A great variety of sealants for connecting pipes have appeared. Threads or joints are covered with whatever they can, and every master praises what he likes. We have collected for you the main types of sealants and invite you to figure out in which cases which sealant is best to use for sealing threaded connections.

Main types of pipe seals

From the entire arsenal, the following can be distinguished:

The question “which pipe sealant is better and which is worse?” - incorrect. In order to understand this question, it needs to be posed somewhat differently: “What type of sealing of threaded connections should be used in specific conditions?”

Let's start with what sealant should not be used for threaded connections:

- Silicone (good for flange connections);

- Ship's red lead;

- Whitewash, various types of paints.

So, there are 4 types of material left:

Reasons for the popularity of the Record rewind

Plumbing thread "Record" (50 m)

It is a polymer fiber impregnated with a hydrophobic composition. They are well suited for sealing a wide variety of joints and pipes. Record has a SEZ for use in drinking water systems. The winding material was previously used in the military aerospace and high-tech engineering industries and has only recently entered the wider market. Available in blisters, thread length - 50 meters.

Main technical characteristics:

- Polymerization lasts 20-30 minutes;

- Installation is possible at temperatures from +18 0C;

- Does not interfere with dismantling;

- Can be used in pipes with cold and hot water, natural and liquefied gas and compressed air;

- Retains its properties at temperatures from -60 to +150 0C.

Advantages of "Record":

- Instant sealing;

- Material: synthetic. This means that the thread is not hygroscopic and, unlike plant fibers, is not prone to absorbing water, does not swell and is suitable for thin-walled pipes;

- Convenient to use;

- Can be used on wet threads;

- Will not clog filters or narrow passages with its particles;

- Since the winding contains silicone, the connection will be protected from corrosion;

- Several times more affordable than similar imported products;

- Possibility of use in unforeseen situations: lack of time, lack of experience of the plumber or urgent need for repairs.

Absolutely anyone can use Record; no special plumbing knowledge or skills are required. The material will perform its functions even when installed in the cold and with wet threads.

This winder is immediately ready for use, and its packaging is equipped with a special knife for cutting. A few seconds are enough to seal, after which the solder is ready for use - the thread does not require time to seal.

Used on dirty and wet threads, fragile and thin-walled pipes. Even if the connected devices are far from aesthetically ideal, the place where they are connected always looks good. Nothing leaks or bulges, as when using linen winding. This thread is non-toxic and non-allergenic; it is completely safe for workers and consumers. Since it is produced in the Russian Federation, it has all the necessary certificates for use in water supply, heating systems, etc.

A polymer thread will be the best solution in case of a sudden emergency. It applies quickly, copes well with leaks, and lasts a long time. When sealed with this winding, the joint is also resistant to vibration and temperature loads. And its initial use for pipes will protect your home from sudden breakdowns of connections, which always lead to financial losses.

Consumption of "Record" winding when installing a steel pipeline:

| Pipe diameter | Coils | Cm |

| 15 | 5-8 | 35-55 |

| 20 | 7-10 | 60-85 |

| 25 | 8-12 | 80-125 |

| 30 | 9-15 | 120-200 |

Seal flax

Flax for winding threaded connections

You can use flax as a winding for pipes on all metal parts: brass, cast iron, steel. With limitations, flax can be used where metal threads are soldered into plastic threads. A bad option would be to use linen on completely plastic parts. When sealing threaded connections where the sealant is flax, a large tightening torque is required. This moment can sometimes exceed the capabilities of plastic parts, which is why it is possible to break the thread itself.

A little about gas riser connections

Most often, gas is transported using steel pipes. Gas plastic hoses are also used indoors. Almost always, a gas pipeline consists of several risers, which raises the problem of their connections.

Gas can leak out of fittings and threaded connections. Therefore, perfect sealing of gas pipe connections is the number one task when installing or repairing a gas pipeline.

For such work, special sealants, seals, etc. are used. Let us pay attention to the most popular of them, which have won the trust of citizens with their quality.

