Everyone knows what heating radiators are, but few can imagine what plate heating radiators look like. Meanwhile, these are simply metal heating devices that release heat more efficiently, made from straight or curved tubes through which the same coolant flows. But for accelerated and more complete heat transfer, plates are welded or crimped to the tubes, which increase the heat exchange area between the radiator and the atmosphere in the room many times over. Plate heating batteries are used both when connecting centralized heating and when working with autonomous heating systems, in private houses, apartments, public and industrial premises. Their connection ensures savings in energy resources, the radiators themselves, minimization of the heating circuit and high system efficiency.

Options for plate radiator models

Radiator design

Depending on the design features, radiators can be divided into several subtypes:

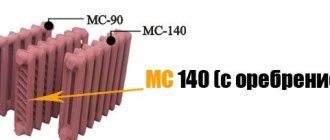

- Sectional heating radiators - these batteries have several sections, so you can assemble a radiator of the desired size and power. The sizes and shapes of sections may vary.

- Tubular radiators are a solid metal structure that has an upper and lower horizontal collector and vertical tubes welded to it. Such batteries are the prerogative of centralized heating, for which they were designed.

- Panel batteries can be either steel or concrete. Concrete ones are built inside walls; they can only transfer heat by radiation.

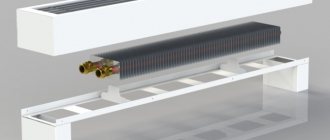

- Plate batteries - have convective heat exchange, consist of a core and ribs made of thin metal plates mounted on it.

Separately, there are corner heating radiators. They can be made in any given design option. However, corner radiators are designed for installation in the corners of rooms.

Corner radiators

Heating convectors or registers

A heating convector is a pipe on which thin steel plates are attached. The design is simple and rather primitive. They were often used in Soviet-built houses. But now, having undergone some evolution, they have somewhat changed their appearance and functionality.

There is a very large selection of them on the market. Along with the cheap ones, quite expensive, elite, imported models are also offered. Electric convectors are becoming increasingly popular. They are used when installing heated floors. Plinth convectors, popular in Western countries, are considered a new product.

These seemingly modest, relatively cheap products have many advantages. The simplicity of the design provides the convectors with good reliability. Small dimensions do not interfere with the implementation of design ideas.

Another big plus is the affordable price. A significant drawback is the low heat transfer with the convection heating method. Simply put, the air is heated unevenly due to a kind of thermal draft.

Heating convectors on the left are wall-mounted, on the right are floor-mounted.

Kinds

Taking into account the arrangement of sections in the structure, tubular radiators are of the following types:

- horizontal;

- vertical.

Based on the shape of the heating structure, the following radiators are distinguished:

- radius;

- flat;

- corner;

- designer

The radial device follows the bends of the arc; in a flat radiator, the sections are arranged in a row. Corner devices are divided into two sections, which are located opposite each other at an angle, and as for designer radiators, such models are notable for their originality; in such models, the pipes can be curved in different ways, for example, repeating the shape of a wave or being round.

Taking into account the method of installation of tubular radiators, they can be of the following types:

- wall;

- floor;

- corner.

The first type of radiator is purchased most often; however, the height of the product has limitations. Floor heating devices are installed on metal fasteners - legs, corner models are produced to order, they are mounted to the wall, the number of turns is selected individually, in each specific case. As a rule, a complex device configuration implies a higher cost of the finished radiator.

You will learn more about the types of radiators by watching the following video.

Precautionary measures

Like working with any other tool, operations with an extractor require compliance with certain rules. For safe and fruitful work, you need to follow a few simple rules:

- To protect your eyes from damage, you must use safety glasses. Flying chips or metal fragments pose a serious hazard to your eyesight.

- Using a larger extractor will destroy the walls of the fragment, making them difficult to remove.

- The tool is made of hard but brittle metal. To avoid breakage, distortions must be avoided.

- The body of the bolt remaining inside the surface must not have radial cracks. Otherwise, it will not be possible to drill a hole without compromising the integrity of the walls.

- It is not allowed to use non-standard objects to rotate the extractor: pliers, pliers, etc., or to extend the crank handles with tubes. This may cause the rod to fail.

