Popular gas equipment - heaters, water heaters, gas stoves and boilers - have been produced in St. Petersburg for more than 50 years. After the creation of the Baltic Gas Company concern, the enterprise became part of it, maintaining its production capacity and specialization. Current name. It is rapidly developing and produces high-tech boilers equipped with modern automation. For example, a popular and sought-after series is Neva Lux gas boilers, which is presented in two categories.

e1

Error e1.

This malfunction indicates low fluid pressure in the heating circuit. The reasons may be as follows:

- The heating circuit has become airy or the pressure has dropped to its minimum point. Increase the fluid pressure in the system, remove air from the heating circuit.

- The bypass valve is installed incorrectly or is faulty; to check, follow these steps: set the boiler to heating mode, then close the shut-off valve to the heating circuit.

The bypass should redirect the liquid not into the heating circuit, but pass it through the bypass line (at the same time it will heat up). And, if it is faulty, replace it with a new one, installing all the taps in the position in which they were before the check. - Pump failure. It is necessary to remove it from the device, disassemble it, wash it, and clean it of accumulated deposits. If this does not work, replace it.

- There is a breakdown in the electrical circuit of the pressure sensor.

Using a multimeter, test the circuit for an open; if found, repair it. DHW sensor Visually check all contacts and connectors. If this does not give the expected result, replace it with a working device. Occurs often in Neva Lux 2073. - A slow-moving rod or sticking of the measuring device rod in the heating circuit, the cause could be a failure of the membrane on the flow sensor.

To begin, remove this sensor from the device, turn the boiler (pump) on and off, in a similar way you can remove the boiled rod. If this does not work, check the condition of the membrane; if it is worn or deformed, replace it. - There is a malfunction in the flow sensor, or the integrity of the connecting wire is broken. Perform an electrical circuit check and also check the connections of the controller board connectors. If the problem persists, replace the flow sensor. Typical for the Neva Lux 2083 model.

- Failure in the electric motor of the three-way valve. Repair is not possible, complete replacement is necessary.

User Guide...

Page 5

- Image

- Text

User Guide

5

First aid after the release of the victim depends on his condition. If he's in

consciousness, then you need to provide him with complete rest for a while, not allowing him to move until the doctor arrives.

If the victim is breathing very rarely and spasmodically, but a pulse is palpable, you should immediately

perform artificial respiration using the “mouth to mouth” or “mouth to nose” method.

If there is no breathing, immediately take the victim to a warm room with fresh

air and perform artificial respiration until the doctor arrives.

The lineup

The manufacturer's product line includes several wall-mounted Neva Lux models with compact dimensions, the power of which varies from 12.7 to 30 kW.

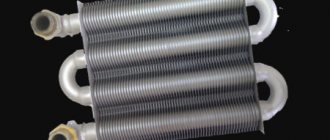

The model is initially intended for use in apartments and small houses with an area of up to 110 square meters. m. This unit has two circuits and a closed chamber, with a power of 12.7 kW. Equipped with a bithermal heat exchanger and an electronic ignition system. Capable of heating up to 9 l/min when using DHW. The use of a common heat exchanger led to a reduction in cost while maintaining functions. Features low gas consumption.

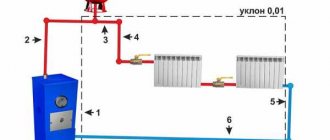

Heater diagram Neva Lux 7218

- The power of this double-circuit heater with one bithermic heat exchanger is 18 kW. Designed for living space up to 180 sq. m. It features a more powerful pump, as a result of which the heating rate of hot water reaches 14 liters per minute.

- A double-circuit boiler with one bithermal heat exchanger is designed for rooms with a heating area of up to 240 sq. m. m.

- It differs from the above model by connecting a remote control, an outdoor temperature thermostat and a personal computer. There are two heat exchangers, one of which is copper and the other is made of steel plates. Designed for 240 square meters of area. Runs on liquefied gas. Equipped with a closed chamber, cooled by water and a forced smoke removal system.

- This double-circuit model with an open chamber is intended for use in heating systems of apartments and houses with a total area of up to 300 sq. m. m. Equipped with one bithermic heat exchanger.

- Neva Lux 8624. This model, with a power of 24 kW, is equipped with two heat exchangers and an open combustion chamber. The Italian electronic board is adapted to our conditions.

As you can see, along with proven budget models, the manufacturer supplies their updated versions at a higher price. The firebox of the latter (the designation begins with an eight) was water-cooled. The heat exchanger for heating water is made from tubes of increased diameter, which slows down the appearance of scale.

The external cladding is made of metal-plastic. Three layers - primer, galvanization and enamel - reliably protect the boiler from corrosion. They feature improved control panels.

Neva service centers

Especially for your convenience, we have collected all the necessary information related to the service of tools and equipment. Here you will find the addresses of licensed service centers located in your city (the locality is determined automatically or by your choice).