Plumbing thread

Sealing threads with plumbing thread

Plumbing thread is an excellent winding material for pipes with one drawback: its high price. It cannot be torn by hand and is suitable for sealing all threaded joints (even those that have a torn surface from a bad thread cutting tool). As for plastic parts, the tightening torque required when using threads is not the same as when using flax. Plumbing thread can be used for all parts.

Sealing paste

Paste is the easiest way to seal threads. A special hardening or non-hardening paste made from synthetic resins with oils and other fillers.

Application of sealing paste

The sealing paste is used for threaded connections of water and gas pipelines , for systems with a non-aggressive environment .

Characteristics of sealing paste

Divided into hardening and non-hardening paste.

Hardening paste

- Withstands temperatures up to 210°C without sanitary flax, and up to 140°C with the use of flax.

- Pressure for gaseous phases up to 20 atm and up to 100 atm for water . The listed characteristics begin to operate after complete hardening. The time for complete hardening ranges from several minutes to several hours, depending on the manufacturer and the ambient temperature.

- Maximum pipe diameter 3 inches.

Non-hardening paste

- Suitable for use in lines with low pressure of liquids and gases.

- Not used for systems with aggressive environments .

- Shows the greatest effectiveness in combination with tow .

- Withstands up to 135°C.

Advantages of sealing paste

For hardening paste:

- High-quality seals the connection.

- Easy to use.

- Can be used for high pressure systems .

For non-hardening paste:

- Easy to use.

- Protects the joint from corrosion

- Possibility to easily dismantle the connection.

- Immediately after installation it is ready for use.

Disadvantages of sealing paste

For hardening paste:

- shrinks after drying .

- Once cured there is no possibility of adjustment.

For non-hardening paste:

- Cannot be used in aggressive environments.

- Suitable for systems with low pressure or no pressure at all.

How to use sealing paste

Before using sealant, the threads should be degreased and dried . Apply the paste evenly to both parts of the connection and mount immediately (this is especially true for hardening paste). For non-hardening paste, it is possible to use tow.

Manufacturers of sealing paste

- Russia MasterProf . Russian manufacturer of seals.

- Europe Unipak. A very popular company producing various types of seals.

- China Viscotex . Chinese company producing sealing paste.

Anaerobic sealant

Anaerobic sealant is certainly suitable for sealing all plastic threaded connections, for brass, for cast iron, factory-made, but there is one peculiarity on steel parts.

When threads are made in a steel part, various types of lubricants are used that get onto the threads. When applying glue, once it hits a greasy area, it lingers there. This may not be noticed. Once the coupling begins to be turned, a channel may form through which the liquid will then flow out.

It is not always possible on site to remove grease from the surface of the thread. Therefore, it is not recommended to use glue-sealant as a sealant for steel threads and parts, since there is flax and thread.

When using sealant, pay attention to what kind of adhesive sealant you got. Some grades require heating when disassembling the joint. Imagine a metal connection with a metal coupling followed by a plastic pipe. To disassemble it, you must first heat it up (obviously more than 100 degrees). For the metal part this does not matter, but the plastic pipe may later be damaged. Therefore, look at what type of threaded connections you seal with sealant!

Sealing water pipes: methods, advantages, disadvantages and application features

The variety of products for sealing in the retail chain is so great that buyers sometimes cannot choose what is best to seal the threads on a water pipe during repairs. However, there is no universal seal; you need to understand which material will be more suitable in a particular situation.

Linen seal

Linen is the cheapest sealant, but it is difficult to work with

To process flax, they use sanitary paste, otherwise it will rot and crumble on the hot water supply (DHW) pipe, and it will rot on the cold water supply (CWS) pipe. A water supply threaded connection treated with paste can be adjusted (corrected by turning it backwards) at an angle of up to 45°, parts are easier to screw on, and the thread is protected from corrosion.

Advantages:

- the lowest price;

- flax seals threads of all sizes;

- The surface is suitable in any condition: dirty, wet, rusty, damaged.

Flaws:

- It is difficult and time-consuming to work with linen sealant;

- hands, pipes and instruments are always dirty from flax fibers and paste;

- when tightened and swells, it creates stress in the thread.

