Home / Articles / How to properly insulate interpanel seams in a panel house / Repair of interpanel seams and the technology for their insulation / How to determine the series of a house and calculate the volume / How to seal interpanel seams in an apartment / Sealing seams - determining the price / Who should repair interpanel seams in a house / How force the management company to seal the interpanel seams? / Reasons for the appearance of mold on the walls of an apartment / The walls in a panel house freeze, what should I do? / Typical mistakes in sealing joints between panels / How is the technical condition of interpanel joints, roofs and balconies inspected? / Frequently asked questions about sealing seams, what should I do if the seams are leaking? / How to get rid of fungus and mold on the walls of an apartment / Album of technical solutions: insulation and repair of open and closed joints / Technical instructions for sealing joints of prefabricated buildings with polymers

Primary sealing

It is carried out during the construction of a building and includes the following stages:

The seam between the panels is filled with foam; it provides not only insulation, but also additional waterproofing;

Vilatherm is placed in the seam. This is insulation with a high elasticity index, made from foamed polyethylene. The material may be cylindrical, sometimes with a hole inside. Thanks to its elasticity, the material can withstand repeated stretching and compression, which is important when a new house undergoes shrinkage. When laying the material, you need to ensure that it fits tightly to the concrete surface. If connections are made to vilates of different diameters, then the upper edge is trimmed with a wedge downwards, and the lower edge – upwards.

A sealant (mastic) is applied over the vilatherm; if all work is done correctly, the seam should be completely sealed.

Often, insulation and sealing of the seam is carried out without the use of foam; this is acceptable and does not greatly affect the final result.

Material selection criteria: what to look for

To keep the walls dry, you need to choose materials with zero vapor permeability. The following characteristics should also be assessed:

- Thermal conductivity. The lower the level, the better the insulation will be.

- Compliance with environmental standards. This parameter is especially important for residential buildings. If the insulation releases toxic substances during operation, it cannot be used to insulate seams.

- Fire safety. The minimum flammability class of the insulation must comply with the G1 standard.

- Life time. The performance properties of the material must remain identical at different stages of use.

Additional selection criteria include ease of installation and minimal volumes of construction waste after installation.

Professional polyurethane foam

Sealing joints with polyurethane foam without the use of harnesses or sealing tapes is suitable for partial or economical repairs without opening the joints.

This building material allows you to fill all the cracks and holes, and its hardening period lasts from 12 to 24 hours. The remaining parts of the foam can be cut off with any suitable device.

Sealing joints with polyurethane foam is suitable for economical repairs.

Experts do not recommend using insulation without carefully sealing moving seams. During thermal deformations, cracks may appear that allow cold and moisture to pass through.

The advantages of this option include:

- Quick and convenient placement with a nozzle gun.

- Good adhesive properties.

- Uniform distribution at the joint.

- Thermal resistance from -50 to +90 °C.

However, construction foam also has its downsides. Foaming is carried out at a temperature not lower than -10 °C, and the sealing process is accompanied by high costs associated with the cost of a foam cylinder.

Gernite cords

Elastic insulation is made on the basis of foam rubber. Due to its special structure, it is characterized by maximum water and air tightness, allowing you to simultaneously solve the problems of waterproofing and insulation. In addition, the material is characterized by durability and low cost.

Gernite cords are elastic insulation.

One of the disadvantages is the heavy weight - a linear meter of gernite cord with a cross-section of 50 mm weighs 1.5 kg. If the surface layer is damaged, the thermal insulation properties of the material will be greatly reduced.

Polyethylene foam harnesses

Cords based on foamed polyethylene are actively used for heat and waterproofing work when processing seams between the slabs of a panel house.

This elastic insulation is not subject to deformation during compression and retains its shape well throughout the entire period of operation. The list of negative aspects is limited only by the high cost of the harnesses.

Mineral wool

Mineral wool refers to an insulating material that contains extruded stone chips. The internal cavities of the slab consist of 90% air, which has a minimum thermal conductivity coefficient.

Mineral wool contains stone chips.

There are 3 types of mineral wool on sale:

- Basalt. It is in greatest demand due to ease of installation, accessibility and effective thermal insulation. But the material is not used to process the façade of the house.

