Electric boilers are used for heating private houses where other types of energy sources are not available. And although they run on the most expensive “fuel,” many owners do not consider this a disadvantage. It is much more important that the equipment has an optimal power/price ratio, a long service life and does not cause problems during installation.

Features of electrical equipment

The manufacturer produces climate control equipment that is initially adapted to work in Russian conditions. And one of the most popular are electric boilers. Their main advantages, noted in reviews of owners and specialists:

1. Reliability and long service life.

2. Decent efficiency – 93%.

3. Compliance with strict European quality standards.

4. Easy to install and operate.

5. Smooth adjustments and the possibility of programming, which has a positive effect on the efficiency of the electric boiler.

6. Immunity to changes in the network up to 10% of the nominal value.

7. Adequate price.

Most Evan products can be controlled remotely via GSM or Wi-Fi. Only budget EPO models of minimum power do not have this function. But not everything is so rosy if you read the reviews of owners of economy class boilers. Many people complain about incorrect and loud operation of the starting relay. In fact, this is a real problem due to which the electric heating boiler simply does not heat the water to the desired temperature. Buyers are also concerned about the small cross-section of the wires, which leads to overheating and burnout of weak contacts. But in fairness, we note that such “diseases” are found only in the Evan budget lines: Economy and Standard.

History of the brand

This domestic manufacturer appeared on the heating equipment market in 1996. It was at this time that Evan CJSC was created, which produced products using modern schemes.

Currently, the company offers a wide selection of heating devices, in particular electric boilers. In 2008, Evan was included in the NIBE Energy System, which is one of the divisions of the concern, which occupies a leading position in the field of heating equipment.

Products manufactured by Evan JSC have many different diplomas and certificates.

The best models of Ariston storage water heater

The products of this brand have the following categories:

- traditional boilers;

- floor boilers;

- condensing boilers;

- floor boilers;

- boilers with indirect heating;

- gas instantaneous water heaters;

- water heaters equipped with heat pumps;

- gas storage water heaters;

- electric water heaters with storage function.

Each device is equipped with heating elements, control devices and additional accessories.

Features of Evan electric heating boilers

Such units are in great user demand. This is due to the fact that such equipment is inexpensive, and its quality is high.

Let us note the key distinctive features of Evan electric boilers:

- the devices are easy to use;

- a larger selection of different models; the market offers both very simple designs and more

- improved with remote control;

- the assembly is of high quality;

- There are industrial models of high-power boilers; such units are designed to supply heat to industrial, administrative, and residential premises;

- boilers operate on various coolants, incl. and non-freezing;

- You can connect remote control modules that operate via GSM or Wi-Fi channels.

How to choose a boiler?

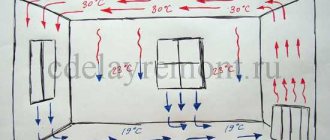

Before you find the answer to the question of how to choose a boiler for heating your home, you need to develop a detailed plan. Usually, the desire to save money on designing a heating system and performing thermal calculations leads to even greater expenses. By combining a heating system design with a ventilation design and additional inspection of the thermal insulation, you get a heating system that functions extremely efficiently. Think through everything wisely, and then you will be able to get maximum pleasure and not have to overpay for anything.

Date: 04/24/2018 12:19:00

Read more

Advantages

Evan heating boilers have the following advantages:

- long service life;

- high reliability and durability;

- high productivity, efficiency - 90% or more;

- products are made in accordance with European standards, which are of high quality;

- installation is simple;

- simple device control and the ability to program, which saves electrical energy;

- tolerate power surges well;

- acceptable cost.

Advantages and disadvantages

Heating devices such as induction boilers, like other similar units, have their pros and cons. It is necessary to familiarize yourself in detail with both their positive and negative sides if you are going to install such equipment in your home. First, let’s look at what is good about induction types of heating boilers.

The main advantage of such units is their reliability. If such products have automation, then they can operate autonomously, and the owners do not have to constantly monitor them. In this case, only the absence of a thermal fluid can lead to a breakdown of the device - then the core body in the system can overheat too much and, as a result, melt.

Induction boilers are distinguished by high efficiency (over 90%). Of course, the specific value mainly depends on the design of the heat exchanger in the unit and other structural features of a particular model. The advantages of such units include the fact that their efficiency does not decrease over the years, so even after a long time you will not notice that your heating system has become less efficient.

