Solid fuel boilers continue to hold a strong position in the heating equipment market. Modern models are able to squeeze out maximum thermal energy from firewood, coal and briquettes, and transfer it to the coolant with minimal losses. Automation for solid fuel boilers helps improve the quality of work and simplify maintenance and operation. A very effective way to control the combustion process and maintain a given coolant temperature is achieved simply by the presence of a blower fan and a command controller that controls it and the circulation pump.

How does it work

It seems very difficult to control the combustion process of coal or wood. At all times, setting up a boiler was purely individual for each boiler, was done manually and required a lot of experience and skill. As a good result, maximum efficiency was achieved in combination with fuel economy. However, if the settings were incorrect, most of the heat simply flew out into the chimney.

The automation process, which has long become commonplace for any other types of boilers, has also reached solid fuel boilers. It turned out that it was enough to use a very limited set of tools and sensors to ensure a controlled combustion process, increase the safety of boilers and accurately maintain the temperature of the water in the heating circuit.

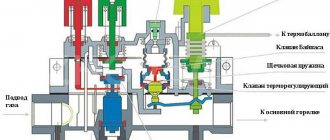

Automation for solid fuel boilers includes:

- blower fan;

- controller;

- circulation pump (optional);

- draft regulator (optional).

The operating principle of the automation is extremely simple. It is enough to take over the control of the blower and control the volume of air entering the combustion chamber to ensure optimal fuel combustion and the safe operation of all boiler equipment.

The fan is installed instead of a standard damper, through which fresh air enters the combustion chamber. The controller controls the fan and, in accordance with the settings, is able to change the volume of incoming air:

- If it is necessary to obtain maximum thermal power, the fan turns on at full speed and supplies a large volume of air saturated with oxygen. Active combustion of fuel is accompanied by an increasing output of thermal energy

- In operating mode, the fan switches to moderate speed and maintains combustion at the optimal level necessary to obtain the desired coolant temperature.

- If the target water temperature in the circuit overheats or decreases, the fan stops and without access to oxygen, the fuel only barely smolders, releasing a minimal amount of heat.

A similar cycle is repeated over and over again, providing, albeit stepwise, regular combustion control.

The reference data for the controller is the readings of the water temperature sensor in the boiler. In fact, this is enough to ensure normal operation of the automation. In addition, some types of automation control the temperature of the exhaust gases entering the chimney, the temperature outside the house and inside the room. In this case, additional protection and safety is provided, and the possibility of advanced boiler settings with automatic correction of the target water temperature in the boiler and the ability to control heating to maintain a comfortable temperature in the house appear.

In addition to the controlled fan, the automation can control the circulation pump to promote constant and even distribution of heat throughout the heating circuit. By increasing or decreasing the speed of water circulation in the circuit, you can influence the efficiency of heat transfer from the combustion chamber to the coolant, directly increasing the efficiency of the boiler.

Additional functions of the solid fuel boiler automation unit may include:

- GSM module for remote control of the boiler operation and the possibility of remote configuration.

- Planning the operation of the boiler, according to the schedule, setting the desired temperature depending on the time of day and day of the week.

- Introduction of a solid fuel boiler into the overall Smart Home control system.

Automation operation diagram

With automation for solid fuel boilers, there is no longer any need to constantly and independently monitor its operation, adjust damper settings, or worry about the fact that the fuel will be wasted or clearly ineffective. In addition, real cost savings result, because with precise adjustment and constant control of fuel combustion, less fuel is spent, used more efficiently and purposefully. The controller monitors the condition of the water and controls the combustion process 24 hours a day every day throughout the heating season.

The cost of automation for solid fuel boilers, if we take offers from the average price range, is comparable to the cost of fuel for half the heating season or even a third. If we take into account that using the controller saves fuel on heating, the equipment will pay for itself in literally two to three seasons. And yet, the main advantage remains that the user does not have to, as before, check the operation of the boiler every half hour or hour and adjust it in the hope of obtaining the desired water temperature, moreover, with a large error.

Automation for solid fuel boilers is often produced by manufacturers that are not directly involved in the production of boilers. These are firms and companies that specialize, in principle, in process automation. Therefore, it will be useful to find out the list of the most common and already proven manufacturers of command controllers on the market.

Fuel requirements

Pyrolysis stoves for home use, using briquettes, can be fully automated and the comfort of their maintenance in this case is comparable to gas stoves. The fuel for them is waste compressed under high pressure without chemical binders. This technology makes it possible to produce relatively dry briquettes with a high calorific value. Their properties, however, may be different.

Pyrolysis furnaces and boilers operate on a wide variety of fuels

Most of them are not destroyed during combustion in the firebox, while others can only be used in a mixture with lump wood or brown coal. Small briquettes are fed using screw conveyors and are therefore used in automated systems; larger briquettes are only suitable for manually operated long-burning pyrolysis ovens. Wood pellets intended for automatic installations are obtained in the same way as conventional briquettes. Their only significant difference is size. White pellets made of soft wood without bark are considered the highest quality.

