Expansion tank for heating of a closed type, installation of pressure , principles of operation, malfunctions and methods for eliminating them. Expansion tanks ensure safe and reliable operation of circuits with hot and liquid media and are mandatory elements for closed water heating systems and auxiliary elements for domestic hot water. The choice of a specific model depends on the circulation volume, pressure and other parameters of the system and is justified by calculation; the selection and installation rules are taken into account in advance.

What types of expansion tanks are there?

Depending on the membrane, expansion tanks are divided into types. In the first, the membrane is replaceable - if necessary, this most vulnerable part can be removed to be replaced with a new one. This type of tank is also different in that the water is inside the membrane, that is, it does not come into contact with the inner walls. The solution protects the metal from destruction, and water from accidental contamination, spoilage, and odor, which has a positive effect on its hygienic qualities and extends the service life of the unit.

In tanks of the second type, the membrane is fixed strictly in one place and cannot be removed. This membrane cannot be replaced. Damage to it will entail the need to replace the tank, which will require additional costs, often unforeseen. Another disadvantage of such tanks is the direct contact of water with the walls of the container, which affects the condition of the metal and corrodes it. To avoid this, the inside of the tank walls are coated with a special compound, although such protection does not ensure exceptional durability of the device.

Tanks are available in horizontal or vertical layout - the choice is determined by the chosen installation location.

Expansion tank problems

One of the reasons for the drop in pressure may be a breakdown of the expansion tank. There are two reasons for this: wear of the membrane and damage to the chamber. It is not very difficult to detect a breakdown in the tank: you need to press on the nipple. If air comes out and a characteristic sound is made, then the tank is in good condition. If water comes out, it is necessary to replace the membrane or the expansion tank itself.

You should not try to glue the membrane, because in the process of constant compression and stretching, the hole will appear again. There is a boiler with a built-in tank. In this case, there is no need to look for components for boiler equipment; it is easier to install an external tank and install a plug on the old one.

We recommend: How to repair a heating circulation pump yourself?

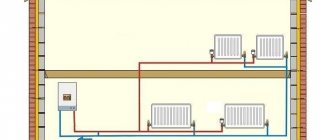

Place of the tank in the heating system

The expansion tank of the heating system serves to compensate for the increase in coolant volume as a result of its thermal expansion.

If the circulation is forced, then the pressure at the connection point of the unit is equal to the static pressure at this point at a given temperature (the rule only applies if there is one membrane). If we assume that it changes, then it turns out that in a closed system a certain amount of liquid appeared out of nowhere. This is counterintuitive.

An open heating system is a vessel with a complex shape, with specific convection currents. All components must ensure the rapid rise of the hot coolant to the highest point and its subsequent gravity drainage through the radiators into the boiler. In addition, the design of the system should not prevent air bubbles from moving upward.

In this case, the expansion tank is always located at the highest point of the single-pipe system, as a rule, at the top of the accelerating manifold.

Leak search

As we already understood, if there is no tightness, there will be a sharp loss of pressure. Of course, it is necessary to conduct a full inspection of the system to identify all problems. The main thing here is not to rush!

The best thing is that leaks can be seen quite quickly, since in places where there are leaks there will be accumulations of moisture or a white coating.

During the inspection, you need to inspect everything very carefully, without rushing. It is especially worth paying attention to the connection points. So, for example, pipes made of metal are more likely to leak at the seams. You have found the leak, but what to do next? We need to start fixing this problem.

How does this happen? The detected leakage area is repacked, new gaskets and seals are installed. Be sure to install new parts a little thicker than the previous ones. If it turns out that the pipeline is severely damaged, then it is worth replacing with a new one.

How to install the tank correctly

When installing an open tank in the attic, a number of rules must be followed:

- The container should stand directly above the boiler and be connected to it by a vertical riser of the supply line.

- The body of the vessel must be carefully insulated so as not to waste heat heating a cold attic.

