Solid fuel boilers are a popular type of boiler equipment. They are widely used for autonomous heating in facilities where it is not possible to use models running on natural gas. Modern equipment of this class is capable of providing high-quality heating and at the same time is inexpensive, convenient and easy to operate. For maximum heating efficiency, it is important to have an idea of how to properly heat a solid fuel boiler.

The firing of a pyrolysis boiler has some peculiarities. A few wood chips and a sheet of paper are placed in the combustion (screw) hole, and firewood mixed with coal is placed in the loading door - most often it is located above the combustion door. A sheet of paper is set on fire, after which the fire is directed towards the fuel with a stream of air, starting the combustion process. For normal operation of the boiler, a constant supply and normal circulation of air is necessary.

How and what kind of coal is best to heat a solid fuel boiler

Several grades of hard and brown coal are usually offered for household consumption; in addition, charcoal is also used. But, before loading the firebox with new fuel, you must carefully read the instructions for using the solid fuel boiler; it contains the brands of fuel recommended by the manufacturer.

For domestic and industrial heating boilers, the documentation indicates the optimal grades of coal for use. The fact is that during the production of boilers, finished products are tested and certified for use with different types of fuel. The heat capacity of coal of one group may be higher than the heat capacity of the brands recommended by the manufacturer, which is why the normal operation of the equipment may be at risk.

One of the conditions for how to properly fire a boiler with coal is the correct choice of fuel; in addition to indicating the type and brand, manufacturers recommend focusing on the amount of harmful impurities, dust, ash content and calorific value. This information is indicated in the fuel passport, but what specific qualities a particular brand has is worth finding out in more detail.

Coal

This type of coal is the most common. In most brands, the calorific value averages about 5500-6000 kcal/kg. This indicator is associated with a high hydrocarbon content; this substance makes up about 75% of the mass. When burned, coal produces from 2 to 5% ash, but it is worth saying that this applies to a high-quality product that has been cleaned from rock. Coal grades are divided by fraction size, weight and calorific value. In addition, there is a gradation based on how quickly the fuel burns. Almost all grades of coal are suitable for firing universal solid fuel boilers of the classic type. But such fuel is not suitable for long-burning devices; it has a rather high temperature index, which has a detrimental effect on the equipment.

Brown coal

This fuel is mainly used in the areas where it is mined. It so happened historically that brown coals were not widely used and are mainly a product of local consumption. The calorific value of brown coal is lower than that of hard coal, it is approximately 3000-3200 kcal/kg, this figure is almost 2 times lower than that of the lowest grade of hard coal. A special feature of this product is that after combustion it leaves more ash. In domestic heating installations, brown coal is used, and briquettes made from it with a mass fraction of humidity of about 50%.

Anthracite

When choosing a fuel with the highest calorific value, you should focus on anthracite, one of the best types of coal for combustion in a boiler. The calorific value allows the release of 9000 kcal/kg during combustion, which is one of the highest values. However, after combustion, anthracite forms a large amount of ash, up to 7%, and up to 5-7% of coal that is not burned.

Lignite

This type of coal raw material is intended for consumption in industrial installations. Many manufacturers do not recommend using it in everyday life due to its specific structure and large amount of ash residue.

Coal processing products

Conventionally, these types of products are difficult to attribute to any type of solid fuel made from natural hydrocarbons, but it is also quite difficult to ignore them. This type of product includes coal processing products - coal briquettes and coke.

The first is a briquetted type of fuel obtained by pressing waste from coal recovery at processing plants. Simply put, this is a pressed fine fraction of graded coal that remains after sifting the main mass. Such fuel is mainly used in industrial enterprises, since during combustion it releases a large amount of sulfur, and the ash content in the residue often exceeds 10% of the initial mass.

Coal dust in its pure form is practically not used in individual heating systems, since the technology of burning dust in solid fuel household boilers is not provided. In industrial production, in the energy sector with thermal generation and even in metallurgy, the use of dust is justified; it, in the form of a water-dust mixture, competitively replaces expensive natural gas, but in small boilers designed for 7-15 kW of power, this method is too expensive.

Coking coal, which is the main fuel for blast furnace production of pig iron, can be successfully used at home. However, you need to remember that the energy value ranges from 5.6 to 7.0 thousand kcal/kg. The average ash content is about 8%, volatile substances from 3.2 to 4.2%, sulfur in coke is 1-2%. Pure carbon makes up at least 87% of the substance.