- It is necessary to correctly distribute the applied forces so as not to break the thread of the spiral extractor.

It is clear that it is more effective to carry out operations to unscrew broken fasteners using a special device. To do this, it must be of good quality and made of high-alloy tool steel or chrome vanadium alloy.

https://youtube.com/watch?v=C1J7z64mjJM

Of steel

Steel panel radiators - as a rule, such radiators are installed in private houses, cottages, or low-rise buildings. Thermal indicators are the most highly efficient.

If you put such a radiator in a high-rise building, you will not receive the required amount of heat, and use in central heating systems can lead to radiator malfunction (due to high pressure and possible water hammer).

Flaws:

- In open heating systems (with access to oxygen), steel radiators rust. Because of this, they are not recommended for open heating systems.

- Without coolant, steel begins to rust.

Connection options for heating elements

Connecting a plate battery.

Any factory-made plate heating element is equipped with a kit with a built-in valve insert. It, together with the thermostat, participates in the process of adjusting the temperature of the radiator. In addition, there are batteries with an integrated complex through which they are connected to the heating circuit pipes located under the floor or mounted in the wall.

Convectors in most cases can have either a side or bottom connection. In the case of the lateral connection method, the fittings of the heating element are brought out to the side of its casing. With horizontal heating wiring, the owner of the battery will have to buy a special fitting. It will help adapt a horizontally located device and a vertically rising section of reinforcement from a horizontal contour. Things are better if the heating circuit runs vertically through the room. Then the fitting is not needed.

With a bottom connection, the radiator pipes exit to the surface of the casing from below. This simplifies the connection of the heating element to a horizontal circuit, but complicates the installation process in the case of vertical wiring.

A steel plate heating radiator should only be connected to a system with forced coolant circulation. Otherwise, water will move at a low speed through the system, which will degrade the performance of the heating element.

It is not recommended to install steel plate convectors in a heating system with an open expansion tank. In this case, the coolant is regularly enriched with oxygen due to direct contact with air. As a result, the acidity of the coolant increases, which leads to corrosion of the inner surface of the radiator tubes. Their service life is reduced.

If water convectors are nevertheless installed in an open heating system, then the circuit must be equipped with an anti-diffusion barrier. It prevents oxygen from entering the heating circuit.

Steel radiators: technical characteristics, advantages and disadvantages

When arranging their own home, many homeowners are faced with the problem of choosing radiators for heating structures. A fairly good option are steel radiators whose technical characteristics are impressive.

Information regarding the technical characteristics of heating devices, and more specifically:

- working and testing pressure;

- coolant temperature;

- other parameters that influence the efficiency of a particular model.

This information is completely understandable for every consumer. This article talks about the technical characteristics of steel heating radiators.

Heating batteries made of steel come in two types:

Characteristics of flat radiators and their design

Flat steel radiator with a smooth surface Steel products are included in the category of thin heating radiators. To make them, metal sheets are taken and passed through stamping. Using welding, iron blanks are connected into an appropriate structure, which ensures the reliability and strength of the connection. To connect to the general system, pipes are used. The coolant moves through a special channel located between two plates.

The design is:

- single-row and multi-row;

- with a smooth surface;

- with a profiled surface on one or both sides;

- flat;

- with or without ribs;

- with thermostat.

A small depth is characteristic of each stamped sheet, which is associated with other design features:

- Two panels welded together have high heat transfer.

- A small internal cavity for coolant movement. This is not only a plus, but also a minus. On the one hand, saving on coolant saves the budget, on the other hand, it is necessary to constantly monitor the level of supplied temperature.

With thermostat With ribbed surface

Dimensions

The depth of the product depends on the number of ribs inside

- Type 10. This group includes products with a depth of 46 mm.

- Type 11. The thickness of these products is slightly increased, corresponding to 59 mm. This is due to the addition of convection fins to one side of the battery.

- Type 12. The thickness of such radiators is 64 mm, due to the arrangement of convection fins between two panels.

- Type 22. Product made of two panels equipped with fins. The depth of the product reaches 102 mm.