Induction heating equipment is not subject to breakdowns - it will not require frequent and expensive repairs. To install such a unit, there is no need to additionally construct ventilation or a chimney, which often costs users a tidy sum.

Such equipment serves for quite a long time. If you use these types of heating boilers correctly, they can last more than 30 years, since there is nothing to burn in them, because the inductor is hermetically sealed in the housing and is reliably insulated from contact with the coolant. In addition, the coils are not twisted tightly and are filled with a special protective compound. For this reason, the possibility of damage to the turns is minimized.

The liquid in such systems is heated to high temperatures. The minimum value is 35 degrees Celsius. Such units are installed quite simply. Household models are a small piece of pipe, which is sealed on both sides. There are 2 fittings on the housing, which are necessary for connecting the coolant supply and return. There is also a cord to connect the automation. Connecting such systems is not particularly difficult - you can cope with this simple work without the involvement of specialists.

Induction heating systems are characterized by high operating efficiency. They are characterized by low inertia, so heating of the coolant begins very quickly (immediately after the system starts). Such boilers turn off just as quickly. In such a device, the waste coolant does not need to be changed too often. It is enough to do this once every 10 years.

These types of heating devices, as a rule, do not leak, since they do not have detachable internal connections. These units are capable of operating at both direct current and low voltage. According to experts, harmful scale does not accumulate on the heating element in such devices. This occurs due to the vibration of the core (because of this, excess particles cannot be deposited on it). In addition, scale will not accumulate due to the temperature of the coolant (not higher than 90 degrees Celsius) and the closed nature of the system, in which a limited number of carriers may be present.

Now it's time to get acquainted with their disadvantages:

- First of all, a number of disadvantages of such devices include their high price. They cost several times more than devices with heating elements. However, the high cost is due to the presence of automation.

- Usually these devices have an impressive weight. For example, a cauldron with a diameter of 12 cm and a height of 45 cm will weigh as much as 23 kg.

- These boilers are suitable exclusively for closed heating systems.

- Such units can create wave interference at a short distance. For this reason, experts advise installing them as far as possible from any household appliances.

- If you are going to install an induction boiler in a large house with 2-3 floors, then you will have to additionally install a high-power circulation pump - this is necessary for the device to operate stably.

- Induction units are energy dependent. If the electricity in your home is turned off, the heating will also stop working. Of course, this problem can be solved - you can purchase diesel generators, but this will be an additional expense.

Models of electric boilers Evan

All products manufactured by Evan are divided into series, depending on their functionality, performance and cost.

Standard-Economy

This model range is represented by inexpensive wall-mounted electric boilers with a wide power range. The units with the lowest power produce only 2.5 kW and provide heating of one room from a 220 V network.

Externally, the devices look very simple; the package includes a control module that allows you to control and adjust the temperature in the range from +30 to + 85°C. To heat a large private house you will need a three-phase electric boiler Evan.

Today the most popular heating boilers are Evan EPO-18 kW 380 Standard-Economy. Productivity - 18 kW allows the use of such devices to supply heat to houses and apartments up to 180 m² in size. The boilers heat water up to +30-85°C, and even in such an inexpensive series there are controllers for turning on/off the heating element in case of changes in the characteristics of the coolant. The control panel is separate, because EPO models do not have a body as such.

Standard

This series is also budget-friendly; electric boilers are equipped with the necessary automation. Compared to EPO devices, here the control panel is built into the boiler body. The power range of the devices here is smaller than that of the previous series.

All models up to 7.6 kW can be connected to a single-phase network. You can adjust the temperature settings using the rotary knob. However, such changes will not affect energy consumption in operating mode.

Based on the specified heating, the relay will simply turn off the boiler at the moment when the coolant reaches the desired level. If the temperature of the liquid in the heating system exceeds +92°C, then the heating element will be automatically de-energized.

Electric boiler Evan Standard C1.5 - 7.5 is available in two variations: with the ability to connect to a dedicated single-phase line and a three-phase network (380 W).

At the same time, the technical characteristics of Evan Standard electric boilers and their cost remain exactly the same. Externally, the model is neat and small in size.

Electric boilers Evan S1 are mainly used to supply heat to residential and administrative buildings that do not have a connection to gas mains. Their main advantages are a very reasonable price and a fairly attractive appearance.