Flax is good for sealing connections between metal pipes and fittings, but thin-walled parts and small threads must be handled with care. Of the combined elements, it is better to take those whose plastic part is made of more elastic polypropylene.

It is impossible to seal joints of parts made entirely of plastic with flax - due to the high tightening torque, damage to the walls and thread breakage is possible.

Fum tape

Fum tape is suitable for small undamaged threads

Advantages of fluoroplastic sealing material:

- soft, parts are easy to screw in and unscrew, you don’t have to worry about breaking or cutting new threads with metal on plastic due to strong compaction;

- The cleanliness of the threaded surface does not matter;

- almost doesn't get dirty.

Flaws:

- even with a slight displacement of the connection, leakage is possible;

- If the thread is tightened incorrectly, it is impossible to align the thread by feeding it back; an attempt will lead to leakage; the connection can only be disassembled and reassembled by re-winding the tape.

For beginners, FUM tape for sealing water pipes creates the most problems. It is advisable to use it in temporary engineering systems or where a slight leakage is not critical, for example, in a country water supply system.

Parts made of any material with medium-sized threads in good condition are suitable for sealing. The material is safe when sealing thin-walled fittings. It is contraindicated to seal threads on a water pipe with tape in case of possible shifts, in the area of impact loads or vibration.

Silicone tape

Using silicone tape you can instantly eliminate a leak

Combines the advantages of these materials. It differs better from FUM tape in its resistance to vibrations and the ability to adjust at an angle of up to 180°.

Flaws:

- cannot be used on narrow and thin threads;

- costs much more than thread and FUM tape.

It is recommended to use silicone tape to seal water pipes and fittings made of metal and plastic with large threads.

Anaerobic adhesive sealant

The latest generation of sealant hardens only after twisting and hardens within 20 minutes.

The viscosity, hardening speed and fixation strength of the compositions vary. The thinner the glue, the smaller the thread it is designed for. The connection, mounted using a strong anaerobic sealant, can be disassembled only when heated.

Advantages:

- fastest installation;

- assembled without keys, with just one hand;

- fills the entire inter-threaded space;

- when tightening, no distortion occurs, the load on the thread is transferred evenly;

- before setting begins, adjustment to any angle is possible;

- the connection does not have to be tightened, as is the case with flax, ribbons or thread;

- there are no protruding parts of the seal;

- protects against corrosion;

- resistance to increased water pressure.

Flaws:

- the most expensive seal;

- the junction must be perfectly clean and grease-free;

- You can use the water supply only after the sealant has cured;

- difficult disassembly of the connection;

- after heating during dismantling, a leak may occur at the junction of dissimilar materials;

- Gets your hands dirty.

Used for assembling new threaded connections made without the use of lubricant. Anaerobic sealant for water supply pipes is convenient for installing connections in hard-to-reach places. Considering the complexity of disassembly, it is better to use for units that are not planned to be disassembled.

Cold welding

A plasticine-like two-component composition based on epoxy resin, when connecting both parts, turns into a strong glue.

Advantages:

- some types of cold welding can be applied to a wet surface and under water;

- the resulting mass can be given the desired shape and processed after hardening.

The disadvantage is the high price.

Cold welding is indispensable when it is necessary to eliminate a leak, but there is no time for disassembly or the possibility of shutting off the water supply. Usually this solution is temporary.

Cold welding can restore a thread or a broken part. It is enough to apply the mixture to the damaged area, screw it on, and then unscrew the joining element and wait for it to cure.

How to seal a joint with flax?

When sealing threaded connections, you need to be very careful. Accuracy is the key to ensuring that nothing leaks. When working, you will need a special paste, which you cannot do without. It can be applied to the thread immediately or to already wound flax.

Paste gets your hands dirty. It's not very pleasant to wipe them off. Therefore, there is a life hack - the installer first sits down, winds flax onto a threaded connection, checks the quality of the winding (everything should be smooth) and then uses the paste, making a dozen connections at once. The connection must be free of protruding hairs, the first two turns remain free so that you can safely screw the coupling onto the external thread. And towards the end of the thread a roller or thickening is formed.

