

- A fan with a two-phase electric motor supplies air to the boiler room or to the common air duct.

- Filters purify the air using coarse types or the method of electrostatic sedimentation. Coarse elements are placed in front of thin filters, protect them from damage and are easily replaced.

- Heating or cooling devices change the temperature of the incoming stream. Heat pumps, electric heaters or evaporators are used.

Balancing devices, shock absorption and sound insulation in the system eliminate vibration and reduce sound during operation. The vibrations are isolated and damped by obstacles, and the fan is placed on spring supports.

Natural circulation in a room with a gas boiler

It is necessary to install a polypropylene pipe into the vent. If the heating equipment has a power of 30 kW, then the pipe is suitable with a diameter of Ø15 cm. A metal mesh protects the entrance from the outside. To prevent foreign odors and debris from entering the room, a valve is installed inside the pipe.

Combustion products go directly into the exhaust pipe installed above the heating equipment. The supply air pipe is designed to bring fresh air into the combustion chamber, so this air duct is installed immediately behind the firebox. The efficiency of natural ventilation in a boiler room directly depends on weather conditions. And according to the standards, the air in such a room must be renewed 3 times every 1 hour.

It is impossible to calculate the air exchange rates for this ventilation system. In practice, it often happens when, for natural ventilation, a hole is made through a wall with a diameter of 150 mm, a ventilation pipe is inserted into the hole, it is protected from the outside with a mesh, and a check valve is mounted on the other side. From a financial point of view, this option is quite inexpensive, and the performance is very good.

How to organize air flow

To ensure that fresh air is constantly supplied to the kitchen where gas equipment is installed, there are special air supply devices.

Types of supply equipment:

- Supply valve built into the frame of a plastic window. Can operate in manual or automatic mode. In severe frosts it may fail as it is susceptible to icing.

- Supply valve built into the wall. To install it, make a hole in the outer wall. Can be operated both manually and automatically.

- A device for ventilating a room, which is switched on from the mains. It is attached to the bottom panel of the plastic door. Performs the function of filtering and heating the air flow.

Any type of ventilation for a gas boiler, water heater or stove can be installed independently if desired.

Coordination of boiler installation

You need to go through several authorities to obtain approval for the installation of a gas-fired boiler. Doing it yourself, without approval, the installation process will be illegal and unsafe, and not only for the home owner, but also for the other residents of the house if the boiler is installed in a high-rise building.

Specifications

To connect a private house or apartment to the gas supply, you will have to obtain technical conditions from the gas supply organization that permit this procedure. To do this, a statement is written to the controlling organization. It must indicate the approximate demand for gas volume per hour. The registration procedure lasts seven to fourteen days. Upon successful completion of this event, a document will be issued - technical conditions for the installation of equipment operating on gas fuel. This is a permit for preparatory construction and installation work.

Project

Having the technical specifications in hand, you can proceed to the second step - developing design documentation. The gas supply project includes plans for laying a gas supply pipe from the boiler installation site to the central gas pipeline.

The project will also indicate sections of the gas pipeline crossing the site

If the home is located in the private sector, and the pipeline must cross the land, then a diagram of the gas pipe on the site is also drawn up, indicating the location of its entry into the wall of the house. The project is developed by engineers licensed for such activities, based on the provisions of the GOS.

Coordination with the gas supply organization

The completed project is submitted for approval to the organization that controls gas supply in the applicant’s area of residence. Project approval takes from seven to one hundred days, depending on the volume and complexity of the document. The following materials regarding the heating device are attached to the project:

- examination of the boiler’s compliance with all requirements necessary to ensure normal operation and safety;

- technical passport of the device;

- certificates of compliance with technical and sanitary-hygienic requirements;

- operating instructions.

All documents specified in the list are prepared by the manufacturer and must necessarily accompany any product of this type.

They are transferred by the seller to the buyer when purchasing the device - special attention should be paid to this

If the project was rejected for the first time, the applicant is given a document indicating the reasons for the refusal and a list detailing all the problems of the project that require correction.

If the project is approved, it is certified by the signature and seal of the responsible person. This document is the final permission to install the heating device.

How to do it yourself?

Schemes and calculations

Natural ventilation scheme:

- The air supply is located opposite the hood.

- The air is exhausted through an exhaust pipe, the beginning of which is on the ceiling, and the end is above the roof ridge. If the ventilation system is located on the wall, then this should be done as close to the ceiling as possible.

Mechanical ventilation scheme:

- The pipe with the fan must be discharged either through the roof to the street or through the wall outside the house.

- The air duct exits into the existing ventilation shaft with a fan.

During the heating season, it is recommended not to turn off the exhaust fan, leaving it to run on a regular basis.

Calculation of ventilation for a boiler room with a gas boiler is carried out taking into account the area of the room, the frequency of air exchange, and the number of family members regularly living in the house. Using these parameters, you can calculate the required hood cross-section for a gas boiler.

