Gas instantaneous heating boilers are designed for heating rooms with heat losses of up to 35 kW.

Standard boilers (models 5107, 5109, 5111, 5113, 5115, 5117) are used for space heating, and can also be adapted for heating domestic water in an attached storage water heater.

Combination boilers (models 5106, 5108, 5110, 5112, 5114, 5116) are used for both heating and domestic water heating.

Boilers with combustion products exhaust

"turbo" - version C12

"turbo" - version D1

Boilers with combustion products exhaust

"turbo" - version C12

"turbo" - version D1

Important instructions and warnings

When installing, commissioning and servicing the boiler, it is necessary to comply with certain rules established by state regulations and the requirements of the manufacturer. The user must carefully study the “Operation Manual”, “Warranty Card” and subsequently follow the rules set out in them.

Installation

When installing the boiler, for its further safe and economical operation, it is necessary to have a qualified design for the entire heating system.

The boiler may only be installed by an authorized service organization.

To operate the boiler, only the type of gas indicated on the type plate of the product can be used.

An installed and assembled boiler must not be moved to a new location. The boiler must be installed so that the socket for electrical connection of the boiler is located in an accessible place. The phase wire must be connected to the left sleeve, the neutral wire to the right, and the ground pin to the top pin. Failure to comply with this condition will result in the burner flame going out after ignition. ATTENTION!

The emergency thermostat, reverse draft fuse, fan and pressure switch are energized at 230 V. If it is necessary to interfere with the operation of these elements, be sure to remove the plug from the electrical outlet.

Commissioning Commissioning

of the boiler can only be carried out by an authorized service organization that has a permit (license) from the relevant State Supervision services.

The organization putting the boiler into operation is obliged in the future, if necessary, to repair the boiler during the warranty period. When putting the boiler into operation, a specialist from an authorized service organization must do the following:

check the tightness of connections

adjust the boiler (if necessary)

check all boiler functions

familiarize the User with the rules for servicing and caring for the boiler

warn the User about the need to maintain safe distances from the boiler to walls made of flammable material and about ways to protect them

Fistulas in the heat exchanger

You can find out the whole truth about the conspiracy associated with the selection, operation and maintenance of gas water heaters (instantaneous water heaters) of all manufacturers and models.

One of the most common failures of Mohr columns is the appearance of microholes on the heat exchanger tubes. To detect them, you need to carefully inspect it with the tap turned off (this achieves maximum pressure inside). Some leaks will be visible by drops of water, the smallest fistulas will be visible by green or rusty stains.

Before starting repair work, the water is drained. You can fix the problem in the following ways:

At the end, the water heater is filled with liquid, and the places of former leaks are carefully inspected. You need to check first with cold water, and then with hot water on.

Main Dimensions

MORA 5106, 5107, 5110, 5111

MORA 5108, 5109, 5112, 5113

Description of boiler functions

With connected room thermostat

The boiler will start working when it receives a signal from the room thermostat about a decrease in temperature in the heated rooms. After receiving the signal, the pump accelerates and the gas fittings open the flow of gas to the main burner. Heating water flows from the pump to the heat exchanger, where it is heated and then enters the heating system. The heating water temperature is recorded by the heating water temperature sensor. Heating of heating water continues until the boiler is turned off when the desired (set) temperature in the heated rooms is reached. Thus, the process is repeated as long as the boiler is connected to the electrical network. The heating water temperature is set to the maximum value.

Without room thermostat

The pump runs constantly. The operation of the boiler is controlled by a control and regulation unit in accordance with the heating water temperature set by the User.

Process of heating domestic water (combined boilers)

Heating of domestic water has priority over heating of heating water.

The flow of water through the domestic water flow fuse will introduce the boiler into the process of heating domestic water when the 3-way controlled valve changes the direction of movement of the heating water, and it passes through the secondary heat exchanger, and from there back to the pump. From the heated heating water in the secondary heat exchanger, in accordance with the temperature set by the User, the service water is heated. By changing the burner power, the electronics system maintains the temperature of the domestic water at the selected level.

