Finned tubes are equipped with metal ribs, which increases their outer surface. This leads to an increase in heat transfer efficiency by one and a half times. Finned products are used in industry and in everyday life. They are used for the installation of heat exchangers and coolers, heating systems, industrial refrigeration chambers, and metal communications.

Finned pipes - products with special properties and characteristics

Design and applications of finned tubes

Finned tubes are monometallic or bimetallic structures consisting of two elements:

- Inner pipe. This is a load-bearing element through the internal cavity of which the working medium moves. It is made of metal, most often steel. Cast iron and non-ferrous metals are used much less frequently. The material from which the internal part of the structure is made is resistant to temperature changes and high pressure, and has anti-corrosion properties.

- External ribs. They can also be made of steel, cast iron and non-ferrous metals. External fins effectively transfer heat coming from the load-bearing element.

Finned tubes are used in various areas of human activity:

- the engineering industry uses them in refrigeration units, oil coolers and compressors;

- chemical, oil refining and petrochemical - in condensers, gas heaters and gas coolers;

- nuclear energy - in gas coolers, intermediate refrigerators, steam air heaters, drying towers;

- in air conditioning technology;

- in heat exchange units.

Pipes with metal fins are used as cooling, heat exchange and other devices at facilities for various purposes.

Operating principle of the economizer

In essence, this unit is a heat exchanger for a steam boiler. A typical device is a multi-row structure of bent pipes, the sections of which are arranged in a checkerboard pattern. In this unit, with the help of gases escaping from the coolant, water begins to preheat to 30-40 degrees, after which it enters a stationary heating unit.

This fact allows you to significantly increase the efficiency of the heating system by reusing exhaust gas energy. This is why installing an economizer is beneficial. Thanks to the additional structure, the rate of gas release is significantly reduced. Before being released into the atmosphere, they manage to give up all their thermal energy. Thus, the use of an economizer in production pays for itself within 1-2 years.

Water and steam boilers are either boiling or non-boiling. Cast iron economizer pipes are used only for the second option. A distinctive feature of such boilers is the need for steam removal, since they are not designed to operate at too high a pressure. Among other things, the ribbed section can be an independent element of the heating system.

Production and characteristics of finned tubes

The method of production of products depends on their purpose and related technical characteristics.

Typically, fully automated helical fins are used, in which a continuously welded helix runs around an inner tube. This can be done in three ways:

- Rolling.

- Aluminum winding.

- By winding with welding.

No further processing is required, the product has the following features:

- heat transfer coefficient increased by half;

- increased resistance to loads;

- maintaining specified characteristics when pressure increases, temperature changes and other sudden changes in operating conditions;

- increasing the productivity of the equipment that was equipped with it.

Important! Spiral fins reduce tube consumption while reducing the weight of heat exchangers.

Coating a previously degreased finned tube with magnesium oxide and subsequent annealing allows it to be given a heat-resistant coating. Such products have:

- increased heat transfer coefficient by more than one and a half times;

- increased resistance to various corrosions;

- increased productivity;

- long service life;

- increased resistance to changes in pressure and temperature;

- possibility of use in aggressive environments.

The method of pipe production, the shape of the fins and the method of their fastening are reflected in the technical characteristics of the products and determine the scope of application

terms of Use

This product is characterized by a high level of unpretentiousness when used in heating systems. An important factor for operation are the characteristics of the base coolant:

- The operating temperature of the boiler should be within 90 degrees. In this case, short-term increases up to 150 degrees are allowed;

- constant pressure – 1 MPa, maximum possible – 2.4 MPa;

- linear flux density – 0.6 kW/m.

To ensure optimal operating conditions for such pipes, certain rules must be followed during installation. First of all, when choosing an installation location, it is necessary to take into account that the distance from the floor to the middle axis of the economizer must be at least 0.2 m. You should also leave a sufficient gap between the battery and the wall. This distance must be at least 13 cm. If you plan to install a two-row or more structure, a distance of 0.25 m must be maintained between the axes of the pipes.