All compaction occurs on the last two threads. They are not completely cut through, smaller than the other turns. They are sealed by gluing the sealing material between the two parts.

How hard to tighten

As far as I know, GOSTs do not specify the tightening torque of pipe threads in Nm. Therefore, here you can focus on the documentation of the manufacturer of plumbing parts. Here are the directions from one manufacturer of brass threaded fittings:

In our realities, we come across many low-quality parts that can crack even from minor stresses. Therefore, the best solution would be to use high-quality fittings.

However, it is not always possible to work with reliable parts, so it is better to tighten doubtful knots a little more tightly than with your bare hand. A well-assembled flax joint will hold pressure even when hand-tightened. The main problem here is to prevent the knot from unwinding in the future due to mechanical stress. Therefore, in those units where loosening is theoretically possible, locknuts should be used. The locknut can be used to tighten the assembly well without stress from the inside being applied to the internal threads of the part.

By eye, the optimal tightening can be considered a little tighter than if the parts were tightened with bare hands. In general, you need to learn to feel the material...

After twisting, the paste that has come out is removed with your finger. The result is a neat connection, without flax fibers sticking out in all directions. That's all science!

In conclusion, I would like to say: in fact, working with flax is quite simple, you just need a little practice and patience. Well, don’t be afraid of mistakes - who doesn’t make them?!

How to apply adhesive sealant?

It is impossible to apply sealant to many joints at once, as with flax. The glue is applied to the thread immediately before the “sausage” connection, which is then well spread over the entire thread. This is necessary to prevent empty spaces from appearing through which water can then seep through.

The threads should be checked after sealing the connection. Therefore, sealant is used quite rarely, in the most necessary cases. For example, when you need to connect a plastic part with a metal one, you can’t think of anything better than glue.

The manufacturer recommends applying sealant to only one part, but experience says otherwise. If you are sealing a threaded connection that will be difficult to get to, then apply the glue well with your finger to the coupling and threads so that there are no unpainted areas anywhere. It has a blue or red color, it is clearly visible. It is necessary that all the streams are filled and then the parts can be connected. For steel parts, it is better not to use glue as a sealant for pipes.

If you are a professional, then you must have 3 types of pipe seals in your suitcase:

If you are not a professional and want to do something for yourself, then you will have a choice between flax and thread. Most likely you won't need any glue at all. You can practice with flax or thread if you don't want to spend a lot of time and effort.

Cold welding

A plasticine-like two-component composition based on epoxy resin, when connecting both parts, turns into a strong glue.

Advantages:

- some types of cold welding can be applied to a wet surface and under water;

- the resulting mass can be given the desired shape and processed after hardening.

The disadvantage is the high price.

Cold welding is indispensable when it is necessary to eliminate a leak, but there is no time for disassembly or the possibility of shutting off the water supply. Usually this solution is temporary.

Cold welding can restore a thread or a broken part. It is enough to apply the mixture to the damaged area, screw it on, and then unscrew the joining element and wait for it to cure.

Rewinding threaded connections using flax

Today, the problem of winding threaded connections has become urgent. In our stores we see different materials and methods of winding. How to understand this and find your own way of affordable and reliable winding (sealing) of fittings? Let's talk about this.

On display the following are presented as winding materials: Lena Fum, special thread, sealants and more. But in our work, for 18 years now, we have been using regular good quality flax and special paste for flax to wind threaded connections. Linen is simple, reliable and inexpensive.

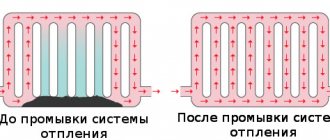

Now there is a fashionable trend to fill heating systems, for example, with a special coolant based on antifreeze. Therefore, if you do not use flax as a winding for threaded connections, then you may end up with additional work draining the system and repacking the fittings. As with all rules, working with flax has its own nuances and secrets.

How to seal threads on a water pipe?

