When the question arises about installing heated floors in an apartment, you should take care in advance of purchasing the necessary tools and components for water heated floors, because nothing slows down work more than not having the right tool at hand.

The tools for laying heated floors will be discussed in the article.

Roulette

A tape measure is a universal measuring tool that allows you to mark out the installation diagram for warm water floors.

It is a flexible metal tape rolled into a compact skein in a plastic or metal case. This design allows you to take measurements of fairly long objects, as well as areas with bends.

Pipes

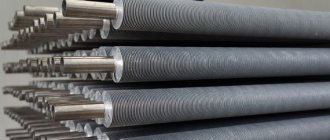

There are several options for pipes that are used for underfloor heating systems. Each of them has its own installation and operation features. Pipes with a diameter of 1/2 and 3/4 inches are mainly used. But it all depends on your needs. Let's look at them separately.

Types of pipes for warm water floors: 1- cross-linked polypropylene; 2 - polypropylene; 3 - metal-plastic; 4 - copper; 5 - aluminum; 6 - stainless steel.

Cross-linked polyethylene ( PE- X) – is a flexible polyethylene pipe reinforced with polymer threads and an adhesive base. The most common material for laying heated water floors. Suitable for both dry and wet installation.

Metal-plastic - pipes made of two layers of plastic. Between them there is a reinforcing layer of aluminum, treated on both sides with glue. It gives strength and prevents cracks from thermal deformation. Due to this, the pipe bends poorly; when installing complex shapes, it is necessary to use fittings. High temperature glue is used for connection.

Polypropylene is a solid pipe made entirely of polymer. This is the cheapest option, inferior to others in terms of deformation indicators. They are practically not used for installation in screeds. In terms of service life they are inferior to other options.

Copper - such pipes are resistant to low-quality water and have a service life of up to 50 years. For installation you will need a special tool - a pipe bender. Soldering and special fittings are used for connections. Copper pipes are often used where coolant rather than water circulates in a warm floor.

Aluminum - rarely used for warm water floors. In terms of performance, aluminum pipes are inferior to copper ones. They have lower tensile strength.

Stainless steel - pipes made from this alloy are the most expensive. But the price is compensated by the service life - more than 50 years. They can be supplied in the form of corrugation, which can be bent by hand. Stainless steel pipes can be used for heated floors with aggressive coolant or low-quality water.

You can read more about the characteristics of different types of pipes in the article “Which pipe to choose for a heated floor - expert advice.”

Pliers (pliers)

Pliers are a metal clamp that allows you to grab any object, such as the end of a wire, the head of a nail, a bolt or a nut. The pliers are equipped with wire cutters for wires or wires of various diameters.

The handle of the pliers should be made of dielectric material, as they are often used when working with electrical wires.

The main feature of high-quality pliers is the absence of a gap between their jaws and minimal play between the two moving components.

Level

A level is a device for determining horizontal and vertical planes. It can be of two types: bubble and hydraulic.

The bubble level is a bar of a certain length, equipped with small reservoirs with liquid and a bubble. The simplest devices have 2 reservoirs with a bubble. One for the horizontal plane, the other for the vertical.

The principle of operation is as follows: the bar is applied to the leveled surface, for example, the floor, and the location of the bubble in the tank is determined. The plane is considered level if the bubble on the bar is exactly in the middle of the tank.

The hydraulic level is a long transparent hose with reservoirs at the ends. In other words, these are two communicating vessels. The principle of operation is as follows: the tanks are set to the same level and filled with water until the level reaches half of the scale drawn on both tanks.

A mark is made on the wall indicating the level of a plane, for example a concrete floor screed. In order for its surface to lie in one horizontal plane, it is necessary to mark it on the wall in the form of a solid horizontal line.

One tank is installed so that the point is within the scale. The second tank is applied to the same wall at some distance at approximately the same level and the cap on both vessels is opened to allow air to enter. The second reservoir is then moved up or down so that the level of the liquid in the first container matches the level of a point on the wall.

The physical law states that fluids of communicating vessels are in the same horizontal plane. That is, a mark is made opposite the liquid level of the second vessel - it will be at the same level as the first point.

