Introduction

Before starting work, carefully read the instructions for assembling the fireplace insert. The stove manufacturer does not accept any responsibility for any damage that may occur as a result of failure to follow the instructions in their manual, which will void the warranty. Damage to components may occur if assembly procedures are not followed. The manual for professional installation and assembly of the firebox must contain all local rules and regulations regarding national and European standards. Keep this manual in a safe place.

Functional purpose of individual parts

Fuel is loaded into the firebox and ignited. The combustion activity and intensity of heat release are directly related to the damper - with a larger opening, maximum air enters the firebox and the wood burns better. If the design involves an open firebox, the intensity of the fire does not need to be adjusted.

To regulate the air supply you need a grate. An important point is the timely removal of ash, which collects through the grate into the ash pan. Usually it is raked out or shaken out, depending on the presence of a built-in or retractable system.

The fireplace chimney removes the accumulated combustion products to the street. To prevent gases from spreading inside the house, the chimney is often equipped with forced draft force. It is a fan. For the construction of a chimney, it is allowed to use only heat-resistant bases: brick, ceramics, heat-resistant steel.

Cladding the fireplace allows you to fit the product into the desired interior style. The portal can be stone, brick, marble. A special box is often built over a part of the pipe located within the room, which serves as an interior decoration.

There are many designs and varieties of fireplaces, but different systems differ only in details and proportions. The most famous varieties are French, German and English fireplaces.

French fireplaces are distinguished by their exquisite shapes, elegance and charm. Such a fireplace not only emphasized wealth and luxury, but was also an individual means of heating. French classic fireplaces are ideal for homes with high ceilings. Usually the design is equipped with a high and deep wall shelf. It is specially moved forward to emphasize the massiveness of the structure.

German versions are distinguished by the absence of a thermal dome. Typically, the system involves leading the pipe into the wall, and then into the chimney. A characteristic feature of modern German fireplaces is that they are equipped with a remote control. Fireplaces can be equipped with a cassette-type gas system, but there is also an electric firebox.

A classic English fireplace is usually equipped with a sloping back wall; this is necessary to reflect heat in front of the portal. In the firebox, the side mirrors serve as reflectors. It is believed that the trapezoidal shape of the structure allows heat rays to be more fully reflected into the room.

The Flemish fireplace is less common. It is an open area where fuel is ignited. The smoke from combustion is collected in a special smoke collector, with a cap hanging above the device.

Rules for installing a fireplace

When choosing the correct position for the fireplace insert, the following requirements must be taken into account: 1. The installation of the fireplace insert must be approved by the fire service (EMERCOM). 2. There must be a sufficient supply of air in the room. To burn 1 kg of wood, approximately 12 m3 of air is required. 3. There should not be any electrical cables passing through the wall or ceiling at the installation location. 4. Distances from wooden walls and floors, as well as distances from electrical cables and flammable materials on walls and ceilings, such as wooden beams, must also be taken into account. 5. The fireplace must be installed with appropriate floor loads.

The firebox should not be located in the following rooms: 1. Where there is no combustion air supply. 2. Where flammable and explosive substances and mixtures are processed, stored or produced. 3. Rooms where air is sucked out (fume hoods, ventilation and heating equipment, dehumidifiers, etc.). The fireplace insert must be installed on a base with adequate load-bearing capacity. The cassette must be located on a foundation slab and not on an unstable or moving surface. The distance from the fireplace insert to the floor can be adjusted by turning the adjustable legs. Use adjustable legs to balance the height up to 10 cm. The firebox must be horizontally balanced.

Hull masonry technology

It is not difficult to guess that each master begins work according to his own personal scheme, which provides step-by-step instructions. We will describe the most popular of them.

- The pedestal is laid out in several layers of bricks with regular shapes. It has a cavity that will serve as an ash pan, but the main portion of air enters through the gap between the walls of the fireplace and the combustion chamber.

- Do not rush into work, as a special degree of accuracy is required at this stage. After installing the next row, you should check the horizon. You can turn the bricks with a mallet. Excess fragments of the solution are immediately removed.