Comfort

This series is very economical, the boilers regulate the consumption of electrical energy according to the temperature difference: actual outside and indoors, according to the requirements. These devices have all kinds of automation systems, flame modulation, remote control, automatic temperature control and many other important and necessary options.

The Evan Universal boiler is equipped with weather-compensating automation and multi-stage power control; external control panels are connected to them. The electric boiler Evan Warmos iv 5 is equipped with reliable heating elements, automatic temperature control, and a special power limiter. Also, such units can operate at low supply voltage.

They have two auxiliary operating modes: “anti-freeze”, “warm floors”. The most advanced modifications include the electric boiler Evan Varmos-RX and Warmos-M; they are equipped with auxiliary safety systems and built-in circulation pumps.

The power of Comfort series units varies from 3.74 to 120 kW. Thanks to this, such devices can heat rooms up to 1200 m²

Electric boiler EVAN Warmos M 7.5

Lux

Electric boilers for private homes in this series operate in accordance with the specified settings. Apart from setting the required parameters, owners do not need to do anything else; the devices will independently coordinate the operation of all heating systems and ensure safety.

The Lux series includes Expert boilers, which are available in several power options - from 7.5 to 27 kW. The electric boiler Evan Expert 12 and the boiler Evan Expert 9 have found the widest demand among users.

Such devices have the following characteristics:

- An intelligent system that optimizes the operating mode based on the analysis of street and indoor sensors, as well as programs that the owners set independently.

- Full set of electronic security system.

- Built-in automatic air separator.

Technical characteristics Evan Expert for heating a standard private house, the area of which is 150 m² - you need average ones. The set of electric heating boilers of this series contains all the necessary sensors and control systems. In order to be able to heat water, it is possible to aggregate it with an indirect heating boiler.

Please note that you will still have to purchase a storage tank separately. An electric boiler will be responsible for its operation, which will respond to temperature changes and hot water supply.

VIP

This series includes multifunctional electric boilers, which can be used not only to supply heat to premises, but also to organize water supply in buildings of any type.

Assembly of electric boilers Evan VIP - Finnish!

These units are recognized as one of the most powerful, with thermal characteristics reaching up to 1.6 mW. Heating devices are equipped with various automation systems, durable fillings, remote controls, powerful heating elements - in some models their power reaches 105 kW.

Principle of operation

The purpose of the boiler is to increase the temperature of the coolant in the heating circuit. The heating method depends on the design features of the device.

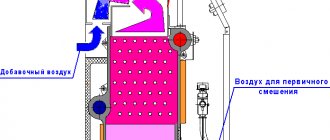

Heating elements new boilers

The heating element of the installation is a metal tube, inside of which ceramic chips or quartz sand are placed. In the middle there is a rod made of nichrome or tungsten. The contacts are connected to electrical wires. In operating mode, voltage is applied to the spiral. Due to its high resistance, it begins to heat up and transfers thermal energy to the water. The heating elements are placed inside a tank filled with liquid.

The container can be placed vertically or horizontally. When the boiler is operating, the heating element is always hidden under the liquid, otherwise the heating element will quickly fail. To control the temperature and pressure inside the tank, sensors are used that transmit operating parameters to the control unit. To ensure coolant circulation in the circuit, many models are equipped with an electric pump.

Commissioning is accompanied by a sharp jump in energy consumption, because All heating elements are turned on at the same time. When the coolant reaches the specified parameters, the boiler maintains the water temperature at a constant level.

Induction boilers

Devices of this type use the effect of electromagnetic induction. A metal rod is placed in a coil with a given number of turns. In this case, eddy currents are formed, causing an increase in the temperature of the element. The core heats the circulating coolant.

The device is a cylinder with an inductance coil built in along its entire height. There is a metal core inside. The free space is filled with coolant. Thyristor starters are used to regulate power.

Induction installations are reliable and long-lasting. The efficiency of the devices reaches 99%. Using demineralized water or antifreeze as a coolant relieves the consumer of problems with scale.

The units are compact, which allows the devices to be mounted on the wall of the room. There are productive devices whose power reaches 60 kW.

Electrode boilers

The operation of these installations is based on the conductivity of water containing metal salts. A current is passed through the coolant, which causes ionization of the solution. Charged particles move towards the electrodes. Due to the internal resistance of the molecules, the liquid begins to heat up.

