- Home →

- Heat guns, air heaters, heat generators →

- Waste oil furnaces, waste heaters

Waste oil heaters have a number of significant advantages over thermal heaters running on other types of fuel.

Furnaces in use pay for themselves in 1 season, so purchasing this equipment is extremely expedient. Prices for installing waste oil heat generators Selection of equipment by parameters Sort by price Table Pictures

Waste oil heat generators POLARUS P

Heat generators, or POLARUS waste oil furnaces as they are also called, are powerful and high-performance thermal equipment for heating large areas, with economical and rational fuel consumption. Such an air heater is capable of quickly and efficiently heating an industrial warehouse, hangar or garage with a volume of more than 3000 m³. In addition, the design of the heat generator is equipped with several features that significantly increase its efficiency and increase heat transfer. Absence of injectors and the possibility of their clogging, Fuel supply through a system of communicating vessels, Protection against overheating, Powerful turbine, Heating of fuel and protection against its overflow, Regulation of operating power, Stopping operation during a power outage, Efficient blower fan, Warranty - 1 year.

| Name | Power, kWt | For premises, m² | Ventilation (m³/hour) | Dimensions w/h/d | Price |

| Waste oil furnace POLARUS P 11M 60 | 10–60 | 100–600 | 3000 | 70/130/60 | 72,900 rub. |

| Waste oil furnace POLARUS P 11M 80 | 10–80 | 100–800 | 3000 | 70/130/60 | RUB 75,900 |

| Waste oil furnace POLARUS P 11D | 20–60 | 200–600 | 3000 | 90/130/65 | removed |

Heat generators (furnaces) using waste fuel Teplamos NT

High-performance, economical and easy-to-use waste fuel heat generators Teplamos NT are especially indispensable for heating warehouses, garages with equipment, workshops, hangars, and facilities under construction where people are located. Such semi-automatic air heaters are fully equipped with everything necessary and the only thing required when installing heat generators is the installation of a chimney. All models are equipped with a fuel tank, the ability to precisely regulate operating power and the absence of odor or smoke during operation. Model NT-612 heats the room by natural air circulation, and the thermal power is -5 - 15 kW, Compact dimensions, Protection system against overheating and fuel overflow, Absolutely does not require additional heating or fuel filtration, Economical in maintenance and fuel consumption, Installation required chimney (optional), 1 year warranty.

| Name | Power, kWt | For premises, m² | Ventilation (m³/hour) | Dimensions w/h/d | Price |

| Waste oil heat generator Teplamos NT-602 | 15–30 | 150–300 | 1100 | 72/110/45 | 62,000 rub. |

| Waste oil heat generator Teplamos NT-605 | 40–70 | 400–700 | 4100 | 95/120/52 | 99,000 rub. |

| Waste oil heat generator Teplamos NT-603 | 20–55 | 200–550 | 1500 | 72/110/45 | removed |

| Waste oil heat generator Teplamos NT-612 | 5–15 | 50–150 | before | 41/61/26 | removed |

Automatic heat generators (furnaces) using waste oil Teplamos HD (without fuel tank)

Heat generators using waste oil Teplamos HD are distinguished by an automatic operating principle, which allows them to turn off after reaching the required temperature in the room, and to automatically start working when the temperature drops. This feature contributes to rational fuel consumption and high efficiency. In addition, the Teplamos HD furnaces are distinguished by the presence of a protection system against overheating and fuel overflow. All air heaters are reliable in operation and are characterized by a simple start-up and commissioning process. Heat generators HD 95/100/150/200 can work with heat distribution throughout the premises (air duct length up to 50 m), Setting the desired temperature using a remote thermostat, Operating modes: heating/ventilation, No smell or smoke during operation, Use as fuel all types of used machine, technological, vegetable oil, Exhaust pipe, air compressor and fuel tank - must be purchased additionally! Warranty – 1 year.

| Name | Power, kWt | For premises, m² | Ventilation (m³/hour) | Dimensions w/h/d | Price |

| Waste oil heat generator Teplamos HD 80/55 | 37–54 | 370–540 | 3200 | 119/93/119 | RUB 296,000 |

| Waste oil heat generator Teplamos HD 95/70 | 56–81 | 560–810 | 4500 | 166/119/104 | RUB 322,000 |

| Waste oil heat generator Teplamos HD 95/100 | 81–100 | 810–1000 | 4500 | 166/119/104 | RUB 337,000 |

| Waste oil heat generator Teplamos HD 95/150 | 93–147 | 930–1470 | 7500 | 166/119/104 | 370,000 rub. |

| Waste oil heat generator Teplamos HD 95/200 | 131–190 | 1310–1900 | 7500 | 166/119/104 | RUB 394,000 |