Select your city: ArkhangelskBalashovBarnaulBlagoveshchenskVeliky NovgorodVelskVladimirVoskresenskVyaznikiGagarinGus-KhrustalnyDmitrovZhukovkaIvanovoKalugaKasimovKineshmaKovrovKolomnaKorolyovKostromaKubinkaLobnyaLyudinovoMalakhovkaMaloyaroslavetsMoscowMuromNovomoskovskObninskPavlovsky PosadPo chepPuchezhRzhevRostovRybinskRybnoyeRyazanSasovoSerpukhovSkopinSmolenskSobinkaTorzhokTulaTutaevUglichElektrostalYaroslavlYasnogorsk

e2

Error e2. Ignition failed, check the following:

- Open the shut-off valve on the gas pipeline; if you are using liquefied gas, the cylinder may be empty. There is a breakdown in the gas line, contact the gas service.

- The spark plug is broken, replace it with a new one.

- There is a fault in the electrical circuit of the spark plug. Using a multimeter, test the contacts for an open or short circuit.

- There is insufficient distance between the spark plug and the burner section, set the gap to 5 mm.

- Dust accumulation on the spark plug, clean it from deposits and degrease it.

- Disturbance in the electrical ionization circuit. To check, do the following: while the device is operating, remove the wire from the spark plug. The boiler operation should stop and 01 will appear on the monitor.

Then connect the wire back and hold down the K6 and restart keys, after which the device will turn on. The flame is detected by the principle of monitoring the ionization current. Its measurements are carried out using a microammeter, alternately connecting ionization candles into the circuit.The optimal value is from 3 to 5 microamps. A possible reason for the decrease is its leakage or insufficient connection, incorrect connection (swap the spark plug and ionization plug).

- Insufficient distance in the ionization candle and separation by the burner. Set it in the 3mm range. Ionization candles for boilers Neva Lux

- The ignition transformer has failed. Replace it with a new one.

- Damage to the electrical circuit in the ignition transformer. Check it for breaks and check the integrity of the connectors.

- Burner block clogged. Clean it.

- There is a malfunction in the electrical circuit of the fuel supply regulator. Check the circuit with a multimeter and test the controller board. Repair if you find a break; if the board is faulty, purchase a new one.

- The electronic board is broken. Needs to be replaced.

Inspection, Boiler care, Operations performed during maintenance

Storage rules

- Image

- Text

User Guide

10

4.1. Inspection

Before each start-up of the boiler, and in the case of boiler operation during the heating season, once a day,

necessary:

make sure there are no flammable objects near the boiler and chimneys; make sure there is no smell of gas in the room (if a smell of gas is detected in the room

contact the gas service);

make sure there are no water leaks in the heating system, if leaks are detected

contact a specialized service organization;

carry out an external inspection of chimneys for damage. If found

damage to chimneys, contact a specialized service organization.

4.2. Boiler care

regularly, especially before the start of the heating season, clean the system water filters

heating;

periodically remove air from the heating system (see clause 10.1, page 15); add water to the heating system to the required pressure (see clause 10.1, page 15); the boiler should be kept clean, for which it is necessary to regularly remove dust from the top

surface of the boiler, and also wipe the lining first with a damp and then with a dry cloth. In case of significant contamination, first wipe the lining with a wet cloth moistened with a neutral detergent, and then with a dry cloth. It is prohibited to use strong detergents containing abrasive particles, gasoline or other organic solvents to clean the surface of the cladding and plastic parts.

ATTENTION! do not change the water in the heating system unnecessarily, this will allow

reduce scale formation in the heat exchanger. Before the upcoming long-term downtime of the boiler in winter, it is necessary to drain the water from the heating system to avoid damage to the pipelines when it freezes.

ATTENTION! All boiler maintenance operations should be performed only after it has been

disconnecting from the network and cooling down.

4.3. Operations performed during maintenance

During maintenance the following work is performed:

1) cleaning the burner block (burner); 2) cleaning the heat exchanger from soot and cleaning (rinsing) the heat exchanger pipes from scale (if

necessary);

3) replacement of seals in gas and water systems; 4) checking the tightness of the gas and water systems of the boiler; 5) lubrication of moving joints (if necessary), it is recommended to use thick

silicone-based lubricants;

6) checking safety devices, they must work without failures; 7) the combustion product exhaust system must be checked for leaks; Checking the heating system for blockages.

7) the combustion product exhaust system must be checked for leaks; Checking the heating system for blockages.

ATTENTION! Maintenance operations associated with disassembling it

gas or water communications must be carried out only after the boiler has been completely turned off (the taps on the water and gas lines in front of the boiler must be closed, the boiler must be disconnected from the electrical network).

5. STORAGE RULES

the boiler must be stored and transported in packaging only in the position indicated on

manipulation signs.

the boiler must be stored in a closed room that guarantees protection from atmospheric and

other harmful effects at air temperatures from −50 ºС to +40 ºС and relative humidity not exceeding 98%.

when storing the boiler for more than 12 months, it is necessary to carry out preservation according to

GOST 9.014−78.

the openings of the inlet and outlet pipes must be closed with plugs or plugs.

Comments

Select → I found the instructions for my water heater here! #manualza

- Click →

I'm not stupid, I strictly follow the instructions.

Manualza!manualza.ru

Still not with us?