- It is imperative to organize an emergency overflow so that in an emergency situation hot water does not flood the ceiling.

- To simplify level control and make-up, it is recommended to install 2 additional pipelines into the boiler room, as shown in the tank connection diagram:

Note. It is customary to direct the emergency overflow pipe to the sewer network. But some homeowners, in order to simplify the task, take it under the roof straight to the street.

Installation of a membrane-type expansion tank is carried out vertically or horizontally in any position. Small containers are usually attached to the wall with a clamp or suspended from a special bracket, large containers are simply placed on the floor. There is one point here: the performance of a membrane tank does not depend on its orientation in space, which cannot be said about its service life.

A closed-type vessel will last longer if it is mounted vertically with the air chamber upward. Sooner or later, the membrane will exhaust its resource and cracks will appear. When the tank is positioned horizontally, air from the chamber will quickly penetrate into the coolant, which will take its place. Installing a new expansion tank for heating will have to be done urgently. If the container hangs upside down on the bracket, the effect will appear faster.

In a normal vertical position, air from the upper chamber will slowly penetrate through the cracks into the lower one, just as the coolant will reluctantly go up. As long as the size and number of cracks do not increase to a critical level, the heating will work properly. The process takes a long time, and you will not notice the problem right away.

A sure sign of critical wear and cracking of the membrane in a closed expansion tank is a drop in pressure in the home heating network. Periodically monitor the pressure gauge readings on the safety group.

But no matter how you place the vessel, you should adhere to the following recommendations:

Hydraulic accumulator malfunctions and how to fix them yourself

The reason for this may be: lack of or too low gas pressure in the accumulator; damage; damage to the body; difference in pressure when starting - turning off the pump; incorrectly selected tank volume. To eliminate these malfunctions, you should accordingly: - pump air with a garage or other type of compressor through the tank nipple; — repair of rubber or bulb is not considered justified and therefore the bulb can be easily replaced, and the membrane is better restored in a service center; — any work on the integrity and tightness of the housing should be carried out by a service center. — set the pressure switch to an increased differential for matching pump activation; — check that the tank capacity is sufficient.

Water flow through valve

Evidence of damage to the membrane and the need for it (preferably for service).

Low pressure in the accumulator (below design) air

The seal of the nipple is broken, for which you need to blow it out and, after installing it in place, restore the appropriate pressure in the air part.

Low water pressure

This can be caused by a lack of air in the tank. Pumping air with a compressor is not difficult.

Low water pressure after the pump

In this situation, it is necessary to establish the correct choice of pump or its serviceability.

By the way, in order to detect whether the membrane has ruptured, you need to disconnect the container from the system and drain the water. If air comes out of the drain valve, it means that the membrane has ruptured.

Based on the recovered pear, the nature of its damage can be determined. Before installing new rubber, you need to clean the inner surface of the tank from possible uneven welds and dirt.

Experts do not recommend pumping air in advance, since its pressure in the cavity leads to incomplete filling of the cylinder, which is reflected in the early activation of the pressure switch. In addition, the liquid should be pumped into the cavity of the pear within 1.8 atmospheres, and then stabilized to the required level. They also summarize that it is better to check the air supply by bleeding the water before starting the pump.

Open type plastic heating tank

The standard material for an expansion tank is metal, but such containers often corrode when exposed to air and water. The way out of this situation is to install a plastic tank, for example, a plastic 20-liter canister with a cut bottom, or a plastic bucket.

At the bottom of such a container, a tap is installed on an elastic band, then a piece of hose is secured, which is securely fixed in the metal pipeline.

Hydrogen release

If you have an aluminum radiator installed, then you may clearly have a situation where water will decompose into its constituent elements, including hydrogen. This occurs due to the presence of a static charge in the metal.

Due to the fact that sometimes manufacturers are negligent in the production of radiators, you may experience corrosion on the radiator.