A level for installing heated floors is used at the surface preparation stage before installing heating elements, since the floor must be level and have a deviation of no more than 3 mm.

Adjustable wrenches

Adjustable wrenches are universal for working with nuts, bolts and other fasteners. A pair of adjustable wrenches can replace an entire set of regular wrenches.

When choosing a tool, you should pay attention to the following features:

- A good quality wrench will have jaws that move well and will not have any play

- A key with a rubberized handle will hold your hands much better and will not slip out.

- Presence of markings on the key. Helps quickly set the wrench to the required nut size.

Regular wrenches

Wrenches are a type of locksmith tool that will help you tighten or unscrew any bolt, nut, coupling or tap head.

There are several types of wrenches:

- Cap. It is a popular key in the form of a polyhedron.

- Rozhkovy. The most popular is the U-shaped open-end wrench. The nut is clamped on both sides. However, such wrenches have their drawback - with their help it is difficult to get the nuts in the recesses.

- Tortsevoy. The advantage of such a wrench is that it can be used to reach hard-to-reach nuts.

- Combined. Combines several types of keys.

For home use, you can purchase budget wrenches made in Russia, China, Taiwan, and India. For professional use, you should buy expensive keys from well-known manufacturers.

Mounting options and fixation methods

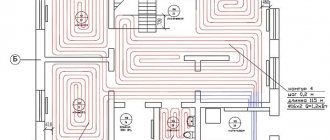

Effective operation of underfloor heating is possible provided that the pipes are correctly installed and connected to the central heating system. The key task of the contractor is to correctly distribute the linear footage of the pipeline on the surface of the subfloor to ensure uniform heating of the floor covering.

As a rule, pipes are installed in a “snake” pattern, i.e. First, the pipe goes in one direction, then makes a 180-degree turn and is laid in the opposite direction so that the two sections are located relatively close to each other (up to 30 cm).

This way, the coolant energy is effectively distributed over the entire floor area in the room. The pitch between pipe branches depends on its thickness, material, flexibility and intended heating mode. Thin plastic pipes made of polypropylene or polyethylene are laid in frequent increments.

Important! Methods of laying in a spiral, “snail”, as well as irregular arbitrary shape are also allowed. The main thing is that the distance between the turns of the pipeline is approximately the same for uniform heating of the area.

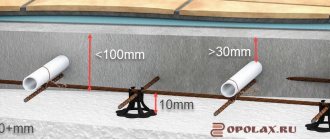

Before installing a heated floor, prepare a rough surface - a concrete screed or a wooden plank floor, on which film waterproofing is laid. One of three types of underlay is placed on the subfloor:

- reinforcing metal mesh;

- polystyrene boards;

- mounting rails.

A special fixing substrate is a mandatory requirement for the correct installation of underfloor heating pipes, otherwise the pipes may move during the process of pouring the cement screed, and the system will not work correctly.

Reinforcement mesh - advantages and disadvantages

Metal reinforcing mesh is the most popular way to fix underfloor heating pipes. It is sold in the form of identical lengths or in coils, and is laid on a concrete floor. Pipes are distributed along it and fixed using various fasteners.

The advantage of this method is the availability of reinforcing mesh and its low cost in construction stores. The disadvantage is the labor-intensive installation process and the high risk of damage to plastic pipes.

We recommend that you read: Bypass valve and its role in the operation of the heating network

Pros and cons of polystyrene backing

Polystyrene boards are shaped products with protrusions equidistant from each other - bosses, between which pipes are laid. There are various shapes and configurations of bosses.

The main advantage of this installation method is the speed and ease of installation of pipes, which can be arranged in any way: “snail”, “snake” and other patterns. Thanks to the protruding elements of the polystyrene plates, the pipes are protected from mechanical damage. Disadvantages include the high cost of materials and the need to use additional fasteners.

Mounting rails for laying heated floors

Tires are long products with special clamps with which pipes are secured. With their help, you can easily and quickly install flexible plastic pipes that will be protected from damage.

Compared to reinforcing mesh, mounting bars are less labor-intensive in terms of installation, but their disadvantage is that they are rarely available for sale and can be quite expensive.