Master waste oil heaters

Stationary waste oil heaters Master BG and WA have a number of features, which have both their pros and cons. One of the disadvantages is the need for regular maintenance of the burner, given that waste oil heat guns must be regularly inspected and cleaned; this point in some cases causes difficulties since it is a somewhat dirty job. But what savings in everything else! The high efficiency that Master heaters provide and free combustible materials, taking into account the high productivity of the equipment, allow for significant savings. Reliable stationary waste oil heaters Master effectively heat the room and are economical to operate. Power adjustment, built-in fuel tank. Production: Poland. Warranty - 1 year.

| Name | Power, kWt | For premises, m² | Ventilation (m³/hour) | Dimensions w/h/d | Price |

| Stationary air heater Master WA 33 | 21–33 | 30–330 | 1000 | 86/137/54 | 150 100 rub. |

Kroll W air heaters using waste oil

Kroll air heaters are actively used for heating facilities where there is a large amount of waste oil. Ability to work on any type of used oil. It is advisable to use at such production facilities as car markets, car services, garages and various industries. Availability of built-in fuel tank. The Kroll W401 K model comes with a built-in fan. Warranty - 1 year.

| Name | Power, kWt | For premises, m² | Ventilation (m³/hour) | Dimensions w/h/d | Price |

| Waste oil air heater Kroll W401 K | 11.2–35 | 67–350 | 77/100/60 | RUB 215,814 |

Euronord waste oil heat guns

Heat guns or heat furnaces Euronord (Euronord) using waste oil will become an indispensable assistant and quite a significant source of savings on maintenance and fuel purchases, which helps speed up the payback of the equipment several times compared to gas and diesel analogues. Warranty - 1 year. Manufactured in Germany.

| Name | Power, kWt | For premises, m² | Ventilation (m³/hour) | Dimensions w/h/d | Price |

| Waste oil furnace Euronord AT-55 | 20–55 | 200–550 | 2270 | 87/133/67 | 185,000 rub. |

| Heat gun Euronord EcoHeat | 15–35 | 90–350 | 79/117.5/65.5 | Price request |

Hiton HP air heaters using waste oil

Hiton waste oil heat generators are actively used in enterprises whose production by-products include waste oils. A real find for heating the premises of car service centers and motor transport enterprises.

| Name | Power, kWt | For premises, m² | Ventilation (m³/hour) | Dimensions w/h/d | Price |

| Heat generator Hiton HP115 | 15–22 | 90–220 | 600 | 54/125/75 | RUB 132,409 |

| Heat generator Hiton HP125 | 22–30 | 132–300 | 1000 | 54/137/85 | RUB 144,041 |

| Heat generator Hiton HP145 | 30–42 | 180–420 | 2660 | 70/140/120 | RUB 167,430 |

EnergyLogic EL H waste oil air heaters

EnergyLogic EL H air heaters using waste oil with a special metering fuel pump. The burner opens easily and provides trouble-free access to the combustion chamber. Universal installation. Manufactured in the USA, warranty – 1 year.

| Name | Power, kWt | For premises, m² | Ventilation (m³/hour) | Dimensions w/h/d | Price |

| Air heater EnergyLogic EL 350H S | 102.6 | 800–1026 | 4740 | 297/56/56 | Price request |

| Air heater EnergyLogic EL 200H S | 58.3 | 349–583 | 2520 | 26.7/46/46 | Price request |

| Air heater EnergyLogic EL 140H S | 41.6 | 246–416 | 1680 | 234/46/46 | Price request |

| Air heater EnergyLogic EL 340H S | 99.6 | 597–996 | 4740 | 252/112/56 | removed |

Omni Waste Oil Air Heaters

Omni automatic waste oil air heaters do not require constant cleaning and adjustment. Used oil with a viscosity of up to 90 units according to the SAE classification is used as fuel. Stainless steel heat exchanger, high performance axial fans and wide air flow louvers. Production - USA.

| Name | Power, kWt | For premises, m² | Ventilation (m³/hour) | Dimensions w/h/d | Price |

| Automatic air heater Omni OWH 500 | 146.5 | 879–1465 | 15290 | 183/97/88 | removed |

| Automatic air heater Omni OWH 350 | 102.6 | 615–1026 | 10660 | 137/75/72 | removed |

| Automatic air heater Omni OWH 250 | 73.3 | 439–733 | 7588 | 112/76/72 | removed |

| Automatic air heater Omni OWH 150 | 44 | 264–440 | 6392 | 107/56/65 | removed |

DanVex waste oil air heaters

DanVex waste oil heat generators are available in wall-mounted and floor-standing models. Air heaters are designed for efficient and economical heating of car service centers, garages, industrial and warehouse premises. All air heaters are supplied with a burner and can therefore be put into operation within 1 day. The use of waste oil as fuel makes such heat generators in maximum demand at the onset of the heating season. Ease of operation is ensured by the presence of an appropriate panel, as well as the ability of the burner to automatically maintain the required fuel temperature and control its consumption. All presented heat generators can be operated as independent units or in a large ventilation and heating system. Fuel pump, Fuel filter, Fuel preheating, Stainless steel combustion chamber, 1 year warranty.