The constant formation of plugs gives you a signal that hydrogen is present in the system. The problem can only be solved by replacing the radiator. Don't try to repair it, it will lead to even bigger problems!

Installation of a membrane expansion tank: subtleties of work

To install expansion tanks, you must use the following algorithm:

- the tank itself and its volume are selected (for forced systems a membrane-type model is required);

- Next, the device is fastened (the installation location of the tank must be level, reliable fixation is required, for open containers additional connecting pipes are laid);

- Next, a connection is made into the return pipeline, for which you can use plastic or steel pipes of the appropriate diameter (it must correspond to the diameter of the expansion tank chamber);

- after connecting the pipes and installing the American tap, it is necessary to check the pressure and operating conditions of the heating expansion tank (the container is filled with water, excess air itself leaves the gas chamber through a special valve);

- if necessary, you can install an emergency drain, which will be located after the American tap (for this, a tee with a branch is installed to install a half-inch tap to drain excess water).

At this point, the installation of the expansion tank for heating is completed, you can begin setting up the system and starting it up. To correctly determine the operating pressure, it is necessary not only to pre-calculate the volume of the tank, but also to determine parameters such as pressure indicators in the general system, the air chamber of the tank, for recharging equipment (if necessary) and the level of the maximum possible pressure.

Peculiarities

The question of how these tanks should normally operate is related either to operational irregularities or to the need for maintenance. The main purpose of using a tank is to eliminate the expansion effect of heating water. It is getting larger, but the volume of pipes, radiators and storage tanks is finite. In closed heating circuits, 100% filling is required, and this means that the excess coolant mass must be dumped somewhere. The tank becomes a suitable place.

If suddenly there is no way out, the liquid will certainly find a path through which the excess will escape. Safety valves usually become such a place, but still this is rather an emergency equipment. Even if they work exactly as they are supposed to, you will have to remove the spilled water and refill (top up) the system. Installing tanks in advance helps prevent this from happening. And even when the coolant boils, keep everything in perfect order.

The need to install an additional tank

Expansion tank device

If the house is heated using a double-circuit gas boiler, then the built-in expansion tank should compensate for the excess water. When the liquid in the heating system heats up, the pressure increases. The incoming valve of the expansion tank opens and part of the liquid enters the container. As the temperature drops, the volume of water decreases, and excess liquid in the tank fills the pipes and batteries. This way the heating system maintains the required water level.

Double-circuit gas boilers are most often equipped with expansion tanks with a volume of 6-8 liters. Such a container can work successfully in small houses. If it is necessary to heat a large area, and the heating system uses many radiators, then a large volume of capacity is required. The expansion tank built into the gas boiler is not able to accommodate the entire volume of excess water. Therefore, for the smooth operation of the heating system, the installation of additional capacity is required.

If you neglect the additional capacity, then after the standard tank is completely filled, an emergency discharge of water from the boiler will occur. The liquid will continue to be removed from the heating system until the pressure in the batteries stabilizes. After the temperature drops, water from the tank will begin to flow into the heating circuit. But after an emergency release, the pressure in the system will drop so much that the boiler will not be able to automatically start working. Delay in refilling the heating system with water may result in its defrosting or destruction.

Installing an additional tank will avoid an emergency discharge. After filling the container installed on the gas boiler, water will begin to fill the auxiliary tank. And when the water temperature drops, the liquid goes into the radiators, maintaining a constant volume in the circuit.

It is better to install an additional tank of a larger volume than the calculated value. In most cases, a 10-12 liter expansion tank will cope with excess fluid.

What malfunctions may occur

The expansion tank of the cooling system has such a simple design that it does not even suggest possible breakdowns. It would seem like a plastic container with a lid, why should it fail? But it is the lid that can sometimes cause problems. It contains a pressure valve, the correct functioning of which directly determines the performance of the engine cooling system as a whole.