Attention Formula for calculating the amount of air exchange:

L (boiler power, kW/h) = N (air renewal rate) × S (room parameters) × H (boiler room ceiling height, m).

Attention Formula for calculating the number of family members:

L (boiler power, kW/h) = N (number of family members) × Lн (minimum air consumption per person, m³/h).

Generally accepted minimum air consumption standards per person:

- sleep – 20 m³/h;

- rest – 40 m³/h;

- vigorous activity – 60 m³/h.

Boiler room ventilation diagram:

Materials and tools

Basic materials and tools:

- Hammer or drill with a crown attachment.

- Saw for processing pipes.

- Tools for marking - ruler, pencil.

- Air ducts and adapters for them.

- Protective grilles.

- Adapter with check valve.

- Protective sleeves for slabs.

- Self-tapping screws, dowels, mounting clamps.

- Sealant or polyurethane foam.

- Hacksaw.

- Protective equipment: gloves, glasses.

Installation

Installation of natural ventilation:

- The installation location is outlined. The necessary calculations are made, a diagram or drawing is created.

- A pipe is applied to the wall, its dimensions are noted.

- A perforator is used to make a through hole with a slope of 60 degrees outward to drain the condensate (with exhaust ventilation, the slope is not made, the pipe is installed evenly).

- A pipe with insulation and a grille on the outside is inserted into the finished through hole.

- A housing with a check valve is attached to a part of the pipe inside the house and the wall with dowels (how to make a check valve for ventilation with your own hands?).

Installation of forced ventilation:

- A through hole is made in the wall with a slope towards the street. It is recommended to use a hammer drill or a drill with a diamond bit.

- A pipe is installed in the hole.

- The gaps between the wall and the pipe are filled with sealant or foamed.

- A duct fan is installed.

- Electrical wiring is laid and connected.

- The rest of the equipment is installed - filters, sensors, sound absorber.

- Grates are attached to both sides of the pipe.

separate article

Why choose metal air ducts

It is necessary to determine not only the cross-sectional diameter, but also the material from which the ventilation pipe consists. Air ducts are:

- metal;

- metal-plastic;

- non-metallic.

For boiler room ventilation, it is better to use metal ventilation ducts. They meet all fire safety requirements. Such pipes are made of aluminum, steel or galvanized. The main requirement for such ventilation ducts is resistance to corrosion.

Air ducts made of metal can withstand both static and shock loads. Therefore, the risk of destruction of the ventilation structure is minimal. Some pipes are flexible, so you can bend them with your own hands at any angle. High structural strength - allows you to withstand maximum internal pressure.

The only disadvantage of metal pipes is that they cannot withstand condensation and become rusty over time. Only 2 types of metal are definitely resistant to moisture - aluminum and stainless steel. When installing such pipes, you must also take care of the fasteners. Choose ones that can withstand the load. Therefore, the installation process may be delayed. The price for such pipes is also higher than for air ducts made of other materials.

Boiler room in a private house in a separate room (built-in or attached)

Separate boiler rooms for the installation of gas boilers with a power of up to 200 kW must be separated from other rooms by a non-combustible wall with a fire resistance rating of at least 0.75 hours. Brick, cinder block, concrete (light and heavy) meet these requirements. The requirements for separate combustion chambers in a built-in or attached room are as follows:

- The minimum volume is 15 cubic meters.

- Ceiling height. with power from 30 kW - 2.5 m;

- up to 30 kW - from 2.2 m.

If the boiler room is located in the basement or basement, the minimum size of the boiler room will be larger: 0.2 m2 is added to the required 15 cubic meters for each kilowatt of power used for heating. A requirement is also added for walls and ceilings adjacent to other rooms: they must be vapor-gas-tight. And one more feature: the furnace room in the basement or ground floor, when installing equipment with a power of 150 kW to 350 kW, must have a separate exit to the street. Exit to the corridor leading to the street is allowed.

It is not the area of the boiler room that is standardized, but its volume; the minimum ceiling height is also set

In general, it is advisable to choose the size of a boiler room in a private house based on ease of maintenance, which usually far exceeds the standards.

Special requirements for attached boiler rooms

There aren't very many of them. Three new requirements are added to the points stated above:

- The extension should be located on a solid section of the wall; the distance to the nearest windows or doors should be at least 1 meter.

- It must be made of non-flammable material with a fire resistance limit of at least 0.75 hours (concrete, brick, cinder block).

- The walls of the extension should not be connected to the walls of the main building. This means that the foundation must be made separate, incoherent, and not three walls must be built, but all four.

The extension is made of non-combustible building material

Things to keep in mind. If you are planning to install a boiler room in a private house, but there is no room of suitable volume or the ceiling height is slightly lower than the requirements, they may meet you and demand that the glazing area be increased in return. If you are planning to build a house, then you must meet all the requirements, otherwise the project will never be approved for you. They also take a strict approach to the construction of attached boiler houses: everything must comply with the standards and nothing else.

