The first boilers were huge. They were installed only in industrial premises. Gradually, the size of the equipment decreased, and at the beginning of the 19th century, models were created for domestic conditions. But they also took up a lot of space. We also had to build a brick chimney. And relatively recently gas wall-mounted boilers appeared. They radically changed the approach to heating. If you want to know why they became popular, read this article. At the same time, I’ll tell you how to choose a wall-mounted boiler.

What are wall-mounted gas boilers?

Gas mounted models are compact in size - from 55 to 90 cm in height and from 40 to 45 cm in width. They are less universal, exclusively energy-dependent, but more efficient, compact and, in practice, according to statistics of service calls, almost as reliable. In addition, already in the factory configuration of all wall-mounted boilers, all components necessary for the heating system are provided: a circulation pump, a safety group, a set of sensors, sometimes an expansion tank, etc. All that remains is to connect the supply and return lines to the boiler, as well as the sanitary water supply circuit if the boiler is a double-circuit one.

Compact dimensions, stylish design, a minimum of communications that can be hidden in the walls and a coaxial chimney allow wall-mounted gas boilers to be built into a standard kitchen cabinet.

The installation of wall-mounted models is further simplified by the absence of the need for a traditional chimney. To get rid of gas combustion products, install a coaxial pipe, which is simply routed through the wall. The pipe consists of two parts. The internal one is used to eject combustion waste. Air enters the boiler through the outer part. A fan is used for this, which is why such boilers are called turbocharged.

Design and principle of operation

The most typical internal structure of a wall-mounted gas boiler using the Protherm Panther as an example.

The technical device may vary from model to model, but the standard design used in more than 70% of wall-mounted units is simple and straightforward: the burner to which gas is supplied is ignited by ignition electrodes and heats the heat exchanger above it → the primary heat exchanger transfers heat to the coolant circulating through the circuit heating, and the secondary heat exchanger, if available, to the sanitary water of the DHW circuit → the combustion product removal system naturally or forcibly removes gases from the combustion chamber through the chimney.

Heating circuit type

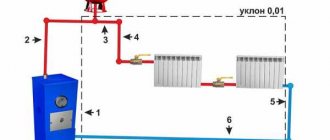

The type of heating circuit, that is, the circulation of the coolant, plays a significant role. Fluid movement has a couple of ways:

- water circulates from the heating of the boiler, rising to the top;

- circulation is forcibly enhanced by a special pump. Such devices, as a rule, are wall-mounted and the pump is included in the system. If it is missing, you can install it in the lower part yourself.

The photo of the gas boiler shows two types:

The floor-mounted one is installed directly on the floor, but such a system requires a separate room and chimney. This equipment is quite heavy and therefore requires installation on a durable concrete or iron base.

The advantages include high power and performance, easy care and maintenance, a wide range of models, and operation on a variety of fuels. At the same time, many models do not require an electrical charge.

Despite all the advantages of floor-standing options, wall-mounted boilers are still the most popular among consumers. They are usually installed in the kitchen or hallway.

This design is distinguished by: low weight category (maximum 50 kilograms), high degree of automation, ease of use, silent operation, and the absence of a separate chimney. At the same time, a boiler on the wall cannot simultaneously fully heat both the room and the water. It is limited in power level and depends on the supply of electrical energy.

Reviews of household mounted models: advantages and disadvantages

Let's look at the specific advantages of wall-mounted boilers. They also have disadvantages, but I don’t consider them that significant. Why? You will learn about this a little later, but for now look at this table:

| Advantages | Flaws |

| Higher efficiency - despite the compact size, the technologies, alloys used and more advanced automation make it possible to achieve on average 3-5% higher efficiency in comparison with floor-standing boilers of the same price category. | Fragility - due to weight restrictions, heavy and durable cast iron heat exchangers are not installed in wall-mounted models, while the service life of steel ones is on average 12-15 years, copper ones - 14-17 years. It is important to distinguish durability from reliability, despite the widespread myth, according to service practice, the number of serious breakdowns of wall-mounted models is practically no different from the statistics of breakdowns of floor-standing models. |

| Small dimensions - even powerful models with a heating capacity of over 40 kW are small in size and weigh up to 100 kg. | Volatility - all models of mounted gas boilers are volatile; their design uses electronic control boards, turbine fans, servo drives and other mechanisms that require a connection to the electrical network for operation. |

| Free placement - since models with a closed combustion chamber take air from the street, the space requirements for their installation are much less. Such boilers can be installed next to furniture and appliances, including stoves. | Sensitive to changes - most models are not adapted to the unstable quality of the domestic power supply network and after the next voltage drop they may simply not start due to the failure of the control board. We always recommend installing a voltage stabilizer along with the boiler. |