After the end of the selection of warm domestic water, the boiler will automatically switch to the heating process.

During the process of heating domestic water, the gas pressure supplied to the main burner changes so that the temperature of the domestic water corresponds to the set one, regardless of fluctuations in water flow under the influence of fluctuations in inlet pressure, i.e. increased water flow will cause an increase in gas pressure, and vice versa.

Boiler capabilities taking into account its power

Method of heating domestic water (standard boilers)

Boilers intended for heating can also be used to heat domestic water in the MORA storage water heater. The storage water heater is connected to the heating system, domestic water is heated with warm heating water ("WATER-WATER" system). If the boiler is installed together with a storage water heater, you can use the MORA 9510 connecting elements, which make it possible to carry out the installation and electrical connection of the devices without any problems.

Electrical connection diagram for storage water heater

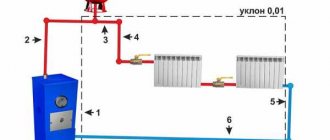

Example of installation of a storage water heater

Boiler safety

Safe operation of the boiler is ensured by the following elements:

Electronic control and regulation unit

— ensures and controls the activity of individual boiler elements (pump, thermostats, 3-way controlled valve, flow sensor, etc.).

Heating and utility water flow sensors

- will not allow ignition of the main burner if there is insufficient water flow.

Emergency thermostat

— closes the gas supply to the boiler when the maximum permissible water temperature in the heat exchanger is exceeded.

Backdraft fuse (boilers with combustion products discharged into the chimney)

If the chimneys become clogged (even partially), which will allow combustion products to enter (leak) into the room, the backdraft fuse will register an increase in the temperature of the surrounding space and cause the gas supply to the main burner to close. The boiler can be put back into operation only after the fuse has cooled down, i.e. after approximately 10 minutes, by pressing the “RESET” button.

Pressure switch (boilers with exhaust of combustion products "TURBO")

If the pipes for removing combustion products become clogged (even partially), or fuel combustion deteriorates (below the established norm) under the influence of a decrease in fan speed (voltage drop in the electrical network), or the fan does not work, then thanks to the pressure switch the boiler will not turn on, so that combustion products did not accumulate in the closed combustion chamber.

The backdraft safety device or pressure switch must be functional during boiler operation and their functions must not be affected by anything (for example, a change in position).

If the backdraft safety device or pressure switch fails repeatedly, contact an authorized service organization to troubleshoot the problem and perform an operational test.

Scale deposits in the heat exchanger

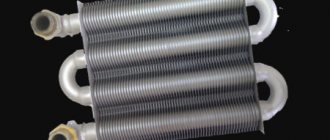

Mora heat exchangers are made of high-quality copper, 1 mm thick. The water heats up inside the tubes and scale accumulates on their walls. This leads to an increase in heating time and a decrease in pressure. The main sign of clogging of the heat exchanger pipes will be that water flows actively from the tap, but the pressure through the column is weaker.

To clean scale yourself, you should remove the casing from the water heater, drain the water and unscrew the union nuts from the heat exchanger outlets. After this, a special liquid for dissolving salts, which is sold at a hardware store, is poured into the tubes using a hose. Instead, you can use a solution with citric acid or vinegar. You will need to wait a few hours for complete cleaning.

For prevention, the heating temperature should be set to no more than 50 degrees. If the temperature is higher, scale deposits especially actively.

Controls

ON/OFF button

When you press the “ON/OFF” button, the boiler turns on or off. When the boiler is turned on, “ON” will appear on the display. If the boiler is set to the “OFF” mode, but is connected to the electrical network, then the pump mileage and frost protection functions will operate.

“RESET” button

In the event of a malfunction caused by the burner flame going out, pressing this button will return the automatic ignition system to a ready state, unless the malfunction is caused by the emergency thermostat. If there is a malfunction caused by the backdraft fuse, you need to wait approximately 10 minutes and then press the “RESET” button again.

Heating water temperature adjustment buttons

Heating water temperature adjustment is performed using the following buttons: - increase temperature;

- decrease in temperature. The heating water temperature is set in the range:

from 30 to 80°C - for a heating system with radiators.