Household plumbing consists of many detachable threaded connections that must be securely sealed. High-quality sealing is the protection of a house and apartment from floods, damaged furniture, and scandals with neighbors. Not only professionals and amateurs, but also plumbers with different approaches to this, in general, simple work, argue among themselves on the topic of how and how to seal threaded connections of water pipes.

Let's evaluate the pros and cons of popular water pipe sealants and try to find the best one.

Sealing of threaded connections

Sealing of threaded connections

Every person who independently replaces plumbing in an apartment or house sooner or later faces such an important point as the correct sealing of threaded connections. After all, even the eccentrics of the mixer, even those, need to be packed. In any average apartment, you can count at least 15 threaded connections that require sealing (often there are much more such connections). Therefore, we invite you to master such a necessary, and at the same time, simple skill as sealing (packing) threaded connections of pipes and fittings.

The first, quite reasonable question that a beginner asks is: “What should I pack?” After all, the modern market provides different materials and sealants, and it is not easy to decide and choose the one, the only, best material for sealing. Many experts are skeptical about tow (flax), which has been used for centuries to seal threaded pipe joints, giving preference to fum tape, which looks very neat and is, at first glance, easier to work with. And most people associate tow with a sloppily wrapped and painted connection “a la a housing office plumber.”

tap for radiator or heated towel rail

In fact, everything is not like that. Most experienced specialists pack with tow (linen), since such a connection is more reliable than sealing with fum tape. And if for threaded connections packed on linen it is possible to make adjustments with return (partial unwinding), then for pipes packed on fuma such a maneuver is practically impossible, since this will break the seal and you will have to repack the connection again. With a certain skill, a connection packed in tow can be made neat, so that even its individual turns will not come out, leaving the appearance of such threaded connections absolutely unchanged. As for paint, it has long been replaced by all kinds of sealants, the advantages of which are not only reliable sealing of threaded elements, but also facilitating sliding when assembling and disassembling threaded connections. Examples of such sealants are UNIPAK and GREENPASTA. Let's look at an example of how threaded connections on tow (linen) are sealed: Any threaded connection has an external thread and an internal one. A fitting with an external thread is lubricated with sealant, and a thin bundle of flax is carefully placed along the thread, in the direction of rotation, into the grooves of the thread. In order to ensure that when twisting the connection, the flax (tow) does not “slip” or slide off the thread, you must first make several diagonal turns in relation to the thread, and then, on top of them, carefully place the tow in the groove of the thread. An excess of tow is just as harmful as a lack of it, since the excess tow will be cut off when twisting the joining elements, and what is most offensive, will take with it most of the “useful” tow. Therefore, we strongly recommend: “Don’t overdo it!” In order for the connection to have a beautiful aesthetic appearance, wind the tow only on the thread. After winding the tow, lubricate it again with sealant, after which the connection can be twisted. Excess tow, which can get out of the joint, is carefully removed with a sharp knife. If you follow all the recommendations, the connection will be reliable and accurate. You check the connection at maximum system pressure, and if it doesn’t leak, then it definitely won’t leak. If it oozes very weakly, it is possible that it will linger later, because tow has such a wonderful property - to swell when wet. But it’s best to repack the dripping compound: You’ll sleep better and gain experience.

Sealing with other materials

In addition to the above-mentioned seals, the following are often used for sealing:

- epoxy resin. It is clear that the principle of its operation is the same as that of the glue of the same name produced on its basis. this substance is used to connect the risers of the sewer system;

- Portland cement. With its help, more than one sealing mixture is produced, which, in combination with asbestos rope, is used to caulk socket joints of pipes of a cast iron sewer system;

- petroleum bitumen or asphalt mastic. These substances are very effective in cases where it is necessary to seal ceramic or cast iron sockets;

- technical sulfur. When using this substance, sealing cast iron joints and similar sockets is almost ideal.

Important! Before use, sulfur must be broken into small pieces, heated to a liquid state and poured into the cracks. The uncured substance allows the connection to be adjusted.

Sealants have different purposes, depending on the material of manufacture. Before installing the seal, you need to remember that they come in trapezoidal, shaped (U-, H-, T-shaped) and other profiles.