| Low cost - prices for all the most common, best in terms of price-quality ratio models are in the range of 28-35 thousand rubles. Some of the most budget options can be found for 20-25 thousand rubles. | They are more demanding on the quality of water - this is due to the service life of the heat exchanger; the more contaminated and hard water is used as a coolant, the more often it is replaced, the more scale forms on the walls of the heat exchanger and the more its service life is reduced. The problem can be partially solved by regular washing. Also, in almost all dual-circuit models, manufacturers prohibit the use of antifreeze as a coolant. |

| Simplicity of installation - all the necessary elements of the heating system are already located in the boiler body, which simplifies the wiring as much as possible. Models with a closed combustion chamber and a coaxial chimney (of which the majority) require only a small hole in the wall; there is no need for a traditional, more labor-intensive chimney. | More demanding to maintain - wall-mounted boilers, like floor-mounted ones, require regular cleaning, but much more often if you want to extend its service life and prevent breakdowns. |

| Safety - all mounted boilers are equipped to varying degrees with elements of automatic control and protection (against overheating, freezing of the system, blocking of the circulation pump). Floor-standing models are also equipped with such systems, but not budget models. | |

| Large selection of models - the market for mounted gas boilers today is much larger, competition is higher, which means that manufacturers are constantly working to improve characteristics at a lower cost. Even when approaching a choice with a large list of desired parameters, there will always be at least several models to choose from. |

I compiled all these pros and cons from owner reviews. Separately, I would like to say that the wall mounts are volatile, this is not so bad. Firstly, now electricity is practically never turned off even in villages. Secondly, even if they turn it off for a couple of hours, the house will not cool down completely. And it depends more on the insulation of the room, and not on the boiler. Thirdly, if you are very afraid of a power outage, you can buy uninterruptible power supplies or generators. By the way, in terms of electricity consumption, this is a maximum of 80-100 kW/month.

Current requirements for installing a gas boiler in a private home

LLC "GAZLUX Trade"

The company produces its wall-mounted gas boilers under the Gazlux brand. The manufacturer took care of the domestic consumer and manufactured heating devices that have advantageous advantages over foreign analogues:

- resistance of the heat exchanger to hard water;

- the ability of the burner to operate at low gas pressure;

- lack of susceptibility of automation to power surges in the network.

Gazlux gas boilers are available in three trim levels: Gazlux Economy, Gazlux Standart, Gazlux Premium.

…

Gazlux Economy

Gazlux Economy is the most popular modification due to its simplicity, low price, as well as the ability to heat and supply hot water. The boiler has the following characteristics:

- the throughput of the water circuit is 11 l/min;

- power 17 kW;

- heated area – up to 150 m²;

- electric ignition;

- service life is 12 years from the date of commissioning of the device.

Note! The Gazlux Economy line includes both models running only on natural gas and units adapted to run on liquefied fuel.

Gazlux Standard

The Gazlux Standart package differs from the previous one in the updated control panel. A daily programmer has also been added. Gazlux Standard has improved characteristics:

- water circuit capacity – 12 l/min;

- power – 21 kW;

- capable of heating a room up to 190 m²;

- open combustion chamber type;

- gas filter;

- electric ignition

Read how to install a wall-mounted boiler yourself

About the types and characteristics of modern gas boilers

https://oteple.com/sovremennye-gazovye-kotly-vidy-xarakteristiki-osobennosti-konstrukcii/

Gazlux Premium

Gazlux Premium is distinguished by ease of use and the ability to automatically control the work process. Additionally, these boilers are equipped with security and self-diagnosis systems. They have the following characteristics:

…

- power – 30 kW;

- water circuit capacity – 17.5 l/min;

- capable of heating a room up to 260 m²;

- water filter;

- gas filter;

- closed combustion chamber.

In this modification, it is possible to set the mode for a week in advance.

How to choose a wall-mounted gas boiler for a private home

The choice of wall-mounted models is huge, but you don’t need to understand all the nuances of operation: it’s enough to understand what to look for and what this or that technical solution provides in practice.

Convection or condensation

The operating principle of conventional convection (efficiency 88-94%) and condensing (efficiency 104-116%) gas boilers.

The operating principle of a convection boiler is quite simple. The water passes through a heat exchanger, which is heated by a gas burner using an open flame. But the problem is that some of the heat escapes into the chimney. To use this heat for its intended purpose, condensing boilers were invented. They have an additional heat exchanger installed, which collects condensate and extracts additional thermal energy from it. Its design is more complex than that of convection models.

On the other hand, condensing boilers are much more expensive, since an additional heat exchanger requires expensive, condensate-resistant materials, and radiators for them must be taken with a large power reserve. After all, for maximum efficiency, condensing boilers should be used in a low-temperature heating system with a temperature within 50°C. But the efficiency will be more than 100%. This will help save 5-10% of gas per season. Convection mounted boilers rarely have an efficiency exceeding 95%.

It’s difficult to choose here: either save on purchasing equipment, or then pay less for gas and recoup the initial costs within 8-11 years.