The apparatus consists of a cylindrical tank, the outer part of which is covered with insulation. An electrode connected to the phase is installed inside. The housing is connected to the neutral cable. When voltage is applied, the temperature of the coolant begins to increase sharply.

Devices operating on the principle of solution ionization are compact in size and highly reliable. Powerful units are designed for connection to a 3-phase electrical network. Sequential installation of several boilers is allowed. A feature of electrode generators is the inability to control the power of the device. The device can only operate at full capacity. Adjusting the water temperature is achieved by turning the device off and on.

The most popular models of electric boilers Evan

In this section we will give examples of models that are in greatest demand and have many positive user reviews.

The most frequently purchased model is the Evan Epo 4 electric boiler. This device includes a heating element with a power of 4 kW. The maximum size of the room that such a device can heat is 40 m², the coolant temperature ranges from +30 to +85°C. The device is supplied with an external control panel and is connected to a single-phase 220 V network.

Electric boilers Evan Epo 6, 8, 9, 15 are also widely popular. The Evan 15 boiler is used for operation in three-phase electrical networks.

Electric boilers Evan Warmos IV-5 are equipped with heating elements whose power reaches 5 kW. Such devices can heat rooms with an area of 50 m². The unit is controlled via a built-in remote control or using a connected remote control unit. With the help of such boilers you can regulate the temperature with high precision, down to 1°C.

Review of the electric boiler Evan Warmos IV-5

They can also regulate power automatically and are equipped with built-in automation systems. If necessary, a circulation pump can be connected to them.

Electric boilers Evan Warmos QX-15 are designed for heating rooms up to 150 m². They are produced in wall-mounted versions and are equipped with self-diagnosis systems, air vents, safety valves and room thermostats. Also on board there is a built-in circulation pump and a 12-liter expansion tank. Such boilers combine functionality and an affordable price - they are well suited for ensuring a comfortable temperature in any building.

How to wire an electric boiler?

Principles for choosing an electric boiler

When purchasing a boiler, there are several other factors to consider.

A very important parameter is the boiler power. For modern OK it varies from 2.5 kW to 60 kW. A weak boiler will not cope with providing heat to the room; an overly powerful one will lead to unreasonable expenditure of electricity and money. The required power is calculated using a special formula. To find out the power, you will need to multiply the area of the room by the specific power (DP). The second indicator is set separately for each region. The figure obtained as a result of multiplication must be divided by 10. Let's say the house is located in the Moscow region, where the UD is 1.2 kW. The area of the house is 200 square meters.

Power adjustment deserves attention when choosing. It comes in two types:

- stepped;

- smooth.

The first type of regulation is used in devices with independent electric heaters. As a rule, with this adjustment option, the boiler can be operated at 25, 50, 75 and 100 percent of the designed power.

For smooth regulation, a rheostat is required.

In cheap units whose power is low, there is no possibility of regulation.

When purchasing an OK, rated for 380 volts, it is necessary to be able to connect a three-phase power line to the house.

You should look at how many circuits the OK is designed for. Electric boilers are usually not used to heat two circuits because they consume too much electricity.

Automation OK is important. It ensures the safety of the unit and allows you to rationally use electricity by regulating the temperature

It is practiced to install two types of thermostats:

- mechanical;

- electronic.

A mechanical type thermostat operates either on bellows filled with gas or liquid, or on bimetallic plates. When the temperature reaches the set value, the thermostat opens the electrical circuit. After the temperature drops below a certain level, the thermostat turns OK again. Mechanical automation is simple, resistant to voltage surges, but not sensitive enough. Deviations from the set temperature by two to three degrees are possible.

Electronic automation can control both the temperature of the room and the coolant. It is characterized by high sensitivity and accuracy in operation. The temperature can be changed using the control panel or by preset programs. The cost of such automation is higher than mechanical.

OK are sold in a basic configuration and with additional options (expansion tank, remote thermostat, etc.) They may or may not be needed. Before abandoning the purchase of additional devices, you should calculate the results of such a step. If you need to purchase them after purchasing the basic version of the electric boiler, it will cost more.

OK housings can be made of various materials (steel, copper, plastic, etc.). The material affects the strength of the body and fire safety.

The price of the unit is influenced by several factors:

- power;

- number of circuits;

- additional options;

- type OK;

- manufacturer.

For example, electric boilers from well-known European brands will, of course, cost more than Chinese or Russian ones. Heating element OKs cost less than electrode or induction ones.