Gas coal

This type of coal is often called flammable coal in everyday life. Saturated with light flammable gases, coal of this group has a small fraction, only 3, maximum 4 cm in diameter. This product is excellent for kindling, because it quickly begins to maintain combustion and also quickly raises the combustion temperature to 400-600 degrees, which is quite enough to ignite the bulk of the main fuel coals. But it’s unlikely to be used for a full-fledged combustion chamber; its calorific value is low, and the combustion time is 4-5 times higher than that of anthracite or coke.

Charcoal

Until the recent past, charcoal was one of the most common coal products. Today this coal has given way to hard coal, but it still remains in demand in private households. When burned, it produces from 7000 to 8000 kcal/kg, which is a good indicator compared to ordinary firewood. After combustion of 84% carbon, 2 to 2.8% ash is formed. It is especially good to use charcoal in solid fuel pyrolysis boilers and long-burning boilers.

Features of models with DHW support

There are boilers that already have a boiler installation in their basic configuration, which allows you to heat water as the fuel burns. Other models allow the possibility of optionally adding water tanks, but this solution will be more expensive and less profitable in terms of reliability.

Therefore, you should plan the DHW support option in advance. Its basis, as already noted, is a boiler installation, that is, a container for heating water, which is usually located next to the equipment. Its volume can vary from 50 to 200 liters, if we are talking about home use of a solid fuel boiler. In this case, coal will act as the basic energy resource for both heat supply and hot water supply. As the water heats up and flows, the controls will open or close the shut-off valve. The liquid resource can be used for heating needs and for servicing the bathroom and kitchen. For each of these cases, its own configuration of water supply and heating circuits is provided.

How to heat a boiler from theory to practice

Getting the optimal result when burning coal depends on how correctly the technology of all stages of the combustion process is carried out, from loading firewood to replenishing the main fuel in the firebox. Success largely depends on how to light the boiler. The fact is that coal, anthracite or coke, enter the combustion process when the temperature in the combustion center reaches 400-600 degrees. It is simply impossible to achieve this with paper, and solid fuel itself will not be ignited by the fire of a match or a sheet of paper.

Owners' opinions

Below are some reviews from stove consumers.

“We purchased a stove for the Rus bathhouse with a fireplace door. It looks great and very presentable. And it works even better - a couple of clutches, and the steam room is already 110°C. Comfortable warmth without the feeling of suffocation. Economical fuel consumption coupled with a stylish design and an affordable price - Teplodar with both hands!”

Zarina Radina, Sverdlovsk region.

“The most affordable option for our home was the opportunity to buy a Teplodar gas stove. We doubted for a long time whether this would be an effective solution. But in reality everything turned out to be very simple and functional. The latest design of the stove allows you to steam comfortably after just 30 minutes of intense heating. No worse than wood heating. Thanks to the manufacturer, we were satisfied."

Sergey, Moscow.

“Based on feedback from friends, I decided to purchase a Rus stove from the manufacturer Teplodar. Outwardly, it is presentable; I was attracted by the increased manufacturer’s warranty of up to five years. Well constructed - thick, good steel. It’s a pity I didn’t immediately buy a tank for heating water; then I had to run around looking for a suitable one. I haven’t found any complaints in operation yet.”

Mikhail Badin, St. Petersburg.

“Our bathhouse is small, we only have enough money for it, so an electric stove is enough for us. We purchased a very inexpensive and practical option from the Teplodar company. We steam with pleasure, just like in a real Russian bathhouse. Installation is simple and consumes little electricity. Considering that we use the bathhouse once a week, the operating costs are quite reasonable. Overall, the result exceeded all expectations.”

Peter, Ekaterinburg.