They are mounted on pipelines, car windows, and house windows. Such products are excellent waterproofers and sealants. They can also be used in the form of shock-absorbing materials.

For their manufacture, special rubber is used, which is highly resistant to oils, gasoline, water, and high temperatures.

On those pipelines where oil and gasoline products are transported, you can often find the NT 42-75/7 seal, which is distinguished by its hardness, high heat resistance, and reliability.

What is the best way to wrap a threaded connection on a heating system? — Household Forum — Ulanovka.Ru

What is the best way to wrap a threaded connection on a heating system? — Household Forum — Ulanovka.Ru — The largest forum in Buryatia

On sale you can find many different materials that are designed to seal pipeline joints. The question arises: which material should be used in which cases? And also, how to properly use this or that seal?

It is often possible to use two or more thread sealants at once; then clarification is required as to which to prefer. The recommendations given should help to understand these issues and find a solution that will ensure sufficient reliability of the connection of pipes and threaded fittings for the entire period of operation.

Linen winding

Flax is a cheap material for threaded joints that creates a very high-quality seal. The only thing is that it cannot be used in all cases.

It is intended for connecting metal parts, as it creates significant density. It is very durable; the force applied by the keys to the two parts being connected is required to be significant.

Therefore, flax is not compacted:

- plastic parts - the tightening torque exceeds the strength of the material, the parts will be crushed and destroyed, at least the threads.

- parts in which a metal coupling with a thread is embedded in a plastic (polypropylene) shell, due to the danger of rotation (disconnection).

For all metal products, flax is the No. 1 material for winding threaded joints.

Next, let's look at how to apply it correctly. Flax cannot be used “dry”; it must be lubricated with a special plumbing paste. It is applied either directly to the thread or to wound flax.

People's experience also suggests that sunflower oil can be used instead of paste, but the quality of the joint does not decrease, at least there is no such information.

A strand is separated from the flax and wound along a thread along each stream. Winding is done tightly and neatly. There should be no protruding hairs. The first two turns are not filled, but a shoulder is made at the end of the thread.

Special plumbing thread

A special thread for seals, of high strength (cannot be torn by hand), wound on spools, is sold in stores. Its main drawback is its high price, but otherwise it has solid advantages.

- It can be used on any parts, the tightening torque is less compared to flax, so you can also wrap plastic.

- It seals very well and can be used even on torn threads.

If it were not for the cost of this material, then only such plumbing thread would be used for joints.

Winding is carried out in exactly the same way as with flax - the first two turns of the thread are left empty so that the parts can be joined, and then winding is carried out along each thread of the thread, at the end of the winding - a double layer, i.e. shoulder

Fum tape

Fum tape is not suitable for creating reliable connections on pipelines. The material is not very durable; there is no sufficient density in the threaded connections of metal products with it. But for plastic connections that will be dismantled, for example, a summer pipeline for irrigation, fum tape is the most suitable sealant.

With fum tape, the parts to be joined can be wrapped by hand. In this case, a small density of the joint along the thread occurs, so that leaks do not occur for some time. A slight tightening force does not provide sufficient tightness and does not guarantee that the joint will not leak. For fixed connections, especially if they will be inaccessible during operation, it is recommended to use other materials. Heating in the house can be done independently - the main installation issues

If the connection to the fum tape, which is already in operation, is turned, a leak will most likely occur. This is a serious drawback, considering that rotation does not require much effort.

At the household level, fum tape can be used (and is popular due to its low cost, ease of use, and low effort) for connections that are in plain sight - when connecting showers, taps, etc. Which heating scheme is best to use in a private house?

Plumbing adhesive sealant for threaded connections

The material is special, not exactly cheap, seals well, no cases of leakage have been recorded after its correct use. But only after the wrong... The obvious disadvantage of sealant adhesive is that the quality of the joint will depend on the “human factor” more than with windings. The fact is that glue does not work well on oily surfaces.