- Glass wool. It was widely used in the 20th century, but due to the likelihood of crumbling and rapid damage, it lost popularity. When laying glass wool slabs, it is important to use high-quality personal safety equipment.

- Cellulose mineral wool. Complies with environmental standards, but is highly flammable.

Sandwich panels

The material is in demand due to its ease of installation. It is made in the form of a 2-layer plate based on the following components:

- Foamed polyurethane. It is distinguished by high quality in thermal insulation of seams.

- Mineral wool. When combined with a sandwich panel, mineral wool is not subject to the destructive effects of moisture.

- Foam plastic. Cheap insulation is lightweight and affordable.

Styrofoam

The most common insulation on the domestic market, which is not afraid of precipitation or ultraviolet radiation.

The service life is 30-50 years. The foam boards are fixed with dowels or using special glue. The negative point is the release of toxic substances when ignited.

Polystyrene foam is the most common insulation material.

Sealant

Using sealants, you can seal hard-to-reach seams and cracks in building structures. When filling the voids with this material, a dense elastic layer is formed.

Now let's look at what mistakes are most often made when sealing interpanel joints?

For insulation, only polyurethane foam is used. Some companies consider this a simplified option, but our specialists do not use this technology, as it has disadvantages. Over time, the house will settle, causing the slabs to move. Polyurethane foam is not elastic, therefore, as a result of the movement of the slabs, the integrity of the foam will be compromised, which means water and cold will freely penetrate into the seams.

Use of low-quality Vilaterm. The use of high-quality insulating material is a very important fact, so we check the quality of vilatherm every time we purchase it. In our practice, there have been cases when, with vilatherms, such material does not provide a tight fit to the panels, that is, the material simply falls out of the seam.

Using vilatherm of the wrong diameter. When laying, it is important that it fits tightly to the walls of the seam and is in a compressed state.

Incorrect connection of insulation. One of the common mistakes that leads to the destruction of the sealing material and the opening of the seam.

Secondary sealing

Repeated work on sealing the joints between the slabs can be carried out using two technologies:

Without opening the seam. New sealant is applied to the old sealant (mastic joint repair) or over the concrete joint. In this case, it is very important that the seam is cleared of foreign debris and elements that are weak to adhere to. A carpet brush is used to clean the joint, after which the seam is treated with a solvent.

The second option involves opening the seam and completely cleaning it, removing the old sealing material. For cleaning, a hammer drill and a chisel and hammer are used to remove old material. After which the seam is degreased and goes through the stages of primary sealing.

Often, when carrying out this procedure, companies with unqualified employees make a mistake - poor-quality cleaning of the seam from old material.

Preparatory activities

At the preparation stage, you should purchase the optimal amount of building materials. It is calculated based on the area of the walls without taking into account windows. The result obtained should be increased by 20%.

In addition to the insulating material, you need to buy a sealant for sealing the seams, as well as a number of consumable components. Among them are dowels, reinforcing mesh, plaster, and glue. For laying mineral wool, iron slats and screws are used.

A drill is included in the required tool kit.

If work will be carried out at height, it is necessary to prepare scaffolding. The tool kit also includes a safety net, a drill and a set of spatulas.

When preparing the walls, you need to get rid of the old coating by removing plaster and cracked paint from the surface. At this stage, it is important to coat the joints with putty and seal with plaster. The insulation is installed only on a flat and clean wall. If it is skewed, it will need to be leveled.

A little about the technology of sealing interpanel joints

The simplest and cheapest sealing option is to coat the joints, but unfortunately, this method does not bring the expected results, moisture penetrates the seams and enters the home, drafts continue to flow along the walls and bring cold into the home.

The fact is that during rain, a large amount of water collects on the roof of the bay window and it flows along the seams, constantly leaking into the apartments, especially in areas where a vertical seam intersects with a horizontal one. The surface sealing method is often used by home management companies, where the main thing is to make the work look like it is done, and not to do the job properly.

Sealing the seam between the panels and filling it with foam is a good option, although not strong enough. This technology involves drilling the seam to create holes through which the void between the panels will be filled with polyurethane foam. This method is usually used when the distance between the slabs is minimal or the interpanel seams are firmly closed with cement-concrete mortar.