During operation of a vehicle with a tank, the following malfunctions may occur:

- rupture of the container body;

- the appearance of a coolant leak from under the cap;

- the plug valve is broken or dirty.

If the tank is seriously damaged, for example, due to a rupture, the tank cannot be restored

Many car owners, if the cap or tank breaks, simply buy a new part, due to its low cost and availability. But if desired, these elements can be repaired: seal the container and clean the lid from contamination. If smudges appear, the reason, as a rule, comes down to a loose fit of the lid to the body due to design features.

Most car owners, when a tank or cap breaks, buy a new part so as not to waste time on repairing them

Pressure in the membrane tank and checking it

For a closed heating system to work properly, the pressure in the expansion tank must be 0.2-0.5 Bar lower than in the system. The larger the system, the greater the pressure difference. But, as already said, at the factory they are pumped up to 1.5 Bar, so before installing the expander, it is better to check it and adjust it to your heating system.

The spool is often hidden under a plastic cover

We check the pressure with a pressure gauge by connecting it to the outlet with the spool. If the pressure is higher than you need, bleed off a little. This is not difficult to do - press the petal in the nipple with something thin. You will hear the hiss of escaping air. When the pressure reaches the desired level, release the petal.

If the membrane tank is inflated too weakly (this also happens), it can be inflated with a conventional pump. But it’s more convenient to use a car one, with a pressure gauge - you can immediately control the pressure. After verification, you can install it on the system.

Why does pressure drop?

When the system is running, sometimes a malfunction occurs in the form of a pressure drop in the pipeline. This may be due to two reasons:

- depressurization of the system;

- The expansion tank is not adjusted correctly.

Leaks can be detected visually. Smudges are visible where the liquid leaks. In operating mode, liquid usually appears. Sometimes the boiler itself or the expander may leak. If depressurization occurs on metal surfaces, they are repaired by welding or replaced. If the membrane in the tank breaks, it is replaced; if this is not possible, you will have to purchase a new container.

The second malfunction occurs during the initial period of operation or when gas is removed from the expander by mistake. In this case, it is necessary to re-adjust the pressure.

Why is an expansion tank needed in a heating system?

Water heating has been and remains the most popular among us. For this system to work properly, it is necessary to maintain stable pressure in the network. An expansion tank solves this problem

Creating a heating system is expensive, and each element entails new costs. Is an expansion tank mandatory? Perhaps we can do without it? To answer this question, let’s remember the basics of physics. As you know, a heated liquid has a lower density than a cold one. Due to the difference in these values, hydrostatic pressure arises, pushing hot water to the radiators. But a decrease in density leads to an increase in volume. This means that excess coolant is formed in the network, due to which the pressure in the pipes will increase to critical values. Where should we put them? The answer is obvious - into a separate container, namely into the expansion tank. Water or antifreeze remains in it until it cools (and reduces in volume). After this, the liquid returns to the pipeline. It is clear that the expansion tank is a necessary component of the heating system.

Open type heating scheme

What should you pay attention to when choosing it?

First of all, the type of heating system.

There are only two of them. Open (self-flowing)

assumes that the coolant is water circulating through pipelines naturally, without the use of any forcing mechanisms. These systems use tanks without a lid and install them at the highest point of the circuit. Since water from such a container inevitably evaporates, its level must be constantly monitored. If you neglect this, air will accumulate in the pipes, interfering with the operation of heating devices.

Antifreeze cannot be used in open systems, as it will quickly evaporate from the tank

In a closed (autonomous)

heating system there is a pump that encourages the fluid to move. The entire system is sealed, and therefore evaporation of the coolant is excluded. This, in turn, allows you to use not only water, but also antifreeze. Obviously, in such a scheme a closed tank is used.

