How does an electric water heater for heating work?

In accordance with the power indicator, flow heaters are powered from a single or three-phase electrical network. The unit has a simple design and is a tank with heating elements installed inside. When liquid enters, they heat it to a predetermined temperature. When using the unit, a heat exchanger is installed in the heating system.

Electric water heater device.

To obtain hot water for domestic purposes, the coolant is supplied through a special connecting tube to the faucets in the bathroom and kitchen. At the same time, the warm air mixture enters the living quarters. Before installing a heating unit in a private house, perform the following steps in sequence:

- Organize the circulation of coolant in the heating system.

- Create a sealed circuit.

- An expansion tank, an electric pump and shut-off valves are installed.

- Provide the ability to regularly supply liquid from a centralized water supply.

With constant fluid renewal, the heating rate is low. You can get detailed advice on the technical characteristics and operating rules of such units in the Kvanta+ online store in Tyumen.

Check valve for pump

When you open a water tap while the pump is not working, parasitic circulation of water may appear along the circuit: from the water supply through the pump - the boiler and the boiler. A check valve installed after the pump prevents this. The opening pressure of the check valve (the minimum differential pressure of the valve opening) must be such that the parasitic circulation of water in the circuit does not start the boiler into operation. As a rule, installing a conventional spring check valve for heating is sufficient for this.

There are commercially available check valves with different spring forces (minimum opening pressure) or even with adjustable “opening pressure”. For example, a Genebre valve has an opening pressure of 0.04 Bar, almost 2 times more than Valtec (0.025 Bar) or Barberi (0.02 Bar). See valve data sheet.

Be sure to choose a check valve whose body and spool plate are made of brass. The valve must be designed for an operating temperature of at least 95 °C and a pressure of at least 10 bar.

In addition, I recommend connecting the pipe from the water supply to the system as close as possible to the boiler pipe.

Electric boiler or water heater

In heating systems, boiler boilers are more often used, designed specifically for this purpose. In terms of the ratio of the amount of thermal energy received to the resources spent, storage boilers are significantly more efficient than instantaneous water heaters. The efficiency of the first reaches 90%, and that of the second does not exceed 70%. This is due to:

- design;

- specificity of purpose;

- method of heating the coolant.

Models of water heaters.

Instantaneous water heaters are designed for use in closed systems with forced circulation of liquid. The units have the following advantages over storage electric boilers:

- Fast water heating.

- No restrictions on the volume of hot liquid.

- Simplicity of design.

- Ease of use.

- Ease of installation.

- No need for regular maintenance.

In addition, you can make heating from a water heater with your own hands. Among the disadvantages of flow-through units are:

- the need for careful monitoring of the functional state and performance of the device;

- relatively high cost;

- low energy efficiency.

Electric boilers provide constant access to hot water within the volume provided by the design.

Instructions for starting the boiler for the first time

Boiler installed

Whether the installation work was carried out by specialists or the owner does not matter. In any case, you need to check the operation of the system

To do this, following the given tips, you need to start the heater for the first time.

We start by checking the correct connection of the systems that are responsible for heating the water. Fidelity, reliability of connection of phase and neutral wires, presence of grounding. The functionality of the circuit breaker should also be checked. To do this, use a device - a tester or a special electrician's screwdriver.

Next comes the search for leaks in the system. It would be useful to control the connection of underwater pipes. Presence and diagnostics of check valve operation.

Running water into the boiler

Attention, the correct sequence of actions for the first and subsequent starts of the system will be described in the next section. Repeated search for water leaks in pipe installation areas.

Diagnostics of heater operation. Turn on the device by pressing the power button.

Fixing the initial temperature sensor readings.

Recheck after 15 minutes

An increase in indicators indicates the correct connection of the heating elements.

Method of heating water with a water heater

In terms of the method of increasing the temperature of the energy carrier, a flow device does not differ from a storage boiler. The sealed tank is filled with liquid from a centralized water supply. Electric heating elements increase the temperature to a given level. Units of 2 types are characterized by some loss of thermal energy.

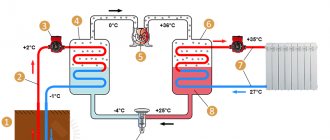

Diagram of water heating by the device.

In a storage boiler, the temperature of the liquid rises inside a sealed container with an integrated heater. Since the volume of the chamber is small, the process proceeds rapidly and with little heat loss. The design of such units includes:

- Electric pump.

- Storage tank.

- Mechanism for controlling water supply and heating temperature.

Flow units lack the first 2 components.