Where do greasy surfaces come from? It could simply be carelessness - they dropped oil on the thread or rubbed the part in oil with their hands. Parts can be stored in a lubricated state (primarily steel ones). But the main thing is that a lubricant is used when cutting threads. After such an operation on steel parts, glue and sealant are completely unsuitable.

Please note that there are glue samples with which undocking the pipes requires heating of more than 100 degrees. Such heating is often difficult, not safe, plastic can be damaged, etc. Therefore, the adhesive-sealant is still selected according to the circumstances.

The glue is easy to apply. It is applied only immediately before joining, squeezed out of the tube onto the thread and smeared with your finger over the entire thread without skipping.

In what cases should you choose glue?

- When connecting plastic parts to metal ones, glue will be preferable. But such a connection does not occur often.

- The second case is when access to the docking site will be difficult. It is better to place such a connection with glue, and lubrication is carried out generously, without saving, on both parts being joined.

Winding Features

Winding on threads requires great care. The thread must be filled in an even layer without gaps, and there must be sealing material in each groove. It is laid to the end of the thread, where a shoulder is formed from it. The main tightening of threaded connections occurs on the last two threads. On parts, more often than not, the last two turns of the thread are not cut to the full depth. Therefore, in this place the material is wedged between the two parts very tightly.

It would be nice if, when carrying out work, you organize additional (cross-cut) quality control of the flax winding. This is especially true when several dozen similar connections are performed at once.

conclusions

- For those who are constantly engaged in installation, it is recommended to always have flax, plumbing thread and adhesive sealant with you in order to quickly and efficiently complete any connection. It is recommended to apply all this in accordance with the tips given above.

- When doing work at home with your own hands, when doing something simple and in plain sight, you can use cheap fum tape, but you need to wrap more. When installing entire systems with your own hands, it is better to use flax (with vegetable oil) on metal, and for small volumes of work it is even better to use thread. Maximum attention should be paid to the quality of winding on the thread.

What should never be used to seal threaded connections:

- There is no need to use simple silicone; it is designed for flange connections.

- There is no need to use paints, whitewash, or red lead, which are of little use, but make the connections semi-dismountable - this is long outdated.

FUM tape

FUM tape is a sealant made of fluoroplastic. The full name is fluoroplastic sealing material. Used to seal threads of predominantly small diameters , up to 1 inch.

Application of FUM tape

The main purpose of FUM tape is to seal the threads of the water main. Depending on the brand of the paddle, it is used in many other areas of industry. Such as the food industry, pharmaceutical industry.

FUM tape brands

- Brand 1 . The most popular tape among those presented. Used in fixed threaded connections. Suitable for use in aggressive environments with acids and alkalis. Contains up to 20% lubricant .

- Mark 2 . Mainly used for oxygen lines. There is no lubricant , as it can cause a fire if it comes into contact with oxygen.

- Mark 3 . The rarest brand of fumka of all. It is used for industrial pipelines in gas and water supply. Contains no or very small amounts of lubricant.

Yellow FUM tape is used to seal gas pipelines . But despite its main purpose, it is successfully used for sealing water mains, due to its higher density than grade 1.

Characteristics of FUM tape

- Temperature limit from − 60°С to + 300°С.

- Very tear resistant . High-quality tape, depending on the brand and manufacturer, can stretch by 200% .

- Increased elasticity . Allows for tight filling of threads.

- Service life 10 years or more.

- Insoluble in alkalis and solvents.

- Withstands pressure up to 100 atm.

- It has a high slip coefficient , which allows the thread to be tightened more tightly.

Advantages of FUM tape

- Well suited for small diameters .

- Does not decompose when exposed to moisture.

- During operation, keep your hands clean.

- Low cost of the product.

- Easy to install.

- The presence of lubricant provides anti-corrosion protection to the metal.

Disadvantages of FUM tape

- Not suitable for use with large diameters.

- Not suitable for heating systems .

- Does not withstand temperature changes and vibration.

- After installation cannot be loosened without disturbing the tightness of the connection.

- There is no expansion effect.

How to wind FUM tape onto a thread

This is what a thread looks like with a wound FUM tape.