Structural components

From a technical point of view, the Neva wall-mounted gas boiler is impeccable. It implements all the technical advances in heating engineering, as well as developments in the field of electronic control of heating circuits.

Structurally, the Neva double-circuit gas boiler consists of the following interconnected systems:

- a control system consisting of an electronic unit that controls the operation of the boiler and ensures safety, and an electrical harness that connects sensors, an electronic board and other devices into a single system;

- hydraulic system, including a pump for forced circulation, an automatic valve for removing air, a heat exchanger for heating the coolant, a secondary heat exchanger for the hot water system;

- the gas system includes a burner unit, which ensures uniform and complete combustion of the gas-air mixture in the combustion chamber, and an ignition transformer to create a spark on the spark plug, which automatically ignites the gas mixture;

- smoke removal system, which includes a fan for forced removal of combustion products and a chimney;

- a setup and adjustment system consisting of a gas supply regulator to the burner block, a heating circuit temperature sensor, a DHW temperature sensor, and a DHW circuit flow sensor.

. CONTENTS OF DELIVERY …………………………………..

Page 2

- Image

- Text

2

21.

CONTENTS OF DELIVERY ……………………………………………………………………………………………………………………………. .31

22.

NOTE ABOUT BOILER INSTALLATION AND MAINTENANCE …………………… 32

Appendix I………………………………………………………………………………………………………………………………………… …………………………….. 35

Appendix II…………………………………………………………………………………………………………………………………… ……………………………. 38

Appendix III ……………………………………………………………………………………………………………………………………… ………………………….. 39

Model range of boilers Neva Lux

The luxury series, well known to consumers, is divided into two categories:

- For heating an apartment or house, a wall-mounted single-circuit Neva boiler is best suited. Instead of a DHW circuit, you can install an indirect heating boiler. The modulation burner installed in such boilers, thanks to automatically changing combustion intensity, makes it possible to achieve high efficiency of the equipment. The 8618 single-circuit gas boiler attracts buyers with its low cost and simplicity of design, as well as the absence of complex energy-dependent automation.

- The double-circuit boiler 7218 luxury series from the Neva company has extremely positive reviews due to its practicality and efficiency. Modern automation allows you to accurately monitor the temperature of the coolant and water in the DHW circuit. In addition, some models provide additional outlets for the underfloor heating system. The installed automation is capable of controlling each circuit separately. The most popular models are 7218 and 8224.

Advice! You can install a separate thermostat that will monitor the temperature in the room and transmit a signal to the gas boiler to turn on only when the temperature drops. This feature allows you to significantly reduce heating costs.

Now let's take a closer look at which models of Neva boilers are most popular among consumers.

Model Neva Lux 7218

For heating a living space up to 180 m2, the Neva Lux 7218 unit is best suited. The hot water circuit is designed to increase comfort and provides residents with hot water. This dual-circuit device is equipped with a bithermal heat exchanger, which reduces the cost of the 7218 boiler and maintains all user functions at a high level.

The heating gas apparatus Neva 7218 has the following technical characteristics and design features:

- A closed combustion chamber is used.

- The operating temperature range in the heating and DHW circuit of device 7218 is from 30 to 85 °C.

- Additional settings will help convert the unit to operation on liquefied gas.

- The efficiency of the model 7218 is 90%.

- The electronic safety unit continuously monitors the flame. This happens both during heating and DHW circuit operation.

- The ergonomic boiler Neva 7218 Lux goes on sale with European components, which has positive customer reviews.

Model Neva Lux 8224

This wall-mounted device Neva Lux 8224 has the following design features:

- The increased power allows the use of double-circuit boilers 8224 for heating an area of up to 250 m².

- The unique combustion chamber is water-cooled, which significantly increases the service life of all parts.

- Microprocessor software installed in 8224 boilers ensures that the set temperature is maintained. The error is less than 1 degree.

- In addition, the gas apparatus 8224 is equipped with two heat exchangers: a copper one for the heating circuit and a stainless steel plate one for DHW.

Also, equipment management in the 8224 model has reached a new level: the ability to remotely control and connect a PC has been added for diagnostics and more precise settings.

Advice! The Neva 8224 Lux units have a digital display; all current information from the automatic self-diagnosis system is displayed on it.

All these innovations have received praise from consumers.

Model Neva Lux 8618

The Neva Lux model 8618 is a single-circuit gas boiler. Compared to floor-standing units of the same power, the Neva 8618 model has a higher efficiency (up to 90%) and is characterized by reduced gas consumption.

Wall-mounted boilers Neva Lux 8618 have the following features:

- Compact dimensions allow the unit to be installed even in small rooms without cluttering up the space.

- The reliability and complete adaptation to domestic operating conditions of the 8618 model is confirmed by numerous positive reviews about this device.

- The circulation pump built into the gas boiler 8618 from the Neva company allows installation in already installed heating systems.

In addition, such wall-mounted boilers have the ability to connect:

- Indirect heating boiler.

- Forced smoke exhaust fan.

- A room thermostat, which makes the unit even more economical.