Conclusions and useful video on the topic

A used gas cylinder is often used to make homemade devices. We present a video on how to make a BKN from a cylinder body.

Here we describe only one option out of all the possible ones that exist and are successfully used. It should be noted that there are many options for independent designs of indirect heating boilers.

For example, instead of a cylindrical storage tank, rectangular vessels are used. The winding of the coil spiral is not single-layer, but multi-layer. The water heater is supplemented with an electric heating element. Design ideas have no boundaries.

Would you like to share your own experience in making an indirect heating boiler or useful information on the topic? Please write comments in the block below. Here you can ask questions, express your opinion and post photos.

Heating inertia

Boilers are characterized by the rapidity of temperature rise in the pipes of the heating system. In 15-20 minutes the water heats up to 60°C. In this aspect, flow devices are inferior to traditional boilers. Heating water in a storage tank with a capacity of 150 liters takes 40-50 minutes. The rate of temperature increase is affected by the performance of heating elements. After turning off the electric boiler, the water in the heating pipes quickly cools down.

Instantaneous water heaters require several recirculation cycles to lower the liquid temperature to room temperature. In the event of an unexpected power outage, the water remains hot for some time. Necessary conditions for the use of flow-through units in heating objects such as a private house:

- A small heating area, which is dictated by the ratio of 1 kW of consumed electricity to 10 m² of area.

- High quality coolant for durability and normal functional condition of the working elements of the unit.

- To circulate the liquid, you need a pressure similar to a centralized water supply system - 4 atm. In models equipped with a circulation pump, 1.5 atm is sufficient.

Appearance of instantaneous water heater.

Instantaneous water heaters are used to heat a small cottage with an area of up to 80 m². This applies to outbuildings and country houses. Another area of application for such heating equipment is the installation of heated floors.

Solenoid valve for DHW system with water recirculation

Solenoid valve UNIPUMP BCX-20 3/4″ (normally closed)

Operating medium temperature range – 0…+120 ºС Operating pressure – 0.5…16 bar Power supply parameters – ~220 ±10% V, 50 Hz Protection degree – IP65 Normal closed 20 – DN (nominal diameter) in mm

A normally closed valve opens the way for liquid flow when voltage of ~220 V enters the valve coil (solenoid).

Indirect heating boiler

This unit is a sealed tank with a built-in electric coil. The water in it is heated by circulating liquid in a closed circuit and coming into contact with the heating element. Electric operation allows you to constantly have a supply of warm water, and an intelligent control system ensures comfortable operation of the device. Such equipment is made of stainless steel with a heat-insulating glass-ceramic coating.

A sealed container with a volume of up to 1000 liters can provide hot water to a large mansion. Depending on the design and type, the indirect boiler is connected to the gas supply system or to the electrical network. Such equipment is equipped with an automated control mechanism. In winter, the unit can be used for heating and hot water supply, and in summer only for heating liquids.

Indirect water heater device.

Such devices are characterized by high performance, efficiency and good ergonomics. Indirect boilers are either wall-mounted or floor-mounted. The unit takes some time to initially heat the water. Subsequently, the set temperature is maintained automatically. Heat loss is minimal thanks to reliable thermal insulation. Similar heating equipment can be purchased in the Kvanta+ online store in Tyumen.

Criterias of choice

How to choose a boiler for heating your home? To do this, you need to consider the following factors:

- Design features. The best option for a heating boiler is to place the inlet on top of the tank, and the outlet on the bottom, and their diameter should be more than 2 inches. When the inlet and outlet are located on one side, a pump is installed.

- Device power. When using a boiler to heat water, it is necessary to select a device with maximum power - 3.5-5 kW, which will make it possible to heat a room of up to 50 m². A specialized heating boiler must have a power of at least 7-8 kW.

- Volume of the tank. For heating, only a device with a large tank is suitable, which will make it possible to operate the heating element in a gentle mode - the maximum power is set during initial heating (1-1.5 hours) to form a reserve of coolant, and then decreases. In domestic boilers, the tank volume should be about 70-120 liters, in specialized ones - more than 200 liters.

- Materials used. During operation, the tank material is subject to significant corrosion.

When choosing a boiler, you should pay attention to the presence of a protective coating and the material used:

- Porcelain glass or enamel coating provides good protection against corrosion only if it is intact. Mechanical stress and sudden temperature changes cause cracks and other damage, which creates an active corrosion zone.

- The tank body made of stainless steel or titanium is strong and durable, not subject to corrosion. The main disadvantage is that such boilers have a higher cost.