| Name | Power, kWt | For premises, m² | Ventilation (m³/hour) | Dimensions w/h/d | Price |

| Wall-mounted heat generator DanVex H-30 | 35.6 | 240–356 | 1680 | 234/46/46 | 255,000 rub. |

| Wall-mounted heat generator DanVex H-60 | 62.6 | 500–626 | 2520 | 267/46/46 | 275,000 rub. |

| Wall-mounted heat generator DanVex H-100 | 94 | 750–940 | 4740 | 252/112/56 | RUB 325,000 |

| Waste oil air heater DanVex H 150 | 147 | 1000–1470 | 8000 | 117/165/74.6 | 515,000 rub. |

Furnace in production: options for making the device yourself

With the approach of cold weather, many craftsmen are coming up with various designs for heating the room and heating water. First of all, the question is about the type of fuel. In search of the most rational and cheapest option, many choose to work off, the average consumption of which is about 2 liters per hour. A waste oil furnace has a number of advantages. Knowing all the intricacies of its manufacture, you can create a budget-friendly and efficient source of heat in the house. Garage stove: photo examples, varieties, how to make it yourself (read more)

Creating a homemade stove for mining is not a labor-intensive process.

Where can I get drawings, diagrams and ideas?

Before starting to develop a stove project, we recommend that you familiarize yourself with forums where users discuss the manufacture and operation of such heating devices.

There you will find answers to many questions and various technical solutions that will help you make your stove more efficient and safe.

Here are links to such forums:

- www.forumhouse.ru.

- termoportal.ru.

- mastergrad.com.

- forum.auto.ru.

- forum.homedistiller.ru.

- www.chipmaker.ru.

- forums.drom.ru.

- www.bylkov.ru.

- forum.stovemaster.ru.

- chiptuner.ru.

- forum.homedistiller.ru.

- forum.ulmoto.ru.

Advantages and disadvantages of a waste oil stove

A factory or homemade waste oil furnace is characterized by a number of advantages:

- ensuring fast and efficient heating of enclosed spaces in the form of greenhouses, domestic buildings, warehouses and technical rooms;

- independence of the device from electricity and gas;

When ensuring normal operation, the stove does not create a lot of soot and burning.

- unique design features of the device that allow you to carry out the cooking process;

- ease of operation;

- no open flame;

- reliability of the structure, which is made of metal products connected by welding;

- when ensuring normal operation, the stove does not create a lot of soot and burning;

- due to its light weight and dimensions, the device can be transported;

- the stove can be made from scrap metal;

- during operation of the device, combustion of oil and its vapor is ensured;

- The stove can be combined with a water heating system by installing a tank on top.

A closed type furnace is not without its drawbacks, among which are the following:

- the possibility of clogging the supply tube with waste oil;

- the need to install a chimney with a length of at least 4 m;

- presence of hot open surfaces;

The exhaust furnace provides fast and efficient heating of various types of enclosed spaces.

- weekly cleaning of the chimney and oil container from accumulated waste;

- high probability of contamination of clothing and premises during contact with fuel;

- the container with fuel should be located in a warm room;

- unpleasant smell of used oil;

- the flame in the apparatus can be extinguished only after the fuel has completely burned out;

- if used incorrectly, the fire hazard increases;

- characteristic humming noise during operation of the furnace;

- The fuel ignites only when it is heated to its flash point.

Note! Before pouring oil into the system, it should be filtered.

Security measures

A stove for a working garage is a simple and inexpensive solution for heating a technical room. And if the garage is a workshop where people often come for oil changes, then there will be no problems with fuel - there will always be plenty of it. When using the oven, you should be careful:

- Do not light faulty stoves;

- Do not use gasoline, alcohol or other aggressively burning liquids for ignition.;

- Do not overheat ovens;

- Do not leave equipment unattended;

- Do not touch hot elements;

- Keep a fire extinguisher nearby;

- Homemade stoves during testing must be tested in outdoor conditions.

By following these rules, you will ensure complete safety of the premises and protect yourself from injuries and burns.

Operating principle of a waste oil furnace

The prototype for oil furnaces operating on waste oil is kerogas, which was previously used in villages and dachas. It used kerosene as fuel, the vapors of which were burned in a separate chamber. To save on fuel, a waste oil burning option was developed. It can be purchased for free or at a reasonable cost at any service station.

Components of a waste oil stove.

Creating a homemade stove during mining is not a difficult process. The main task is to properly organize the system for a productive oil combustion process. To ensure complete combustion of vapors, heavy components must first be split into light ones, which is carried out as a result of pyrolysis. The oil must be properly heated for efficient evaporation.

The operating principle of an oil furnace during mining is as follows. First of all, the mining is ignited in the lower chamber of the apparatus. The combustion intensity is regulated using a throttle valve in the device body, through which air enters the chamber. Oil vapor mixed with oxygen rises upward through a vertical pipe. The pipe is connected to the upper tank, which is the afterburner chamber.