- The ash pit is completely covered by the fourth row, but how to provide support for the bricks above the void? The answer is to use corners that are laid parallel, these corners will support the masonry. Having filed each brick with a grinder, we build a base on which we will install the product. Don't forget about the level, check it.

- Before installing the fireplace insert with your own hands, let the masonry dry a little; you may have to make some changes. Any cast iron fireplace should have a mantel; this is a horizontal surface that is decorative. The shelf can be cut out of a piece of porcelain stoneware. The edges of its contact with the wall are deepened, providing additional support. Now everything is ready to continue working.

- The installation of a cast iron firebox itself is not difficult. The contact area between the firebox body and the stove is treated with heat-resistant sealant or glue. The firebox must not be moved close to the wall. Measure the distance from the back wall of the chamber to the wall of the house on one side and the other several times. Equality of indicators indicates that the design is straight and symmetrical.

- All joints formed by the installed firebox and mantelpiece are sealed with gypsum mortar. The cladding of a cast iron firebox consists of laying a brick frame around it. As before, it is necessary to observe the level when laying. Another similar slab is attached on top of the masonry. It is recommended to apply more glue under it, since with its help you may have to adjust the desired level. Remaining glue is immediately removed.

- When laying out the cladding, you can use creativity. If the outer bricks are pushed forward more with each row, you will get a cornice along the perimeter of the portal, and some facing bricks are already specially prepared for this; they just need to be laid in the last row.

Gas outlet options

Smoke removal depends on the fireplace insert in combination with the flue storage system. The following versions exist: Fireplace insert with cast dome. Recommended for connection to an air storage system with an internal diameter of 180 mm. Fireplace inserts with heat exchanger. Recommended for direct connection to pipes with an internal diameter of 200 mm. Fireplace insert with 45° heat exchanger. Recommended for direct connection to pipes with an internal diameter of 200 mm. Fireplace insert with a heat exchanger with a vertical outlet. Recommended for connection to a storage air duct system or for direct connection to a chimney. Fireplace insert for connecting accumulative rings. Recommended for connection to storage rings with an outer diameter of 440 mm. Fireplace insert with cast iron smoke collector. Recommended for direct connection to pipes with an internal diameter of 200 mm. The fireplace insert is right-handed. Recommended for lateral connections with pipes with an internal diameter of 200 mm. The fireplace insert is left-handed. Recommended for lateral connections with pipes with an internal diameter of 200 mm.

In what cases is a foundation required for a metal furnace?

Metal stoves are very common in country wooden and frame-panel houses due to their high heat transfer, efficiency, safety and ease of operation. However, these characteristics directly depend on compliance with all technological requirements during the design and installation of the heating system.

There is a certain number of rules that provide for the arrangement of a foundation for a metal furnace. Let's consider in what cases it is necessary to fill the foundation:

If the weight of the stove is small (up to 100 kg), you can do without arranging a foundation, but the product should be installed on a strong, non-combustible base, for example, on a sheet of iron.

Metal heating systems whose weight does not exceed 750 kg are recommended to be mounted on a concrete base. Depending on the design features, a foundation may be required. All this must be written down in the product’s operating book.

It is more advisable to line heavy cast iron stoves, weighing more than 700 kg, with heat-resistant bricks

In this case, when deciding on the type of foundation, it is necessary to take into account that the mass of 1 m2 of brickwork is approximately 1.5 tons.

Any stove requires a reliable foundation Source decorexpro.com Regardless of the weight and design of a metal stove, before installing it yourself, you must consult with a qualified specialist who will suggest the best option for installing it.