- Type 33. The widest radiators, their thickness is 157 mm due to the arrangement of three plates with three parts of fins.

Power depends on product type, height and length.

The lowest heat transfer is characteristic of products of types 10 and 11 with a height of 300 mm and a length of 400 mm. It is 265 W. If we compare a radiator with the same parameters of class 21, the heat transfer will be 370 W.

Basically, flat heating radiators are produced with a height from 300 mm to 600 mm, and radiator lengths from 400 mm to 3000 mm.

Manufacturers

The German manufacturer Kermi has been producing flat radiators for more than 10 years, and since 2011 they have been actively supplying products to the Russian market. Kermi batteries quickly gained the trust of users and took leading positions. And this is not surprising, because radiators from this manufacturer are famous for their high quality, efficiency and long service life. Kermi provides a 10-year warranty on its products, which is quite a high figure. Kermi flat radiators are produced in two variations: with a corrugated or smooth front surface. They are painted using the cataphoresis method in two layers. Due to the fact that the top and side grilles are easily removable, the radiators are very easy to clean from dust.

The company's line includes the Profil series with a profiled front surface and the Plan series with a smooth front side. The following varieties are available in both series:

- ThermX2 - valve batteries. The radiator has built-in control valves in accordance with the power.

- ThermX2 Kompakt - flat radiators of compact size. They are universal, suitable for low temperature conditions.

- Kompakt Hygiene - hygienic batteries coated with a double layer of varnish. Such devices are suitable for hospitals, they can be washed with disinfectant solutions, and they are also easy to clean due to their open shape.

Tubular steel heating radiators

Steel heating radiators of this type are installed much less frequently than panel appliances. The reason for less popularity is the high cost of tubular devices. The structural solution of such heating radiators is a series of vertical or horizontal steel pipes that are connected to collectors. As a result, the heater quickly heats up and cools down, and its operation is controlled using an automatic controller.

The design of tubular radiators can be very attractive; they are often made in the form of interior items, as in the photo. They have the following parameters: height 190 – 3000 millimeters, depth – no more than 225 millimeters, length has no limit. Experts recommend: if tubular steel heating radiators are installed under a window, make sure that their length is at least 75% of the width of the window opening.

These devices have the following parameters:

- working pressure not higher than 12 atmospheres;

- crimping pressure up to 25 atmospheres;

- maximum coolant temperature 120 °C.

Since tubular devices can withstand strong water hammer, they are considered an ideal solution for installation in apartments of multi-story buildings.

Types of screens for heating devices

In modern interior styles, the appearance of an accordion battery is not always suitable. For this reason, special casings are often used that fit over the device and provide the required design. You can use a sheet of steel to cover the facade of the device, but in most cases this is not enough. The best solution in terms of aesthetics and functionality is special screens for radiators. Such products completely cover the surface of the battery, but do not interfere with heat transfer. Air circulation is not disrupted and the device still effectively heats the room.

Screen designs are very diverse. The main ones include:

- Box It completely covers the radiator, but its surface is not flush with the wall. There are many ready-made solutions available on the market; each type of heating device has its own type of protective casing. The floor screen is simply attached to the wall, and the wall-mounted version is attached to a vertical surface with dowels. To regulate the temperature in the room, special devices with a remote sensor are used. Such equipment can be used for completely closed heating radiators.

Screen for the battery in the form of a box Source rusolymp.ru

- Screen. This product does not have end walls, which is the main difference from the previous version. The screen is located on top of the battery; it is quite light, since it is made of tin. Materials based on fabric, plastic and wood are also sometimes used. Such screens are combined with a radiator in cases of constructing a false wall. As a result of its construction, the device ends up in a niche, which is closed using a flat screen.

Screen for a radiator in the form of a screen Source peskiadmin.ru

Despite many advantages, screens also have certain disadvantages. They disrupt the circulation of heated air, which reduces the efficiency of the devices. The heat mainly heats the walls, since it stagnates in the area of the heat exchanger. In this case, it is better to insulate the wall with polystyrene foam, otherwise you will not heat the room, but part of the street.

