With a thorough and correct study of the drawings of solid fuel boilers, it is quite possible to make a long-burning boiler with your own hands, reliable and economical.

Solid fuel boilers have been very popular for decades, although they have one significant drawback - they require constant loading of fuel (coal, firewood, etc.). Because of this drawback, they are often abandoned when arranging a heating system, but it is easy to get rid of it - make a long-burning boiler with your own hands, operating on almost all types of fuel (exceptionally solid, of course).

Do-it-yourself long-burning boiler

You can use coal to light the boiler.

How the unit works

Conventional solid fuel boilers can operate on one fill for about 6-7 hours. If after this time the next portion of fuel is not added to the firebox, this will lead to a decrease in the temperature in the house. The reason lies in the circulation of the main heat in the room according to the principle of free air movement: after heating, it rises up and goes outside. The thermal resource of one stack of firewood of a long-burning device is designed for 24-48 hours. In some models, combustion is maintained for almost a week.

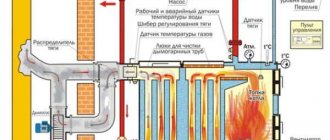

The secret here is this: unlike traditional boilers, the long-burning boiler design includes not one, but two combustion chambers. The first of them is intended for burning fuel, the second is for gases coming from the first chamber. The quality of the process largely depends on the timely supply of air, for which the design has a fan. This approach is innovative: it was first introduced by the Lithuanian company Stropuva in 2000, after which the drawings of long-burning solid fuel boilers were adopted by leading manufacturers of boiler equipment.

Today, units operating on this principle are the most inexpensive and practical option for heating houses in areas without gas supply. The essence of the operation of devices of this type is the combustion of the upper fuel. Typically, the location of the firebox is the lower part: as a result, cold air, after heating, has the opportunity to rise upward. Long-burning boilers are very similar to pyrolysis boilers: the main portion of heat is released not from the combustion of solid briquettes, but from the gas released during this process.

There is a special closed space inside the structure for combustion. The chambers are connected to each other by a telescopic pipe, through which the released gas from the first compartment enters the second. The process of its afterburning is accompanied by mixing with cold air forced by a fan. This procedure occurs without pause, until the fuel burns out completely. It has a fairly high temperature regime - up to +1200 degrees.

The chamber for burning solid fuels has larger dimensions: its volume sometimes reaches 500 dm3. You can load coal, sawdust, firewood, and pallets into it. Stable air supply is ensured by a built-in fan. The combustion process is characterized by a very slow rate of fuel consumption. As a result, the efficiency of boiler equipment increases sharply.

The reason for slow burnout is the injection of air, as a result of which only the upper part of the fuel fill burns out. An increase in air supply occurs only after the top layer has completely burned out. There are a number of heating devices on sale, the essence of which is the same drawing of a long-burning wood-burning boiler. Their varying degrees of economy and efficiency are explained by differences in sizes, materials of manufacture and the presence of additional functions. To operate universal TT boilers, you can use any fuel, which greatly simplifies their maintenance. Wood-burning TT boilers are considered the most economical models.

The best mine boilers

Pyrolysis-type ShKs are now in demand among the population living in one-story and two-story houses, since they have proven their effectiveness and demonstrated ease of operation.

The market responded quite quickly to customer requests and was filled with a wide variety of units from domestic and foreign manufacturers.

In online shopping ratings for 2022, the greatest demand is for units with a service life of more than 20 years and innovative heating surfaces.

Main characteristics of mine boilers.

| Indicators | Pyrolysis 43 Kp-10 | Heiztechnik (12 kW | Wirbel ECO CK Plus 25 |

| Price | 67100 rub. | RUB 215,760 | 277845 rub. |

| Model | 66694 | 90128 | 80023 |

| Manufacturer | Pyrolysis 43 | Heiztechnik | Wirbel |

| Short description | Duration of work on 1 tab is up to 10 hours. Efficiency 85% to 90%. Energy intensity, low fuel consumption. Automatic heating temperature maintenance. | Power 12 kW, new EU product, innovative technology. Eco-friendly heating installation with an advanced burner with auto-ignition and a self-cleaning system. Efficiency - 91%, heating temperature - 85 C. | Universal unit for liquid and solid fuels. Range of heated medium – 40/90 C, efficiency on solid fuel – 85%, on liquid fuel – 90% |

| Power, kWt: | 10 | 12 | 25 |

| Weight, kg | 210 | 350 | 271 |

| Dimensions (HxWxD), mm | 1070x500x800 | 1370x1150x550 | 1260x915x1070 |

| Chimney diameter, mm | 160 | 150 | 160 |

| Manufacturer country | Russia | Poland | Germany |

Thus, to sum it up, we can say that shaft-type boilers are efficient devices with low specific fuel consumption. Such units are used today for individual heating of residential and public buildings, significantly reducing owners’ heating costs.

Design features and device

The chamber for storing fuel in any long-burning boiler is impressive in size. This parameter directly affects the burnout time of the fuel filler. Currently, there are two successfully competing technologies implemented in TT boilers: we are talking about Buleryan and Stropuva devices. The high cost and complexity of making a drawing of a long-burning boiler with your own hands poses certain obstacles to the spread of the last of them in our country. In contrast, the Buleryan method is widely used by craftsmen for independently organizing heating of country houses.