Instantaneous water heater

A good solution for small residential and technical facilities is an instantaneous water heater. The average productivity of a 2 kW unit is 12 l/min up to a temperature of 60°C. This device is suitable for both private cottages and country houses with non-permanent residence. It is used to provide hot water and space heating. Advantages of instantaneous water heater:

- compact dimensions allowing you to place the equipment in any free space;

- low heating inertia value;

- the ability to adjust the temperature;

- integrated system for automatic shutdown of heating elements in the absence of coolant;

- a variety of models varying in power and price.

The only drawback of such a unit is its low efficiency, which is associated with high energy costs.

How to ensure water supply through pipes - connection diagram

First, let's look at the internal components of the boiler itself. It includes the following parts:

- coil: located inside the water heater and is required to heat the liquid using circulating coolant;

- thermostat: designed to control the temperature of the water inside the boiler itself; when the control temperature is reached, the device turns off automatically and starts working again when the water cools down;

- insulation: ensures long-term heat retention inside the water heater and does not allow the water to cool quickly;

- water supply pipes: they connect the device and the heating system, connecting to the coolant source.

When the boiler itself is already installed in its place, you can begin to connect it to the heating network. It is necessary to remember that the water heater has 4 pipes through which cold and hot water supply passes. They need to be connected according to this diagram.

During one circle with water, the following happens:

- cold water enters the device through 1 pipe;

- using a coil it heats up and remains in the boiler until the thermostat stops heating;

- Water flows through the pipes into the batteries and heat supply occurs.

So you can see that installation does not require much effort. You just need to understand the structure of the device itself. Connecting a storage water heater with your own hands.

Advantages

Such a system has its undeniable advantages. After all, the boiler in this case performs two functions at once, which makes it the most indispensable device in a house or apartment. The device has the following advantages:

- wastes significantly less heat than conventional heaters, this is due to a special layer of thermal insulation;

- simple and convenient installation that does not require much energy;

- saves a lot of money and does not require large installation and maintenance costs; heating boilers are much more expensive than average boilers. Old water heaters are the most economical to use;

- you can independently adjust the required temperature level or stop the heat supply altogether;

- easy to assemble yourself at home, no special tools or plumbing equipment, skills and knowledge in this area are required, just strictly follow the instructions;

- the heating itself comes from the coolant, which reduces the risks of breakthroughs and improper functioning of the system;

- You can use hot water and heating at any time, even if an accident occurs at the station; this is especially common among pipe breaks at thermal power plants in winter - the house will always be warm.

As you can see, this device has a lot of advantages, which, without a doubt, favor the installation of a boiler as a source of heating in the house. Less costs than heating from a management company, but greater efficiency, and most importantly, reliability.

Flaws

Water heaters of this type also have some minor disadvantages. They appear either in the early stages or already during long operation of the boiler. The disadvantages of the technique are as follows:

- the device is subject to corrosion and other unpleasant phenomena that destroy the metal and walls of the pipes, and sometimes even the water heater itself. First of all, boilers that operate continuously without stopping are exposed to this risk;

- it is necessary to spend a lot of labor resources to install the heater: little time, but many tools that must be used during installation;

- designed only for a small heating area due to insufficient power: water heating boilers, of course, cope better with this responsibility;

- it takes a long time to warm up a large amount of water: from two hours to twelve, depending on the power of the boiler;

- It is mandatory to purchase a thermostat, without it the device will not function fully, this indicates additional costs;

- an efficient water heater takes up a lot of space in the room, and sometimes even requires a separate room for placement;

- There is no chance of using the device outside of the heating season, otherwise this will mean additional costs when paying for utilities.

There are as many disadvantages as there are advantages. Accordingly, everything is individual for each user of such a device. Some do not experience any problems, while others have difficulties. Therefore, you need to try different models and only after that draw conclusions about the difficulties of operating the devices.

Selection of coolant for water heater and installation

The main technical parameter of the unit is the rate of heating of the coolant to a given temperature. When choosing a suitable model, you cannot be guided solely by the rated power indicated in the accompanying technical documentation. The expected operating conditions and heated area should be taken into account. The unit should be installed in a warm room to minimize energy losses. The electrical wiring must be able to withstand the maximum load generated by the water heater. Such data is indicated in the technical data sheet of the equipment.

Distilled water is considered the best filler. It has optimal heat capacity. For use in hot water supply and space heating systems, it is better to purchase a unit with closed heating elements. This design avoids scale formation. It is important to choose a device of the required power that is capable of coping with the functional tasks assigned to it.