Advantages of using heat-resistant finned tubes

Heat-resistant finned products obtained as a result of the use of new technologies have a number of advantages that have led to their widespread use. They differ:

- high manufacturing technology. The use of resistance welding does not require a large amount of energy, special consumables, or complex equipment;

- increased intensity of convective heat transfer. In the space of the intercostal channels, turbulization of the flow of the working medium occurs, and all sections of the fins work equally well;

- excellent thermal contact between the load-bearing structural element and the ribs. The use of resistance welding made it possible to achieve almost ideal thermal contact;

- lower thermal resistance of heat transfer. Since the thickness of the condensate film has decreased, the level of condensation of vapors of the process fluid flowing through the pipeline has decreased. This is due to the presence of a heat-resistant coating.

Steel bends for welding GOST 17375-01

Flange bends - price

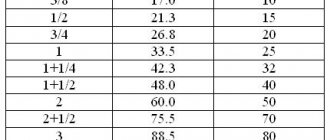

| BK-Armature offers for sale steeply curved steel elbows for welding in accordance with GOST 17375-01 version 2 and in accordance with GOST 30753-01. The product is available at the warehouse in Shchelkovo, Moscow region. Delivery to the regions - through transport companies. Delivery of the paid goods to the transport company - . | Bends to/from |

| Bends to/from 15 isp. 1 (21.3x2.5) | 16,90 |

| Bends to/from 20 isp. 1 (26.9x2.5) | 21,50 |

| Bends to/from 25 isp. 1 (33.7x2.5) | 27,90 |

| Bends to/from 32 isp. 1 (42.4x2.5) | 40,70 |

| Bends to/from 40 isp. 1 (48.3x2.5) | 47,70 |

| Bends to/from 50 isp. 1 | 59,90 |

| Galvanized bends Du-15 | 18,70 |

| Galvanized bends Du-20 | 22,90 |

| Galvanized bends Du-25 | 33,70 |

| Galvanized bends Du-32 | 44,90 |

| Galvanized bends Du-40 | 57,70 |

Ribbed cast iron pipe

Technological advances have made it possible to produce ribbed cast iron structures. This made it possible to use cast iron finned heating pipes. After all, heating systems are literally the ideal environment for using ribbed cast iron products. They have the following advantages:

- high resistance to corrosion caused by both the influence of the working fluid from the inside and the external environment;

- ease of installation;

- high heat transfer coefficient;

- compactness;

- low cost.

Finned pipes made of cast iron have many advantages, one of them is resistance to high temperatures

Ribbed cast iron products are not without their drawbacks. They:

- tend to accumulate poorly cleaned dust between the ribs;

- weigh a lot;

- fragile under mechanical stress.

Note! The listed disadvantages make it possible to use ribbed cast iron pipes to create heating registers in production and warehouse premises.

For registers, ribbed cast iron pipes are specially produced in the form of hollow radiators, sometimes equipped with connecting threads or flanges at the edges to ensure docking with other elements of the heating system.

And cast iron radiators for residential premises continue to be in high demand, as they can withstand temperatures of one and a half hundred degrees. A cast iron starting pipe is often built into the design of heating systems. Thanks to this, the heating stove warms up the surrounding space faster.

Heating register. How to calculate how much power is needed?

There are five main types of heat exchanger configurations. You can make such a device yourself, but to do this you need to make a basic calculation of the register. To do this you can use the formula:

Q = Pi x dn x l x kh (tg - to) x (1 - ηiz), where

- Pi = 3.14, dn - indicator of the outer diameter of the pipeline, measured in meters, l - length of the section or section;

- k is the heat transfer coefficient, the value is constant and equal to 11.63 W/m²*°C;

- tg is an indicator of water temperature in the pipeline;

- to — temperature in the room where the register will be installed;

- ηiz is the coefficient of heat conservation (heat transfer) by insulation (if the device is insulated, then its coefficient is 0.6-0.8, and if the device is ordinary, then its coefficient is zero).

For example, let’s make calculations given the following data: pipe – 5 meters, diameter – 159 mm, carrier temperature – 80 degrees, room temperature – 23 degrees.

After substituting these data into the proposed formula, we get 1655 W. This is the power of the registers, which is applicable to a horizontal pipe laid in one row. If there are several rows, then for each additional row a reduction factor of 0.9 is applied.