Chimney connection

Before connecting the firebox to the chimney, check the size and condition of the chimney (according to directives and standards). The correct operation of the chimney must be checked by a certified technician. When calculating the chimney, it is necessary to include the parameters of the fireplace insert. It is necessary to make sure that when adding firewood (the firebox is open), the firebox consumes a safe amount of air, as during normal operation (the firebox is closed). The chimney duct should not be smaller in diameter than specified by the manufacturer. More than one heat source cannot be connected to one pipe. Therefore, the calculation must be made according to the instructions for the firebox. The parts used for connection must be purchased together with the manufacturer's kit. The steel pipe (chimney) intended to connect the fireplace insert to the chimney must contain the CE mark (Minimum thickness of the casing walls 2 mm, for stainless steel 1 mm). If the chimney draft is too high during operation of the fireplace insert, it is recommended to install a damper. In this case, make sure: that the valve does not close automatically, the valve has simple and clear controls in the closed and open positions, the valve has holes in the clear section of at least 3% of the total cross-sectional size.

Material

In fact, it doesn’t matter at all what material you choose for cladding.

This can be either ordinary brick, plasterboard, or even installation with aerated concrete blocks or porcelain tiles. By the way, cladding is necessary not only to create a beautiful appearance, but also to ensure that the processes in the furnace are more efficient. The fact is that in the presence of the same drywall, much less heat will be uselessly dissipated in space. At the same time, its cost is quite low.

Almost everyone can also afford to buy bricks. Those people who have private plots often keep them after construction.

Combustion air supply

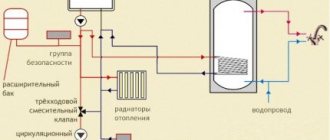

Fireplace inserts should only be used in rooms with a sufficient supply of combustion air. Air exhaust equipment (such as vents, steam, etc.) that operates the fireplace insert in the same room can affect the air flow to the fireplace. Make sure that the room has the specified pressure difference in the room (should not be less than 20 Pa). For smooth operation, the air supply must flow to the bottom of the firebox. It is recommended to use the shortest route for air supply and deviate from the direction only if absolutely necessary. Use diagrams (see professional rules for specialists - TROL) and determine the cross-section of air supply lines

Peculiarities

A metal fireplace is an excellent device that can heat a room and relieve you of the cold. The heat output of such a stove depends on the level of preheating and the amount of firewood inside. A metal fireplace, thanks to its special qualities, will not let you freeze even in the winter cold. Another advantage of this stove is the ability to make it an elegant addition to your interior. Thanks to its varied design, it will fit into any room of any stylistic direction.

A metal fireplace is considered an invention of the Land of the Rising Sun. The Japanese have always been considered very practical, wise people with a high sense of style and the ability to competently decorate their homes.

This heating product is the full embodiment of all the qualities of its authors; it is light in weight, especially in comparison with its stone counterpart, and is easy to carry from room to room, as well as dismantled. Due to its lightweight design, a metal fireplace does not require an additional foundation, which will allow you to save a considerable amount.

A huge advantage of a metal fireplace, which will delight housewives, is its ease of maintenance. They are easy to clean, and with regular care they will not lose their original appearance. During cleaning, it will be enough to clean off all the soot from the inside and outside, wipe with a damp cloth and lightly polish to give additional shine. As a rule, the above actions do not require any special means; you can clean everything with improvised means that are found in every home: soda, vinegar or citric acid. If desired, purchase special household chemicals for cleaning fireplaces, which are presented in household stores.

However, in addition to a large number of advantages, metal stoves for the home also have a number of features that should be taken into account before purchasing. Perhaps the most important disadvantage of such a fireplace is the increased fire hazard - if used improperly, the fire can spread to other objects.

Another disadvantage is the very rapid cooling of the unit after all the wood has burned out, unlike a fireplace stove, which continues to produce heat even after the fuel has burned out.