Preparing the boiler for operation

When preparing the boiler for operation, you must do the following:

- check the water pressure in the heating system

- open the inlets and outlets of heating water (or utility water) - (valves under the boiler)

- open the gas supply to the boiler

When putting the boiler into operation, a qualified specialist from an authorized service organization must:

- Check the pump mode - it should be set to stage 3.

- Start the boiler.

- Carry out ignition control:

- turn on the boiler using the button on the control panel.

- after 5 seconds, a series of sparks will ignite the burner - ignition lasts 5 seconds,

- Repeat ignition 5 times.

- Check the functions of the ionization electrode - blow off the flame from the ionization electrode - after 3 seconds the burner should go out. The electronic control of the boiler will automatically switch to ignition mode (another attempt to ignite the burner will follow). If the burner does not ignite, fault code E2 will appear on the display - loss of flame. To ignite, you must press the “RESET” button on the control panel.

- Perform burner control:

- check the main burner, the flame should only be near the outlet openings,

- check the stability of the flame along the entire length of the burner plates.

- Adjust heating and starting power

Preventative repair work

For proper operation, the Mora water heater requires regular maintenance:

- From time to time it is necessary to replace the batteries. If they sit down, the spark continues to be produced, but its power is not enough. The standard size of the nutrients is R20 at 1.5 volts. The container with them is located at the bottom of the device.

- If you have hard and dirty water, you should clean and change the strainers on time. They are installed on the cold water inlet pipe. Failure to do this will result in a decrease in pressure over time.

- The igniter is clogged. In semi-automatic models with a wick, the jet becomes clogged with dust over time. You can clean it with a thin soft wire.

If after diagnostics you cannot find the cause of the malfunction, call a specialist.

This instruction manual in Russian is intended for the Mora-Top Meteor heating boiler; it describes the principle of operation and the main points of operating the device.

The manufacturer strongly recommends that you carefully study these instructions before turning on the heating boiler.

Radiator contamination

You can find out complete information on the selection, operation and maintenance of gas water heaters (instantaneous water heaters) from all manufacturers if you go.

In addition to specific information on the site, you can also study specific problems from other people on this topic who have already purchased a gas water heater or instantaneous water heater and thus avoid them. You will find a regularly updated list of such problems and their solutions.

The radiator is made up of metal plates with a small distance between them. Since they are exposed to the flame from the burner, soot accumulates between them over time.

Gas water heater radiator

This can be seen from the yellow color of the fire. The flame can be directed not in the upward direction, but to the side, thereby heating the casing. The water takes longer to heat up even when the column is running at full power, and black soot pours out from under the device.

For repairs, you should remove the column shell, disconnect the heat exchanger pipes and completely dismantle it, first covering the burner with a rag so that it does not become clogged. The most convenient way to clean the radiator is in the bathroom under running water. If necessary, it is left to limp in a container with chemicals. At the end, it is cleaned with a soft long bristled brush, dried and installed back.

Installation of instantaneous water heater

Before installing the speaker, you need to decide on the room and installation location. The room must have ventilation, and the wall must be made of non-combustible material

. Installing a column is usually straightforward and consists of the following steps:

mounting the device to the wall. Standard brackets included in the delivery kit are used.

Pay attention to the strength of the wall and its flammability; connection of cold and hot water pipes. It is advisable to install shut-off valves in front of the inlet pipes; Expert advice: between the wall and the speaker body you need to lay a gasket made of non-flammable material!

Expert advice:

Between the wall and the speaker body you need to lay a gasket made of non-flammable material!

- chimney connection. The chimney is connected with pipes with a diameter no smaller than the outlet of the device. The chimney material must be resistant to combustion products and high temperatures, its length must be minimal;

- main gas connection. It is better to entrust this procedure to professionals involved in the installation and operation of gas equipment.

Control Panel

The control panel in boilers MORA 5118, 5120, 5121, 5122, 5124, 5125 is located in the lower part of the boiler behind the casing and will be accessible if the casing is lifted up approximately 100 mm.