These heating devices are installed in accordance with GOST. This will require welding and rigid fastening to withstand the significant weight of the device, as well as water.

Economizer cast iron pipe

In the production of industrial heat exchangers, finned cast iron pipes are simply irreplaceable. For industrial registers (economizers), cast iron pipes with ribbed walls are available either with round fins or rectangular shapes. The internal diameter is seventy millimeters, the external diameter is 175 mm. The large difference between the values of the internal and external diameters makes it possible to obtain a relatively low temperature on the surface, despite the fact that the coolant will be very hot.

Cast iron pipes most often have a flange connection

Economizer cast iron pipes are available for sale in lengths of two or three meters. They are equipped with two blind plugs and two plugs with holes - left-sided (marked as “L”) and right-sided. The inconveniences associated with transporting heavy and weakly resistant to mechanical damage economizer cast iron structures more than pay for themselves if they are used correctly. When using economizer elements, it is recommended:

- expose mounted structures to minimal external influence;

- do not allow the coolant temperature to exceed. Economizer pipes can withstand heating of the coolant up to one hundred and fifty degrees for a short time, but it is advisable not to raise the temperature above 95º C;

- apply a constant operating pressure of six to ten atmospheres. Although it is possible to connect to steam boilers with operating pressures up to 24 atm;

- coat the outer surface with a special primer;

- When performing installation, pay attention to the fact that the distance from the middle axis of the register to the side wall is more than 130 mm, and to the floor - more than two hundred millimeters;

- By installing the registers in two rows and connecting them to each other using a special arc, they maintain a distance between the middle axes of 250 mm.

By adhering to the operating rules, you can achieve the greatest efficiency in the functioning of economizer cast iron pipes.

Heat transfer coefficient calculation

Since metals have low thermal resistance, the pipe wall can be considered flat. Then its heat transfer coefficient from one medium to another is found using the formulas:

- for a flat surface (Fig. 5.10):

- for ribbed wall:

In these formulas, the heat transfer coefficient (αpr) and the area of the protrusions are determined:

where Fр is the area of one edge, and n is their number.

Based on what should be accepted

Suppose that it is necessary to calculate the heat flux density (q, W/m2) transmitted through the wall of a cast iron pipe with hot water (t = 70 ⁰C) to the surrounding air (t = 20 ⁰C). The temperatures of its inner and outer planes are t1 and t2, respectively.

The thickness of the product, the thermal conductivity coefficient of cast iron and the degree of emissivity of the surface are equal: δс = 3 mm, λ = 63 W/m K, c = 0.9. Convective heat transfer coefficient from water to the inner plane α1 = 3500 W/m2 K, from the outer wall of the pipe to air α2 = 6.5 W/m2 K.

For calculation we take t2 = 69 ⁰C. Then

Using the obtained result, we determine the temperature t2:

The discrepancy between the accepted and calculated indicator, equal to 0.77 ⁰C, is neglected, since this does not significantly affect the accuracy of the calculation. Determine the value of t1:

Result: q = 652 W/m², t1 = 69.8 °C, t2 = 69.77 °C.

Caulking of cast iron pipes

Since external sewer networks are made mainly of cast iron, it is impossible to do without caulking and caulking. Caulking is carried out when assembling a system that includes cast iron pipes to seal the gaps that arise at the site where the transition to another cast iron pipe is made. It is produced using:

- Resin sealant and cement mortar.

- A slightly moistened mixture of cement and asbestos fiber.

- Gray fills.

Important! When caulking, the pipes are carefully tapped with a hammer so that the bell moves freely.

If the bell could not be freed, it means that sulfur filling was used. They carefully burn it out, making sure to wear a respirator. Having freed the bell, it is thoroughly cleaned. A sealing ring coated with a special lubricant is inserted into the socket, and a new part is inserted into it.