The drawing of a long-burning solid fuel boiler Buleryan consists of the following components:

- A metal case covering the internal chambers.

- Lower chamber for burning fuel.

- Upper chamber for gas combustion.

- Doors for storing firewood. It is located in the upper part of the structure due to the large size of the lower compartment for storing the resource.

- Smoke pipe. It is located at the top of the boiler and is connected to the chimney.

- Ash chamber. It is located at the bottom of the boiler and is intended for cleaning it.

There is also another interesting detail. As you know, in conventional furnaces the function of the ash pan is performed by the ash pan: it is through it that the air necessary for combustion flows. In the case of Buleryan, the ash compartment is made completely sealed: the air supply channel here is the upper air chamber. To regulate the oxygen supply, there is a damper at the top of this chamber. As combustion progresses, the wood in the firebox gradually settles, which causes the distributor to lower. This ensures a continuous supply of fresh air.

To carry out a new load, the distributor can easily be returned to its original position by pulling it up. The position of this lever serves as a kind of reference point for the level of remaining fuel: in this way you can determine how long it will take to load the next portion of firewood. Buleryan boilers are highly environmentally friendly, which is explained by the complete burnout of fuel and gas: virtually no carbon dioxide enters the atmosphere. Read also: “How to make a wood-burning boiler with your own hands - step-by-step instructions.”

The design of a long-burning solid fuel boiler is as follows:

- Firebox. The main structural element of any boiler or furnace. Designed to burn fuel in it.

- Gas afterburning section. Here the gases coming from the furnace burn out.

- Ash pit. Compartment for collecting ash. It needs regular cleaning.

- Chimney. A channel for discharging combustion products outside the home.

Classic long-burning boiler

In this section, we bring to your attention a homemade heating unit using wood and coal, designed and made by our expert Vitaly Dashko. The master assembled several dozen similar heat generators of varying power to order, constantly improving the design. For a brief overview of the TT boiler, watch the video:

The reliability and efficiency of boilers has already been time-tested at various facilities. The technical characteristics of the presented unit model are as follows:

- power – 22–24 kW;

- burning time (on average) with wood is 10-12 hours, minimum – 8 hours;

- the same, on coal - up to 1 day;

- Efficiency - 75-77%;

- maximum operating pressure in the heating system – 3 Bar, nominal – 1.5 Bar;

- the amount of water in the boiler tank is 50 l;

- product weight - 150 kg;

- loading opening size (width x height) 360 x 250 mm;

- total volume of the firebox - 112 l, useful volume (for loading fuel) - 83 l;

- firebox depth - 46 cm, optimal log length - 40 cm.

For reference. The master manufactures long-burning boilers of various powers; the line includes units of 16, 24, 36 and 130 kW. The price of a finished product for 24 kW when ordering from a specialist is about 450 USD. e. All questions and clarifications related to the design of a solid fuel boiler and its manufacture can be discussed personally with Vitaly, whose contacts are listed on the “Our Experts” page.

The design and overall dimensions of a long-burning wood-burning boiler for DIY production are shown in the drawing:

The heat generator operates successfully on both wood and coal fuel. The useful capacity of the firebox is calculated up to the lower edge of the loading opening, since it is undesirable to fill the chamber to the top. The boiler operates in the following order:

- After loading and igniting solid fuel, the doors are hermetically closed.

- The electronic control unit sets the desired coolant temperature; it is recommended not lower than 50 °C. Then the unit is put into operation by pressing the corresponding button, and the fan starts.

- When warming up to the set temperature, the fan turns off and air access to the firebox stops. The TT boiler is in standby mode, the wood smolders very weakly and produces virtually no heat.

- After the temperature in the boiler tank drops, the controller gives a command to start the fan and the combustion process in the furnace resumes.

The controller changes the fan performance at its discretion in order to achieve maximum combustion efficiency. There is no smoldering combustion in this homemade boiler; it is either in a standby state or burns wood and coal in an intensive mode.

The internal structure of the unit is shown in the sectional drawings of the boiler:

The heating installation implements the classic method of burning solid fuels with direct heat transfer to the walls of the water jacket and the vault, which is the bottom of the boiler tank. A fire tube heat exchanger is immersed in this tank, removing heat from the flue gases. The air heated in the channel is supplied to the firebox from below, through the grate. Burning duration is ensured by:

- Large firebox volume.

- Completely blocking the access of air to the firebox in standby mode. After the fan is turned off, the gravity damper is activated, closing the air duct and thus preventing the chimney draft from blowing up the coals.

The structure of the rear part and the fire tube heat exchanger is shown in the following drawing:

Tools and materials for manufacturing

The blanks for assembling a long-burning solid fuel boiler are usually made from low-carbon steel grades St 3, 10, 20. The best option is St 20; heat generators made from it last up to 15 years. Steel containing more carbon (St 35, 45) tends to heat up at high temperatures, and is therefore unsuitable for welding a heat generator.