The mixture is mixed under the influence of the Coriolis force (force of inertia). The intensity of the process is achieved by choosing the correct diameter and length of the combustion chamber. To ensure complete combustion, air must flow through the damper in sufficient quantity. To do this, it is additionally sucked through holes made in a vertical perforated pipe connecting the tanks.

The combustion intensity is regulated using a throttle valve in the device body.

The gas flow is directed to the final combustion chamber, in which the upper part is expanded. During its manufacture, a horizontal separation is made between the chimney inlet and the combustion chamber outlet, which is necessary to ensure a temperature jump between the nitrogen oxide and oxygen afterburning zones. At temperatures below 600 °C, nitrogen oxides are more active than oxygen. As they decompose, they oxidize fuel particles. With increasing temperature, oxygen acts as the main oxidizing agent. Harmful substances are released into the atmosphere through the chimney.

Note! To ensure efficient oil combustion in the upper tank, the temperature must be low.

Heating oil

As we have already said, any type of fuel can be used as fuel for waste furnaces. The easiest option is to purchase used machine oil. Its cost is from 25 rubles per liter. If you try hard, you can find oil at more affordable prices. In this regard, car oil change shops are lucky - they can get it from customer cars (usually no one takes it).

In addition to processing, you can use any types of oils:

Vegetable oil ignites quickly if heated thoroughly. It even causes fires.

- Vegetable - the most common sunflower oil burns well, releasing a large amount of thermal energy ;

- Gear oil - if you are lucky enough to get a barrel of this oil, you can use it to run your stove;

- Synthetic oils are excellent liquid fuels for waste furnaces.

In addition to oil, you may need kerosene to light the stove - it is used in pyrolysis stoves.

The use of gasoline and solvents to ignite stoves is strictly prohibited - they are highly volatile and ignite with pops and explosions. The same kerosene is ignited softly and safely.

Waste oil furnace: types of designs

There are several types of oil furnaces that operate on waste oil. The classic model is the pyrolysis apparatus. It is made from ready-made containers in the form of barrels, pipes, cylinders or from alloy sheets. Oil is poured into the lower vessel, which splits when there is insufficient air. In the upper tank, intensive combustion of its vapor occurs, due to which a lot of heat is released.

Temperature regulation is carried out by air supply. Such a furnace requires constant cleaning of the chambers from accumulated fractions. It does not have mechanical temperature control.

Oil is poured into the lower vessel of the stove, which breaks down when there is insufficient air.

At the oil recovery stove, a guaranteed air supply to the second chamber is realized with the help of a fan. The combustion process is more efficient, so warm air evenly enters the room.

The operating principle of a stove with a drip supply of fuel is similar to the operating mechanism of diesel engines. It is economical. However, the independent process of manufacturing the device is very labor-intensive, so it is better to purchase a factory device of this type. In addition, it should be taken into account that homemade drip stoves are picky about the quality of the oil, which must be preheated before feeding into the stove.

The most efficient model is a supercharged waste oil furnace. It, in comparison with a potbelly stove, has a higher cost. Additional heat comes from blowing fans. Supercharging can be done using a car cooler motor, and the heater is blown by a 220 V home propeller.

Standard layout of a waste oil furnace.

Requirements for installation and operation of an oil furnace

It is required that the stove be located in an empty room, near which there should be no flammable surfaces. Particular attention is paid to self-made devices. They should not be placed on a shelf or other support that could catch fire.

A homemade furnace for mining should be located on a flat base, which can be concrete or brick. It is necessary that the distance between the apparatus and the wall be at least 1 m. To create good draft, the chimney must have a length of more than 4 m. Insulation should be provided on its external side to prevent the formation of acid condensation.

The used oil should not contain any solvent or other flammable element, so such components should be kept away from the furnace. It is also unacceptable for moisture to get into the container with oil. This will cause a fire in the oven. In the event of an emergency, a fire extinguisher should be used to extinguish the fire.

Note! In the room where the stove is located, there must be a good system of natural supply and exhaust ventilation.

The operating principle of a stove with a drip supply of fuel is similar to the operating mechanism of diesel engines.

Before starting work, oil is poured into a container in an amount equal to half the volume of the tank, which will provide the necessary space for the formation of vapor. For the vapors to become enriched with oxygen, you need to wait some time. Then the fuel is ignited using long matches. As soon as the process of ignition of vapors begins, the damper is closed halfway.

To increase the performance of the mini-furnace during mining, you can install a sealed tank with liquid above its upper chamber. To supply and drain water, fittings are attached to it, which are located at different levels. Another option for increasing productivity is the necessary air convection, which is carried out using a fan located near the upper chamber. By taking warm air from the stove, it helps to cool it, which has a positive effect on the life of the device.

DIY options for increasing the efficiency of a mini-oven

Waste oil furnaces are often used to heat a garage or small workshop. It is not recommended to use such a device in a building where people are constantly present. This is due to the fact that the stove absorbs oxygen, which has a negative effect on the human respiratory organs. If the device is intended to heat a living space, it should be located in a separate room.