The fireplace body gets very hot and can cause severe burns if touched carelessly, so it is strongly recommended to wear special thick gloves when working with it

This is interesting: Mirror above the fireplace (22 photos) - location of the fireplace with candles and mirror according to Feng Shui

Installing a fireplace insert

When assembling the firebox, comply with all rules and regulations regarding national and European standards. During the work, pay special attention to the provisions regarding fire safety, options for using materials and the size of ventilation ducts. When assembling a fireplace, it is important to provide access to clean the firebox and chimney. The diagram shows the individual security elements and structural elements in standard and protected walls. 1. Walls 2. Insulation layer (chimney) 3. Chimney connection 4. Insulation layer (back wall) 5. Convection zone 6. Grilles for convection air supply 7. Concrete slab min. 10 cm 8. Ceiling 9. Insulation layer (floor) 10. Air supply to the fireplace 11. Fireplace box 12. Insulation layer (ceiling) 13. Grids for extracting air convection 14. Protective floor made of fireproof material 15. Insulation layer 16. Fireplace lining 17. Radiation zone 18. Flammable material 19. Ventilated protection of combustible material 20. Wall protection 21. Fire protection of the smoke duct passage 22. Firewall made of mineral material 23. Furniture made of combustible materials - at least 5 cm from the firebox lining

Recommendations for selection

It is recommended to pay attention to:

- Power. You should not buy powerful units to heat a small room.

- Price. It is impossible to buy a high-quality device for pennies. We need to find a “golden mean”. There is no point in buying cheap stuff from China. It will not last long and may be unsafe.

- Design.

Semicircular

Angular

- Door material.

Glass door

Convection zone

If heated air is not used, there must be a gap of at least 6 cm between the firebox and the insulation layer (4, 15) for the rear and side areas. The convection zone must be isolated from all walls, with the exception of the walls that form the heat exchanger. The walls, floor and ceiling of the convection zone must be clean and abrasion-resistant. All convection pipes must be made of non-combustible materials. When laying the corrugation for supplying hot air: the corrugation must be securely connected to the hot air flange on the inlet grid. Operation of the air grid (hypocaust): heated air circulates in a closed space. Heat from the convective zone is transferred into the room through heat exchange zones. The heat load in the hypocaust convection zone is higher than that of conventional ventilation grilles.

Types and features of stove foundations in frame-panel and wooden houses

When arranging furnaces, several types of foundations are used, each of which differs in its design features. Before deciding on the type of foundation for furnace equipment, you need to consider the following factors:

- The final price of installing

the foundation, which consists of the cost of purchasing materials, preparatory and construction work. - Structural features

of the foundation and type of soil. - Calculation of the dimensions of the foundation

for the furnace, based on its characteristics.

In addition, the construction of stoves in a wooden house may involve the construction of a foundation for them simultaneously with the general foundation of the building. Common types of foundation for a stove or fireplace are concrete, piles and pillars. Note that most stoves can be mounted directly on the floor. To do this, it is necessary to take into account all fire safety requirements and recommendations of the stove manufacturer.

Most often, a concrete foundation is used to install a fireplace or stove Source vbanepar.ru

Sequential installation of a fireplace

1. Stage one. Here we are talking about preparing the foundation, which is different from the foundation of a house. We dig a hole that is 15 cm wider and 60 cm deeper than the intended foundation of the fireplace. Next, we fill in 20 cm of crushed stone, and the next step is pouring concrete. The foundation must be able to withstand the load of the future fireplace; here it is important to correctly calculate the depth of the pit.

2. Stage two. Before installing the fireplace, you need to perform a few more steps. First, prepare a mixture of clay and water, with which bricks or blocks will be laid. It is done 3 days before work. When choosing a brick, preference should be given to materials that are intact and even in both shape and color.

When laying the first row, you need to use cement, since it holds all the others and must be strong. And then a standard solution of clay, sand and water is used. Before laying a brick, immerse it in water and wait until air bubbles stop appearing and coming out. Remember that you need to ensure the symmetry of the work being performed so that the walls do not move in different directions. In the place where the pipe and roof meet, we again use cement. The outlet pipe, or rather the hole, is insulated using iron blanks. After work, the walls are wiped to remove excess solution. The floor around the fireplace is also covered with iron or tiles.

3. Stage three. The work has been completed. The fireplace has been laid, now it is painted, whitewashed or lined with stone to add brightness and make it look presentable.