Advice! Another feature: gas boilers of this model are capable of operating at a pressure drop of up to 0.3 bar in the gas main.

https://youtube.com/watch?v=9S2J_tGLzK4

. SECURITY MEASURES …………………………………..

NEVALUX water heaters

- Image

- Text

1

CONTENT

SECURITY MEASURES ……………………………………………………………………………………………………………………………… … 4

TECHNICAL DESCRIPTION …………………………………………………………………………………………………………………………. 6

2.1.

Purpose of the boiler…………………………………………………………………………………………………………………………………….. 6

2.2.

Technical specifications ………………………………………………………………………………………………………… 6

2.3.

Overall and connection dimensions………………………………………………………………………………… 7

USING THE BOILER ……………………………………………………………………………………………………………………………………… 7

3.1.

Turning on the boiler…………………………………………………………………………………………………………………….. 8

3.2.

Adjusting the coolant temperature………………………………………………………………………………………… 8

3.3.

Turning off the boiler……………………………………………………………………………………………………………………………………….. 9

BOILER MAINTENANCE ……………………………………………………………………………………………………………………. . 9

4.1.

Inspection…………………………………………………………………………………………………………………………………………… …….. 10

4.2.

Boiler care……………………………………………………………………………………………………………………………………… . 10

4.3.

Operations performed during maintenance ……………………………………………………………. 10

STORAGE RULES ……………………………………………………………………………………………………………………………………… … 10

GENERAL REQUIREMENTS ……………………………………………………………………………………………………………………………… … eleven

OPERATIONS BEFORE INSTALLATION …………………………………………………………………………………………………………………….. 11

7.1.

Heating system ……………………………………………………………………………………………………………………………………… 11

BOILER INSTALLATION ……………………………………………………………………………………………………………………………………… ………… 12

8.1.

Mounting the boiler on the wall……………………………………………………………………………………………………………. 12

8.2.

Installation of pipelines……………………………………………………………………………………………………………. 12

8.3.

Connecting the boiler to a liquefied gas cylinder ……………………………………………………………………. 13

8.4.

Connecting the boiler to the electrical network ……………………………………………………………………………………………………………. 13

CHIMNEY INSTALLATION ……………………………………………………………………………………………………………………………………………… .. 14

9.1.

Connecting the boiler to the chimney …………………………………………………………………………………………………………….. 14

10.

PUTTING THE BOILER INTO OPERATION (FIRST START-UP) ………………………………………………………………………………… 15

10.1.

Filling the heating circuit with water and pre-start checks …………………………………………………………….. 15

10.2.

Post-start inspection of the boiler……………………………………………………………………………………………………………. 17

10.3.

Additional features (options) ……………………………………………………………………………………….. 18

11.

Conversion of the boiler to a different type and pressure of gas………………………………………………………………………………………… 18

12.

DEVICE and control of the boiler operation…………………………………………………………………………………………… 19

12.1.

Boiler structure ………………………………………………………………………………………………………………… 19

12.2.

Purpose of the boiler components. ……………………………………………………………………………………………. 20

12.3.

Boiler operation……………………………………………………………………………………………………………………………………………… .. 20

13.

Troubleshooting………………………………………………………………………………………………………………. 22

14.

Delivery of the boiler to the consumer ……………………………………………………………………………………………………………………………………… …. 23

15.

Maintenance and operation check……………………………………………………………………………………………………………. 24

15.1.

Maintenance …………………………………………………………………………………………………………. 24

15.2.

Checking the operation of the boiler…………………………………………………………………………………………………………….. 25

16.

PROCEDURE OF OPERATIONS WHEN REPAIRING THE BOILER AND REPLACING COMPONENT PARTS……………………………………………………………. 26

16.1.

Removing the cladding………………………………………………………………………………………………………………………………………. 26

16.2.

Replacing the burner……………………………………………………………………………………………………………………………………… 26

16.3.

Replacing the heat exchanger……………………………………………………………………………………………………………. 26

16.4.

Replacement of the water-gas unit ……………………………………………………………………………………………………………. 26

16.5.

Replacing the water unit ………………………………………………………………………………………………………………….. 27

16.6.

Replacing the membrane of the water unit …………………………………………………………………………………………………………….. 27

16.7.

Replacing the water unit rod seal ……………………………………………………………………………………… 27

16.8.

Replacing the water assembly plate ………………………………………………………………………………………………………………… 27

16.9.

Replacing the gas unit…………………………………………………………………………………………………………………… 27

16.10.

Replacing the solenoid valve (magnetic plug) ………………………………………………………………. 27

16.11.

Replacing the thermocouple……………………………………………………………………………………………………………………. 28

16.12.

Replacing the cold water supply pipe to the heat exchanger ………………………………………………………………………………… 28

16.13.

Replacing the hot water outlet pipe from the heat exchanger………………………………………………………………. 28

16.14. Replacing the thermal relay (water overheating sensor) ……………………………………………………………………………….. 28

16.15.

Replacing the thermal relay (traction sensor) ……………………………………………………………………………………………………………. 28

16.16.

Replacing the pump………………………………………………………………………………………………………………………………………… 28

16.17.

Replacing the thermostat………………………………………………………………………………………………………………………………………. 29

16.18.