It is not recommended to use such a stove in a room where people are constantly present.

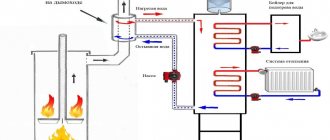

To improve the efficiency of the device, additional devices can be used. A waste oil furnace with a water circuit is organized by tying the coil body or installing a water jacket on the chimney. In the first case, the coil is made of copper pipe. It is built into the heating system of the house.

The water jacket is made of sheet metal in the form of a container, which is located in the upper part of the housing. It circulates a liquid coolant. For the stove to operate efficiently, the tank must contain up to 30 liters of water. Such a device will allow you to heat a large area.

An exhaust furnace with a water circuit must be equipped with an expansion tank with an emergency drain, necessary in case of boiling of the liquid. It is not recommended to install a membrane container here.

Another option for increasing the efficient operation of the furnace is to use an air heat exchanger, which is represented by a fan. No design changes are made to the device, and the heating of the room is improved. The fan is located near the upper chamber. When it cools, the heated air spreads across the area of the room. You can also pass air through a box located on top of the stove, or through a pipe that is installed in the afterburner chamber.

An exhaust furnace with a water circuit must be equipped with an expansion tank with an emergency drain.

No. 1. Water heating system

The water heating system is organized in the garage by analogy with residential premises. The coolant is heated in the boiler, and then it passes through pipes and radiators, uniformly heating the entire garage room. After the heat supply stops, the pipes remain heated for another couple of hours. This is the main advantage of this system.

The main disadvantage is the complexity of the organization. In addition, the water in the heating circuit may freeze, so if the system will not be used in the coming days, it is better to drain the water. On the other hand, frequent water changes lead to rapid corrosion of pipes and radiators. To avoid this problem, it is better to use metal-plastic equipment. It is better not to use ordinary water in the heating system - it is replaced with antifreeze, a non-freezing coolant.

The complexity of the arrangement results in another drawback - the high price. The most economical way to heat a garage is to connect its circuit to a home boiler. The cost of general heating will increase, but it will still be cheaper than organizing an independent heating system.

If it is not possible to connect to your home system, you will have to install a separate boiler. It can run on different fuels. The following types of boilers are used in the garage heating system:

- An electric boiler is the easiest to install, extremely safe, but expensive to operate. Even if you are not worried about electricity bills, you should not use such boilers in areas with frequent power outages, power surges, or in regions with severe windy winters, because the wires may break, which will ultimately lead to freezing of the water in the system. If you do not manage to drain the water in time, the pipes may burst;

- gas boilers are used extremely rarely in garages, since not everywhere there is access to a gas pipeline. If the gas pipeline runs nearby, then you are very lucky - gas heating is inexpensive, and such systems are quite simple in terms of operation. The main thing is to follow safety precautions;

- boilers for liquid and solid fuel. You can choose a stove that runs on wood, coal, diesel or waste oil - it all depends on which resource is more accessible in your case. Solid fuel boilers require constant monitoring and frequent loading of fuel. Pyrolysis and pellet units are more convenient in this regard, but they are not cheap; the most economical option is a potbelly stove, which can also be used in a water heating system.

For all boilers, except electric ones, you will have to organize a chimney. In addition to the boiler, radiators, heating pipes and chimney pipes, you will need a circulation pump and an expansion tank. All this costs money, so using a hydronic heating system only makes sense in large garages. Often such heating is done at service stations and commercial auto repair shops. If the garage is small, then there is no point in organizing such a complex water heating system - this is an option for more or less spacious rooms where constant heating is required.

The operating principle of a water heating system is quite simple. The coolant heats up, passes through the pipes, gives off heat and returns to the boiler. The system can be one- or two-pipe. A single-pipe system is much easier to organize and cheaper; it is best suited for a small private garage. In this case, the heated coolant sequentially enters the radiators, i.e. in the first radiator the temperature will be higher than in the last, where the antifreeze reaches it already cooled down. The two-pipe system allows for more uniform heating, but much more materials will be needed.

Even if the garage is not attached to the house, but is located nearby, you can try to connect it to the home heating system, but there are limitations. The distance from the garage to the house should not be more than 20 m, and the pipes must be properly insulated.

If antifreeze is used as a coolant (a liquid that does not freeze even at -45C), then you must work with it carefully, because it is a toxic substance that becomes even more dangerous when heated. Antifreeze is not recommended for use in two-pipe systems

The coolant is replaced every 5 years.

Popular options for pre-fabricated furnaces, their characteristics

The Teplamos NT-612 stove is often chosen as a device used for heating a garage. The power of such a drip fanless heater can vary between 5-15 kW. Fuel consumption is 0.5-1.5 l/hour.

This furnace for use in a garage is a closed type device. It is equipped with a chimney, an air supply pipe and a built-in tank designed for 8 liters of fuel. Fuel combustion occurs in the inner chamber. The operation of the device begins with electrical heating of the plasma bowl. When the required temperature is reached, fuel is supplied and air is forced into the combustion chamber. The average cost of the device is 30 thousand rubles.