For wood-fired pyrolysis stoves, the size and type of feedstock can significantly influence performance—more wood surface area results in more gas being released per unit time. Hard rocks gasify more slowly.

Atos

- Manufacturer: Poland;

- Power supply: 220V/50Hz;

- Connected pump power: up to 130W;

- Fan power: up to 130 W;

- Coolant temperature setting range: 35-80°C;

- Temperature measurement accuracy: 1°C

- Room temperature setting range: 25-50°C;

- Alarm when the set temperature range is exceeded;

- Relay output for additional alarm;

- Manual target temperature setting and circulation pump control.

- Estimated cost: 6750 rub.

Automation originally from Poland has proven itself well in combination with heating boilers of various types and designs with a capacity of 25-50 kW. Among the advantages is the possibility of igniting fuel in any weather conditions, increasing the efficiency of the boiler while maintaining a stable coolant temperature, according to the set value.

The control unit is compact, with a simple interface and a two-digit dial for setting all key parameters.

Air

- Manufacturer: Ukraine;

- Power supply: 220V/50Hz;

- Connected pump power: up to 450W;

- Fan power: up to 220 W;

- Coolant temperature setting range: 40-85oC;

- Temperature measurement accuracy: 0.1°C

- Room temperature setting range: 20-45oC;

- Estimated cost: 3000-3500 rubles.

Compact automatic control unit for solid fuel boilers. Allows installation and control of a powerful circulation pump and fan with a corresponding load current of 2 and 1 ampere; the modification allows load currents of up to 5A.

Tech

- Manufacturer: Poland;

- Power supply: 220V/50Hz;

- Connected pump power: up to 200W;

- Fan power: up to 200 W;

- Coolant temperature setting range: 30-80°C;

- Temperature measurement accuracy: 1°C;

- Room temperature setting range: 20-45oC;

- Manual target temperature setting and circulation pump control.

- Estimated cost: 6500-7250 rubles.

Functional control unit with practical overheat-protected housing. User-friendly interface. The presence of an LCD display and an expanded set of control keys makes it easier to configure the automation and control the operation of the boiler.

Types of control units

The units are either electronic or mechanical.

The electronic version is considered more efficient, but is characterized by energy dependence.

Mechanical, on the contrary, is energy independent. It does not require connection to the electrical network and is cheaper. At the same time, it is reliable and easy to use.

When choosing, you need to pay attention to the following important parameters:

- compatibility of the unit with a specific boiler model;

- thermal operating mode;

- economic efficiency;

- required degree of temperature level adjustment.

Comfort Eco

- Manufacturer: Poland;

- Power supply: 220V/50Hz;

- Connected pump power: up to 300W;

- Fan power: up to 300 W;

- Coolant temperature setting range: 35-80°C;

- Temperature measurement accuracy: 1°C;

- Room temperature setting range: 20-45oC;

- Estimated cost: 7900-8200 rub.

Compact control unit mounted on the boiler body with simple controls and a two-digit dial. Allows you to adjust the operation of the boiler depending on the set target temperature in the heated room. Provides boiler protection from overheating and freezing.

What can be controlled using automation

Automatic systems perform a number of important tasks:

- optimally dose the air supply required for traction;

- control the performance of the heat generator;

- regulate the power of the device depending on weather and temperature factors;

- guarantee the safe operation of the water heating installation of the device;

- feed firewood, pellets, briquettes or coal automatically;

- ignite and extinguish the firebox.

How to connect and configure

Installation of any automation for a solid fuel boiler is approximately the same. You need to follow a number of simple steps:

- Place the automation unit in a place inaccessible to overheating. It is not at all necessary to install the automation unit very close to the boiler or on its body. It is much more important to define it in such a way as to avoid overheating, even taking into account possible emergency situations. The maximum distance is determined by the permissible length of cables for connecting the fan, circulation pump and sensors, which can range from 2 to 10 meters.

- Connect a fan to supply air on the combustion door instead of the ash damper or in a separately prepared hole. For older boiler models, you will have to manually cut and prepare a hole for the fan. In modern boilers, installation is carried out in a prepared place.

- Install the coolant temperature sensor. It is best to measure the water temperature directly in the boiler heat exchanger or inside the main heat storage tank. For this purpose, boilers often provide a special seat or hole up to 60 mm deep. If it is not possible to fix the sensor on the heat exchanger, then it is transferred to the boiler outlet pipe through which the hottest coolant flows. More often, the manufacturer advises using a clamp with a thermal pad for better contact.

- Connect all equipment to the controller using power and signal wires. For the fan, circulation pump and sensors, corresponding pairs of terminals are allocated, mounted on the body of the automation unit. Their markings and position should be checked with the instructions from the manufacturer.

- The initial settings are set: target coolant temperature. The maximum and minimum volume of air supplied by the fan to the combustion chamber. Limits of permissible change in water temperature in the boiler.

The programming algorithm and settings of the automatic control unit for solid-fruit boilers are established by the manufacturer and are described in detail in the instructions.