ON/OFF button

When you press the “ON/OFF” button, the boiler turns on or off. When the boiler is turned on, the button will light up.

Heating water temperature adjustment knob

Designed to set the required heating water temperature in the range from 30 to 80°C. If the room thermostat is functioning, the heating water temperature is set to the maximum value.

“SUMMER-WINTER” mode switch (installed only on combination boilers)

When the switch is set to the “WINTER” position, the boiler is prepared for operation - heating heating water or domestic water. When the switch is set to the “SUMMER” position, the boiler is ready only for the process of heating domestic water. This mode is used mainly in the summer, when there is no need to heat the premises.

Thermometer

Shows the temperature of heating water leaving the boiler.

For boilers MORA 5119 and 5123

— the thermometer is installed on the boiler casing — the “ON/OFF” button and the heating water adjustment button are located on the left, under the boiler

Decommissioning of the boiler

Long term

Long-term decommissioning of the boiler is carried out during maintenance and repair:

- move the ON/OFF button to the “OFF” position

- unplug the power cord from the socket

- close the gas and water supply taps

Short-term

- Move the ON/OFF button to the “OFF” position

- leave the power cord plug in the socket

- Leave the gas and water supply taps open

If the water temperature in the primary circuit drops to 5°C, the boiler will turn on and heat the water to 19°C, thereby protecting the boiler from freezing.

Every 24 hours the pump will run automatically to prevent the so-called. “jamming” of the pump under the influence of sediments.

Review of Mora floor standing boilers

Mora Top floor-standing gas heating boilers are presented in more than ten modifications, the main difference of which is the type of burner and combustion chamber used.

- Atmospheric burner - installed in the model range of Mora Top boilers of the ELITE series. It is believed that the ELITE modification is one of the ten best models of heating equipment. The burner is made of high-alloy steel and has a long service life. To increase convenience during operation, it is possible to connect an indirect heating boiler (for domestic hot water) and install temperature sensors. Technical characteristics make Mora's gas-independent floor-standing boilers the optimal solution for heating a cottage or private home.

Pressurized burner - closed type boilers are equipped. They have an automatic ignition unit that automatically starts the boiler in the event of a power outage or a drop in gas pressure. The device has two separate circuits. The primary heat exchanger is made of steel, and copper is used to produce the second. Gas consumption is minimal. This is especially noticeable when changing fuel. Conversion to liquefied gas is carried out by replacing burners.

To increase performance and heat transfer, it is recommended to use antifreeze. The heat exchanger and internal structure are designed taking into account the use of this liquid as a coolant.

As practice shows, the Czech water-heating energy-independent floor-mounted instantaneous gas heating boiler Mora Top is the optimal solution for heating country houses. The absence of complex automation, electricity-dependent components, high productivity - all this distinguishes the equipment of this series.

Carrying out installation work

Mora gas appliances are designed in such a way that installation and maintenance of boilers are as simple and easy as possible. All volatile models have a self-diagnosis function. Information about all violations is displayed on the LCD display. The boilers are equipped with Mora equipment. As a result, automation, burner and other components ensure stable and long-term operation.

Commissioning and adjustment of the boiler is carried out as follows:

- Volatile boilers are connected to the network. The self-diagnosis function starts automatically. The controller checks the presence of pressure in the heating system and gas pipeline. When deviations are found, a signal is issued in the form of a digital value. After troubleshooting, the boiler starts up.

Non-volatile units do not have self-diagnosis functions, automatic flame ignition, etc. Therefore, before starting up and putting the equipment into operation, the company representative must ensure that all installation recommendations are followed. It is mandatory to install a water treatment system and a safety group; you may need to connect an expansion tank and a circulation pump.

Czech Mora gas boilers generally start up without any difficulties, but there are exceptions, mainly related to transportation or installation problems.

One of the common malfunctions of a double-circuit boiler is the failure of the thermocouple. After replacement, the functionality of the equipment is fully restored.