Determination of thermal power of plate heating devices

The formula for determining the thermal power that a steel plate heating radiator can produce, and a real example of calculating this parameter, are given below. To calculate the power of the device, it is enough to know the heat loss coefficient of the heated room, the area of the room and its total volume. The passport of any radiator indicates its calculated power at a hot water temperature in the system of 60 0 C. Also, the attached documentation indicates recommendations for the heated area for a specific radiator model.

The thermal output (power) of heating devices depends on the length of the body and the number of plates. The standard height of radiators is 200 mm, the number of plates varies. For example, heat transfer for a radiator with one tube and a body length of 600 mm will be equal to ≈ 347 W. When the length is increased to 3000 mm, the heat transfer will increase to 1730 W. But with the same body length (3000 mm) and an increase in pipes to 4, heat transfer there will already be 4179 W, and with a body length of 1000 mm, four tubes with coolant will give 1393 W of power. Therefore, which radiator is best to buy for a specific room is determined based on the following requirements:

- To heat 1 m2 of a room with a ceiling height of 3 m, you need to spend 100 W;

- For a room with an area of 16 m2, the radiator must have a thermal power of 1600 W, provided that the room has no more than one window, the room is not corner and the ceiling has a height of no more than 3 m. For other initial conditions, correction factors Kp are introduced:

- For two windows Kp = 1.8 / 1600 x 1.8 = 2880 W;

- For a corner room Kp = 1.8 / 2880 x 1.8 = 5184 W;

- For a ceiling 2.65 meters high Kp = 2.65 / 3.0 = 0.88 / 5148 W x 0.88 = 4547 W;

- For PVC windows Kp = 0.8 / 4547 W x 3637 W.

What threats does centralized heating pose?

On the one hand, supplying heat from outside is more convenient than autonomous heating - you don’t have to bother with installing the boiler and setting it up. Autumn will come, and hot water will happily run through your radiators, warming your apartment.

But not everything is so smooth in the centralized heating system:

- Water that has traveled a long way contains many chemically active impurities that can cause corrosion of pipes and radiators.

- And small particles of sludge, which inevitably fall into the coolant, scratch the batteries from the inside, wiping them to holes after a few years.

- And the water temperature is not always stable - sometimes the batteries are at room temperature, or sometimes it’s impossible to touch them.

- And the most important danger is a sudden huge surge in pressure in the heating system, the so-called water hammer. It happens, for example, for the reason that the mechanic closed the tap of the pumping station too abruptly.

This is interesting: Laying heated floors under tiles - system installation technology

Radiators made of Corado steel

The Czech company Corado is already well known on the domestic market. This is due to the design features of its products.

Corado steel radiators (technical characteristics in the product data sheet confirm this) are made from pressed sheet cold-rolled steel:

- The material from which Czech panels are made is chemically inert, so it is not affected by low or high pH values of water.

- A large model range allows you to choose a heater of the required power, color and size (table of steel heating radiators from this issue).

- They contain less coolant, which reduces energy consumption for heating it.

As experts note, Corado radiators offer unsurpassed quality at an affordable price.

To summarize, we can say that steel panel radiators are an opportunity to choose an effective model from a wide range of products with the required level of heat transfer, which will create pleasant warmth and microclimate in any room.

Of steel

This category includes heat devices with high efficiency and a working pressure of 9 atm, withstanding 13 atm. crimping. Such batteries are in demand in individual construction, or if multi-storey buildings have their own heating unit.

Radiators are made of steel sheets with stamped recesses for coolant. Protruding fins are welded on the back side to increase thermal output: they enhance the conventional air flow. Heating devices are made of low-carbon steel with high anti-corrosion properties. Coating – powder enamel.

They are divided into two categories: panel and tubular. Panel ones represent a continuous heat-conducting surface, tubular ones consist of sections in the form of vertical pipes and can be different in design, as a result of which their cost is slightly higher.

Restoration of an accordion battery

Floor wooden screen-box.

In one of the articles we talked about the decor of heating pipes. Today we’ll talk about how you can restore a radiator to its human form with little effort by restoring it:

- clean;

- paint;

- You can also paint the radiator if you have the desire and artistic talent.