If you have sufficient experience in welding and the opportunity to buy more expensive metal, then the combustion chamber can be made of heat-resistant steel alloyed with chromium and molybdenum (for example, 12ХМ, 12Х1МФ). How to independently determine the steel grade with sufficient approximation is described in this article.

The list of blanks from which you will assemble a solid fuel boiler with your own hands is given in the form of a table:

Advice. It is best to cut blanks using guillotine shears somewhere in a workshop. This will save you a lot of time on manual cutting and deburring.

Additionally you will need the following materials:

- equal angle angle 50 x 4 mm for making grate bars;

- pipe DN50 – for the heat exchanger and heating system connection pipes;

- pipe DN150 – to the chimney pipe;

- profile pipe 60 x 40 mm for the air channel;

- steel strip 20 x 3 mm;

- basalt insulation with a density of 100 kg/m³ and a thickness of 2 cm;

- smooth sheet metal 0.3-0.5 mm with polymer painting;

- ready-made door handles;

- cord, asbestos cardboard.

Among the tools, it is worth noting a welding machine, a grinder and a drill; ANO-21 or MP-3S electrodes are used for welding. The rest is a standard set of measuring devices and tools available in every home.

The Polish-made fan and control unit fits any homemade TT boiler

The automation kit used in the TT boiler, consisting of a control unit, fan and temperature sensor, is made in Poland (do not confuse it with the Chinese one, it looks the same). The marking of the control unit is KG Elektronik SP-05, the fan is DP-02.

Assembling the heating unit

The first stage of manufacturing a long-burning boiler consists of assembling the firebox body from metal 4 mm thick by tack welding. It all starts from the bottom of the unit, to which the side walls, vault cover and door openings are attached, as shown in the photo:

The bottom sheet is issued in each direction in accordance with the drawing, at the same time it serves as the lower frame of the ash pan door. Inside the chamber, shelves from the corners are fixed by welding, where the grate will rest. The assembled firebox is thoroughly boiled at all joints and checked for leaks.

The second stage is the installation of a water jacket made of 3 mm metal. Its thickness at the side walls is 2 cm, so sections of steel strip should be welded to the firebox body, extending them by 20 mm. Steel sheathing sheets are attached to them.

Attention! The water jacket begins at the level of the grate and does not wash the ash chamber.

In the middle, so-called clips are placed in a checkerboard pattern. This is a steel circle passed through holes in the wall of the boiler tank and butt welded to the firebox. The second end of the clip is welded around the hole, as shown in the photo:

In the photo on the right you can see where the bottom of the water jacket is, on the left - the boiler tank

A few words about how to make additional clips along the edges of the water jacket of a homemade solid fuel boiler. You need to take a 20 mm strip and insert it from the end between the walls to a depth of 50-100 mm, and then weld it on both sides.

The third stage is the installation of flame pipes in the upper part of the boiler tank. To do this, holes are cut in the rear and front walls according to the drawing into which pipes are inserted. Their ends are hermetically welded, like all joints of the water jacket.

The flame tubes of the heat exchanger fan out from the chimney pipe

The fourth stage is the manufacture of doors and grate. A strip in 2 rows is welded to the inside of the doors, and an asbestos cord is placed between them, this will seal the vestibule. The grate bars are made from corners No. 5, welded with the outer corner down. So they serve as diffusers of air supplied by a fan to the ash pan.

At the fifth stage, fittings are cut into the walls of the boiler tank to connect the supply and return pipelines, a chimney pipe and an air duct from a 60 x 40 mm pipe with a fan mounting flange are installed. The air duct enters the ash chamber in the middle of the rear wall, just below the water jacket.

Stage six - welding of door hinges and embedded parts 2 cm wide for attaching the decorative lining of a long-burning boiler.

Stage seven , last. The boiler tank is lined on the sides and top with basalt insulation, the latter being secured with a cord. Then all that remains is to screw the sheets of painted metal with self-tapping screws to the embedded parts and install the doors.

Dense basalt fiber insulates the body well and can easily withstand high temperatures. Glass wool should not be used

At the end, a fan is attached to the counter flange of the air duct, and the control unit is installed on top of the boiler. The temperature sensor must be placed under the basalt insulation on the rear wall of the unit. In addition, a number of useful additions can be made to the design of a homemade long-burning boiler, at your request:

- install a water heating circuit for hot water supply into the boiler tank;

- provide an immersion sleeve for installing a thermometer - in case of a power outage when the controller display goes out;

- the same for installing a security group;

- install an electric heating element that heats the coolant after the wood burns out.

A few words about how to circulate hot water in a solid fuel boiler in order to heat it for household needs. You need to take 10 m of copper tube with a diameter of 8-12 mm and bend a coil from it in the form of a spiral. The latter is wound inside the boiler tank around the flame pipes, and the ends are brought out from the rear side of the unit. We get a long-burning double-circuit boiler.

Note. The practice of operating these heat generators has shown that the installation of an electric heater is necessary for those homeowners who want to heat their house at a nightly rate. In other cases, the burning time is enough to avoid running to the boiler room in the middle of the night to add more firewood.

It is better to remove the film from the painted metal immediately, and cover the doors with heat-resistant enamel.