Floor-standing

Atmospheric floor-standing boilers MORA SA 40 G are recommended for heating facilities located in areas with unstable power supply. Classic series models are equipped with a stainless burner device that operates stably even with low gas parameters. They belong to the class of cast iron boilers and have proven themselves to be reliable, inexpensive and fairly economical heat generators.

Note! According to buyers, today in Russia they are the most common among similar devices. The burner device is simple and operationally reliable. Its advantage is silent operation and low energy consumption

The developers have provided the Mora boiler with maximum resistance to frequent pressure changes in the gas main, including modes with low gas inlet pressure

Its advantage is silent operation and low energy consumption. The developers have provided the Mora boiler with maximum resistance to frequent pressure changes in the gas main, including modes with low gas inlet pressure

The burner device is simple and operationally reliable. Its advantage is silent operation and low energy consumption. The developers have provided the Mora boiler with maximum resistance to frequent pressure changes in the gas main, including modes with low gas inlet pressure.

The longevity of the device is ensured by the inclusion of a cast iron heat exchanger, which does not suffer from low-temperature corrosion, like steel, and does not burn out, like copper. The unit has a burner flame control function using a thermoelement that prevents gas leakage. The backdraft fuse works as part of the protection system and prevents flue gases from entering the room. Electronic regulation with a temperature limiter in the boiler controls the level of heating of the circulating water, and in the event of overheating in an emergency, it will send a signal to the shut-off valve to shut off the flow of gas into the boiler and take it out of operation.

Built-in reliability features

Reliability of units of this design is ensured by the following boiler functions:

- Protecting the secondary boiler from scale formation by applying a special agent to the heating surface.

- Preventing water from freezing in the internal circuit of the heater.

- Guaranteed operation of the pump and three-way valve without jamming.

- Boiler overheat protection. After the gas supply is stopped, the pump will continue to circulate until the medium cools down to an acceptable level.

- Stable operation of the unit at parameters in the electrical network of 160–250 V.

Note! When the circulation circuit is clogged, it is possible to provide movement in the primary boiler with a bypass line

Features of Mora TOP boilers

The device starts working by turning on the main burner, which is ignited by a piezo igniter depending on the speed of the circulating water, starting from 5.5 l/min. This indicator corresponds to the minimum power of the unit; the nominal one is achieved with a flow of 8 l/min. The unit is supplied without the By-pass function, so when starting the system, leave the valve on at least one radiator open. Adjustment of the technological process occurs in several modes, but always starts in the same way - by turning on the pump.

The main adjustment is made by a capillary thermostat in the network water range of 7–77 °C. More efficient regulation will be performed by a 220 V room thermostat, depending on the user-set indoor air temperature in the room. In this case, this thermostat is connected in series with the capillary one.

To prepare domestic hot water, the Mora TOP boiler can be connected to an indirect heating boiler using additional equipment. In this case, regulation occurs based on the demand received from the DHW thermostat of the boiler (ON/OFF). The capillary and room thermostat remain unconnected, the water temperature is regulated at 85 °C. If the capillary is installed in the “snowflake” position, the unit is in frost protection mode, and as soon as the temperature of the network water drops below, the heated internal circuit water will begin to circulate.

Main types of gas boilers Mora TOP

The main modifications of gas units are divided according to the installation principle - wall-mounted and floor-mounted, according to the design of the firebox - open and closed, and according to the method of removing flue gases, there are three options.

Varieties of MORA-TOP TITAN:

- A device with an atmospheric burner and exhaust of flue gases into the chimney, version B11BS. The boiler will not start up without working pressure of the network water. This is the basic version, comes with a temperature limiter in the boiler, which prevents the water from overheating and turns off the gas supply.

- The atmospheric gas boiler "Mora" is equipped with a thermoelement, an expansion tank in the heating system and a reverse draft fuse that prevents gas leaks in the room.

- A unit with a “Comfort” burner reduces the temperature of the flue gases in the chimney by installing an additional boiler to generate thermal energy for the needs of hot water supply.

Important! The boiler has a function to prevent water from freezing in the heating circuit. When the water temperature in the network circuit drops below +5 °C, it will begin to heat it to protect the system from freezing

Wall mounted

Wall-mounted boilers “Turbo” with a heating capacity of up to 24 kW are produced with a closed combustion chamber, and “Combi” for combined heating and hot water supply. The device meets all the latest requirements of domestic and European standards regarding the safe and economical operation of heating units.