Price

You can buy sauna stoves in many dealer stores, as well as on the website of the manufacturer Teplodar. The table shows the price of equipment without taking into account the cost of additional installation of a gas burner.

| Name | Dimensions (WxHxD), mm | Steam room volume, m3 | Price, rubles |

| Blast furnace 25 LC | 615x995x705 | 10-25 | 26000 |

| Cascade 18 LP Panorama | 380x920x770 | 10-18 | 20500 |

| Kuban 20 L | 500x865x700 | 10-20 | 19900 |

| Laguna 12 TK | 855x330x690 | 6-12 | 15000 |

| Teplodar Rus 18 LNZP Profi | 335x810x790 | 10-18 | 22600 |

| Rus Panorama 27 LNZP | 440x930x800 | 18-27 | 30800 |

| New Rus' 18 L (2004) | 395x815x805 | 10-18 | 13800 |

| Sahara 16 LRK | 785x380x755 | 8-16 | 17500 |

| Siberian cliff 20 health care facility | 835x565x730 | 10-20 | 26500 |

| Siberia 20 LRK Panorama | 785x375x750 | 10-20 | 23200 |

| Taiginka 10 TU | 405x330x705 | 4-10 | 8500 |

| Electric heater SteamFit 3 | 560x400x240 | 12 | 16700 |

| SteamGross 3 oven | 580x530x643 | 26 | 41000 |

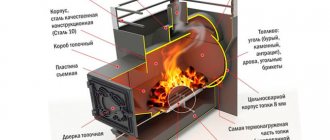

The process of igniting a solid fuel heating boiler

The technology for igniting a solid fuel boiler is no different from the process of igniting a boiler with wood. There are just some nuances here. The first nuance is that a special grill for coal fuel must be installed in the lower part of the firebox. The purpose of this grate is that it allows the coals to be mixed during combustion. It is made in the form of a massive cast iron casting with a distance between the grates of 1.5-2 cm. This grate is installed vertically in the lower part of the firebox, and is closed by a blower door with a gate that regulates the oxygen supply.

Paper is placed in the lower part, on top of which wood chips are laid. The next layer includes splinters and small logs to ignite an active flame. 4-5 large logs are laid on top. The top layer is laid so that coal can be poured onto it, and at the same time, fuel does not spill into the blower.

For kindling, softwood chips are taken, it quickly flares up, maintaining combustion, creating sufficient temperature for the hardwood logs to ignite. Hardwoods are used as firewood - oak, birch, hornbeam; they create the necessary temperature to light the coal.

For the first laying, fine coal is used - with a diameter of 3-4 cm; the ideal option here would be gas coal or flammable coal.

It is important to remember that dry wood is used for ignition. Under no circumstances should flammable mixtures or liquid fuel be used. If you pour gasoline, biofuel or diesel into the firebox, there is a high probability that it will spill into the duct and even leak onto the floor. In this case, a fire cannot be avoided. It is better to put more crumpled paper at the bottom than to add even a drop of gasoline.

You can light a fire with a match or a lighter, there is no difference, the main thing is that the fire engulfs the wood chips and the top logs as quickly as possible.

The heating device is the warmth in the house

Many settlements today have not yet been gasified. Therefore, residents of such villages have to look for an alternative to gas equipment. The best solution in this case is to heat a country or private house with a solid fuel boiler.

It is becoming increasingly popular not only due to its ability to work on wood or coal, but also due to its complete autonomy.

After all, a solid fuel boiler does not require either gas or electricity. It can only operate on wood, while maintaining a comfortable room temperature. However, such devices are available in various modifications, and in order to make the right choice, you need to at least briefly get to know each of them.

Main combustion period

Conventionally, the process of how to properly heat a boiler with coal can be divided into several stages - the first ignition, the second period of main combustion, the stage of achieving stable combustion and finally, attenuation.

The main period of combustion usually occurs at the moment when the firewood forms productive coals for backfilling the stone fuel. How to properly heat a solid fuel boiler depends on when the moment of filling the first portion of fuel is chosen. In terms of time, from the moment the paper begins to burn until the logs of the main tree are engulfed in flames, it usually takes 4-5 minutes, but this is with normal draft and an open blower damper. You can check what is happening in the firebox by opening the firebox door - when opened carefully, the firebox will be illuminated with an even, bright flame, which means that the time has come to add the first portion of coal.

First, fine coal 2-4 cm in diameter is poured into the firebox. At approximately this stage you will need from 0.5 to 1 kg of fuel or 1-2 scoops. Coal is poured through the fire door and made so that its layer is evenly distributed over the entire fire area. Immediately after backfilling, the door closes, and the valve on the vent door opens slightly to increase the access of oxygen to the combustion space.