The legs of the unit can be attached at any stage by selecting suitable pieces of rolled metal. For details and secrets of assembling a TT boiler, watch the author's video of the master - the creator of the heating unit:

Strengths and weaknesses

The large dimensions and difficulty of making a drawing of a long-burning solid fuel boiler with your own hands makes it favorable to use such devices only in large cottages. As for small dachas, it is recommended to choose more economical options for them.

The main advantages of long-burning TT boilers are:

- High efficiency (about 95%)

- Autonomous heating.

- Economical.

- Reliability and durability.

- High efficiency.

- Availability of fuel.

- Environmentally friendly.

- Wide choice of fuel (coal, firewood, sawdust, pallets).

There are also disadvantages:

- Large dimensions.

- The need to equip a separate boiler room.

- Complex design of a long-burning wood-burning boiler.

- Need for constant maintenance.

Boilers of this type have a fairly decent price, but such designs can be made independently.

Advantages of homemade units:

- Cheapness.

- Versatility in terms of fuel used.

- Possibility of subsequent modifications to increase efficiency and add power.

The most difficult thing is to make the structure cylindrical: for this you need to use a rolling machine. If you don't have one, there is an option with old propane tanks. Any pipe of a suitable cross-section will also work: the thickness of the metal walls must be at least 5 mm. In villages they are accustomed to being content with small brick stoves, which demonstrate good efficiency in heating one-story houses and cottages. If you need to heat a large cottage, then in this case you will need a large supply of fuel. In addition, large temperature changes cannot be avoided as you move away from the stove, and caring for it is much more difficult than a solid fuel boiler.

Enlargement of the combustion chamber

By correctly calculating the size of the combustion chamber and the firewood supply door, you will not only increase the efficiency of the boiler, but also make your life much easier when operating it.

The easiest way to achieve long-term combustion in a wood-burning boiler is to increase the volume of its combustion chamber. Let's assume that we need to heat a household with an area of 100 square meters. m. To do this, we need 2.3 firewood per hour (the average calorific value of wood is about 4.3 kWh/kg. Therefore, in order to achieve long-term combustion for 12 hours, we need a combustion chamber that can hold 28 kg of firewood. With an average wood density is 1.73 kg/dm³, the approximate volume of the chamber will be 16.18 liters.

Since we are interested in loading for 24 hours, the volume of the combustion chamber will be 32.26 liters. But you need to take into account that firewood is far from water. They do not occupy the entire space, so we can safely multiply the resulting value by two - the total will be about 65 liters. It is also necessary to leave a reserve for normal combustion, so that there is room for the flame to rage, although here everything depends on the design of the boiler.

When calculating the dimensions of the combustion chamber, focus on the length of the logs - this will help create a firebox that is convenient for loading.

It becomes obvious that to realize ultra-long combustion it is necessary to create a very large combustion chamber. And in order to further increase the efficiency and duration of combustion of one portion of fuel, you should use certain types of wood - we recommend choosing birch and oak. Despite the fact that their calorific value is lower than that of the same pine, these types of wood are denser. And they burn at a higher temperature (almost +900 degrees).

Recommendations for making a homemade boiler

When starting to make a long-burning boiler with your own hands, you need to arm yourself with the following tips:

- So that any fuel can be used during operation of the device, it is better to make the combustion chamber from heat-resistant alloy steel. The use of grade 20 seamless steel pipe helps to reduce the cost of the work somewhat.

- Before bringing a home-made unit into the boiler room prepared for it, it is recommended to test it outside, equipping it with a temporary chimney. This will make it possible to check the reliability of the heater and make sure that the housing is assembled correctly.

- The main chamber, made of a gas cylinder, is able to provide a duration of 10-12 hours, because There is not much wood in it. The initially small interior space of a propane tank is reduced by removing the cap and ash pan. To increase the performance of the boiler, it can be made from two cylinders. This will allow you to get a combustion chamber large enough to heat large rooms and increase the time between adding firewood.

- The ash pan door must be tightly closed, which will prevent outside air from leaking into the chamber. This is achieved by laying an asbestos cord around the perimeter of the door. If the boiler has an additional door for adding fuel without removing the lid, it is also sealed in a similar way.

Standard solid fuels use firewood, anthracite, sawdust, briquettes, peat, hard and brown coal. There are usually no special complaints about fuel quality. However, it is desirable that the fuel material be as dry as possible, which will guarantee high efficiency.

Advantages and disadvantages

The mine unit has the following main advantages:

- Versatility, availability of work on different types of fuel, including liquid for modified installations.

- High boiler efficiency, productivity and autonomy without additional fuel loading up to 24 hours.

- A well-thought-out design that simplifies maintenance; loading/unloading is carried out through separate hatches.

- Reliability and safety, therefore, indoor gas pollution and carbon monoxide poisoning can be said to be reduced to “zero”.

The disadvantages include:

- increased soot and tar formation during fuel combustion;

- huge dimensions of the installation.

Safety regulations

To achieve good efficiency, durability and efficiency of home-made long-burning boilers, during their operation it is necessary to follow basic fire safety recommendations:

- Make sure that the temperature inside the circuit does not exceed the limit values.