What requirements must be met?

After the stage of construction or creation of the boiler room, they move directly to its design, and here again SNiP standards come to the fore. There are quite a lot of them, so we will consider only the most important ones that directly affect cost and design:

- for each boiler , if there are several of them, it is necessary to equip its own ventilation system;

- a gas boiler requires a separate room if it is more powerful than 30 kW, otherwise installation in another room (for example, a kitchen) is allowed, but its area should not be less than 15 m and the ceiling should not be lower than 2.5 m;

- if the boiler room is equipped in a separate extension , then the latter should stand on the foundation;

- it is necessary to provide conditions for convenient cleaning of the hood;

- the vent (ventilation hole) for each kW of power should be 8 cm2 in the case of intake from the street, or 30 cm2 if the ventilation takes air from other rooms;

- the hood for a boiler in a private house must be located on top ;

It is advisable to supplement the ventilation system with an extractor hood for a gas boiler in a private house Source tigerrupakix.tumblr.com

Ventilation requirements

Gas boilers are classified as high-risk devices, which is why high demands are placed on them and on ventilation systems. Norms and rules for boiler room equipment and exhaust requirements are regulated by SP 89.13330.2001 “Boiler installations”.

Requirements for buildings and premises

Any building designed taking into account the installation of independent gas heating is subject to a number of serious requirements. It is planned to allocate a separate room equipped in accordance with regulatory documents - a boiler room. It is allowed to create it in the following places (the list is compiled taking into account decreasing preference):

- in a separate building;

- in an additional extension;

- in the attic;

- in the basement (basement).

Conversion of a basement or basement into a boiler room is permitted in exceptional cases if the condition is met: the presence of two ventilation systems - the main one and the backup one. This requirement especially applies to boiler houses operating on liquefied gas. It has a higher specific gravity and, if leaked, accumulates near the floor, leading to an explosive situation.

The requirements for the location of wall-mounted boilers up to 30 kW, intended for heating a summer house or a small individual house, are less stringent. The devices have an isolated combustion chamber and air circulation for them is created simply: a coaxial air duct installed in the outer wall is sufficient. It simultaneously provides suction of outside air into the chamber and removes combustion products to the street.

Wall-mounted boilers can be placed directly in the house: in the bathroom, utility room, storage room, kitchen.

Ventilation for a gas boiler in a private house

The following restrictions apply to rooms with a floor-mounted gas heater:

- area from 4 m²;

- total volume more than 8 m³, ceiling height from 2.2 m;

- doorway width - from 0.8 m;

- arrangement of 1-2 window openings with double transoms opening outwards;

- unhindered supply of oxygen - a device in the window frame or the outer wall of the technological opening;

- according to SNiP 31-03-2001, the total glazing area is taken to be up to 0.05 m² per cubic meter. meter of boiler room volume.

Boiler installation requirements

According to SP 89.13330.2001, when installing a gas heater and arranging a ventilation system, the following standards must be observed:

- Only one or two boilers can be connected to the air duct, regardless of their location.

- The ventilation duct must be completely sealed.

- The seams are sealed with sealants, providing reliable insulation at high temperatures.

- Each element is made of fire-resistant materials.

- Horizontal sections are arranged from two channels. The first is intended for the removal of fuel combustion products, the second - for the continuous supply of air flow.

- The cleaning channel should be located 250-350 mm below the main one.

There are no less stringent ventilation requirements for distances and sizes:

- The horizontal pipe is placed at a distance from the ceiling of more than 200 mm.

- All surfaces are made only from fire-resistant materials.

- At the external outlet of the pipe from the wall, all combustible surfaces are covered with a fire-resistant insulating layer.

- The distance from the external wall with the exit pipe to the end of the air outlet is set from 300 mm.

- The pipe is located from the ground surface at a distance of 200 mm.

- If there is another wall opposite the pipe, the distance to it is taken from 0.6 m.

Types of ventilation for operation of gas heating equipment

Convection can be natural or forced. Spontaneous air flow is ensured by the presence of windows, vents, doorways and an exhaust duct, the outlet of which is mounted in the room with the boiler.

The natural ventilation system consists of an air duct that connects the outlets from the kitchen, boiler room and bathroom to a pipe on the roof. The width of the box is not calculated, but selected according to SNiPs, because For an accurate calculation, it is necessary to take into account the direction and speed of the wind, atmospheric pressure and other parameters. A 30 kW gas boiler must have an air duct 150 mm wide, for 100 kW - 230 mm.

The hood is mounted directly above the device, and the pipeline is mounted behind the fuel chamber.

Forced ventilation is organized by pumping air and creating an area of low pressure. The local vacuum provided by the fan stimulates the suction and rapid removal of the air mass.

To calculate the blower parameters, you need to multiply the volume of the room by the loss and air change coefficients. The cost of resistance during the passage of the chimney is about 40%, therefore, with room parameters of 4x2x2.2 m, the fan power should be at least 74 m³/h.