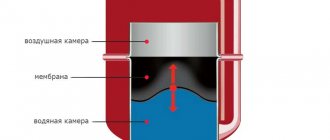

Design of a closed expansion tank

The mechanism of action of the expansion tank depends on the design features of the membrane installed in it. A device with a membrane in the form of a diaphragm is a steel barrel or a flat rectangular tank divided in half by a rubber partition. Even at the factory, air is pumped into its upper chamber, creating the initial pressure. And after installation on site, coolant flows into the lower part of the tank, setting the flexible membrane in motion. When it rests on the water/antifreeze surface, the system can be started.

During operation, excess heated coolant is discharged into the tank, compressing the air contained in it. This forces the membrane to move into the air chamber, thereby making more room for excess liquid. When the water/antifreeze cools, decreasing in volume, the pressure on the diaphragm decreases and it returns to its initial position. This is how the pressure in the system is regulated.

In tanks with a balloon-type membrane, a rubber container for the coolant is installed, surrounded by air around the perimeter of the tank. When a heated liquid enters, it expands, like an inflated balloon, and returns to its original size when the coolant cools.

Tanks of this kind have two noticeable advantages. Firstly, they allow precise control of the pressure in the system. Secondly, their membranes can be replaced as they wear out, which cannot be said about diaphragm tanks.

Additional Information

The expander helps to absorb hydraulic shocks created by air pockets and sudden closure of the valve. Tanks can perform this function if they are placed on the return flow of the coolant directly in front of the boiler. Do not assume that the pressure set at the factory will be ideal for practical needs. It is reconfigured using a spool valve.

Important: any pressure gauge, when measuring pressure in the expander, registers only an excess value; to obtain an absolute figure, add 1 bar.

A pumped tank does not work well, since the air will push the coolant out. If everything is configured correctly, but the fuses continue to periodically discharge water, most likely the problem is in the expander being too small. Therefore, it is worth choosing tanks that hold 10% of the total coolant circulating in the system, or even more. Since the tank does not have fittings for pressure gauges, they must be connected to the nipple. It is located on the side opposite to the coolant-filling circuit.

Since car and bicycle pressure gauges measure pressure in MPa, you need to compare their readings with the pressure in the heating system (expressed in bar or kgf/sq. cm). One bar is equal to 100 kPa. When using a car meter, it is recommended to wait 10 minutes after turning off the boiler for the circulation to stop. When the tank is built into the boiler itself, it is necessary to shut off not only the shut-off valves, but also the coolant supply and its return. By following these recommendations, you can significantly simplify your life.

To learn how to check the serviceability of the expansion tank, see the following video.

The circulation of coolant in the heating system is ensured not only by pumps, but also by maintaining the required pressure. In the event of low pressure, the movement of liquid in the pipes slows down, for this reason the automation mechanisms are triggered. This leads to a reduction in the operating period of the heating system.

How to set the optimal pressure?

The heating system has pressure gauges that control the pressure in the circuit. On the expansion tank itself there is no fitting for installing a measuring device. But there is a nipple or spool for releasing and pumping air or gas. The nipple is the same as on car wheels. Therefore, you can check the pressure level and adjust it using a conventional car pump with a pressure gauge.

Before releasing excess pressure or pumping air into the expansion tank of a domestic gas boiler, it is necessary to prepare the system. The car pressure gauge shows the value in MPa; the data obtained must be converted into atmospheres or bars: 1 Bar (1 atm) = 0.1 MPa.

Pressure measurement algorithm:

- Turn off the gas boiler. Wait until water stops circulating through the system.

- In the area with the hydraulic tank, close all shut-off valves and drain the coolant through the drain fitting. For boilers with a built-in tank, the return flow is shut off, as well as the water supply.

- Connect the pump to the tank nipple.

- Pump up the air to 1.5 atm. Wait a little for the remaining water to pour out, then let the air in again.

- Close the valves of the shut-off valves and use a compressor to pump up the pressure to the parameters specified in the passport or to the level - pressure in the system minus 0.2 atm. If the tank is pumped, excess air is released.

- Remove the pump from the nipple, screw on the cap and close the drain fitting. Fill the system with water.