Note! For normal operation of the stove, it must be preheated with a small amount of diesel fuel, which is poured into a special bowl.

Another popular model is the Zhar-25 (MS-25) stove. This device can operate not only on waste oil, but also on diesel fuel. The device operates from the electrical network, which powers the internal fan. The thermal power of the furnace varies from 25 to 50 kW. It is designed to heat a room up to 500 square meters. m. Maximum fuel consumption is 4.5 l/hour. The device has large dimensions. Its weight reaches 130 kg. This stove needs to be equipped with a good chimney. You can buy it for 45 thousand rubles.

The exhaust furnace is equipped with a chimney, an air supply pipe and a built-in tank.

How should the heating be in the garage?

For many motorists, the garage is almost a second home. Here they delve into their hobby, take a break from the hustle and bustle and take care of the car. Therefore, first of all, you should think about the comfort of the person who spends hours indoors.

Heating is also necessary for the car, because... low temperatures negatively affect its technical condition and significantly reduce its service life.

When it gets cold, the garage becomes too humid. Condensation forms on metal parts, which provokes corrosion processes. In a cold room, the car body quickly rusts and becomes unusable.

To keep the garage dry, you should take care of good waterproofing and ensure the normal operation of the ventilation system. However, moisture still gets into the room on the wheels of the car. It evaporates and drops of water settle on surfaces.

If there is no heating, moisture accumulates, causing fungus, mold, and rust to appear. To prevent this from happening, heating is necessary.

Low temperatures cause the oil to thicken and reduce battery capacity. This makes it difficult to start the engine and increases fuel consumption. Therefore, it makes sense to spend time and effort assembling a miracle stove

Features of garage operation determine the requirements for heating systems:

- Efficiency. The oven must heat the air quickly and maintain the desired temperature for several hours.

- Easy to use. When coming to the garage, its owner should spend a minimum of time and effort heating the room.

- Ease of maintenance. The stove must be inspected, cleaned, and repaired in a timely manner, so its design must be simple and understandable, and its parts must be easily replaceable.

- Availability of energy source. When choosing a heating system, fuel availability is of fundamental importance. A stove using diesel fuel, diesel fuel or waste oil is well suited for a garage.

- Safety. There is always some amount of flammable substances in the garage. Since these premises often serve as workshops and sheds, flammable materials will often be found here. Therefore, heating must comply with all fire safety standards.

- Cheapness. The costs of servicing a car and arranging a garage are already high, so saving on heating without compromising its quality is a pressing issue.

When choosing a suitable heating device, you should set priorities, because... the ideal is unattainable. The easiest to use are electric heaters. This energy source is available in almost any location.

However, the price of heating with electricity is too high, so it is worth considering other options.

There is a huge advantage in assembling a diesel stove with your own hands: you choose the design yourself and make a model that is ideal for specific operating conditions. You do not have to adapt the heating device or adapt to the peculiarities of its operation.

Do-it-yourself stove made of sheet metal and pipes

Depending on the type of device, the structure can be created from pipes of different diameters or from iron sheets. To work you will need the following tools:

- grinder with cutting and grinding wheel;

- sheet metal and pipes;

- welding machine and electrodes;

- metal corners;

- metal paint that can withstand high temperatures.

Before making a furnace for testing, a detailed drawing of the apparatus is made. You can create it yourself or use ready-made options that are easy to find on websites on the Internet.

The first step is to make the lower part of the chamber connecting to the fuel tank. It looks like a rounded or straight tank with a lid where two pipes are located. The first is used to supply oil, and the second is used to strengthen the pipe that goes into the middle part of the device. Elements for the tank are cut out with a grinder and connected according to the drawing.

Depending on the type of device, the structure can be created from pipes of different diameters or from iron sheets.

The bottom and metal corners are welded to the walls of the tank, which act as the legs of the structure. To create a lid, a sheet of metal is taken and holes are made in it. The first, with a diameter of 100 mm, is located in the center; the second, 60 mm in size, is located closer to the edge. The lid should be removable, which will make cleaning the stove easier.

A pipe about 37 cm long and 100 mm in diameter is used to supply oxygen. It has holes along the entire length of the element necessary for the supply of oxygen. The pipe is welded perpendicular to the cover at the bottom of the apparatus. An air damper is fixed on it, which will be secured with a rivet or bolts. The hole under the damper should be 6 cm in size. It is intended for supplying oil and igniting fuel.

The design of the upper tank is carried out by analogy with the design of the lower tank according to the drawing of a furnace using waste oil with your own hands. The walls of the product must have a thickness of at least 350 mm. A bottom with a diameter of 10 cm is cut out of the bottom of the tank, which should be placed closer to the edge. A small piece of pipe with a diameter of 11 cm is welded to the bottom of the hole. This is necessary to connect the element to the gas combustion tank.