Russian electric boiler "Zota"

Consumer Reviews

When choosing heating units of this brand, it is necessary to study the opinions of users who already use these boilers. It’s worth noting right away that it’s difficult to make a definite assessment of the equipment, because people leave different opinions and often their views on a particular unit differ.

However, some general conclusions can still be drawn. Most users note the good and high-quality performance of Evan heating devices. It is noted that during operation, electric boilers make virtually no noise, they are easy to operate and maintain, and the performance of such devices is at a high level. Despite the large number of positive reviews, there are also negative ones. Users say that the automation system has some shortcomings and it quickly breaks down.

Review from the owner of the boiler Evan EPO-4

With all this, in general we can conclude that Evan electric boilers are of good quality and affordable for most people.

Installation of a manufactured boiler

Before installing the boiler, you need to choose the most suitable location for it. It should allow the following manipulations to be performed correctly and easily:

- Laying out the necessary heating system pipes.

- Convenient to connect.

- Control the work process.

- Maintain and carry out repair work as necessary.

To achieve this goal, it is necessary to first draw up a detailed diagram of the placement of the radiator and the layout of all pipes belonging to the heating system

In addition, it is very important to choose the best option for the location of the manufactured boiler. As a rule, such equipment is compact in size, so they can be placed on the ground floor of a residential building; many install it in the basement

Experts recommend mounting heating element boilers on the wall using special dowels. If we are talking about electrode boilers, they must be installed on the pipes of the heating system; they can also be secured to the wall using clamps. Due to their heavy weight, induction boilers are recommended to be mounted on the floor, strictly in a vertical position.

The process of connecting a self-made electric boiler is carried out strictly to a separate machine, which is located in the electrical panel and to the grounding circuit. The shield should be designed for the highest boiler power ratings, and it is advisable to entrust the quality check of the grounding circuit to a specialist.

It’s quite simple to make a high-quality electric boiler with your own hands and save money. All that is required is just to approach the process of assembling it as responsibly as possible.

The quality of the work performed is very important, since the boiler operation process is based on the circulation of water, which can leak if there are problems. This will automatically lead to serious waste of material resources. A responsible approach to the implementation of an electric boiler will lead to the fact that it will work as long and efficiently as possible

A responsible approach to the construction of an electric boiler will ensure that it operates as long and efficiently as possible.

Features of choice

After deciding to purchase an electric boiler, you need to understand the types and technical parameters that distinguish different models.

Technical characteristics of electric heating boilers EVP Stanless

Types of boilers

Electric boilers are:

- Heating elements.

- Induction.

- Electrode.

Heating element boilers are the most common. They work the same way as a kettle. Heat is transferred to the room by driving water through pipes, heated by boiler heating elements. Different boiler models can have from 1 to 3 heating elements. The power indicated for an electric boiler is the total power of all its heating elements. The water in the pipes is driven by a circulation pump.

The models have been on the market for a long time - the work has been streamlined, the design has been thought out.

Heating element heating boiler - diagram

Induction boiler. It has a dielectric tube wrapped with wire, inside which there is a core closed to itself (made of any metal to which a magnet can stick). The current passing through the coil creates an electromagnetic field and causes the molecules in the core to move, heating it.

An induction boiler is a very reliable device. The only thing that can break in it is the electronic control unit. The price of induction boilers is higher than others. But the sellers’ assurances about innovative technologies and great efficiency are based on nothing and contradict the laws of physics. Induction principles were discovered by M. Faraday almost 2 centuries ago and have long been successfully used in industry.

Induction electric boiler

Electrode boilers heat by passing current through the water. The problem is that you can only use water that can be called “drinking” according to GOST.

The electrodes in such boilers dissolve over time and require replacement.

Heating element boilers should not be connected to a running water supply - scale forms on the heating elements, which is more difficult to deal with than in a kettle. Therefore, it is better to use the same coolant in the system. Also take a closer look at models that have filters.

Power

The power of the unit will depend on the dimensions of the room to be heated.

An important role will be played by the quality of insulation and thermal conductivity of the building materials used in the construction of the house.

Approximate calculation for a reliably insulated house with a ceiling height of about 3 meters:

For 10 m2 of area, 1 kW of electricity is required.

If the house is located in areas with harsh winters, you need to add 10% to the resulting power indicators.

Choose units in which the power can be adjusted taking into account the weather (the thermostat can be built-in or connected separately). Then the theoretical costs of electricity will actually be much lower.