In addition to the substrate, various fasteners are used to firmly fix underfloor heating pipes:

- Plastic clamps or cable ties are simple products that form a loop covering the pipe and the bars of the metal reinforcing mesh. This is the simplest and most affordable method of fixation, but it is only suitable for reinforcement substrate.

- Plastic clamps with notches are products designed for fastening pipes to a polystyrene backing. They are installed on top of the pipes and pressed into soft polystyrene, held in place by spacers included in the sharp tips.

- Plastic clips are products in the form of a small horseshoe with a flat, level base on which they are installed. The pipe is laid and held motionless.

- Metal clamps in the form of a loop that matches the diameter of the pipe. Such products have a hole for a fastening element - a nail, self-tapping screw or bolt - for fixing on the rough surface.

We recommend that you read: How to choose drainage pipes with perforation when installing drainage systems

Screwdrivers

Screwdrivers are the most necessary tool that is used in various situations. If you are installing a heated floor, you will need to tighten several screws or screws to which the regulator will be attached to control the water heated floor. Nowadays, professionals prefer to use a screwdriver - a power tool that performs the same functions as screwdrivers.

Types of heated floors

There are only two types of heated floors: water and electric.

Water

The water heated floor system operates on the basis of water pipes laid under the floor covering. The coolant enters them either from the heating system or from a separate heating device (boiler, boiler).

For pipeline installation, pipes made of metal-plastic, polyethylene or polypropylene are used. The installation diagram begins with the collector, the circuits are calculated before purchasing materials.

The piping is installed both in a concrete screed and without its use, directly on the polystyrene base under the floor covering.

Electric

This type of floor is heated by electricity supplied to the system through wires (cable electric underfloor heating), special heating films, and carbon rods.

Sander

A grinder or “grinder” is an electric tool with a rotating attachment (disc). Depending on the attachment, it can be used for:

- Polishing.

- Grinding.

- Cutting metal, concrete and stone.

- Cutting a tree.

Depending on the model of the grinder, it has different power and disc diameter.

Welding machine for propylene pipes (soldering iron)

The heated floor project includes piping made of polypropylene pipes. Their connection into a single system is carried out using a special soldering iron. Its operation is quite simple:

- Plug in the soldering iron.

- Wait a while for it to heat up completely.

- Insert the pipe to be connected into the soldering iron, wait 3-5 seconds, remove it from the soldering iron and immediately connect it to the outlet or any other element.

- Wait until the elements cool completely and are firmly connected.

Among the countries producing soldering irons for pipes, the most popular are:

- Czech Republic.

- Türkiye.

- China.

When choosing, you should also take into account the power of the soldering iron:

- For pipes with a diameter of 90-100 mm, a soldering iron with a power of 1.5-2 kW is used.

- For pipes with a diameter of 16-63 mm, use a soldering iron with a power of 680 W.

- For pipes with a diameter of 16-75 mm, use a soldering iron with a power of 850 W.

- For pipes with a diameter of 125 mm and above, soldering irons with a power of 1200 W are used.

Hammer

A rotary hammer is an electric drill that can operate in the following modes: drilling, drilling, and also combine these two modes in one. As a rule, such a tool is required for attaching a heated floor temperature controller to the wall, as well as thermostats for water heated floors.

The choice of manufacturers is varied and depends on the purpose and price-quality ratio.

It is best to choose a tool that has all the necessary elements of various sizes in the set.

Gas-burner

A gas burner is used in various cases: for heating and joining certain elements, for drying the surface, for cutting and soldering metal elements, etc.

When choosing this tool, you should pay attention to:

- Design: it should include a unit for attaching a cylinder, a burner head, nozzles, a gearbox with a regulator, and a holder for installing utensils.

- The presence of piezo ignition, wind protection, adapters for various cylinder mounts, and a transport case.

What method do we use?

For a long time we used the method of attaching pipes to reinforcing mesh. There were many reasons for this: price, lack of other offers and expensive delivery to order. Now we are bringing anchor brackets and securing the pipes with a tacker. This significantly speeds up the installation process. Difficulties usually arise when pipe lines run at close distances. The tucker does not fit into the gap between the pipes and our tucker often makes false alarms. It is still unknown whether this is a feature of all tucker machines or just ours.