On various women's forums there are topics where housewives exchange experiences on how to wash an accordion battery. Indeed, it is difficult to wash away the dirt between the ribs. The fins are very thick, a lot of dust gets clogged there. Besides the fact that it is unsightly, it is also harmful to health.

Heating is carried out by convection method. Hot streams pick up dust and carry it throughout the room. If you constantly breathe such air, asthma, allergies, and cases of respiratory diseases may become more frequent.

You should not wash the accordion battery with caustic chemicals, since you are unlikely to be able to wash it off completely. When the heating is turned on, all the chemicals will enter the air.

Unfortunately, there is only one option - to remove the dirt mechanically. That is, you need to take a stiff brush, a bowl of water, a cloth and clean it. Don't forget to place a cloth under the radiator. Also cover the walls next to the radiator. A hard brush will cause a lot of splashes.

Painting a battery consists of the following steps:

- removing old paint with a remover - available in any hardware store, cheap, sold in glass bottles;

- primer – for the paint to lay more evenly and to adhere more firmly, the heat exchanger must be primed;

- painting - it is advisable to paint when the heating is turned off.

Naturally, only the visible parts need to be painted - these are the ends and the casing. Do not paint the fins under any circumstances. Such batteries already have poor heat transfer, and a coat of paint will make it even worse.

Selecting a radiator type

The choice of model depends on the needs and technical characteristics of the heating system. Any type of radiator is suitable for private houses with an autonomous heating system.

If you are purchasing a device for an apartment located in a multi-story building, you should think about purchasing a panel model, since the operating pressure in such buildings is quite high.

In addition, in multi-apartment high-rise buildings, the heating system “suffers” from pressure surges. Tubular and plate batteries may not withstand water hammer, become deformed or lose their tightness.

When choosing a heater, you should also take into account the interior of the room. There are decorative models, the height of which is only 20 cm. They are installed near the floor and serve not only as heating devices, but also as interior elements.

Which radiators to choose for an apartment?

So which heating batteries are best to choose for an apartment?

Which product will provide enough heat and last a long time? Here you can choose from two options: Cast iron batteries. They easily tolerate deficiencies in the quality of the coolant in central heating networks. In addition, cast iron products are not afraid of pressure changes. Also a big plus is low cost and long service life.

Bimetallic radiators. This is a good alternative to cast iron products. They have similar characteristics, but bimetallic batteries are more aesthetically pleasing.

Of course, if you have enough funds, you can install copper batteries. Such devices will work almost forever and heat the apartment perfectly.

The aluminum and steel option is more suitable for an autonomous system. In this case, the owner himself will monitor the quality of the coolant and prevent foreign impurities from entering it. Also, the pressure in autonomous systems is much less.

What types of low heat exchangers are there?

Devices are distinguished based on the following criteria: the type of material from which they are made, the design features of the main components - sections, plates and height. They are produced in heights from 200 to 450 mm, lengths from 500 to 6,000 and depths from 10 to 230. The following types are distinguished:

1. Cast iron sectional, ribbed. The advantages are good thermal inertia and corrosion resistance. Disadvantages: low operating pressure up to 10 atmospheres, fragility, susceptibility to the accumulation of dirt and plaque inside the channels, which reduces heat transfer over time. Compact batteries made of cast iron are models MC 140M-300 (height 388 mm).

2. Steel panel radiators consist of one or more heating plates enclosed in a ribbed shell. They have excellent thermal conductivity and low inertia, and consume a minimal amount of coolant. For example, a steel radiator measuring 100 mm deep, 300 mm high and 1,000 long can create an effective thermal curtain near a window with a glazing area of up to 4 m2.

Disadvantages: not resistant to water hammer; when water is drained, corrosion can form on the walls of the panels; the convection method of heat transfer contributes to the formation of small dust particles in the room. Of all compact heating devices they have the highest cost. For example, the price of a Kermi radiator with a height of 300 mm, depending on the length and depth, is 1,260 - 5,100 rubles.

3. Aluminum casting and extrusion sections are characterized by light weight, good heat dissipation and elegant design. The technical characteristics of a low aluminum radiator allow it to withstand operating pressures of up to 16 atmospheres. Disadvantages: low convection, service life (10-15 years), instability to water hammer and, as a result, possible leaks between sections. You can buy a 200 mm battery made of aluminum for 340 - 1,250 rubles.