DIY assembly

In order to properly brick the fireplace insert, it is necessary to carry out all work strictly in stages. The first stage is the assembly of the lower base of the furnace.

Assembly instructions:

- The lower part of the base is shaped like the letter M. In order for the fireplace to have the necessary stability in the future, each of its angles must be ninety degrees;

- We prick the first row in the shape of the letter M. Next, each row should lag slightly behind the previous one by about half a brick, thus the structure will have T-shaped joints;

- The number of rows from which the lower base of the furnace unit is assembled depends on the order you used. On average, their number can range from 3 to 7;

Laying is done at a slight bevel

The first rows should go at the same angle

The key point is to assemble the first rows of the fireplace

- At the location of the firewood box, it is necessary to make several gaps. There should be enough of them so that air masses can circulate and move freely, but not too quickly. These gaps are the entrance for cold air masses that will enter the interior of the furnace.

Creating a shelf

In order for the design to be as convenient and functional as possible, we advise you to additionally equip it with a small tabletop or so-called shelf. Knowing how to line the fireplace insert from the bottom, you can proceed to the next stage.

Tip: this element is a reliable support for the combustion chamber. To create maximum comfort and convenience, you can install and place two shelves at once (bottom and top).

Step-by-step assembly of the shelf:

- Based on the size, shape and design features of the planned structure, you need to cut out the formwork from wood;

- Bricks are cut using a grinder according to the dimensions of the shelf;

- The brick is laid out in formwork and reinforced. For reinforcement, you need to use pre-prepared metal rods with a thickness of 3 to 7 millimeters;

Wooden shelf assembly diagram

If desired, a shelf or tabletop

The countertop makes the stove unit

The mantel serves as additional support

- This formwork is completely filled with cement mortar. We compact it in such a way that there are guaranteed to be no voids inside;

- We remove all excess solution from the side parts and leave to dry completely for 2-4 days.

Photos of fireplaces with inserts

Design and calculation

Before building a fireplace, it is necessary to develop a suitable design for this structure. In principle, for your own needs you can order a project from a specialized organization. But if you want to make a fireplace with your own hands from start to finish, then the design should also be done on your own.

Each fireplace has several mandatory elements in its design:

- Portal.

- Cornice.

- Protective area in front of the firebox (fireplace table).

- Under.

- Firebox.

- Grate.

- Ash pit (ash pan).

- Back plate.

- Smoke chamber.

- Smoke tooth.

- Chimney.

A lining is created in the internal space of the firebox - a special finish made of refractory materials (the role of the lining may well be played by refractory bricks).

Calculating the main dimensions yourself is not difficult. In most cases, it is enough to know the area of the room in which the fireplace is installed. Using the table below, this can be done quite quickly.

For fire safety purposes, the bottom plane of the firebox should be designed so that it is at least 30 cm above the floor level.

The lower part of the fireplace with a grate is shown in the diagram. The ash pan can be made completely open so that air can freely penetrate into the combustion chamber. But for fire safety purposes, it is better to install a special door at the entrance to the lower chamber.

The fashionable trend today is to buy ready-made fireboxes. The range of these products is truly huge, and their purchase will be justified. After all, installing a finished firebox greatly simplifies the design and calculation of the fireplace. The combustion chamber with a built-in ash pan can be installed on a special brick pedestal (30 cm high), and the space created below can be used for storing fresh logs.

Operating Basics

In order for the fireplace to retain its original appearance for a long time and work properly, you need to perform a number of the following actions:

- Use only approved fuel and suitable fuel;

- Do not extinguish smoldering coals or a burning fire with cold water;

- A general standard design check is carried out about once every two months;

- After each firebox, you need to thoroughly clean the ash chamber from soot and combustion products;

- At the end of each season, timely cleaning of the inner surface of the chimney pipe is important.

Installing a fireplace insert with your own hands requires strict adherence to important rules and basics. If you follow them, you will be able to complete all the actions on your own and in a fairly short period of time.