Voltage and cable

In both cases, you need to connect through a separate machine on the meter, which will protect the network.

Before buying powerful boilers, evaluate the real capabilities of your electrical networks.

The cross-section of the cable should be larger, the higher the load on it and the more devices will operate simultaneously in the house.

For example, a 4mm2 copper wire at a voltage of 220 v can power an 8 kW boiler, and at a voltage of 380 v – a power of 19 kW. A copper wire with a cross section of 6 mm2 at a voltage of 220 v will pull 10 kW of power, and at a voltage of 380 v - 26 kW.

Manufacturer

The most affordable boilers, which have proven themselves to work well, are from domestic companies - RusNit, Nevsky, Evan.

German units (Bosch) will cost the most. They are crammed with automation and are famous for their reliability.

Wall-mounted heating boiler Evan

Other popular manufacturers:

- Eleko, Elbeva, Protherm (Slovakia) - adapted to the Russian climate;

- Dacon (Czech Republic) - about 30 boilers with a capacity from 4 to 60 kW;

- Kospel (Poland).

Main characteristics of EVAN NEXT:

- Power 3, 5, 7, 9, 12 and 14 kW;

- In boilers with power - 3, 5, 7, 9 kW - three-stage control;

- Boilers with a power of 12 and 14 kW have two-stage control;

- Adjustment of liquid temperature in the heating circuit from 30 to 85 degrees C;

- Thermally insulated body;

- Block heating elements made of stainless steel Backer (Czech Republic);

- Boilers up to 9 kW have the ability to connect both 200V and 380V;

- Block for connecting the circulation pump;

- Block for connecting a temperature sensor or remote control module Evan Climate

- Overheat protection;

- The ability to use water and any certified liquids for heating systems as a coolant;

- When installing a mixing valve, it is possible to use heated floors in the systems;

- Quiet operation;

- Efficiency – 99%;

Advantages of Evan WARMOS – IV:

- Model range with power range from 3.75 to 30 kW;

- 3 power levels;

- Possibility of limiting power in manual mode;

- Automatic selection of the required number of power steps to maintain the specified coolant temperature;

- Setting the coolant temperature with an accuracy of 1°C in the range from 5°C to 85°C;

- Heating elements made of stainless steel Backer (Czech Republic);

- Rotation of heating elements to increase the life of heating elements;

- Time delay for turning on/off the heating element;

- Independent emergency shutdown circuit;

- Stability of operation at low (up to 180 V) and high (up to 260 V) voltage;

- When starting the boiler at temperatures below “0” (when using non-freezing liquid in the system), the boiler’s operability is maintained, “-0” is displayed on the indicator;

- A display displaying the current set temperature and the number of operating power levels. Light indicators displaying all the necessary information - displaying the current temperature in the range from “0” to “+90°C”;

- Thermal insulation of the housing Quiet operation (models up to 12 kW);

- Socket for connecting a circulation pump Socket for connecting an external thermostat / EVAN GSM/Wi-Fi Climate remote control module;

- The ability to use both water and non-freezing liquids certified for heating systems as a coolant;

- The thread of the inlet/outlet pipes is internal G 1 ¼;

- Self-diagnosis of faults Indication of emergency codes;

- Efficiency – 99%;

- Installation method: wall;

- Warranty – 24 months;

Evan WARMOS RX - in these models of electric boilers, along with all the advantages of the WARMOS - IV model, the boilers are equipped with a room sensor

temperature, which allows you to regulate not only the coolant temperature, but also the room temperature. This model of equipment has pressure control in the system and protection against high and low pressure, which allows you not to worry about equipment failure if there is a problem in the line. Protection against overheating of power elements allows the boiler to turn off as soon as one of these elements exceeds the permissible temperature level. Also, this boiler model has protection against incorrect connection and you can be sure that if the wires are mixed up, replacing the fuse will bring the boiler back into working order.

EVAN STANDARD.

In our store the Evan Standard line is represented by electric heating

EVAN NEXT with power from 3 to 14 kW. This boiler is intended for use in heating houses, cottages, small retail and warehouse premises. EVAN NEXT is an ideal backup heat source when using the main gas or solid fuel boiler. The Evan Next monoblock combines a boiler and a control panel. The equipment operates silently and has a compact size, which allows the boiler to be installed in the living area of the premises.