4. Bimetallic ones consist of 2 parts: a core made of steel or copper pipes and an aluminum shell. The advantages are: the ability to withstand high (up to 100 atmospheres) pressure, small volume of water consumed and good corrosion resistance. The sectional low bimetallic radiator Rifar Base 200 has a closed rear surface, which allows it to be mounted in close proximity to glass surfaces. Some models are equipped with legs for installation on the floor. However, in terms of heat transfer, bimetallic batteries are inferior to aluminum products, and their cost is 10-15% higher.

5. The lowest are plate batteries of the convector type. Such linear or plinth radiators have a height of 200 to 400 mm and can be attached to the wall and floor, and, if necessary, covered with decorative grilles. They are characterized by good heat transfer and the ability to withstand operating pressures of up to 20 atmospheres. Produced in the form of solid products of a certain length. If there is a leak, they require a complete replacement, which causes some inconvenience.

What to consider when purchasing

The modern market for heating appliances is saturated with products from Russian and global brands that differ in technical characteristics, quality, and price. In order to avoid unnecessary costs and not make mistakes with quality, experts recommend taking into account the following factors:

1. For centralized heating systems that are installed in residential multi-storey buildings, cast iron radiators are suitable. For buildings with panoramic windows, it is better to use bimetallic or aluminum ones.

A clever meter that saves electricity. Pays for itself in 2 months! Everyone needs to know this in order to save!

For closed heating systems that are installed in private homes, batteries made of steel or aluminum are recommended.

2. The length of the radiator must correspond to the size of the window opening or be 10-20 cm longer. Otherwise, it will not be possible to create an effective thermal curtain, which will lead to uneven heating of the air in the room.

Technical characteristics and cost of the most popular models

Connection to the heating system

For thin, flat plate radiators, the best habitat will be closed heating systems equipped with a special one. Connecting the structures in question to open systems is strictly not recommended due to the high probability of damage to the radiator and a decrease in its service life.

In addition, it is contraindicated to drain water from the system too often, replacing it with fresh water. This recommendation is associated with an increased oxygen content in fresh water, which leads to an increased corrosive effect on radiators and other elements of the heating structure. It should also be avoided in areas where high levels of moisture in the air are predicted - for example, in the bathroom - due to the same risk of rusting.

Flat heating radiators are installed in systems equipped with or metal ones. Therefore, you should definitely consider installing an anti-diffusion barrier. It will help save the system from unwanted and destructive oxygen.

Before purchasing and installing flat batteries, you should very carefully and thoughtfully examine the performance of the heating system installed in the house. If equipped with a special safety valve, the required water pressure can be kept at no more than 2.5 - 3.0 bar.

The best option in case of replacing old heating devices with new ones is to invite specialists who will calculate all the characteristics taking into account the features of new modern radiators.

Flat radiators constitute a separate category of radiators; their depth is 2 times less than the parameters of conventional cast iron models. Compact dimensions help reduce dust accumulation; such equipment can be used in tandem with narrower window sills.

For the manufacture of steel flat heating radiators, stamped metal sheets connected to each other are used. High-tech welding contributes to the formation of reliable, durable joints.

Two connected panel planes exhibit a high degree of heat transfer; a small internal cavity is formed in them, through which the coolant circulates. In order to use the equipment as rationally as possible, you need to adhere to the recommended temperature regime. To optimize fuel consumption, fins were added to the planes, resulting in the formation of a new class of technology - convection finned batteries. Additional elements are attached to the surface using spot welding; in cross-section, the equipment has the shape of a trapezoid.

Flat batteries in the upper part are equipped with perforations - these are zones for the exit of heated air. The casing contains metal pipes with radiator plates. The working fluid, circulating through the tubes, releases part of the heated air; the flow path also passes through the upper zone with metal perforations. In the process of heating the front part, a little more thermal energy is released.

Flat radiators are optimal for closed-type heating systems; they are not advisable to install in centralized networks. These devices work with coolants exhibiting low pressure levels.