Differences and selection criteria for condensing gas boilers

Single-circuit or double-circuit

A visual principle of operation of double-circuit boilers with priority for hot water supply (DHW).

Single-circuit models operate only in heating mode. If the boiler is also capable of heating water, it is called double-circuit. There are two ways to organize a hot water circuit:

- bithermic heat exchanger - It consists of two parts, pipe-in-pipe type. The heating circuit passes through the outer part, and hot water passes through the inner part. Thanks to this design, manufacturers save space inside the housing and resources, however, more scale forms in bithermal heat exchangers, they become easily clogged, and due to their design, they cannot be cleaned mechanically.

- separate (monothermic) heat exchangers - a secondary heat exchanger is used here, which is heated by contact with the primary. When hot water is required, the boiler releases the heating circuit coolant in a small circle inside the housing (or only part of the heating circuit coolant if the boiler is equipped with a three-way valve, which allows the heating circuit to continue heating). It is better to choose boilers with separate heat exchangers; the diameter of the duct in them is wider, and it is easier to clean them if a large amount of scale forms.

I believe that the best way to organize heating and water supply is a single-circuit boiler and an indirect heating boiler. Unfortunately, such equipment is very expensive and takes up a lot of space. Therefore, double-circuit models are more often chosen. They are 10-30% more expensive than single-circuit ones, but you won’t have to buy an additional water heater. And there is usually enough water for domestic needs.

How to choose a gas wall-mounted single-circuit boiler Selection criteria, best models and prices

How to choose a gas wall-mounted double-circuit boiler Selection criteria, best models and prices

Heat exchanger material

Main or primary heat exchangers consist of a tube on which plates are located. Water passes through the tube, and the plates provide maximum area of contact with the fire. First of all, its durability depends on the material of the heat exchanger. The most common in wall-mounted boilers are:

- steel heat exchangers are the cheapest to produce, lightweight, and resistant to temperature changes. Installed in models of the budget and often mid-price segment. A significant disadvantage of steel heat exchangers is their susceptibility to corrosion, which is why their service life is on average 12-15 years;

- copper heat exchangers are more expensive, but also more heat-conducting and more resistant to corrosion. The only drawback is the possibility of burning out, but this happens very rarely. They are usually installed in models of the middle and high price segment, the service life is on average 14-17 years;

- aluminum heat exchangers are a not so common option, used in models of the highest and, rarely, middle price segments. Its properties are similar to copper; its lower weight makes it possible to make the walls of the heat exchanger thicker, which eliminates the possibility of burnout. There is also an opinion that it is even less susceptible to corrosion, however, the practice of using aluminum heat exchangers is quite recent; we can only say that in almost all cases, aluminum heat exchangers have been serving for more than 15 years.

The secondary heat exchanger serves to supply hot water. It is made of stainless steel. Such heat exchangers have two circuits. Heating passes one at a time, which heats the second circuit with sanitary water. Due to the fact that there is no direct contact with fire, such heat exchangers last longer than the main ones and rarely cause problems.

Combustion chamber design and types of smoke removal

A burner with an open flame heats a heat exchanger through which water flows. But there will be no fire without air, and combustion products should also be gotten rid of. For these purposes, two types of cameras are used: open and closed.

Open combustion chamber and natural draft

This method was used for floor-standing boilers. It is also called atmospheric. In such a combustion chamber there are holes through which air enters the boiler from the room. Combustion products fly away into the chimney naturally. Among the advantages, one can highlight the less noise that the boiler makes. After all, there is no fan here. For the same reason, the price of such equipment is slightly lower. There is also no coaxial chimney.

But the disadvantages are more significant. Firstly, the efficiency of a design with an open combustion chamber is 2-5% lower. Secondly, the chimney itself takes up space, and for many it constantly leaks. Thirdly, the requirements for the premises are much higher. And finally, an open combustion chamber gets dirty much faster, especially if the boiler room is not perfectly clean. It is recommended to clean atmospheric boilers at least every 3 seasons.

Closed combustion chamber and forced draft

I believe that it is much better to install a turbocharged model: this is what boilers with a closed combustion chamber are called. Its device is sealed and has a fan. Although it is installed on the outside of the camera. When the burner starts working, the fan turns on. It discharges combustion waste through a coaxial pipe. Through it, air from the street enters the boiler. Since the chamber is sealed, there are simply no other ways for air to pass through.

Due to the ability to regulate the amount of air supplied for combustion, turbocharged boilers are more efficient. They can be installed in any room, even the smallest. Some owners even hide the boiler in a closet. Although gas services treat this poorly, I am convinced from my own experience that there is nothing wrong with this. The only thing to consider is future servicing; there must be enough space inside the cabinet.

True, there are disadvantages in this case too:

- the turbine creates noise at high speeds;

- the cost of models with a closed camera is on average 3-6 thousand rubles more expensive;

- turbocharged models consume several tens of watts more electricity.