It’s worth checking what’s happening in the firebox after 10-12 minutes. This time is enough for the temperature to rise to 400 degrees and the fuel begins to burn, releasing enough heat. During this period, it is worth paying attention to the readings of the thermometer on the boiler; if the temperature rises sharply and the coolant begins to heat up better in the pipes and radiators, it means that it is time to supplement the boiler with another portion of fuel.

According to the rules of how to properly heat a boiler with coal, you need to add from 3 to 5 kg of anthracite or medium-fraction hard coal. The coals should be of average size 4-7 cm in diameter. Just like fuel, filling is done through the combustion door with a spatula or scoop. If possible, the coal is scattered over the entire area of the firebox so that the layer is about 10-15 cm (however, much depends on the size of the firebox). After the firebox door is closed, the thermostat is set and the boiler is switched to long-burning mode, when it itself regulates the opening and closing of the oxygen supply valve.

How to calculate coal consumption

Coal consumption in a solid fuel boiler depends on many factors. Costs are affected by:

- Heated area.

- Amount of heat loss.

- Ambient temperature.

Exact costs can only be calculated after the end of the heating season. Moreover, depending on the winter, the average consumption of coal for heating can vary from 8 to 15 tons (for a building of 200 m²).

If you make average calculations based on actual operating experience, you can obtain the following data:

- Costs for September – October will be 1 bucket per day.

- Fuel consumption rates in a coal boiler from November to February will increase to 10 buckets per day.

- In March and April, you will need to burn 1-2 buckets per day.

Calculating the coal consumption for a 20 kW boiler, using the above data, will show that the costs during the heating season will be 580 buckets or 10-10.5 tons.

Stable combustion stage

The stable combustion stage lasts about 5-9 hours. The main technique on how to properly heat a boiler during this period is to uniformly supply fuel to the firebox. Usually, if at the first filling ¼ of the fuel is used, then during the period of maintaining stable combustion, the remaining fuel is divided into 3 equal parts. After adding anthracite through the vent grate, the burning mass is stirred to prevent slagging of the firebox.

Advantages

The advantage of some models may be the disadvantage of others. Therefore, here we will consider general ones that deserve flattering reviews:

1. Attractive design. They can be built into any interior without compromising its appearance.

2. With excellent quality, prices are not at all prohibitive.

3. There are no difficulties in maintenance: the main maintenance is to add fuel to the stove and remove the ash.

4. Cost-effective. You can use any solid fuel and firewood, while at the same time removing all the trash from your dacha.

5. The range of models is wide: now their range consists of two dozen, and modifications - about a hundred items.

6. Reliability and durability. The ovens are made of 4mm steel. The warranty period of 3 years is somewhat incorrect: the use of the product is not constant. Another number is more correct - 2000 hours.

7. Various sizes and consideration for installation in the desired location.

8. Use at a time convenient for the consumer.

9. Slow burning and high heat transfer, that is, you need to add fuel infrequently, but at the same time the heat in the room is maintained.

Bath stoves Termofor large selection

Siberian bath stoves are widely known not only in our country, but also abroad. The product range of this company is constantly updated. The products are characterized by high functionality, compact dimensions and ease of operation. The attractive appearance of the stoves fits into any bath interior: from classic to the most stylish.

On the forums you can read very different reviews about Termofor stoves, but most of them are positive. Some of them:

And I like my Angara stove. We are on Normal for the 2nd year. We heat it with peat briquettes, it’s very warm and there’s not a lot of fuss with the stove.

Bath stoves Termofor

We bought a MERANO stove (imported) for the house, and a GEYSER bath for the same price. Both the house and the bathhouse are approximately the same area (5x5 and 6x4). So, the Thermofor GEYSER heats the room twice as fast, I regret that I bought such a stove for the house (I thought since it was imported, it was better)! The beauty of the stove is not the only advantage! Let's see how it shows itself over time!

I decided to share my impressions. I have a Termofor sauna stove. I recently bought it for a sauna, it’s called Vitruvia. It’s probably hard to call it a stove anymore, because it’s very sophisticated. However, 21st century #8230 It has a very large screen built into it, it’s convenient to watch the combustion and it’s just beautiful. Diagonal 58 cm! It does not darken, it practically does not even need to be wiped (convenient for lazy people and bachelors) The oven heats up very quickly, the steam room is just what you need. In appearance it fits perfectly into a sauna. The stove itself is small, as I chose for my cubic meters

Do you have a strange smell when firing the stove? I myself recently bought, not this one, but from a different manufacturer. Now I’m thinking: will it fade or not?