Aluminum

Aluminum heating radiators are made not from pure aluminum, but from an alloy based on it. This metal was not chosen by chance, as it has one of the highest heat transfer coefficients - 4-4.5 times better than cast iron and 5 times better than steel.

Table with thermal conductivity coefficients of different metals

That is why aluminum radiators are distinguished by their high power (180-190 W per section), no less high heating rate and low inertia. They work very effectively in tandem with thermostats, allowing you to maintain a stable temperature with an accuracy of one degree. The advantages of aluminum radiators include their low weight (one section weighs 1.5-2 kilograms), which makes delivery and installation easier. Another positive point is that the shape is designed so that it has a large cross-section of channels for the coolant (slightly smaller than that of cast iron “accordions”). This is good, since there is a low probability that these channels will become clogged and the radiator will stop heating.

Now about the disadvantages of aluminum radiators. They are related to the properties of aluminum. As you know, it is a chemically active metal. It actively interacts with most of the chemical table, and reacts especially violently with copper. And in modern heating systems, copper parts are often found. Such a proximity threatens the rapid release of copper parts of the system and system, as well as increased gas formation. They have learned to deal with gases - they install automatic gas vents (valves) in systems, and they save copper by not placing it close to aluminum appliances. The process, of course, is still going on, but not with such intensity.

Aluminum radiators look modern

The chemical activity of aluminum also manifests itself in demands on the quality of the coolant. Not in the sense of its contamination, but in the sense of its acidity. Aluminum radiators work normally in systems with coolant acidity no higher than 7 (Ph 7).

The softness of aluminum is also not very good for the operation of the heating system. The alloy from which heating radiators are made contains additives that increase its hardness, but still, they do not work in high-pressure networks. Typical operating pressure is 8-16 atm depending on the type and manufacturer.

Based on all of the above, there appears to be an area in which aluminum radiators will be the best. These are individual heating systems with boilers controlled by automation. They also do well in apartments, but only in small buildings (up to 10 floors), in which coolant with Ph 7-8 circulates.

Heating elements for cast iron batteries

It is not surprising that today many consumers are looking for alternative types of heating their homes. The cost of utilities is constantly rising, which cannot but cause concern. One of the ways to create autonomous heating in an apartment is a cast-iron battery with a heating element for heating.

A heating element is an ordinary metal tube with a spiral located inside it, which is separated from it using a filler. You can make it yourself from available materials. Batteries with heating elements are distinguished by high performance, economy and reliability, and the fact that they are built into the heating system itself allows you to save space and ensure their unnoticeable presence.

Such a device can be equipped with a thermostat to regulate the degree of heating of the coolant and serve as both an additional and the main source of heat.

There are heating elements of different power on the market, so you should make calculations in advance of how many watts will be required per radiator section to heat each individual room.

Main characteristics of a typical radiator

Regardless of the complexity of the heating system, the main task is to maintain the set temperature in the house or apartment. The heating radiator plays a key role in this, carrying out heat exchange between the air in the room and the coolant.

Uniform heating, efficient heat transfer, microclimate maintenance, stable operation - these are the basic requirements for a heating battery.

In residential premises, single, panel or sectional twin radiators are installed that do not emit toxins when heated

The main parameters influencing the choice of a specific model:

- System operating pressure. Depends on whether the device is connected to an autonomous or centralized network. It is arranged on a gravity or forced principle. On average it varies from 3 to 10 bar or in a similar atmosphere range.

- Thermal power. A characteristic required to calculate the thermal power required to heat a room. It is also needed for selecting individual components of sectional batteries. Approximately 1 kW is required to process 10 m².

- Modularity. The quality inherent in prefabricated radiators, which makes it possible to assemble and disassemble the device to suit individual requirements.

- Speed of reaction to tº. More precisely, the ability to respond to changes in coolant temperature. period of time for cooling and warming up.

- Possibility of equipping with automation. Devices that monitor weather conditions and independently eliminate air jams.

The devices now presented for sale ensure free circulation of the coolant liquid throughout the system. They are characterized by corrosion resistance and attractive appearance.

