Home » Equipment » Warm floor

Warm floors are necessary to maintain comfortable conditions in the house. However, not everyone can create such conditions, especially if it is necessary to lay warm floors under PVC, linoleum and other floor coverings.

Today we will find out what types of heated floors can be combined with such flooring as PVC tiles.

Advantages and disadvantages of PVC tiles

Pros of using tiles:

- the product retains the heat accumulated by underfloor heating well;

- The elements included in the coating are completely environmentally friendly. The possibility of releasing caustic vapors when the structure is heated is also excluded;

- the material is antistatic, that is, it does not conduct electric current and is compatible with electric heating systems;

- the structure quickly warms up due to its small thickness (up to 5-7 mm);

- the coating is endowed with heat resistance and can withstand sudden changes in temperature;

- high-quality sound insulation;

- affordable price;

- pleasant outer layer of coating;

Minuses:

- despite the fact that the tiles are made from high-quality environmentally friendly materials, they are not hypoallergenic;

- the coating tolerates temperature changes in the environment, but not direct exposure to high temperatures when heated. Be careful;

- the material is not resistant to acetone and similar liquids;

- to install the material you need a perfectly leveled base;

An operational life of around 10 years cannot be accurately attributed to a positive or negative quality, since each person evaluates this period in his own way. Someone may not change the flooring at all throughout their life, while others change the design of the room every couple of years, this is purely personal.

One thing is for sure: PVC tiles are an excellent option that is used everywhere. It can be laid either manually or using services. Fortunately, there are plenty of them in Moscow.

We recommend: How to check underfloor heating?

The craftsmen will carry out repair work in such a way that even the disadvantages will become advantages. Do not neglect their help, otherwise you risk constantly overpaying for repairs of both the floor covering and the entire heated floor structure.

Materials Not Recommended

When looking for a solution to the question of which floor covering is best to choose for a warm water floor, you should understand that not all materials offered on the modern market are suitable in terms of characteristics for specific operating conditions. Therefore, it is not recommended to use the following varieties:

- Parquet. Wood does not tolerate temperature changes well. So, when heated to about 28-30°C, it begins to dry out, crack and deform.

- Carpet. Due to the thickened dense structure, the material conducts heat poorly. Therefore, laying it on top of heating elements will make heating ineffective.

What is the best heated floor to lay under PVC?

Installation of heated floors is carried out both independently and with the participation of professionals. However, for both, it is necessary to know what types of heated floors are allowed to be laid under this covering.

Also keep in mind that polyvinyl chloride coating is considered one of the “coldest”; you need to choose high-quality materials for the selected type of heated floor. Keep this in mind when choosing building materials.

PVC flooring is compatible with:

- water heating systems;

- infrared film systems;

- with cable (single- and two-core, as well as self-regulating) systems.

The choice of floor type also depends on whether it is a private house or a multi-storey one, on the skills, desires of the owner and his financial component.

Briefly about the main thing

Warm floors are usually equipped with a water circuit connected to a boiler, boiler or heat accumulator. At the same time, the system itself should not heat up above 50°C, and the finishing coating on top of it should not heat up above 28-30°C. The material must transfer heat well into the room and have sufficient resistance to thermal changes and humidity, and strength to stress.

In this case, it is best to place the following types of materials on the heated floor:

- Ceramic tile.

- Linoleum.

- PVC tiles.

- Laminate.

It is not recommended to use carpet, parquet and foamed linoleum. When choosing a coating, you must follow professional advice on its optimal compatibility with specific operating conditions in a particular type of room.

Laying schemes for PVC flooring

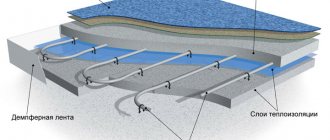

The first version of the scheme may include:

- wooden base;

- a pipe circuit laid between wooden joists;

- layer of plywood/chipboard;

- polyvinyl chloride tiles.

Second option:

- cement-sand base;

- waterproofing layer;

- water floor contour;

- additional screed layer;

- self-leveling mixture to correct differences;

- finishing coating.

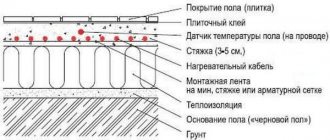

Third option:

- concrete base;

- heat/moisture insulating layers;

- electric heating cable (single-core/two-core/self-regulating);

- cement-based screed to level the surface;

- polyvinyl chloride tiles.

Fourth option:

- cement based screed;

- plywood sheets;

- moisture/heat insulating layers;

- film infrared floor;

- finishing coating (in this case tile);

Each option is unique in its own way, as it is installed based on personal preferences and skills, and is also installed in different types of houses.

Types of vinyl laminate

Despite the general presence of polyvinyl chloride, at least three types of flooring are distinguished:

- PVC tiles;

- quartz-vinyl laminate flooring with heated or LVT (Luxure Vynil Tile);

- stone-polymer element coating SPC (Stone Plastic Composite).

In the family of conventional vinyl tiles, the base is a layer of polyvinyl chloride. Quartz flooring material includes a composite consisting of PVC and quartz sand.

Stone-polymer ones have the same composite, only calcium carbonate (limestone) is used instead of quartz sand. Therefore, it would be more correct to call SPC tiles LPS tiles (from “Limestone” - limestone).

These are the three main types of vinyl materials for heated floors, although each manufacturer, promoting its brand, adds some differences, for example, crushed rock instead of quartz sand.

Installation of the most suitable heated floors under PVC tiles

Laying water heated floors. Water heated floors are much more difficult to install than their electric counterparts. But no other type is better suited for installation in private homes, since its installation in apartments is very difficult and requires special permits.