Note! The main innovation is the control unit.

- protecting the health of residents and the safety of property;

- user function - for setting comfortable modes in heated rooms;

- function of ensuring the technological process of the unit.

The unit has a wide range of heat load adjustment - from 30% to 100%. Initially, the Mora gas boiler heats the coolant in the circuit at maximum mode and then switches to economy mode.

Note! The boiler has protection against frequent switching on/off of the burner device at low operating parameters, when the required heating load is below the lower limit, for example, a sharp increase in outside air temperature at the beginning or end of the heating season.

Structural advantages of wall modifications:

- thermostat for automatically adjusting the operation of the system according to the internal air temperature;

- quiet operation of the burner device during start-up and operation;

- high-quality preparation of hot water with a minimum flow rate of 3 l/min;

- ultra-fine temperature control of the DHW circuit, regardless of the volume and pressure of the source water;

- easy accessibility of the internal elements of the boiler for maintenance and repair;

- LCD display of control unit for setting;

- automatic fault diagnosis.

- built-in processor with software for diagnostic monitoring of all units of the unit;

- protection against the release of gas to the burner at low pressure or lack of water in the circulation circuit;

- protection against low DHW flow rates;

- ionization fuse for gas leak control;

- flame lift-off control.

Additional Information! The boiler software includes the LEGIONELLA function, which allows you to include a cylinder water heater in the system.

Features of Mora Top geysers

We managed to win the sympathy of buyers thanks to a number of unique characteristics inherent in modern models:

- The presence of so-called “dry start” fuses. Without water, the burner simply will not light.

- Control of burner operation using a fuse. This is how any Mora device works, a gas water heater is no exception.

- Combustion products are prevented from entering the building thanks to a backdraft preventer. Water heaters can be installed inside any premises.

- Protection with a special limiter that controls the water temperature. Overheating of the device is practically excluded.

- From 115 mm - the diameter of the gas outlet neck of Mora geysers.

- The diameter of the tubes is up to 18 millimeters. Special turbulators are mounted on the internal surfaces. They prevent scale buildup.

- The heating rate is 15% higher compared to analogues due to the design of the heat exchanger.

- Automatically maintains temperature if the water speed changes while the Mora is running.

- Fittings from the German manufacturer Mertik. At a flow rate of 2.5 liters per minute or more, the column starts to turn on.

Note! The market price of most models does not exceed 16 thousand rubles.* The consumer properties of the Mora dispenser are higher compared to existing analogues

Advantages and disadvantages

Heating a home and hot water supply are two main issues that can be resolved by any buyer who decides to purchase gas water heaters. Cost-effectiveness and compact size are among the main positive aspects of the devices.

There are other characteristics that can attract buyers:

- The security system that Mora Top speakers are equipped with.

- High quality burner design. The igniter is completely protected from any contamination and damage.

- High efficiency, reaching 94% under any circumstances.

- Equipment works efficiently. Even pressure up to 0.2 atmospheres does not prevent the creation of such an effect in the Mora gas instantaneous water heater.

- Over time, heat exchangers do not leak. This is facilitated by the use of copper as one of the main materials.

- No noise when operating the Mora water heater.

Interesting! The disadvantage is that it is difficult to find parts for some models. Especially if they were released quite a long time ago. Mora gas water heaters are cheaper than existing analogues, but some buyers consider existing prices too high.

Replacing the membrane

If you want to find out about which geysers (instantaneous water heaters) you should not choose, about the subtleties and nuances of their installation and connection, as well as hidden information on their proper maintenance for all manufacturers and models, then go here -.

You can find a list of answers to tricky and pressing questions of people who took a risk on their own skin, chose and purchased a gas water heater or instantaneous water heater.

If the gas does not turn on or the burner flame is very weak, the membrane in the water unit may be stretched or damaged. Water may also start leaking from the water block. In a Mora water heater, the water unit is located horizontally.