Replacing the thermomanometer……………………………………………………………………………………………………………. 29

16.19.

Replacing the safety valve………………………………………………………………………………………… 29

16.20.

Replacing the fuse…………………………………………………………………………………………………………….. 29

17.

Disposal ………………………………………………………………………………………………………………………………… …………………. 29

18.

WARRANTY …………………………………………………………………………………………………………………….. 30

19.

CERTIFICATE OF ACCEPTANCE ………………………………………………………………………………………………………………….. 31

20.

CERTIFICATE OF CONVERSION TO ANOTHER TYPE OF GAS………………………………………………………………………………….. 31

Possible faults

The more complex the equipment, the greater the likelihood of it failing. This is especially true for the electronics included in the control system. Despite the fact that Neva Lux heating boilers are considered extremely reliable, some types of malfunctions cannot be avoided. More often for reasons not related to the equipment itself. These include:

- Low gas or water pressure in the system;

- Breakage and attenuation of the flame;

- Mechanical breakdowns.

The built-in self-diagnosis system displays an error code on the display, which is identified by the table on the last page of the instructions. If there is no warranty, you can fix some simple malfunctions yourself, but it is still better to contact the manufacturer’s customer support service or directly to the service center.

Overall and connection dimensions, Using the boiler

Page 7

- Image

- Text

User Guide

7

2.3. Overall and connection dimensions

Overall and connecting dimensions of the boiler are shown in Fig. 1 .

1 – gas regulator handle; 2 – thermostat handle; 3 – thermomanometer; 4 – viewing window; 5 – mounting holes; 6 – gas supply, thread G ½; 7 – heating circuit outlet, G 3/4 thread; 8 – heating circuit inlet, G ¾ thread; 9 – drain plug; 10 – switch button; 11 – piezo ignition button; 12 – safety valve;

Rice. 1. Overall and connection dimensions of the boiler

3. USING THE BOILER

For normal and safe operation of the boiler, the conditions of clauses 2.2.4, 2.2.9 and

2.2.18. Failure to comply with these conditions may lead to incorrect or unstable operation of the boiler or failure. The boiler heating capacity specified in clause 2.2.2 is ensured (with an accuracy of ± 5%) at the nominal gas pressure at the inlet of the operating boiler, specified in the “Acceptance Certificate” section.

Most popular models

Let's look at the models of gas boilers from BaltGaz, which are in stable demand.

Neva Lux 7218

To supply heat to rooms with an area of up to 180 m², the best option is the Neva Lux 7218 boiler. The hot water supply circuit is necessary to increase comfort and provides residents with hot water. This double-circuit boiler includes a bithermic heat exchanger, thanks to which all user functions remain at a high level.

Distinctive features of the device design and technical characteristics are as follows:

- closed combustion chamber;

- the operating temperature in the heating circuit and the hot water supply circuit is between 30°C;

- Thanks to additional settings, you can switch the operation of the equipment to liquefied gas;

- The performance of the Neva Lux 7218 boiler is very high, the efficiency reaches 90%;

- Thanks to the electronic unit, the flame is continuously monitored. This is carried out both during the operation of the heating circuit and the hot water supply circuit;

- All components are European, due to which the unit has a large number of positive user reviews.

Neva Lux 8224

This unit is wall-mounted. Let's look at the design features of the device:

- high power makes it possible to use double-circuit units 8224 to supply heat to rooms with an area of up to 250 m²;

- the unique combustion chamber is water-cooled, which increases the service life of all structural elements several times;

- microprocessor software, which is present in boilers of this model, determines the maintenance of the specified temperature regime. Error - less than 1°;

- In addition, this device includes two heat exchangers: a copper one for heating; plate, made of stainless steel - for hot water supply.

More information about the types of heat exchangers for gas boilers is presented here

The control of the device in the model 8224 has been improved, a remote control option and a PC connection have appeared for diagnostics and the ability to more accurately configure the equipment.

Wall-mounted gas boiler Neva Lux 8224 with a closed combustion chamber

https://youtube.com/watch?v=Lq3SyGwwwN0

Neva Lux 8618

The wall-mounted gas boiler Neva Lux 8618 is a single-circuit gas boiler. Compared to floor-mounted units of the same power, this model has higher productivity, the efficiency is 90%. The boiler is also characterized by reduced gas consumption.

Wall-mounted units Neva Lux 8618 have the following characteristics:

- due to its compact size, such equipment can be installed even in small rooms, they will not take up extra space;

- a large number of positive reviews indicate the reliability of the equipment. The devices are suitable for Russian conditions;

- Thanks to the built-in circulation pump, the boilers can be installed in ready-made heating systems.

In addition, to such boilers you can connect an indirect heating boiler, a forced smoke removal fan, or a room thermostat, thanks to which the equipment is highly economical.

How to buy a gas boiler and not make a mistake?

A buyer, choosing, for example, a wall-mounted gas boiler Neva Lux 8224 reviews for which may be false and written to order, must understand that they cannot be relied on. After all, it often happens that the design is ideal, the equipment is the most modern, but poor-quality assembly worsens all the advantages. For example, in 2014, reviews characterized the wall-mounted gas boiler Neva Lux 8224 as a naturally raw product, which is called “finish it with a file.”