- The supply pipeline must not be equipped with a shut-off valve.

- Flammable materials should not be stored in the immediate vicinity of the boiler.

- Ventilation in the room must be fully operational.

- The device can only be installed in a separate room (boiler room). This point is thought through during the implementation of preparatory activities.

Boiler room equipment is the best option, since TT boilers work slightly differently than conventional wood-burning stoves. In addition, externally the device is not of aesthetic interest, and most likely will disturb the overall interior. Since the use of solid fuel is accompanied by the appearance of dirt, it is best to install the boiler in a non-residential room.

Small devices with a power of no more than 35 kW are allowed to be placed in the main room: for convenience, the installation site can be fenced with a brick wall. The room where the boiler will be located must have good ventilation. It is very important to organize a stable flow of oxygen from the street.

Pyrolysis combustion

Long-burning pyrolysis boilers can increase the efficiency of wood burning. Here's how they work:

- The fuel burns in the main combustion chamber with a minimal amount of oxygen;

- The pyrolysis products released as a result of such combustion enter the afterburning chamber;

- In the combustion chamber, pyrolysis gases are burned, releasing a large amount of heat.

Next, the thermal energy is removed by a fire tube heat exchanger.

A powerful fan and control unit will free you from the need to constantly regulate the combustion process, and will also allow the boiler to operate with much greater efficiency.

The main advantage of pyrolysis is the ability to realize long-term combustion by adjusting the intensity of the pyrolysis reaction. For this purpose, a blower fan is installed in the system. When it turns on, a high-temperature flame is formed in the afterburning chamber, and the coolant begins to warm up . As soon as the automation registers the achievement of the set temperature, the blower fan will stop - the slow-burning boiler will pause its operation, minimizing fuel costs.

The implementation of the pyrolysis combustion scheme in wood-burning boilers is quite complicated, but it allows for long-term combustion and automatic temperature control in the circuit. If you want to do without automation, then the intensity will have to be adjusted manually, using slide valves and a blower.

How to make a long-burning solid fuel boiler with your own hands

To work you will need the following tools:

- Welding machine.

- Devices for metal processing.

- Electric drill.

- Level and roulette.

- Marker.

- Bulgarian.

- Gloves and eye protection.

It is recommended that such a procedure be undertaken only by people who have at least some experience with welding and know how a long-burning boiler works. Special protective clothing is required.

You also need to prepare the following materials:

- Empty gas cylinder.

- A metal sheet.

- Asbestos cord.

- Steel pipe with a diameter of 60 mm.

- Metal hinges and handles.

- Metal corner and hood.

- Basalt fiber.

Wood burning stove with water circuit

Recently, this type of heating has become increasingly popular in country houses. Its use will significantly save the use of hot water, and also if you decide to install a boiler at home with your own hands. it will be able to replace your gas for quite a long time.

It’s quite easy for absolutely anyone to make a water heating system at home with their own hands.

Doesn't matter. Whether you have a huge private house or a small cottage, a water heating system will definitely suit you

After all, it’s quite easy to find materials for it, and it won’t be too difficult to figure out the circuit and install all the necessary equipment.

If you do everything correctly and carry out the assembly efficiently, then according to all calculations, water boilers will work much more efficiently than gas boilers. Also, with its help, warm air will be distributed throughout the room most evenly.

Work on the body drawings

An empty propane cylinder is equipped with markings according to the do-it-yourself drawings of a long-burning solid fuel boiler. A rectangular hole is made for the ash pan door, designed to remove ash. A straight line is drawn along the circumference of the top of the cylinder to cut the cap: trimming is done using a grinder.

In the central part, a niche is marked for the chimney outlet: the dimensions of this hole must exceed the cross-section of the pipe. A hole is made in the lid and a metal ring is welded in, tightly encircling the smoke exhaust channel. A metal ring 4-5 mm thick is used to scald the cylinder inside and out. A lid will subsequently be placed on it.

The chimney at the bottom is equipped with a metal circle that serves as an air distributor. Fastening elements are welded along the cut line of the cylinder on top of a pre-laid asbestos cord. When attaching a cut top, it is important that it can be easily removed. For convenience, it can be equipped with a metal handle.

Pros and cons of wood-burning home heating

The use of solid fuel units is a common way of arranging autonomous heating for private buildings, cottages, garages, as well as industrial facilities.

It is quite possible to construct a wood-burning boiler with your own hands if you understand the operating principles of this equipment, follow the manufacturing technology and at the same time take into account fire safety requirements.

Wood-burning units have the following advantages compared to boilers operating on other types of fuel:

- Wood used for heating is affordable and does not require large energy costs.

- Firewood is an environmentally friendly material that does not cause allergies or other diseases.

- The device is easy to use.

- The room warms up very quickly - after starting the boiler, heat begins to flow into the room immediately.

- Wood-burning equipment is energy independent.

- The appliances can provide hot water at no additional cost. The boiler heats a boiler with liquid, which acts as a water heating radiator.

Wood-burning units have fewer disadvantages:

- The metal body is susceptible to corrosion.