Comparison of boilers with open and closed combustion chambers

Types of gas burners

When the boiler turns on, it opens a valve through which gas enters the burner. It is this that distributes the flame evenly in order to heat the heat exchanger as efficiently as possible. There are 3 types of burners, which differ in the way they regulate the flame intensity:

- Single stage . When the temperature reaches the upper limit, the valve shuts off the gas and the burner goes out. If the temperature drops to the lower limit, the gas valve opens and the burner starts working at full power. This is the cheapest but least effective mechanism.

- Two-stage . At first the burner operates at 100% power. When the temperature reaches a certain value, the power drops to 40%. This is due to the valve, which only covers the flow of gas, and does not close it completely.

- Modulated . They can operate in a wide power range - from 10 to 100%. Everything happens automatically. This ensures the most efficient operation of the boiler. Firstly, less gas is consumed. Secondly, the service life of the heat exchanger increases.

Efficiency

In simple terms, efficiency is a comparison of energy spent and energy released. The higher the efficiency value, the more efficiently the equipment operates. A copper heat exchanger, a closed combustion chamber, a modulating burner, automation and sensors - all this was invented to ensure that the boiler consumes less gas and accumulates more heat. Condensation models have exceeded all expectations in this regard. Their efficiency reaches 116%. For convection boilers, the norm from which to base your choice is considered to be 91-93%.

However, you should also pay attention to efficiency last, having decided on the previous parameters, since a difference of 1, 2 and even 3% will be expressed not in hundreds, but in tens of rubles per month.

Minimum required power

Since everyone’s home is different, you need to select a boiler individually. Of course, you may have high ceilings or good insulation, but I will consider the standard option. Each heating equipment has a thermal power rating. It is usually measured in kilowatts. It is generally accepted that 1 kW of thermal power is required per 10 m². This indicator should be used as a starting point.

For example, if you have a 100 m² house, you need a minimum of 10 kW. But you need to understand that no equipment should operate at full capacity. Therefore, a margin of 20-30% should be taken into account. This means that for 100 m² a 12-13 kW boiler is better suited. But you shouldn’t take too much stock either, unless you plan to expand.

In more unusual cases, if large panoramic windows are used, high ceilings are used, the house is well insulated, and is located in the extreme southern or northern point of the country, correction factors are taken into account that change the final result by 15-30% up or down.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

Additional criteria

In wall-mounted boilers, the fan and circulation pump create noise. And when igniting, you can also hear the burner turning on. Therefore, many models have sound insulation. This is especially important for those users whose boiler is installed in living rooms. But thermal insulation is also present in boilers. For this, asbestos gaskets are usually used inside the combustion chamber.

Some wall-mounted boilers only allow you to regulate the temperature. Other models have a huge number of settings. For example, you can program the boiler so that the temperature is higher during the day and lower at night. Or lower the temperature to 15°C for certain hours, which is beneficial for those whose house is empty while people are at work. You can configure it for days and weeks; this functionality is called a programmer. Of course, the more functions a boiler has, the more expensive it is.

All models can be connected to a room thermostat. It allows you to control the temperature not by heating, but by air. This method saves gas and increases the service life of the equipment, but only if the house is well insulated. In addition, there are various WiFi and GSM modules with which you can control the boiler remotely. And in the event of a malfunction, the owner will immediately receive a notification.

Step-by-step installation of equipment

Before installation, you need to unpack the new boiler and check the completeness of the delivery. The availability of parts is checked according to the operating instructions, which must be included with the device.

If any item is missing, please contact the supplier immediately. One more nuance. The boiler must have an ideal appearance without dents, chips or signs of repairs. If this is not the case, you need to call the sellers.

It is important to make sure that the technical data specified in the technical data sheet of the heating device exactly matches those printed on the device itself. In addition, they must correspond to the numbers specified in the operating instructions for the device.

Immediately before starting installation, you need to flush the boiler pipes, which may contain various debris that got inside during the manufacture of the device and its transportation.

Installing a gas boiler involves connecting heating pipes, water supply and gas mains, as well as installing a chimney

It is also advisable to flush the heating system lines. After the preparation is completed, you can begin installation.

The specifics and procedure for its implementation are determined by the characteristics of the equipment: the number of circuits involved and the type of combustion chamber.

Most often, double-circuit appliances with a closed firebox are installed in houses. Let's take a closer look at the installation of just such a modification.

Stage #1 - preparing the wall mount

To secure gas boilers, a special bracket is used, which should be included in the delivery of the device. Reliable fasteners are used for mounting it on the wall. They should be selected according to the material from which the wall is made.

It is quite possible that those that the manufacturer packaged with the heating device will not be suitable. Then you will need to choose and purchase others.