To get to the rubber membrane, first unscrew the union nuts for water supply and outlet from below. Then the heat exchanger tube going to the rear wall is unscrewed. Use a star screwdriver to unscrew the four bolts and remove the cover of the water block. Three springs are removed and a new membrane is installed.

It is important to buy a membrane designed specifically for your model, as there are now many configurations available. After replacement, all components are assembled in the reverse order, and the operation of the device is tested.

Replacing the membrane in a gas water heater

Review of popular models

Vega 10

| Specifications | |

| Water heater type | flow-through |

| Heating method | gas |

| Capacity, l/min | 10 |

| Thermal power, kW | 17,30 |

| Inlet pressure, atm | from 0.20 to 10 |

| Combustion chamber type | open |

| Ignition type | piezo ignition |

| Gas control | There is |

| Yes | |

| Water heater control | mechanical |

| There is | |

| Protection | from overheating |

| Installation | |

| Dimensions (WxHxD), mm | 320x592x26 |

The market value ranges from 11,500 to 13,800 rubles.

Based on user feedback, we identified the speaker's strengths and weaknesses.

- reliability;

- Batteries do not run out for a long time;

- miniature sizes;

- efficiency;

- automation;

- simple controls.

- the column is demanding on water pressure;

- difficulties in connecting communications;

- overcharge;

- Some parts are made of plastic and therefore are not durable.

Vega 10E

| Specifications | |

| Water heater type | flow-through |

| Heating method | gas |

| Capacity, l/min | 10 |

| Thermal power, kW | 17,30 |

| Inlet pressure, atm | from 0.20 to 10 |

| Combustion chamber type | open |

| Ignition type | electric ignition |

| Gas control | There is |

| Automatic maintenance of leaving water temperature | Yes |

| Water heater control | mechanical |

| Heating temperature limitation | There is |

| Protection | from turning on without water, from overheating |

| Installation | vertical, bottom connection, mounting method: wall |

| Dimensions (WxHxD), mm | 320x592x26 |

Price from 12,700 to 22,000 rubles.

Many users agreed only on positive qualities, such as:

- stable work;

- reliable design;

- simple controls;

- small dimensions;

- efficiency.

Mora Vega 13

| Specifications | |

| Water heater type | flow-through |

| Heating method | gas |

| Capacity, l/min | 13 |

| Thermal power, kW | 22,60 |

| Inlet pressure, atm | from 0.20 to 10 |

| Combustion chamber type | open |

| Ignition type | piezo ignition |

| Gas control | There is |

| Automatic maintenance of leaving water temperature | Yes |

| Water heater control | mechanical |

| Heating temperature limitation | There is |

| Protection | from overheating |

| Installation | vertical, bottom connection, mounting method: wall |

| Dimensions (WxHxD), mm | 400x659x261 |

The pricing policy of retail outlets varies: from 12,500 to 20,4000 rubles.

Vega gas instantaneous water heaters are designed for heating domestic water at home and in businesses. In water heaters of this type, the set water temperature is automatically maintained at a given level, regardless of the amount (volume) of water taken.

Operation and repair

Operating a water heater involves turning it on and setting the required temperature. For this purpose, there are two handles on the front panel of the device. The operation control handle has four positions:

- off, column disabled;

- ignition, ignition of the pilot burner;

- readiness, pilot burner burning;

- operation, normal operation of the device in automatic mode.

The water temperature knob allows you to adjust water heating from a minimum of 25 degrees to a maximum of 55 degrees.

Good to know:

the higher the heating temperature, the lower the water flow through the water heater.

The speakers are highly reliable and have a service life of at least 12 years. Customer reviews indicate that they rarely fail.

If the operating instructions are followed, then the main reason for failure is the formation of scale and salt deposits. In this case, the repair consists of flushing the water path and heat exchanger.

Over time, heating efficiency may decrease and traction may deteriorate.

A possible reason is the deposition of soot and soot. Troubleshooting this problem involves disassembling and cleaning the gas path of the column.

If more complex malfunctions occur, especially in the gas path, you must contact a service center that has qualified specialists and the necessary spare parts.