- The equipment requires regular cleaning of ash collected during fuel combustion.

- A single load of fuel is enough for a short time.

Ash pan

To cut a hole for the ash pan, previously applied markings are used. The door is made separately from sheet metal: it is fixed to the body with brackets. To make it convenient to open and close the door, it is equipped with an improvised handle made of a metal rod or thick wire.

Proper production of wood heating

Modern heating systems using wood fuel have significant differences from the schemes used previously.

The choice of heating device depends on the availability of free space for installation and the area of the building

When choosing a wood heating system, you need to pay attention to the following factors:

- Thermal power of the device. It depends on the area of the house, the degree of its thermal insulation and the climate zone in which it is located.

- The need to allocate space for a boiler or furnace. A device for heating with wood fuel must be installed in a room specially designated for this purpose, which must meet certain requirements. In particular, have stable ventilation.

- Availability of space for fuel storage. Wood must not be stored in a room containing a stove or boiler. They must be stored separately.

To decide on the device that is best suited for heating with wood, you should take into account the parameters of the building and your financial capabilities. As practice shows, the most popular and effective option is to use a double-circuit boiler with a water circuit in a private house

It will allow you not only to efficiently warm the building, but also to always have hot water at hand. But in order to make the final choice in favor of one or another device for heating with wood, you should consider each of them in more detail.

Be sure to read: types of heating systems in a wooden house.

Air supply system

Armed with the parameter for the internal diameter of the cylinder, it is transferred to a metal sheet, reduced by 5 cm. A circle is cut out using a grinder according to the applied markings. Next, six equal segments are made from the metal corner, the length of which should be equal to ½ the diameter of the circle. For this purpose, you can use an impeller with sharp blades. When welding metal elements, it is important to maintain the same direction.

Types of water heating systems

Today, water heating systems “own” up to 90 percent of the “heated area” of private houses. The rest of the territory uses stove, electric, and air heating.

Water heating systems

- radiator;

- "warm floor" system;

- baseboard heating.

Water heating radiators are a common element of the interior of most houses and apartments. Their “family” includes: steel, cast iron, bimetallic and aluminum radiators.

Steel radiator in the heating system

The advantage of such devices is excellent heat transfer, but the disadvantage is the increased “demandingness” of such radiators on the quality and type of coolant.

Radiator water heating in a private house, in a garage or in a country house can be done with one’s own hands by a person who is more or less adapted to technical work and who wants to learn something new.

To learn about what types of water heating radiators you should choose for a private home, read the article: “Which heating radiators are better?”

Water-based “warm floor” system

A water floor can be considered as an addition to a radiator heating system or as an alternative to it.

The advantages of such a system lie in a large heat transfer area - in fact, the entire floor can be called a large radiator, which also warms up the air in the room correctly: a warm zone is below, and a cooler zone above.

Location of temperature zones in the room when using “warm” floors

This allows you to reduce the operating temperature of the coolant, which for a warm water floor should not exceed 55 ° C, and set the thermal power per square meter within the required limits by changing the pitch of laying the heating pipe. The main inconveniences of such a floor are the relative complexity of installation (creating a concrete screed, “nesting” a pipe in a wooden floor) and the impossibility of creating such a system when the repair is completed - it is necessary either to raise the floor (more precisely, its level) or to go deeper. What to do if the door frames and doors are already installed, and there is a concrete floor slab below or.

And now heating systems... baseboard!

What is it and what is it eaten with? An “exotic” baseboard heating system is something between a radiator heating system and a heated floor, or rather similar to both.

Baseboard heating systems

Heating equipment is installed around the perimeter of the room at the baseboard level, which allows you to evenly heat the walls and floor, and, accordingly, the air in the room.

The advantages are the absence of bulky radiators in the interior, and the color range of plinth systems allows you to choose them to suit any style of your home.

Baseboard heating system in the interior of the house

Having considered the undeniable advantages and obvious disadvantages of various heating systems, you need to decide on the type of water heating system in your home. As mentioned above, when work on doorways and floors is completed, it may be impractical to make a heated floor, but installing radiators or using baseboard heating systems can be easy and convenient. Construction is in full swing - also think about warm water floors.

Heat exchanger

When making a heat exchanger, it is easiest to use the water circuit principle. The choice of its parameters depends entirely on the desires of the master. The size of the heat exchanger will directly affect the volume of fuel loaded at one time: the larger it is, the longer the pause between loading firewood. To make the device body, metal sheets 5-6 mm thick are used: they are well welded at all joints. The upper and lower parts of the housing are decorated with pipes for connecting the supply and return pipes. The central part must have a hole for loading fuel.

Selection criteria by type

Heating appliances can operate on coal, pellets, wood chips, wood, and peat.

Main selection criteria:

- power;

- volume of the combustion chamber;

- duration of work on one load;

- features of installation and connection to the system;

- control;

- operating and maintenance rules.

You can make a classic pyrolysis boiler with your own hands with both top and bottom combustion (mine). To install units that ensure autonomy, you need to have skills and experience.

It is easier to assemble a device like Buleryan, which does not use a control unit or automation.