This review appeared due to poor quality assembly, as well as due to unstable operation of the boiler due to a defect in the coaxial chimney, which was not specified in the instructions. Of course, the Neva company has now taken certain measures and eliminated shortcomings in the assembly of the product. There are practically no complaints about the Lux 8618 model and you can buy a single-circuit wall-mounted gas boiler Neva Lux, with delivery to any region, in specialized stores.

Prices for mounted gas boilers depend on their power, type, configuration and demand for the device. For example, the Neva Lux gas double-circuit wall-mounted boiler offered by many online stores, the price of which with a power of 24 kW, but with different configurations, ranges from 31,800 to 35,600 rubles.

The most expensive boiler, Nevalux 8224, is equipped with a built-in storage boiler. When choosing a boiler for heating, if you are satisfied with the gas boiler Neva Lux 8224 price, it is best to get reviews from real owners or gas equipment specialists.

Main technical characteristics and features of Neva company equipment

Please note that wall-mounted gas boilers on the market are available with open and closed combustion chambers. What does it mean? In the first case, combustion products are removed naturally, through the chimney to which the device is connected. The air required for normal gas combustion is taken from the room.

In the second case, the gas boiler is connected to a coaxial chimney, the design of which is made according to the “pipe-in-pipe” principle. Through the inner pipe, combustion products are forced out, thanks to the built-in fan, and air is supplied through the outer pipe, which comes from outside the room.

Wall-mounted double-circuit gas equipment is capable of performing two tasks aimed at heating the coolant and sanitary water. Heat exchangers are installed separately, one is designed to heat the coolant, the second is designed to heat sanitary water.

Household appliances of this type are distinguished by a wide power range, which allows you to select a unit for installation in an autonomous heating system for a house of any size

When choosing a device, it is important to take into account that 1 kW is required for normal heating of 10 m2. So, if a house, for example, has an area of 200 m2 in which there is a need for hot water supply, then in order for the system to operate stably, efficiently and economically, you will need to buy double-circuit gas boiler Neva of any model with a capacity of 24 kW

in which there is a need for hot water supply, then for the system to operate stably, efficiently and economically, you will need to buy a Neva double-circuit gas boiler of any model with a capacity of 24 kW.

Design features of the Neva boiler

Despite the fact that the Neva wall-mounted boiler is small in size, its design contains everything necessary for stable and high-quality operation of the equipment. Therefore, having chosen these heating boilers, you will not need to buy a separate circulation pump or expansion tank, the task of which is to promptly remove air from the heating system. According to experts, the built-in expansion tank can significantly increase the safety, reliability and stability of the heating system.

The main advantage of a built-in expansion tank from a remote tank is that there is no need to constantly check the coolant level; the equipment will do this for you. In addition, since there is no need to install an expansion tank, it is possible to significantly save on the installation of the heating system.

All models of gas boilers presented by Neva are equipped with pressure gauges, which are installed on the equipment panel

It is important to know that as the temperature increases, the pressure in the system increases and vice versa. The system should be replenished if the pressure drops below 1.5 atmospheres. Note that Neva wall-mounted appliances are able to continue to operate effectively at reduced gas and water pressure

Note that Neva wall-mounted appliances are able to continue to operate effectively at reduced gas and water pressure.

Let's return to the contours of the device, namely the one that is responsible for heating sanitary water intended for everyday needs. So, for its manufacture, stainless steel is used, the advantage of which is its high resistance to corrosion, thereby increasing the durability of the device.

If you want to extend the operational life of your equipment, it is recommended to install a filter on the water supply pipe through which water is supplied to the boiler, with the help of which the water will be purified and softened. Shut-off valves should be installed in front of the filter and on the return line, which will allow equipment maintenance and filter replacement to be carried out without unnecessary difficulties.

Security measures

Page 4

- Image

- Text

User Guide

4

1. SAFETY PRECAUTIONS

For your own safety and to avoid boiler failure, strictly

prohibited:

use a faulty boiler; put the boiler into operation without an installed flue pipe or if it is faulty

chimney;

carry out gas hazardous work, all maintenance and repair work of the boiler

must only be carried out by a specialized service organization;

maintain the boiler while in a state of alcohol or drugs

intoxication;

make changes to the boiler design; touch the combustion products exhaust pipe during boiler operation, because temperature

heating of this pipe can reach 100

WITH;

use gas and water supply, as well as a heating system for grounding; touch the boiler if you are standing without shoes (or your shoes are wet) on a wet floor; maintain the boiler if it is not disconnected from the power supply and the gas supply is not shut off; make changes to the operation of security and control systems without permission and instructions from

boiler manufacturer;

damage and deform the electrical wiring elements of the boiler, even if it is switched off

power supply;

expose the boiler to atmospheric precipitation.

To avoid carbon monoxide poisoning, the room in which the boiler is installed must

have ventilation that provides air exchange of at least one volume of the room per hour.