Despite the apparent simplicity of FUM tape, to work with it, still knowledge .

- The thread should be wound along the entire length of the working surface of the thread , from one edge of the thread to the other.

- The direction of the thread must be . For right-hand threads (right-hand threads are twisted clockwise), the nozzle should be wound clockwise.

- Use only a single piece of foam.

- The thread must be free of rust and not damaged.

How much to reel FUM tapes

There is no such thing as an “exact number of turns”. The threads have different diameters and depths, the thread differs in width and thickness, all these parameters directly affect the number of turns.

The tape must cover at least half the depth of the thread. As a rule, this is at least 5-6 turns.

Manufacturers of FUM tape

- Russia . Moment . One of the best Russian manufacturers.

- Europe. VALTEC. Italian fumka, very popular in Russia.

- China. Intertool . Good quality at a good price.

Characteristic properties

All sealants have a special set of qualities that you need to know and be able to evaluate:

Fluidity. This refers to the viscosity of the sealant. So, if you need to close a small gap, it is better to choose a gel or paste. Their texture is perfect for this. If we are talking about sealing a large gap, then it is necessary to purchase the most liquid composition. Remember that the larger the gap, the thinner the sealant should be. This way he can fill all the cracks, tightly fastening the pipe connection.

Temperature. The operating temperature range of sealants is not infinite. At a certain temperature, they will no longer firmly fix the pipe, which can lead to leakage. For most samples on the market, the temperature range is 200 degrees - from -50 to +150. Usually this is more than enough

If it is necessary to seal pipes through which a colder substance flows (for example, pipes for liquefied gas), then you need to pay attention to specialized samples.

Strength. Strength refers to how much force must be applied to separate a joint. If a sealant of low strength was used, then it will be enough to apply strong force with your hands. The fitting, sealed with medium strength sealant, can only be unscrewed when using additional equipment. It is impossible to dismantle the strong fixation sealant: the joint will have to be broken.

Polymerization rate. The packages indicate how long it takes for the sealant to completely cure. You can start using the pipes only after this time has expired.

The maximum thread diameter that can be fixed. It just so happens that not all sealants work on all pipes. If the composition is incorrectly selected, the beneficial effect of its use is reduced to zero.

Possibility of use. Some sealants are not suitable for fixing pipes carrying drinking water because they release toxic compounds into the water

You need to pay close attention to this factor.

Solvent-based sealants

Such products undergo polymerization and completely harden some time after application. Curing occurs after the evaporation of the solvent present in the composition.

You can use sealants together with linen tape or on their own. Their advantages:

- serious level of fixation;

- strength and wear resistance of the seam;

- ease of installation of threaded connections;

- quick drying;

- low price.

Low quality materials may last slightly less, which is why the threads will have to be tightened periodically. If a thread gap that is too large is sealed with such a sealant, the seam will shrink over time.

Sealing of household air ducts

Ventilation in apartments and country houses is carried out using thin-walled elements. Often, air ducts are made of rectangular cross-section or from corrugated pipe. Threading on such connections is not possible. Therefore, sealing ventilation joints is carried out in other ways:

- through flanges,

- applying a bandage,

- using the socket method by inserting one air duct into another.

A flange connection is most often used for non-circular ducts. Sealing is carried out using gaskets made of soft material, for example, porous rubber. The shape of the gasket must match the cross-section of the air duct.

With other methods, the voids formed after joining the air ducts are filled with mastics whose temperature characteristics correspond to the operating conditions of the air line. Sometimes the joint of the air ducts is wrapped with self-adhesive tape.

Bandage clamps used for joining round air ducts

*

Using the Record winder: step-by-step instructions

1.

Attach the first turn to the edge of the fitting in the thread groove.

2.

Make a cross-shaped winding as you cut. It is advisable to do this in such a way that the winding is thicker in the middle and thinner at the edges.

3.

Do the installation. If the winding has been completely squeezed out, disassemble and rewind.

4.

If the connection requires positioning or adjustment, the seal will remain tight until it is rotated 180 degrees.

Read material on the topic: “American” in plumbing: advantages and applications