@Alkard The strange smell is the machine oils that are used to lubricate everything at the factory. I had an odor the first time I used it. Then there were no problems.

Reading reviews about Termofor stoves, you understand that for the most part customers are satisfied with the choice.

Types of sauna stoves produced

Termofor's range of sauna stoves is impressive:

- Osa and Osa INOX are ultra-compact stoves for Russian baths with steam room volumes from 4 to 8 m 3 .

- Compact and Compact INOX – a wood-burning stove for a Finnish sauna, designed for steam rooms from 8 to 14 m 3 .

- Shilka is a wood-burning stove for Russian steam rooms of small volumes - 6-12 m 3.

- Tunguska – middle-class wood-burning sauna stoves for heating rooms from 8-18 m 3 to 12-24 m 3 in the XXL modification.

- Tunguska and Tunguska Vitra are a new version of the popular stove. The firebox has been improved and changes have been made to the design of the heat exchanger for heating water.

- Angara is a stove for a Russian bath, suitable for medium-sized steam rooms of 8-18 m3. All the power of the stove is aimed at heating the stones in an open, unventilated heater.

- Angara is a powerful stove for a Russian steam room with a closed heater.

- Aurora is a powerful stove for medium-sized Finnish dry-air saunas (8-18 m3) with a chimney shifted towards the firebox.

- Geyser is a stove for a Russian bath with a two-stage steam generation system for steam rooms of 8-18 m 3.

- Vitruvia is a fireplace stove with a large glass door (58 cm diagonally) for dry-air steam rooms 8-18 m 3 .

- Sayany - mesh stove for Finnish sauna 8-18 m 3.

- Biryusa is a vertical sauna stove with a closed heater. Suitable for Russian steam room with a volume of 8-18 m3.

- Karasuk is a budget stove made of structural steel 4-6 mm thick.

- Skoroparka is an original wood-burning stove for a Russian bath, designed for steam rooms of 12-20 m 3.

- Kalina is a large stove for a Finnish sauna - designed for a volume of 18-30 m 3 .

- Hekla is a sauna stove for commercial use. Suitable for steam rooms 30-50 m3.

"Shilka"

The wood-burning stove is intended for steam rooms with a small volume - from 6 to 12 cubic meters. Double-walled, with an open heater at the top and a chimney located in the center. It can be made both with a hot water tank (built-in 24 l or mounted) or without it. Firebox with a volume of 43 liters made of heat-resistant steel. The combustion tunnel is extended for embedding into a wall or a regular door without extension. Provides “Russian steam room” bath mode, made of heat-resistant steel with a warranty period of 3 years.

"Biryusa"

The tall and narrow stove for the Russian steam room Biryusa has a closed heater that can hold up to 30 kg of stones. Made of structural steel, has a built-in stainless steel water tank. The updated furnace layout prevents premature boiling of water (the main drawback of the previous design).

Sauna stove Termofor Biryusa

"Wasp" and "Wasp INOX"

The smallest wood-burning stove, the recommended steam room mode is Russian. Designed for mini-steam rooms with a volume of 4 cubic meters or more. up to 8 cubic meters Made of structural steel with a 1-year warranty in the Osa modification and heat-resistant chromium steel in the Osa INOX (3-year warranty).

Prepare firewood in advance

Bring the wood into a warm room 2-3 days before lighting to increase its initial temperature.

The warmer the wood is initially, the:

- They spend less heat on their own heating and more on heating the room. You use heat more beneficially.

- Firewood reaches its optimal combustion mode faster, which further increases its calorific value and reduces the amount of soot emitted. This happens because the resin, creosote, tar, essential oils and other substances contained in wood do not burn at low temperatures and are deposited on the walls in the form of soot. And under optimal conditions, the combustion temperature is sufficient for them to burn entirely and release additional heat.

The difference between the combustion of “warm” and “cold” firewood is immediately noticeable: cold firewood produces a lot of smoke, which characterizes incomplete combustion. And warm, dry wood burns with virtually no smoke.