If the boiler is idle for a long time in winter or if there is a risk of freezing

pipelines, it is necessary to drain the water from the boiler and from the heating system.

Do not store flammable or volatile substances (gasoline, solvents, etc.) in

the room in which the boiler is installed.

During normal operation of the boiler and if the gas pipeline is in good working order, there should not be any feeling in the room.

smell of gas.

IF YOU SMELL GAS:

close the gas supply valve located on the gas pipeline in front of the boiler; open windows and doors to ventilate the room, ensuring maximum air flow

fresh air;

do not use electrical appliances to avoid sparks; do not use the telephone in a gas-filled room; do not smoke or use open flames (lighters, matches, etc.); immediately call the emergency gas service by phone. 04.

Using a faulty boiler or failure to comply with the above operating rules

may lead to an explosion or fire, gas poisoning or combustion products.

The first signs of poisoning are: heaviness in the head, strong heartbeat, noise in the

ears, dizziness, general weakness. Then shortness of breath, nausea, vomiting, and impaired motor functions may appear. The victim may lose consciousness.

To provide first aid in case of gas or combustion products poisoning, you must:

take the victim to fresh air; call an ambulance; unbutton clothing that restricts breathing; give ammonia a sniff; cover warmly, but do not let you fall asleep.

First aid in case of electric shock should be provided immediately, after

capabilities at the scene of the incident, while simultaneously calling for medical assistance.

First of all, you need to free the victim from the effects of electric shock as soon as possible.

current. If it is impossible to disconnect the electrical installation from the network, then you should immediately begin to free the victim from live parts, using insulating objects.

When releasing a person from tension, you should use a rope, stick, board or

another dry object that does not conduct current.

New company boiler Turbo

Neva Turbo boilers are, in fact, a modified version of the already familiar Lux modification, taking into account the shortcomings of previous versions. The models have the following technical characteristics:

Turbo boilers are energy-dependent. The boiler is powered by connecting to a regular 220 V mains voltage. For stable operation, you will need to install a UPS and a generator.

Ease of maintenance and operation

It is enough to connect the installation to the heating and power supply system and start heating your house or apartment. In practice, provided the heating system is already ready, all work takes about 3-4 hours.

After installation, there is no need to worry about the safety of the station. The sequence of operation of the automation completely eliminates the possibility of gas leakage and the creation of an emergency situation, even if an unplanned power outage occurs.

The main differences between Neva boilers

The Turbo modification provides economical gas consumption and, subject to proper operation, fully pays for itself within a few years.

Calculation of power and temperature of a warm water floor

Russian wall-mounted gas double-circuit boilers Neva provide consumers with maximum comfort when switching to autonomous heating and hot water supply. This equipment is intended for use in multi-apartment residential premises and country houses. For the production of boilers, modern materials are used, as well as high-quality components from the best European suppliers. The company's designers conduct a constant scientific research, testing prototypes of new models on an experimental one before launching into mass production.

Thanks to this, it is possible to correct all the shortcomings, improve the manufacturability of production and, which is important for gas equipment, increase the degree of its reliability. The domestic manufacturer BaltGaz has implemented two design options in Neva Lux gas double-circuit boilers

Thus, in the boilers of the 72 series, as well as in the BaltGaz 18 DBF boiler, a single bithermal heat exchanger is installed to work with heating and hot water circuits

This decision made it possible to reduce production costs, which had a positive effect on the pricing of these products. In addition, the products of the 72 series provide precise temperature control with a tolerance of 1 0 C. The models of the 82 and 86 series use a traditional layout with two heat exchangers - copper for the heating circuit and plate for the hot water supply circuit. The entire line of double-circuit boilers, with the exception of the Nevalux-8624 model, is equipped with a closed combustion chamber. In addition to the above, Nevalux gas double-circuit boilers are distinguished by thermal performance and minor design details:

- Nevalux-7211 - thermal power 11 kW, bithermal heat exchanger, maximum heating area - 110 m2

- Nevalux-7218 - thermal power 18 kW, bithermal heat exchanger, maximum heating area - 180 m2

- Nevalux-7224 - thermal power 24 kW, bithermic heat exchanger, maximum heating area - 240 m2

- BaltGaz 18 DBF - thermal power 18 kW, bithermal heat exchanger, maximum heating area - 180 m2

- Nevalux-8624 - thermal power 24 kW, copper heat exchanger (heating) and plate heat exchanger (DHW), maximum heating area - 240 m2

- Nevalux-8224 - thermal power 24 kW, copper heat exchanger (heating) and plate heat exchanger (DHW), maximum heating area - 240 m2

- Nevalux-8230 - thermal power 30 kW, copper heat exchanger (heating) and plate heat exchanger (DHW), maximum heating area - 300 m2

Wall-mounted gas boilers are in great demand among consumers who have a house or small cottage. This is due to the advantages of this type of equipment. Thus, the wall-mounted boiler has small external dimensions, due to which the equipment can be installed indoors with minimal loss of space. The equipment does not make noise during operation and is capable of stably performing assigned tasks, regardless of operating conditions. Many users choose the Neva Lux double-circuit gas wall-mounted boiler for installation in the heating systems of their homes, the advantages and main technical characteristics of which will be discussed below.