The purpose of the bracket is to support the weight of the boiler and additional equipment, as well as to provide it with an even, clearly aligned position without distortion.

To accurately mark the wall, you can use a paper stencil, which usually comes with the boiler. With its help, you can easily mark holes for fasteners.

Once this is done, the bracket is secured in place and the boiler is hung onto it.

Heating pipes are connected to the corresponding pipes of the gas equipment. You can determine their location from a photograph.

Stage #2 - connecting the heating system pipes

Depending on the type of heating system, and it can be single-pipe or two-pipe, the number of pipes connected to the boiler may vary. In any case, we start by removing the plugs from the device’s pipes.

To protect the boiler from the ingress of dirt particles from the heating line, it is recommended to install a mesh filter at the return inlet.

If the water in the system is hard or in other respects does not meet the requirements stated by the heating device manufacturer, you should take care of installing additional treatment equipment.

These could be, for example, polyphosphate dispensers. If this is not done, the device will quickly break down. All connections must be made in compliance with all rules and regulations.

Sealing is required. For this purpose, special sealants are used: traditional paint or tow, or modern thread sealants. In addition, experts recommend the mandatory installation of shut-off valves for supply and return.

This is necessary to facilitate repair of the boiler if it fails. In addition, the fittings will help prevent possible airing of the radiators.

A water filter is an element that must be installed when connecting a gas boiler to a water circuit

Stage #3 - connection to the water circuit

This work is almost the same as connecting heating pipes. The main difference is the taps used and the diameter of the pipes.

The cold water supply must be equipped with a filter, which will eliminate the possibility of contaminant particles entering the heating device. Otherwise the equipment will be damaged.

The taps used to isolate the boiler from the water supply must have detachable connections.

Such models are also called “American”. They significantly simplify installation, and in case of unforeseen situations, they make it possible to quickly replace a worn-out faucet.

It must be remembered that the pipes supplying cold water are located on the heating device on the left side relative to the center, and those supplying hot water are located on the right.

Stage #4 - connection to the gas main

This part of the work should only be carried out by a qualified specialist, since the cost of an error can be very high. In any case, upon completion of the connection, its correctness must be checked by a representative of the gas service. He will also conduct the first start-up of the equipment.

All operations when carrying out work independently must be performed with the utmost care. They start by connecting the branch of the gas main with the corresponding pipe on the boiler.

When connecting the boiler to the gas main, you can only use tow to seal the threaded connection, otherwise it will not be possible to achieve the required tightness

A special filter must be installed on the tap that cuts off the gas supply from the main line. Experts strongly recommend not to skimp on this detail.

A cheap, low-quality filter will not work for long, which can cause the gas boiler to fail. When arranging a connection, special attention should be paid to its sealing.

You must understand that the weight of gas is much less than air, and if the connection is not tight enough, it will leak out of the pipeline. The consequences can be the most dire. Therefore, careful sealing is mandatory.

The main materials for sealing a threaded connection are paint and tow; the use of sealants such as fum tape is unacceptable.

A special flexible connection is installed after the filtration element. You need to know that using rubber hoses for its installation is strictly prohibited.

This is due to the fact that over time, the material from which the part is made dries out and becomes covered with cracks through which gas begins to leak. Therefore, the best choice for arranging such a connection is a corrugated hose.

A corrugated hose is a good choice for connecting the device to the gas main. It is quite strong, durable and does not collapse under the influence of gas

For its manufacture, high-quality durable stainless steel is used. This is a very strong and durable material, particularly resistant to high humidity and the adverse effects of gas.

The hose is secured to the heating device pipe using a union nut. In this case, a paranitic gasket must be used, which provides the necessary sealing of the connection.

Stage #5 - connecting to the electrical network

This operation is only necessary for appliances with a closed firebox that require electricity. It powers the fan that removes combustion products and the automation that controls the system.

Typically a standard three-wire connection diagram is used. Experts recommend connecting the boiler to the network only through a stabilizer, which will make it possible to avoid power surges and thereby extend the life of the boiler.

If you live in an area where there are frequent power outages, then it is additionally advisable to purchase an uninterruptible power supply - this will protect your equipment from sudden power surges

Stage #6 - arrangement of the chimney outlet

The easiest way is to connect a heating device with a closed firebox to the chimney. For them, special coaxial pipes are used. In apartment buildings, the boiler must be connected to the collective chimney.

In individual buildings, a coaxial type chimney is led out to the street through a wall. The height of the pipe suspension in this case is not particularly important, since the necessary draft is created by the built-in fan.

Appliances with an open firebox must be connected to an individual chimney. The boiler is connected to it by a pipe of the required cross-section.

The material for its manufacture is selected so that the part is resistant to combustion products, high temperature and mechanical wear.

You can check the tightness of the gas pipe connections using a soap solution. A gas leak will manifest itself as bubbles

Before starting work, you need to make sure that there are no soot residues, installation debris, etc. in the chimney. When installing a chimney pipe, it should be positioned with a slight slope towards the gas boiler.