We recommend: How to choose a wire for a heated floor?

Most often it is laid according to 3 schemes, which are given above:

- first of all, a manifold cabinet with all its components (circulation pump, valves, etc.) is installed;

- First you need to completely clean the base of debris, unevenness and differences. Then the coating is vacuumed, washed with water and completely dried for 1-2 days;

- lay a thermal insulation layer;

- Now damper adhesive tape is glued around the perimeter of all walls. It is necessary in order to restrain the screed, preventing it from damaging the walls and “blurring” when it expands to the sides;

- A reinforced mesh is laid on the thermal insulation layer in order to attach the future pipe circuit to it with special clamps/fasteners. Do not fasten the pipe too tightly or too loosely to the mesh. In the first case, the pipes will deteriorate prematurely due to overtightening, and in the second, they may move after pouring the screed mortar;

- we retreat 5-7 cm from the walls and begin to lay the pipe contour according to a pre-selected pattern (snake/snail/combined);

- after installation is completed, the pipes are connected to the collector, and the system is checked for functionality;

- upon successful start-up, the pipe circuit is filled with solution and left until completely dry;

- if necessary, the floor is additionally leveled so that there are no differences on it;

- laying the finishing coating - PVC tiles;

Laying infrared film under PVC The floor is laid according to 4 options:

- level the base, remove construction debris;

- level with a screed layer;

- we place sheets of plywood at intervals of 1-2 mm to hide the cable in the spaces between the plywood;

- we lay moisture and heat insulation layers;

- choose a place for the thermostat in the wall and make a vertical groove down;

- a small recess is cut in the thermal insulation for a temperature sensor;

- we install a film heating system;

- we connect all the wires of the sheets to create a single system. The wires are connected to the sheets by soldering, as this method is the most reliable. If you do not know how to do this, seek the help of a specialist;

- Additionally, we glue the heating sheets of the system with glue to avoid shifts during installation of the finishing coating. Glue is applied at the boundaries of the connection of the canvases with each other. For convenience, the boundaries are marked with a pencil;

- connect the temperature controller, sensor and film;

- We start up the system and lay PVC tiles.

We recommend: Features of the “combined heating: warm floor and radiators” system

Laying cable floors. We install according to 3 schemes:

- Moisture- and heat-insulating layers are laid on the prepared base. The cable should not be laid on thermal insulation, as overheating may occur. Floor kits include detailed instructions that describe the details of laying the cable on the thermal insulation, this is individual for each type of cable;

- lay the cable in accordance with the manufacturer's instructions;

- install a thermostat on the wall and a temperature sensor between the cables;

- we connect the elements of the system;

- Apply tile adhesive to the structure and install the tiles.

How to avoid mistakes?

In order to avoid unnecessary problems when laying quartz vinyl tiles, it is necessary to lay them tightly, without gaps, without leaving gaps near the walls. When placing the tile on the glue, it must be pressed firmly. In this case, rolling with a roller is also necessary, going from the center of the surface to its edge. Rolling is performed to squeeze out remaining air from under the coating and remove excess adhesive. This action also improves the adhesion between the tiles and the floor.

To trim fragments, markings should be applied to their front side. Only after this is sawing done to half their thickness. Then you need to bend the tile element along this marking and cut it to the end.

Excess adhesive should be removed with a rag soaked in alcohol. You should not purchase an adhesive that leaves streaks on the surface of the tile; you also need to remove glue stains immediately, otherwise it will set and it will be almost impossible to remove it.

After finishing work on laying quartz vinyl tiles, the floor surface dries quite quickly. You can walk on it almost immediately, but installing heavy furniture and other furnishings is best after about a day.

The first wet cleaning can be done no earlier than 5 days after the coating is renewed.

Before starting installation work, the material should be allowed to rest for at least a day. In this case, the tile should be positioned horizontally, it is necessary to maintain a warm temperature regime and not to place any serious loads on the surface of the material.

In general, quartz vinyl tile flooring is an elastic, easy-to-cut and easy-to-install material.

To learn how to lay quartz vinyl tiles, see the following video.

Features of laying tiles

When the material is purchased, it is laid in the room where the installation will be carried out so that the tiles “soften”.

The tiles are:

- with glue included;

- self-adhesive;

- with locking fastenings.

Tiles are laid along a long wall. Also keep in mind that solid elements are glued first, after which the cut ones are added.

Types and types of fastening of quartz vinyl panels

There are several ways to connect tiles:

- Using adhesive locks. Each tile has 4 adhesive strips: 2 external and 2 internal. Thanks to them, the panels are connected to each other. The gap between them is invisible, even by touch it is very difficult to determine. This type of panel must be laid on a flat surface. In the reviews, many write that it is not necessary to remove the old coating, the main thing is that the base is level.

- Glue installation. In this case, the quartz vinyl tiles do not have any locks and are attached to the base of the floor using special glue. This material is attached only to a perfectly leveled surface, preferably on a cement screed treated with a primer solution.

- Glue method. The entire back side of the quartz vinyl panel is coated with a compound that provides adhesion to any type of surface. According to reviews, most people use this method of attaching tile material.

- Groove method. It is similar to the connection of tiles, where there is a tenon on one side and a groove on the other. To install this coating, you also need a flat subfloor surface.

- Connection with a lock. The basis for it is plastic, with spikes located along the edge in such a way as to be fixed in special locks that are located on the adjacent panel. To install tiles with a locking joint, a flat surface is required, since this material is not flexible and ductile enough.