Final assembly and installation

In order to install the ash pan door, you first need to mark and cut a niche on the body for access to the inside of the chamber. Next, a hermetically sealed door is installed in this opening. The cylinder is inserted inside the heat exchanger. Using a welding machine, the tank is thoroughly boiled from above: this makes it possible to achieve absolute tightness of the body, with a round firebox located inside.

When operating a homemade long-burning boiler with a water circuit, it is important to achieve a dosed air supply. The fuel is loaded as tightly as possible: the voids between the layers should be kept to a minimum. It happens that dense packing of logs of different sizes is difficult: in this case, the remaining niches are filled with paper or shavings. The density of the solid fuel filling directly affects the duration of its combustion.

The procedure for loading fuel into the TT boiler:

- First you need to remove the air restrictor.

- Place the firewood through a special hole, having previously lubricated it with liquid for quick ignition.

- Install the limiter in its original place.

- Next, you should light a match and throw it into the firebox.

- After making sure that the fuel begins to gradually flare up, close the door tightly.

As the fuel burns out, there will be a gradual shrinkage of the pipe inside the cylinder. The height of its position gives accurate information about the amount of firewood in the firebox. The layout of a coal-fired boiler is practically no different.

Rocket tube casting

In addition to calculating the optimal dimensions of the rocket tube, our user needed to decide on the material from which it could be made. The fact is that the “J-pipe” must operate for a long time at temperatures of about 1000°C. Therefore, the material from which it will be made must be heat-resistant and have low thermal conductivity. At the same time, the “J-pipe” itself should have small dimensions.

Needless to say, this is not an easy task. The chimney pipes immediately disappeared - they would not withstand such temperatures. Metal, even heat-resistant stainless steel boiler, will also not last long under such conditions. There was another option - to build a pipe from refractory bricks (for example, fireclay), but this would entail a whole heap of worries. You will have to make a large heat exchanger, then the boiler body, etc. As a result, the boiler, one of the advantages of which is compactness, grows to enormous sizes.

Anyone who wants to follow in Perelesnik’s footsteps should take into account one nuance.

If we accept a forced increase in the dimensions of the boiler, and there is room for such a unit in the house, a linear increase in all sizes will lead to additional consumption of all materials and, consequently, money. Therefore, the J-pipe is not an assembly on which you should skimp.

After weighing all the pros and cons, the user settled on one material option for the pipe - ceramics. The matter was complicated by the fact that it was not possible to go and buy a finished product. There was only one thing left to do - roll up your sleeves and plunge headlong into experiments on selecting the optimal composition of ceramics. Looking ahead, let's say that Perelesnik managed to independently develop a composition that can be cast into a mold without fear that it will crack during the molding process. The composition of the ceramic was so successful that it was possible to melt nails in it without destroying the material.

Perelesnik

The most interesting thing is that one company engaged in the manufacture of ceramic products also tried to make such a composition. Two months of searching were unsuccessful. The product was torn.

The high temperature composition developed by our user includes the following components:

- Chamotte – 40%. The percentage of chamotte can be increased.

- Clay – 50%. You need fatty clay that can be fired at a temperature of at least 1100°C.

- Kaolin – 10%. If the composition continues to stick to the mold after two castings, then the percentage of kaolin can be reduced.

Also, fractions of a percent of deflocculants were added to the composition: surface-active additives that prevent the adhesion of small particles and ensure the fluidity of the mass. In particular, soda ash and liquid glass were used.

Perelesnik

Exactly how much deflocculant to add depends on the fluidity of the slip. One bucket required approximately 1 tablespoon of soda ash and 1.5 tablespoons of liquid glass. The main thing is that the fireclay does not precipitate, and that there is no water on the surface of the slip. If you overdo it with additives, the slip acquires a gelatinous consistency. This is bad for casting. The mixture (its consistency) should be similar to PVA glue. If you leave the mixture for 2 hours, then nothing in the slip should separate, settle or float.

So, after the composition of the mixture was selected, it was time to cast the “J-pipe”. For ease of casting, the vertical section of the pipe was divided into 2 parts. The process itself is clearly visible in the following photos:

Form

Castings

Bottom of pipe

Assembled pipe

Firing was carried out at a temperature of 1100°C. The result was ringing, thick-walled ceramics, indistinguishable in appearance from industrial products. It took 3 days to cast 1 part, including the pouring itself and subsequent disassembly of the mold. Then the blanks were dried for several days and only then fired.

Subsequently, the casting technology was improved and put into production. The design of the boiler turned out to be so successful that our users decided to repeat it and ordered a set of “J-pipes” from Perelesnik.

Installation in the house

The issue of boiler fire safety is a very serious issue. To install it, it is better to provide a separate room or corner, separating it with brickwork. Since the surface of the boiler is metal, there is a high probability of getting burns if you touch it carelessly. It is also important that at the installation site it is possible to conveniently lead the chimney to the street (through the roof or wall). For free access to the device, a space of 50 cm around its circumference is cleared of any objects.

Installation rules:

- Construction of a brick foundation. It should consist of two continuous rows of bricks, and correspond to the dimensions of a long-burning solid fuel boiler.

- The distance from the fire door to the wall is at least 125 cm. The distance between the side parts and the wall must be at least 700 mm.