At the same time, there is emptiness in such seams and dampness and cold pass through them into the room. In addition, when a building settles, the slabs always shift and cavities form, which can expand over time, especially in the seams, since this is the weakest point.

It is impossible to lay vilatherm from the outside, so the voids are filled with foam, and the seam from the outside is covered with mastic. With a competent approach and compliance with all technologies, this is a fairly reliable method, especially if the foam is not affected by climatic influences.

Facade treatment

Insulating a high-rise building from the outside allows you to achieve the best results. But in this case, only specialists will be able to carry out the work, since high-altitude work is required. You can seal the seams yourself by renting scaffolding; they allow you to cover a large width , and there is also room for the tools and materials necessary for the work.

You can also get to the upper floors using a tower, but there is not enough space on the site. Using a tower is appropriate if long-term work is needed in one place, for example, when the seams have expanded, or it is necessary to clear the cavity of old insulation.

When contacting professional climbers, be sure to check the certificate confirming compliance with all established standards. As a rule, climbers do not separately seal seams; they insulate the space between the seams monolithically, so that the cold does not penetrate inside. Insulation is carried out on a thoroughly cleaned and flat surface.

Be sure to check that the joint of the insulating elements is not in the same place as the joint of the slabs. In this case, a cold bridge will form and it will be very difficult to correct the error.

The price for insulating the facade of a multi-storey building depends on the linear meter; as a rule, specialists charge no more than 350 rubles for one meter. You can calculate the approximate cost yourself; you just need to multiply the linear meters of your living space by the cost per meter.

Sealing an apartment does not take too much time, first of all, the time depends on the amount of work, on average it can be completed in 1–2 days. All documents needed for construction work are provided by a company specializing in facade insulation. The client must only provide an application addressed to the Chief Engineer.

Warm seam

This is one of the most effective and common methods. To implement it, the joint cavity is foamed and vilaterm is placed in it, after which a layer of sealant is applied to the surface of the seam. At first glance, the “warm seam” technology is impeccable, but as practice shows, it also has disadvantages, or rather difficulties in operation. Panel slabs are produced with a thickness of 20 cm, while vilatherm is 3-4 cm, with another 16 cm remaining, but there are slabs with a greater thickness and this space will remain empty. The seam will be protected for several years, but then the vilatherm will turn into dust, begin to crumble, and the problem with the seams will again become acute for the owners. If the joint is heavily foamed, the foam will push both the vilatherm and the sealant out, which is, of course, unacceptable. Therefore, when using the “warm seam” technology, the joints must be foamed very carefully. It is described in more detail and in detail with examples on the page about sealing interpanel seams

Useful tips

In old apartments, with the constant destruction of insulation, mold begins to develop on the walls. For this reason, mold areas are treated before resealing is performed. This work is performed in the following order:

- the contaminated area is cleaned;

- dried by natural ventilation for three days or using a heat gun;

- treated with biocide;

- covered with finishing materials with antiseptics.

The walls of old buildings, into which fungi have penetrated quite deeply, are very difficult to “cure”. Therefore, it is better to hire a construction team that will process and clean the surface in accordance with technology.

Sealing seams in panel houses

In this case, it is assumed that the joint between the panels is completely filled, where the final stage is the application of a sealing layer of mastic. When the material is completely foamed, it comes out, so it doesn’t make any sense to lay Vilatherm and mastic right away. You need to wait a few hours, or better yet a day, until the foam gets stronger, then you need to remove its excess, lay the vilatherm and apply mastic. If the joints are filled through holes that are pre-drilled, then the technology is the same. Foam is injected into the holes, which are then tightly closed. The foam, not finding a way out, is forced to fill all the voids inside.

Is it necessary to open the seam?

There are a number of factors under which the seam must be opened, namely:

- The material from the seam disintegrates when struck with the sharp edge of a climbing hammer;

- The seam is surface plastered and a light layer of sealant is applied to it;

- The wall is very old and the material falls off even with a light touch.