A vertical section of pipe is installed at the outlet of the device; its length before turning must be equal to at least two pipe diameters. The total length of the connection section to the chimney should be minimal.

Stage #7 - preparation for the first launch

Before the test run, the heating system is filled with water. The liquid is pumped until a pressure of 2 atmospheres is reached. Pumping water is carried out as slowly as possible in order to remove the maximum amount of air collected inside.

In addition, the system is checked for leaks. All leaking connections must be sealed immediately.

To identify insufficiently tight connections on the gas main, you need to dilute a soap solution and lubricate all connections with it. Then watch.

Air bubbles will appear in poor quality areas. Any faults found should be corrected and re-checked. The first start-up of the equipment should be carried out only in the presence of a gas service representative.

The best known manufacturers and models: characteristics and prices

Now let's look at specific models so that you understand the difference between them. Still, the characteristics differ not only between specific models, but also between different companies. These are the most popular boilers in Russia.

Single-circuit

Let's start with boilers that are designed exclusively for heating.

BAXI ECO Four 1.24

Reliable fourth generation Italian boiler with a closed combustion chamber. The wide LCD display makes it easy to monitor and adjust the temperature. They do this using two modes. The first one is suitable for radiators. You can select a range from 30 to 80 degrees. The second mode involves the use of heated floors. The adjustable range is from 30 to 45 degrees. Safe operation is ensured by the most modern sensors. There is protection against freezing, pump pump blocking and a three-way valve.

Another feature is the modulating burner, which allows you to minimize noise when turned on. The boiler reaches the last 5 degrees of the set temperature at the minimum flame. Gas consumption at an efficiency of 91.2% is 2.78 m³. This model perfectly combines efficiency and European quality. But many owners say that the boiler is afraid of voltage surges, so it is better to install a stabilizer. Otherwise, this is a problem-free, most popular and widespread gas wall system in Russia.

Protherm Panther 25 KTO

The Protherm company produces its equipment in Slovakia and is part of the famous German corporation Vaillant Group. The model has gained quite significant popularity due to its efficiency and reliability: efficiency reaches 92.8%, closed combustion chamber, copper heat exchanger and pipes. Convenient control, high-quality spare parts, protection against freezing, overheating and pump blocking.

If you buy a boiler from the same company, you will get a single compact device. The boiler can be installed directly under the boiler, and all communications can be hidden in a special casing.

The boiler perfectly heats two-story buildings. You don't even have to install an additional pump. The owners themselves say this. Modulating burner and pneumatic gas valve ensure low noise levels. Excellent build quality. But the price is higher than similar models from other manufacturers.

Viessmann Vitopend 100-W A1HB 24 kW

A turbocharged model from a German manufacturer, which is considered the standard of quality. It is distinguished by one of the lowest practical gas consumption indicators in the price segment (although the maximum consumption is not a record low - 2.77 m3/hour). It is also known for its almost silent operation (double noise insulation), modulating burner, and a huge list of safety systems.

Modern automation allows you not only to regulate the temperature, but also to program the operation of the boiler for a week in advance - a rather rare function for this price category. The controls are simple, so don't worry about not understanding the functionality. And if you want to install a backup boiler, then the Viessmann Vitopend 100-W A1HB002 is best suited. After all, it has the ability to cascade connect two boilers. To obtain hot water, you can connect an indirect heating boiler.

Among the shortcomings, one can note only vulnerability to voltage surges (the protective mechanism is designed for 170-253 V, which is not always enough). Please note that today there are three generations of the model: A1HB001, A1HB002 and A1HB003.

<

The best German gas boilers The most efficient, reliable and functional models on the market

BAXI Duo-tec Compact 1.24

One of the best representatives of condensing boilers, repeatedly taking first place in authoritative ratings, is considered one of the “smartest” representatives of the budget segment. For example, Think technology allows it not only to adapt to different operating conditions (weather, gas composition, chimney parameters), but also to control different temperature zones.

The maximum gas consumption is only 2.61 m³ per hour, the efficiency is 105.7%. The heat exchanger is made of stainless steel, so it is not afraid of harsh operating conditions. A filter is installed at the cold water inlet. The model is single-circuit, but the three-way valve is already built-in. Despite the fact that the boiler is a condensing boiler, its dimensions are not particularly large. Yes and weight too. According to reviews from owners and installation experience, the boilers have been operating without problems for more than 7 years and are known for their high reliability.

When compared with the condensing boiler market, the model cannot be called the most efficient, but for its extremely budget price it is one of the best offers in terms of technical parameters.