- A distance of at least 125 cm is maintained between the combustion door and the wall. The space between the sides of the boiler and the wall is at least 70 cm.

- If wood was used to construct the walls, the contact areas between the boiler and the ceiling are additionally decorated with metal or basalt protection. The same applies to areas where the chimney is discharged outside through walls or ceilings.

- The boiler is installed on the foundation strictly level. In this case, the outlet pipe must be located in line with the chimney, otherwise draft disturbances may occur during operation (pro

Rules for organizing a boiler room for wood heating

Diagram of a boiler room in a private house

Professional organization of wood heating of a private house independently implies the arrangement of a boiler room. This must be a separate room in which the boiler and means of regulating its operation are located.

If wood heating to the dacha is done using a gravity scheme, the boiler should be located at the lowest point of the system. There are no such requirements for forced heating. You should also prepare the room in which the heating equipment will be installed. It must meet the following requirements:

- Ceiling height – at least 2.5 m;

- Usable area – from 6 m². Moreover, its minimum volume should be 15 m³;

- Forced ventilation. The air exchange rate is three times the volume during operation of a wood-burning boiler for heating the house;

- Parameters of the chimney channel. The minimum height is 4 m. The diameter depends on the connected boiler pipe, but not less than 100 mm;

- To carry out maintenance and repair work, it is necessary to ensure free access to all sides of the wood-burning heating boiler for the cottage;

- Lighting should be combined - natural and artificial.

An important point is ensuring fire safety. To do this, it is necessary to use only non-combustible materials for finishing the room. If electric elements are used to heat a private house using a wood-burning boiler, a power line must be provided. Installation of a ground loop is carried out only at the request of the manufacturer.

One of the problems in the operation of a wood-burning stove is the possibility of backdraft. To minimize this effect, it is recommended to install a special design on the chimney.

Heating your home with electricity

Diagram of an electric heating device for a house.

Heat in the house using electrical energy can be realized using several options, so anyone can choose exactly the one that suits them. And thanks to flexible prices, now everyone can afford such pleasure

It is important that consumers who prefer this system have a wide choice of equipment and heating installations

Electric heaters come in the following types:

- fireplaces;

- "warm floor" system;

- convectors;

- fan heaters;

- infrared heating.

Fan heaters and fireplaces are most often used as temporary or additional heating of living spaces. And the “warm floor” system is used as a source with which you can constantly receive heat. Moreover, this system is installed not only in the base of the floor, but also in panel walls. And this makes it possible to evenly heat the house without using gas or firewood all winter. But such a system can only be installed at the stage of building a house.

Water jacket

The principle of operation of a solid fuel boiler implies the presence of double walls in its firebox: in the interval between them they are filled with coolant. This design is called a water jacket. As the fuel burns, the liquid in the water jacket heats up. This leads to the appearance of heat flows that lift the hot coolant to the upper part of the container. From here, hot water flows into the heat pipe. After the liquid passes through the entire heating circuit and gives off heat to the home, it returns back in a cooled state. For these purposes it has a lower pipe.

To speed up the circulation of water inside the heating system, special pumps are installed on some solid fuel boilers. However, most models are produced for open heating systems. This refers to schemes where the coolant moves not due to a running pump, but due to a slight slope of the pipeline. This is explained by the simplicity, reliability and efficiency of inertial systems. In addition, they are completely independent of the availability of electrical energy. Thanks to this, they can be used in remote areas deprived of the benefits of civilization.

Advantages of double-circuit heating

Double-circuit heating is the type of heating in which water is heated using a boiler specifically for use in the home and for heating the entire room. Thus, the entire need for hot water is provided by one double-circuit boiler. There are other reasons why it is gaining more and more popularity:

- Makes it possible not to depend on utilities and allows you to regulate the heating yourself, thereby creating comfort at home

- Possibility of installation in any part of the house. since no additional exhaust system is required, ventilation is also not required

- Apart from the boiler itself, you will not need anything, because everything necessary for heating and supplying the house with hot water for a long time will already be built in

- Favorable and affordable price

How a wood-burning stove with a water circuit works. Choosing fireplace stoves for a summer residence with a water circuit and a heat exchanger. Brick stove with a water circuit. A stove with a water circuit in development - how to do it yourself.

Advantages of using a water boiler in a brick stove

One of the key advantages is efficient heat dissipation. It is also an important fact that the pipes can be connected to all rooms from the pipe.

A water-based boiler can be perfectly combined with different heat generators. When using antifreeze, the system will not defrost when the oven is turned off. Among other things, a water boiler in a brick stove can operate both in the presence of central heating and in autonomous mode.

It should also be noted that a water boiler in a brick is very reliable. like the brick oven itself, traditionally considered a reliable heat source. And when such a stove is combined with a water-based boiler, their mutual efficiency becomes many times stronger, and additional heat transfer appears. Together they are able to heat a room of up to one hundred square meters, without forcing you to spend a lot of money on such heating.

For a typical Russian winter, only two fireboxes per day will be enough to create a comfortable temperature in the room. In addition, the temperature can be regulated using modern automated systems.