Before making a furnace for testing, a detailed drawing of the apparatus is made.

Since the top cover of the supercharged exhaust furnace is exposed to high temperatures, a metal sheet with a thickness of at least 6 mm should be used for its manufacture. There is an opening in the lid for the chimney pipe, which should coincide with the opening at the bottom of the container. Between these elements, a partition made of dense metal sheet is mounted, located near the smoke hole. A pipe is attached to the top of the lid, connecting to the chimney part. The self-production process can be seen in detail in the video of the furnace being tested.

Note! To give the structure rigidity and stability, a metal spacer in the form of a piece of pipe with a diameter of 200-300 mm is welded between the chambers.

Making a drip heater

Most often, craftsmen use old oxygen and propane cylinders with a diameter of 220 and 300 mm, respectively, to assemble droppers. The former are preferable because of their powerful thick walls that can last a long time and not burn out. A pipe made of low-carbon steel (St 3-10) with a wall thickness of 5 mm or more is also suitable.

Advice. The ideal option for a durable housing is a pipe made of heat-resistant stainless steel alloyed with chromium, molybdenum or nickel (for example, 15X1MF or 12X18H12T) with a wall no more than 3 mm. Perhaps you or a neighbor has one in your garage. There is no need to buy it specially - it will be too expensive.

Select rolled metal for other parts according to the drawing of the furnace with top feed of waste into the combustion zone. The blower fan is a “snail” from a VAZ 2108 cabin heater or its Chinese equivalent, the fuel line is a stainless tube with a diameter of 8-10 mm.

The manufacturing technology is as follows:

- Make a fire bowl from a piece of pipe or take a ready-made steel container. It must be removed through the inspection hatch, so do not make the tray too large.

- Cut openings in the body for the chimney pipe and cleanout hatch. In the latter, make a frame and install the door (possibly bolted).

- Make an afterburner. Take your time to drill all the holes indicated on the drawing; do the bottom 2 rows first. You will complete the rest while setting up the oven.

- Weld a cover and an air duct with a flange for mounting the fan to the afterburner. Attach the fuel supply device as shown in the photo.

- Assemble the heating unit and connect it to the chimney.

Advice. For greater stability to the body, it would not hurt to weld a frame from a steel profile or angle according to the example shown in the photo.

The afterburner in the photo is a close-up - side and end views

. To regulate the heating power, you need to provide a fan speed control and a device for dosing the fuel supply (as a rule, an auto-drinker with a jet break is used). According to reviews from craftsmen on a popular forum where heat extraction issues are discussed, fuel consumption in the furnace can be monitored visually. The trend is this: if the oil flows in drops at the break in the stream, then less than 1 liter per hour burns, and when a thin stream flows, more than 1 liter per hour.

Recommendation. Control the fan performance using a cheap Chinese PWM controller (price is about 8 USD).

Different designs of drip bowls

After igniting and warming up the heater, it is necessary to set the optimal operating mode. The procedure is carried out according to the same scheme as with the miracle stove: you need to achieve the most transparent smoke from the chimney by drilling additional holes in the afterburner. The ideal flame color is blue, normal is yellow, and reddish is unsatisfactory. In the latter case, low heat transfer, high consumption and soot formation are observed. For details about the design and assembly of the furnace, see the video:

Step-by-step instructions for making a waste oil stove with your own hands from a cylinder

The device can be made from old items using the presented drawings of a waste oil furnace. For this process you will need a gas cylinder with a capacity of 50 liters. You should also prepare:

- pipe with a diameter of 80-100 mm and a length of 4 m;

- steel corner for making a stand and internal elements of the heat exchanger;

- sheet steel for making the bottom of the upper chamber and the plug;

For the manufacturing process of a waste oil furnace, you will need a gas cylinder with a capacity of 50 liters.

- brake disk;

- fuel supply hose;

- clamps;

- half-inch valve;

- loops;

- half-inch oil supply pipe.

An empty gas cylinder is used to make the body. You need to unscrew the valve on it, after which you should leave it outside overnight to ventilate the remaining gas. A hole is drilled in the bottom of the product. To prevent the formation of a spark, the drill must be moistened with oil. Through the hole, the cylinder is filled with water, which is then drained, washing away the remaining gas.

Two openings are cut in the cylinder. The top one will be used for the combustion chamber, where the heat exchanger will be installed. The lower one acts as a burner with a tray. The upper part of the chamber is specially made large. If necessary, it can be filled with other fuel options in the form of firewood or pressed briquettes.

A stove made from a gas cylinder will be more economical and efficient than one made from other materials.

Next, the bottom for the upper compartment of the device is made from sheet metal 4 mm thick. A burner is made from a piece of pipe 200 mm long, as shown in the drawing of a waste oil stove. There are many holes made around the circumference of the product, which are necessary for air to enter the fuel. Next, sand the inside of the burner. This will eliminate the possibility of soot accumulating on the ends and uneven surfaces.