Rinnai BR-UE30

Technological and smart Japanese boiler. A modulating burner with turbocharging, a copper heat exchanger and pipes, the boiler has very compact dimensions characteristic of Japanese models. The maximum gas consumption is only 2.87 m³ per hour, which is very significant for a power of 29 kW. For comparison, European boilers of 24 kW usually have approximately the same consumption. The set includes a remote control that can be hung separately in any convenient place.

It is possible to connect an indirect heating boiler, as well as disinfect it using the Anti-Legionella function. Switching to hot water will occur automatically using a built-in three-way valve. Rubber seals are installed at the joints, an anti-vibration insert is installed on the rear wall, and the front cover is additionally thickened. All this allows you to reduce the noise from the operation of the boiler to a minimum. There are many advantages, but the disadvantages include the high price of the boiler itself and spare parts (the need for which, of course, is rare in practice).

Review of Rinnai gas boilers The closest analogue of standard German quality

Dual-circuit

Most buyers still prefer double-circuit boilers, since they do not need to spend money on an additional water heater.

BAXI ECO-4s 24F

One of the most popular double-circuit boilers on the Russian market. Inexpensive, but very reliable. Closed combustion chamber, primary heat exchanger - copper, efficiency 92.9%. The maximum gas consumption is only 2.73 m³ per hour. The boiler is equipped with protection systems against freezing, overheating and condensation. At the same time, the boiler is well adapted to domestic conditions: unstable gas or water pressure, often not the cleanest coolant, automation and pump tolerate minor voltage drops.

Owners often note changes in temperature, but this is a problem with almost all instantaneous water heaters. To keep the temperature stable, you need good pressure in the water supply. As for unstable voltage in the electrical network, the boiler can withstand small surges. European assembly leaves no doubt about the quality. A filter is installed at the cold water inlet, which can significantly extend the service life of the heat exchanger and circulation pump. Considering the cost of the boiler, there are simply no disadvantages.

BAXI LUNA-3 240 Fi 25

Another, newer model from the Italian manufacturer BAXI. It differs from the previous one in its convenient control panel, which has a built-in programmer. This allows you to set a separate temperature for each day of the week. Capable of operating in underfloor heating mode. The maximum efficiency is 93%, and the gas consumption is quite acceptable - 2.84 m³ per hour. Long service life and efficient operation are ensured by a copper heat exchanger with anti-corrosion coating.

Many users do not understand the difference between the ECO and LUNA series. Everything is simple here. LUNA boilers have higher quality components, which is why they cost several thousand rubles more. It's like comparing a cheap smartphone and Apple. Both the quality and functions are better. For example, the boiler produces up to 14 liters of water per minute, since the secondary heat exchanger is quite voluminous. But LUNA is also a little larger in size. If finances and space allow, I would still recommend choosing this model.

Vaillant turboFIT VUW 242/5-2

German quality, reliability, ease of maintenance and operation - these are the associations that arise in my mind when I hear about the Vaillant company. It seems to me that this is one of the best gas wall-mounted boilers for heating a private home. Firstly, high efficiency, which reaches 93.5%. Secondly, low gas consumption compared to similar models. Only 2.66 m³ per hour. Thirdly, the company has already managed to prove that wall-mounted boilers can operate for 5, 7, 10 or more years without breakdowns. And numerous reviews confirm this.

Separate heat exchangers are installed, so there is no need to worry that the boiler will quickly clog. The main one is made of copper. The secondary heat exchanger, as is customary, is made of steel. A high-quality hydraulic unit, to which the company pays special attention. All pipes are copper, not rubber, connections are threaded, excellent build quality. All necessary protection systems are present. The turbine, servo drive and ignition operate almost silently.

I wouldn’t say that the boiler is budget, but it’s not too expensive either. Of course, when compared with European analogues. The company cares about its customers, so the turboFIT VUW 242/5-2 takes into account the comments of the owners of previous models. Even the price has become lower. Today they are excellent for Russian conditions. The boiler is equipped with a pump from the famous and reliable Grundfos company, as well as Sit automation. The disadvantages include expensive spare parts. Also, do not forget that it is advisable to connect the boiler through a voltage stabilizer.

Minimum characteristics of double-circuit boilers

When choosing a boiler for your home, you need to consider the following parameters:

- Power. Shows how much heat is being produced.

- Efficiency Efficiency of using heat from the flame. Characterizes how economical the boiler is.

- Temperature of the gases released.

- Where heat is conducted. Water or antifreeze.

- Maximum pressure for work.

- Outlet temperature maximum

- Hot water capacity. How much water heats up in one minute. Depends on the desired water temperature.

- Maximum amount of gas required.

- Gas supply. Characterizes stability of operation during sudden jumps.

- Features of electricity consumption: voltage and frequency.

- The power that is expended.

- Dimensions, including weight, fastening features and gas exhaust dimensions. These features do not indicate whether the boiler is good or bad. They must correspond to the purposes of operation. For example, boilers with different capacities are suitable for heating rooms of different sizes.