How to make fins with your own hands

When making it yourself, it should be taken into account that the efficiency of such pipes is lower compared to factory samples. At home, finning can be done on a small area or short workpiece. Depending on the available equipment, use:

- welding;

- winding wire;

- notching + welding;

- cutting deep profile threads using a lathe;

- notch + tension

Registers made of steel with ribs

Before installing registers made of steel pipes with fins, it is recommended to pay main attention to the volume of the pipe. For a private home, craftsmen recommend installations with a volume of 3 or 4 centimeters. When performing calculations, you need to take into account the length of one register rib and its heat transfer per meter of area

To give an example, a meter-long pipe with an internal cross-section of 60 mm can heat approximately one square meter

When performing calculations, you need to take into account the length of one register rib and its heat transfer per meter of area. To give an example, a meter-long pipe with an internal cross-section of 60 mm can heat approximately one square meter.

Having calculated the required number of registers, rounding is carried out upward. But, there are certain conditions under which the obtained indicators increase by 20 or even 50 percent. This includes:

- The presence of a large number of openings for windows and doors in the room.

- Small wall thickness.

- Low-quality insulation of the room, or its complete absence.

A simple heating register has less heat transfer than devices with fins. They not only increase heat transfer, but also turn the register into a design - a radiator, which can play an important role in the aesthetic design of the interior.

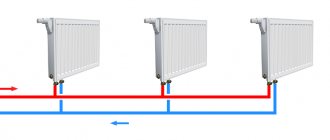

Panel radiators with bottom connection advantages and disadvantages

To choose radiators for your home, you need to decide how much power is needed. To do this, you need to know what temperature the water is supplied by the central heating. In general, with the help of specialists you need to calculate the required power of radiators. To determine which connection is better, side or bottom, you need to think about why the side is worse and why the bottom is better, or vice versa. (See also: How to calculate heating radiators)

Radiators with bottom connections are more expensive, since pipes that are laid on the floor can be connected below. If you need a connection from the side, then you need to choose the option of radiators with side connection. It is possible to connect additional pipes from the side. It all depends on the aesthetic characteristics of each person. Tastes and preferences may vary. Each owner of a house or apartment may find certain options for connecting to a central heating system preferable and more convenient.

Radiators with bottom connections come in two types:

Right-handed

Left-handed

For example, with Purmo panel radiators, you can choose one type of connection or another.

The advantage of such a radiator is largely due to the quality and modern design, which guarantees that the buyer will choose this particular battery manufacturer.

Steel panel radiators Dia Norm are designed specifically for the tastes of modern youth. All requests and whims are taken into account here. The main thing is that the equipment is designed for an energy-saving heating system. And this question is very relevant these days, and it is this criterion that is primarily guided by the buyer when choosing radiators.

Steel is the best material for making batteries at this stage of time, it is better than cast iron and aluminum, since cast iron is too rough, in simple terms, and it is also “old”, while aluminum is too vulnerable and cannot withstand heavy loads

Advantages and disadvantages of an aluminum heating device

Aluminum products have a number of positive qualities, which are the reason for the popularity of these products.

- Aluminum radiators weigh relatively little. which makes them easier to transport and allows you to install them yourself.

- Such batteries look attractive and can not only heat, but even decorate various rooms.

- The characteristics of the material and the well-thought-out design of the batteries result in high heat transfer. Aluminum batteries can significantly save heating costs. by reducing the volume of coolant in each section.

- Such batteries quickly respond to changes in coolant supply. cool down almost instantly. This allows you to warm up the premises in a short time and increases the efficiency of thermostats, which also reduces heating costs.

- Powder coating makes batteries easy to maintain. there is no need for periodic painting.

- There are models that can withstand high pressure.

- All this is combined with a relatively low price.

How to maintain a constant room temperature using a thermostat for heating radiators?

What are the advantages of electric heating. Types of boilers, do-it-yourself installation and connection.

But such products also have several disadvantages. Things you need to know before purchasing:

- Prefabricated devices use rubber sealing elements, which makes it impossible to use antifreeze as a coolant.

- Low protection from corrosive processes. To extend the operating period, it is necessary that the water has neutral acidity and does not contain abrasive particles that can damage the protective film.

- Air may accumulate inside the heating appliance. To bleed it, it is necessary to equip the battery with an air vent.

- The weak point of such a battery is the threaded connections.

Yet, for the most part, the properties and features of aluminum heating devices make them ideal for heating systems.