Burner for testing: varieties, device, how to make it yourself (read more)

The furnace burner is exhausted from a gas cylinder and welded to the bottom of the upper chamber. If there are no mining reserves, wood can be laid on the formed shelf.

How to remake a brick device?

There are two ways to remake a brick oven :

- by making a burner that is similar in shape to a chopped log or thin log;

- make a door with a shield, which you then insert into the open door or mouth of the oven.

The first option is easier to manufacture, but much more difficult to operate, because lighting such a “log” is not easy. The second option is much more complicated , especially if you make a burner with variable flame power, but it is enough to insert it into the corresponding hole in the stove and seal it with an asbestos cord.

Therefore, we suggest using the second option, because it is not difficult to give the shield the desired shape, just cut the blank with a plasma cutter or any other suitable tool, and then trim it with a grinder.

To prevent the burner from falling out of the hole, you will have to weld the legs to it, which is also not difficult, because such a device cannot be made without welding.

The modification will be especially effective if you use a low-power burner with adjustable fuel supply; even in the most minimal mode, it ensures the correct proportions of fuel and air , due to which the formation of soot is minimal.

In addition, starting in low power mode gently heats the bricks, so the masonry does not collapse and the stove does not suffer damage.

Making a tray for working off and installing a chimney for an oil stove with your own hands

According to the drawing of the stove, a cast iron automobile brake disc, which has good heat-resistant characteristics, is used to make a waste oil pan. A steel circle is welded in its lower part, which forms the bottom. At the top there is a lid through which air enters the oven.

A cast iron automobile brake disc is used to make the pan.

On a note! It is better to make the opening wide. This will provide sufficient air draft so that the oil will flow into the pan.

The next stage in the manufacture of a stove using waste oil from a gas cylinder is to make a coupling from a 10 cm long pipe that connects the burner and the pan. Thanks to this element, servicing the stove will be much easier. You can remove the tray and clean the bottom of the burner. To ensure the supply of oil, a metal tube is inserted into the hole in the housing and secured by welding. An emergency valve is installed on the pipe.

The chimney structure is made of a pipe with a diameter of 100 mm. One end of it is welded to the hole in the central upper part of the body, and the other is brought out to the street.

On a note! The chimney pipe through the wall must pass through a special fireproof glass.

By watching the video “Furnace using a gas cylinder”, you can familiarize yourself with the sequence of actions in the manufacture of the device.

Types of homemade models

You can independently make from metal only different types of potbelly stoves, which differ in efficiency, but work on the same principle - while the fuel burns, the device releases thermal energy.

Therefore, the differences concern only:

- method of fuel combustion (burner);

- the material from which the heating device is made;

- a method of transferring heat from a flame to the air in a room.

The choice of burner is determined by the availability of materials and your skills, so evaporators are better suited for primitive potbelly stoves.

After all, their production does not require serious effort, but for air heaters, various nozzle options are better suited.

The heater is much more difficult to manufacture, but its efficiency is 1.5–2 times higher due to more intense air movement through special channels. Therefore, further we will talk about various options for manufacturing such furnaces using different types of burners and heat exchanger designs.

How to make a pyrolysis type stove

A potbelly stove during mining consists of three main elements:

- oil containers with lid and valve;

- closed combustion chamber;

- afterburning chambers.

The stove must have a chimney, the length of which is at least 4 m. The oil container, according to the do-it-yourself potbelly stove drawing, is made from a piece of pipe with a diameter of 345 mm and a length of 100 mm. A sheet metal cover is welded to its lower part. The removable top cover is made of a pipe with a diameter of 352 mm, to which sides with a height of 600 mm must be attached by welding. The lid has a central hole of 100 mm in size, intended for the combustion chamber, as well as a side hole (60 mm in diameter) for air injection, which is closed by a rotating lid.

Note! By adjusting the clearance of the blower, you select the combustion intensity of the stove, which affects the air temperature in the room.

According to the drawing of the stove during testing, a pipe with a diameter of 352 mm and a height of 100 mm is used to make the afterburner. Holes measuring 100 mm are made in its lower and upper parts. The first is for the combustion chamber pipe, and the second is for the chimney. Closer to the chimney opening, it is necessary to weld a partition 70 mm high and 330 mm wide.

Diagram of a pyrolysis-type furnace.

Using a drill, holes are made in the combustion chamber pipe along its entire height, leaving the lower zone 20 mm high and the upper zone (50 mm) unused. After completing all welding work, the tightness and reliability of the seams should be checked. Next, a furnace test is organized. The waste is poured into the oil container. Kerosene is added on top. Careful ignition is carried out with the ash pan open, with the help of which, after heating the oven, the heat intensity is adjusted.

Note! Testing the furnace during testing should be carried out outdoors, which will avoid a fire indoors or other accident.

To heat a garage, small workshop or living space, you can use a waste stove, which has a number of advantages. The device can be purchased ready-made or made independently using drawings from the Internet. Before making a stove, you should study the sequence of actions in order to subsequently obtain a practical and effective device.