Pipe cutter

A pipe cutter is used when it is necessary to dismantle the heating system or shorten pipes during installation, as well as when replacing any section of pipes. It can be used to cut pipes made of steel, copper or metal-plastic.

Pipe cutters can be of two types:

- Telescopic.

- With ratchet mechanism. They resemble scissors and are quite easy to use.

Fastening the pipe to mounting rails

This method is no more complicated than the previous one. The pipes are fixed using special clamps that tightly hold and protect the system from mechanical damage. Also, such systems are easy to install on the wall; the only problem is that it is quite difficult to find such a heating system in specialized stores. In addition, difficulty arises in the preliminary marking. But in general, this method is very convenient and practical.

Cutter (scissors) for metal-plastic pipe

These scissors are similar to a pipe cutter and are used to reduce the length of a pipe when installing a heated floor. For one-time work, you can purchase a cheap tool. But if it will be used frequently, it is better to choose a well-known manufacturer.

If you have all these tools, installation work will be carried out quickly and efficiently. When choosing tools, do not skimp if you want to get a truly high-quality product.

Author: Sergey Vladimirovich, electrical engineer. More about the author.

Mounting methods

There are quite a lot of ways to attach underfloor heating pipelines. Over time, new technologies appear, both means and methods of fastening are improved.

Let's consider the most common of them, which have received the approval of professionals who have been tested by time of operation.

Attaching to reinforcement mesh

In laying a warm pipeline, the reinforcing mesh does not play the role of a reinforcing element, but rather the basis for fastening heating pipes. It is laid on various layers of hydro- and thermal insulation made of expanded polystyrene or polystyrene, and plastic bends are mounted on top, attaching them to the welded mesh using various means.

The following fasteners are used:

Nylon ties, clamps of different lengths. Price from 1 ruble per piece.

Wire fastening connectors made of steel. They tie the pipes to the mesh with a special hook at a distance of 75 cm between the fastening points. The price per piece is approximately 2 rubles.

Plastic swivel clips installed on the mesh. Raise the mesh above the insulation by 0.5-0.8 mm, which better connects the mesh to the screed. The pipe is inserted into the clamp and snaps into place. Price from 5.5 rubles per unit of goods.

Any home craftsman can carry out these methods with his own hands, having made the necessary calculations.

Mounting on mounting rails

Special fixing tires are produced in the form of a plastic track 50 cm long with clip clamps on top. The planks can be connected to each other into a single strip of the required dimensions. They are convenient for laying pipes made of cross-linked polyethylene PEX.

They are attached to the insulation with anchor brackets, and to the concrete floor using dowels. Price from 48 rubles per piece.

Securing the pipe with clamps

In the absence of reinforcing mesh, fastening with staples or metal clamps is used. These mounting parts are attached to the screed with dowels and nails, and to the wooden floor with self-tapping screws.

Fastening with a tucker

The use of a tacker, a device that resembles the principle of operation of a stapler, is becoming increasingly popular among professionals. In sales it is often called that. The tool is designed for fixing pipes to polystyrene foam with anchor clamps. The device is equipped with a magazine bar that can accommodate 100 or more harpoon staples. Design features allow the operator to work without bending over, without putting much effort on his arms and back, significantly increasing the speed of operations.

Previously, the price of the instrument was at least 17-18 thousand rubles; now devices costing from 4 thousand have appeared on sale.

Expanded polystyrene boards with fixation

To facilitate the installation of heated floors, thermal insulation boards made of polystyrene foam have been developed. Today, products have appeared on sale that allow the installation of plastic pipes without the use of additional fixing means.

On the slabs there are bosses in rows, 2 cm high and higher, on which special protrusions are made. Thanks to these protrusions, the pipe is securely fixed to the plate. All the technician needs to do is step on the plastic outlet with his foot, and it gently clicks between the protrusions.

The material is highly durable; you can walk on it without fear of damaging the mat configuration.

The plates are equipped with locks, which allows them to be securely connected into a single field, without gaps or the risk of opening. The advantages of this method include the speed and convenience of installing bends, the ability to mount them according to any scheme: “snail”, “snake” or another proprietary scheme.

The cost of such slabs is 680 rubles per meter2.