Sectional radiators differ in the shape and size of the sections, ensuring the supply of the required amount of thermal energy

The thermal efficiency of a radiator depends on the energy dissipation surface area. A flat metal convector has a much smaller area compared to a sectional aluminum convector of the same geometric size. Because the latter radiates heat over the entire area of the fins.

Product Description

Device design

Dilapidated plate heating radiators in the USSR were used virtually on a par with the usual cast-iron batteries. They were installed in schools, clinics, government institutions - i.e. where it was necessary to heat a large amount of air.

Today, the design of similar devices has been improved a couple (mostly through the use of modern materials), but the non-specialized scheme has remained unchanged:

- The base of the system is formed by a U-shaped curved tube through which the coolant moves . Taps are installed at the inlet and outlet, allowing the radiator to be disconnected from the system.

Note! Simple ball valves are used much more often, because adjustment of the coolant flow is not necessary, but greater reliability is needed.

- Heat exchange plates are placed on the tube . They can be made of the same material as the pipe itself, or they can be made of a different metal.

- Much more often, this entire system is housed in a thin-walled iron casing, the main function of which is to protect the heat exchangers from dust and protect people from scratches and burns when interacting with the heater . To allow warm air to escape, holes are made in the upper part of the housing.

Operating principle

This system functions quite simply:

- The coolant (warm water or high-temperature steam) moves through pipes under pressure of up to 20 atmospheres. Along with this, the high speed of movement leads to the fact that when moving along the circuit, the temperature of the coolant decreases slightly.

- When passing through the area with heat exchangers, water transfers some of its energy to the plates. Those, for their part, quickly heat up to a high temperature.

- Cold air enters the radiator housing through holes in the bottom.

- The large area of the plates facilitates heat transfer, because their entire surface is in contact with air.

- Once the ambient temperature increases, it rises up and exits the housing through the holes in the lid.

Note! There are also open-frame models, but their operating efficiency is lower due to a certain percentage of heat loss.

The process of vertical movement of air during heat exchange occurs continuously and is called convection. The heating devices themselves are often called convectors.

It must be emphasized that the natural rise of air is not always sufficient. In this case, a fan is mounted in the lower part of the case, which supplies the movement of air masses. On the one hand, the price of heating also increases due to the use of additional electricity, but otherwise the efficiency also increases significantly.

Main varieties

Today the market offers a couple of varieties of plate-type batteries.

They can be roughly divided according to a number of indicators:

| Indicator by which classification is carried out | Varieties |

| Material | It is the material that determines how efficiently the device will transfer heat:

|

| Number of pipes in casing |

|

| Connection type |

|

| Installation method |

|

Conclusions and useful video on the topic

Useful tips from experts will help you understand the choice of heating device:

The best choice of heating radiator can be considered the one that achieves the greatest comfort and coziness. The radiator can be invisible or, on the contrary, be part of the overall design. But the most important thing is reliability and no hassle.

You can tell us about how you chose a radiator to replace old batteries in an apartment or to furnish a new home in the block below. Please write comments, ask questions, share useful tips and photos on the topic of the article. We are interested in your opinion.

Useful tips

When purchasing and installing a thin radiator yourself, it is recommended to take into account the following tips from experts:

- Having made a choice towards a flat steel radiator, it is better not to start the risky undertaking of installing it yourself. Even the presence of detailed installation instructions is not an excuse. The heating system is considered a complex engineering structure, the organization of which must be carried out by specialists.

- Since panel radiators for heating cannot boast a large area, they are not recommended to be made part of systems with natural coolant circulation. It is best to use such devices in forced circulation circuits where pumping equipment is available.

- If a forced water circulation system is used, it should only be closed. This will require the installation of an expansion membrane tank.

- The system should not be emptied frequently. Filling in new coolant is necessarily accompanied by air entering the system. Its presence has a negative effect on steel elements. Although manufacturers take certain preventive measures, it is not advisable to expose the system to risk.

- It is not advisable to equip flat panel batteries in very wet rooms. This leads to the fact that metal surfaces sooner or later begin to rust.

- Any ribbed layer on the radiator becomes a place where dust and dirt accumulate, which is quite difficult to clean. Such contaminants can only be removed with a powerful vacuum cleaner.