For a review of the Mora Top Vega 10 E geyser, see the following video:

2017-03-09 Sergey Dyachenko

Let's look at the typical breakdowns of the Mora gas water heater and the necessary do-it-yourself repairs. Before troubleshooting, close the valve on the pipe through which gas is introduced into the water heater. Even if a non-gas part breaks, there is a chance that it will get caught.

Rating of TOP 5 wall-mounted single-circuit boilers

Among single-circuit wall-mounted boilers, the following models stand out:

Buderus Logamax U072-18

world famous concern Bosh. Experts note the high quality of the products, which is not inferior to the products of the parent company. The Buderus Logamax U072-18 boiler is a single-circuit unit with a power of 18 kW, which is suitable for heating a house of 160-180 sq. m. m.

The manufacturer warns that if the water hardness is more than 16°dGH, you will need to use softeners or special filters.

- coolant temperature - 40-82°;

- pressure in the heating circuit (max) - 3 Bar;

- dimensions - 400/299/700 mm;

- weight - 32 kg.

The unit can be connected to an external indirect heating boiler, which will provide the home with hot water.

BAXI LUNA-3 1.310 Fi

The BAXI company is considered Italian, although the enterprises are scattered throughout Europe, and the head office is located in the Netherlands. The LUNA-3 1.310 Fi boiler is a convection unit with a power of 31 kW.

This is a solid device capable of heating a residential building or office with an area of up to 310 square meters. m. High efficiency (93.1%) ensures fuel savings and allows you to get maximum performance from the boiler.

- coolant temperature - 30-85°;

- gas consumption - 3.52 m3/hour;

- pressure in the heating circuit (max) - 3 Bar;

- dimensions - 450x763x345 mm;

- weight - 40 kg.

According to the manufacturer, the service life of the boiler is at least 10 years with a 2-year warranty.

BAXI LUNA Platinum+ 1.32

Another representative of the Italian company is a condensing single-circuit boiler with a capacity of 34.8 kW. Its efficiency is 105.7%, which is nothing more than a clumsy marketing ploy.

A preheating stage has been added to the design of the unit, which allows reducing the intensity of the burner and saving fuel. However, the physical possibility of condensation with the release of heat is possible only under certain and rather narrow conditions, which are impossible in Russia.

- coolant temperature - 25-80°;

- gas consumption - 3.49 m3/hour;

- pressure in the heating circuit (max) - 3 Bar;

- dimensions - 450x760x345 mm;

- weight - 37.5 kg.

The price of the BAXI LUNA Platinum+ 1.32 condensing boiler averages 76-80 thousand rubles.

Considering the uselessness of an additional heating stage in most regions of Russia, the need for such a purchase should be carefully weighed.

MORA-TOP Meteor Plus PK24SK

A product from Czech manufacturers with a power of 23.7 kW. This is the optimal value for a room with an area of 220-240 square meters. m., which corresponds to the size of most cottages.

It is a single-circuit gas wall-mounted atmospheric type boiler. Requires connection to a common stove-type chimney.

- coolant temperature - 30-80°;

- gas consumption - 2.6 m3/hour;

- pressure in the heating circuit (max) - 3 Bar;

- dimensions - 400x750x380 mm;

- weight - 27.5 kg.

Users note the high performance and reliability of the unit, stability of operation.

Protherm Panther 25 KTO (2015)

The Protherm brand is the brainchild of the Vaillant Group, and was created specifically for the production of inexpensive, high-quality gas boilers. Initially, the products were aimed at the market of Russia and the CIS countries.

The Protherm Panther 25 KTO (2015) boiler has a power of 25 kW, which is suitable for heating 250 sq.m. It features low fuel consumption and stable, trouble-free operation.

- coolant temperature - 30-85°;

- gas consumption - 2.8 m3/hour;

- pressure in the heating circuit (max) - 3 Bar;

- dimensions - 440x800x338 mm;

- weight - 41 kg.

When connecting an external boiler, it becomes possible to provide the room with hot water, which makes the unit a fully functional device.