Design and principle of operation of Neva Lux boilers

Neva Lux gas boilers are presented in two variations - wall-mounted and floor-mounted; let's look at their design using the example of some models. Neva Lux 8618 is a single-circuit heating boiler, wall-mounted, has low energy consumption, a fairly high efficiency of 91%, power 18 kW. Can heat a room with an area of 30 to 180 square meters.

Powered by both natural and liquefied gas. It has small dimensions, is equipped with a combustion chamber that is cooled with water, and can also be connected to a room thermostat, which is convenient for use. Equipped with a protection device against overheating (boiling), a thermostat against overheating of the gas exhaust device. Can be connected to both the chimney and the turbo nozzle.

Neva Lux 8224 is a double-circuit gas boiler designed for heating a room up to 240 meters2, as well as for heating water for household needs, with a throughput capacity of 14 liters per minute. Its power is 24 kW, equipped with a closed combustion chamber.

The installation method is wall-mounted, equipped with a built-in 6-liter expansion tank, this makes it possible to connect the boiler to a 70-liter heating circuit. The design provides two heat exchangers, a copper one for the heating circuit, and a second one made of stainless steel for hot water supply.

Powered by natural or liquefied gas, for ease of use it has a display that reflects the current and set temperature in the coolant.

Neva Lux 7224 - installation method: wall-mounted, double-circuit device designed for heating a room up to 240 m2, water throughput for domestic needs is 14 liters per minute. Can run on natural gas and liquefied gas, efficiency 92%.

Equipped with a bithermal heat exchanger, thanks to which it is possible to reduce the final cost of heat. It is equipped with an electronic self-diagnosis system, and a small display is installed on the body to indicate readings.

Neva Lux 7023 - wall mounting, designed for heating a room up to 250 meters2, as well as heating process water 13 liters per minute. It runs not only on natural gas, but also on liquefied gas; for ease of operation, you can connect a room controller.

Smoke is removed forcibly using a built-in fan; combustion air is pumped from the street. It is equipped with a closed combustion chamber, has a coaxial heat exchanger, and an expansion tank with a capacity of 6 liters.

Neva Lux 8023 is a double-circuit wall-mounted boiler that can provide heat to a room whose area does not exceed 240 m2. Liquid circulation in the system is forced, using a pump, equipped with a closed combustion chamber.

Smoke removal occurs thanks to an exhaust fan. The power of the device is 23 kW, there are two heat exchangers, the heating circuit is paramount, made of high-alloy stainless steel.

User Guide...

Page 3

- Image

- Text

User Guide

3

Dear buyer!

Thank you for choosing our product. You purchased

single-circuit wall-mounted boiler with an open combustion chamber “NEVALUX-8618”.

When purchasing a boiler, check:

completeness of delivery (see section 21, page 31) and presentation of the boiler; compliance of the type (natural or liquefied) gas you use with the type of gas,

specified in section (page 31) of this manual and on the plate on the boiler casing.

Also require the sales organization to fill out warranty repair coupons. When purchasing a boiler using a loan, a payment schedule must be drawn up with

indicating the amount to be paid. The payment schedule must be signed by the Buyer, indicating the date and deciphering the signature.

The boiler and this manual are two integral parts of what we offer.

goods. The manual contains information about the procedure for installing the boiler, the rules of its operation and maintenance, compliance with which will ensure long-term trouble-free and safe operation of the boiler. Please read the manual carefully before putting the boiler into operation, follow the instructions contained therein and store it carefully for future use.

Sincerely, OJSC GAZAPPARAT, St. Petersburg

Installation of the boiler is allowed only in non-residential premises with a temperature not lower than +5

0

C in

strict compliance with the Gasification Project, SNiP 42-01-2002 “Gas distribution systems” and SP 62.13330.2011 “Gas distribution systems. Updated edition of SNiP 42-01-2002.”

All installation work, installation, owner instruction, preventive maintenance,

Troubleshooting and repairs are carried out only by a specialized service organization.

The boiler is not intended for use by persons (including children) with reduced mental

abilities or lack of life experience.

Responsibility for the safe operation of the boiler and its maintenance in proper condition

is borne by its owner. Failure to comply with the safety measures and installation, use and maintenance rules set out in the manual can lead to boiler failure, fire, burns, gas poisoning or carbon monoxide (CO).

OJSC GAZAPPARAT is constantly working to improve its products.

products and reserves the right to make necessary changes to the boiler design. These changes may not be reflected in the instruction manual.

September 2, 2011

Maintenance and operation

Regardless of which model you prefer, installation of a wall-mounted boiler is carried out in the shortest possible time without any additional costs.

The manufacturer places the main emphasis on ease of installation and subsequent operation of the unit. That is why the heating devices of the Neva Lux company are a completely ready-to-use station. All you need to do is connect the equipment to the heating system and power supply and start heating the room. As practice shows, all work takes 3-4 hours. After installation has been completed, there is no need to worry about the safe operation of the station. Consistent operation of the automation reduces to zero the risk of gas leaks and emergency situations, even in the event of an unplanned power outage.