But in reality, you will get tired of paying attention to all these characteristics. Just remember that wall-mounted boilers are basically all the same in these characteristics. They differ simply in small details. With floor-mounted ones, of course, more attention is required.

Prices: summary table

| Model | power, kWt | Number of circuits | Efficiency, % | Gas consumption, m³/hour | Cost, rub. |

| BAXI ECO Four 1.24 | 24 | 1 | 91,2 | 2,78 | 40 000-45 000 |

| Protherm Panther 25 KTO | 25 | 1 | 92,8 | 2,8 | 59 000-63 000 |

| Viessmann Vitopend 100-W A1HB | 24 | 1 | 91 | 2,77 | 51 600-55 000 |

| BAXI Duo-tec Compact 1.24 | 24 | 1 | 105,7 | 2,61 | 59 000-65 000 |

| Rinnai BR-UE30 | 29,1 | 1 | 92,5 | 2,87 | 59 900-67 000 |

| BAXI ECO-4s 24F | 24 | 2 | 92,9 | 2,73 | 46 500-47 200 |

| BAXI LUNA-3 240 Fi 25 | 25 | 2 | 92,9 | 2,84 | 62 000-78 000 |

| Vaillant turboFIT VUW 242/5-2 | 23,7 | 2 | 93,5 | 2,66 | 45 600-53 000 |

Conclusion

Wall-mounted gas boilers are economical, convenient and practical heating equipment. They can not only heat the room, but also provide hot water. Choosing is not so difficult if you understand all the characteristics. But you shouldn’t buy the first one you come across, because the comfort and coziness in your home depends on the boiler.

Gas boilersWall-mounted boilers

Boiler power calculation

Like any boiler, a double-circuit boiler must be selected taking into account the required power. You need to select it wisely based on the heat loss of your home, which you can’t always calculate on your own. The roughest approach is to provide 1 kW of power per 10 square meters of your home.

But it's another matter if you are going to use the second circuit on an ongoing basis. Based on the boiler power, the amount of hot water released per minute depends. Everything is simpler here. You need a minimum of 24 kW of power to be sure that you will have enough hot water production. Typically, a boiler of this power is capable of releasing 12-14 liters of water per minute. This volume is just enough to take a shower or completely wash the dishes.

Types by camera type

Depending on the design of the combustion chambers, there are 2 types of boilers: open and closed.

Open

In this case, air intake to ensure the combustion process occurs from the room where the boiler is located. Such devices are also called atmospheric. Exhaust gases are discharged through the chimney.

To take in the required amount of air and ensure trouble-free operation of the boiler, a ventilation pipe is usually installed, located in the same casing as the chimney. The height of the structure must be higher than the cut level of the roof of the house. If ventilation is poor, there may be a lack of air in the room, so the pipes need to be cleaned regularly.

Closed

Gas boilers with a closed combustion chamber are also called turbocharged. The air required for combustion is taken from the street. Exhaust gases are discharged through a coaxial pipe.

This type of chimney is a structure of two pipes inserted into one another. Exhaust gases flow out through a pipe of smaller diameter, and fresh air flows through the gap between them.

Both processes occur using a fan, which is why such a system is called a supply system. Outside air enters the chamber where the gas is burned, already heated, which contributes to a higher efficiency of the boiler. The coaxial pipe simply comes out of the wall to the outside.

The use of boilers with a closed firebox significantly reduces the requirements for ventilation of the room where gas equipment is installed. One of the disadvantages of such units is the noise that the supply fan makes during operation.

The equipment is also more expensive compared to open models. But this disadvantage is compensated by the absence of the need to install chimney and ventilation pipes.

Number of heating elements in the system

Typically, the homeowner begins planning the heating system in the house by choosing the type of heating (radiator, floor) and the number of heating circuits themselves.

The main offer of mounted boilers on the market are low-temperature boilers with a simple design and automatic control for maintaining a constant temperature.

Their main application should be only standard installations with one circuit on radiators. In the case of a system with a large number of circuits (for example, additional heated floors), this type of boiler is not worth buying.

Typically, automatic weather control (specified for underfloor heating circuits) is already available in a series of condensing boilers, the optimal temperature of the heating water contributes to the achievement of high efficiency of these boilers.

- Dividing the heating system into separate circuits (for example, separating floor heating and radiators), among other things, increases the comfort of use. allowing separate control of temperature and heating time.

- On the other hand, mounted boilers that operate (as opposed to standing ones) as flow-through boilers require careful selection of the hydraulic system, and in the case of several circuits, additional circulation pumps, mixing valves and, often, a hydraulic coupling and automation are installed that interact with two or more circuits .

Specially designed boilers with increased water capacity are also available, operating similarly to floor-standing boilers. These types of boilers can operate without maximum flow limitation, even with three circulation pumps connected directly, without the use of a hydraulic coupling. They are therefore an ideal solution for multi-circuit heating systems.