Such seams must be opened, filled and sealed. If the seam is securely concreted or the slabs fit tightly enough to one another, then tearing down the walls is not recommended. It is more advisable to drill neat holes and foam the voids. Some people believe that in order to ensure thermal insulation of the seam, it is necessary to lay vilatherm. This is not so, the fact is that vilatherm itself does not provide heat, it only protects the seam from the penetration of cold by “sealing” the joint. If the seam is foamed correctly and reliably, then heat leakage will not occur.

Rococo embroidery master class for beginners

Among the huge number of different embroidery techniques, it is difficult for a novice master to choose the right one. If there are no embroidery skills, then not everyone will dare to take on something that seems unusually difficult. However, there are those who are not afraid of difficulties and take on what they like best. One of these types is Rococo embroidery. For beginning craftsmen, it seems very difficult due to the ornateness and variety of ornaments and patterns. This is actually a very easy technique to learn.

Features of sealing interpanel seams

Today, before starting renovations on apartments in a new building, owners have to wait several years for the house to settle. As a result of settlement of the house, voids and cracks form between the slabs, which must be repaired. Houses that were built during the cold period have a number of disadvantages. The panels often did not always have time to dry thoroughly and reached their condition already during the construction process. As a result, due to temperature changes and high humidity inside the slab, its integrity was compromised, since in cold weather the water inside the concrete froze and destroyed the slab.

Sealing of joints between panels should be carried out during the construction stage. The work should be carried out from an elastic material that has good resistance to the negative influences of the environment, because practice has already proven that the structure of solid materials is quickly destroyed due to the constant (even microscopic) movement of panel slabs.

Internal insulation of the facade

Internal insulation of the facade is an ideal option when you need to change the situation in only one apartment. You do not need to obtain special permits or negotiate with neighbors. Inside the apartment you are your own masters.

Insulating the walls from the inside will add about 10-15 cm to them. This method actually involves a major overhaul of the insulated wall. The procedure begins with dismantling the trim and plaster. Afterwards, all the cracks and cracks in the façade wall are identified. They are filled with compounds with special additives. After this, the wall is prepared, then a deep penetration primer is applied.

Seam sealing at a professional level

To ensure thermal and waterproofing, it is necessary that all joints and cavities between the slabs be filled and sealed. Only properly sealed seams provide comfortable and healthy living conditions. As practice has shown, the most effective method of insulation today is the “warm seam”.

In the past century, the seam was filled with tow and rubber; recently, new materials and techniques have appeared on the market, which have made it possible to significantly improve the technology of sealing seams and guarantee high results. For this purpose use:

- Swellable cords made on the basis of hydrophilic rubber;

- Cement mortar is common;

- Dowels and specialized profiles.

But such sealing methods cannot give a good result due to:

- Different thicknesses of gaps between plates;

- Chips and microcracks of slabs;

- A defect that could occur as a result of non-compliance with construction technology.

Houses made of sandwich panels once received an unfortunate practice. The first buildings built using the new method had to be strong and warm, since the structure was made of two strong slabs. But over time, it turned out that there was an empty space between the panels, although in theory it should have been filled with insulation, in practice it was not there, as a result, air accumulated in the empty space, which created drafts. Due to the large number of empty cavities, such houses did not warm up well and cooled down quickly. Condensation led to the formation and active reproduction of mold and mildew, which became faithful neighbors.

Insulation during construction

Previously, during the construction of houses, tow or rubber was used to insulate joints. Today, these materials have been replaced by a dowel, cement mortar and a swelling cord made of hydrophilic rubber. But the work made from these mixtures cannot be called high-quality; during installation work, gaps still remain, which later let the cold inside.

Only polyurethane foam can qualitatively fill the voids in the seams between the panels, which spreads evenly and completely fills the entire space, without the slightest gap.

It is used in combination with sealants, which can also boast excellent performance and durability.

Step-by-step sealing of interpanel seams

Sealing seams in buildings of this type is a very painstaking and time-consuming job that requires experience and specific knowledge. Our company’s employees, thanks to many years of experience, have been able to master the technology of closing seams for such houses.

To reliably fill the seams, our employees use special foam, which, when expanded, penetrates even small cracks and reliably fills all voids. Vilater blocks the foam from escaping to the outside, as a result, the entire flow goes inside, and the sealant reliably protects the seams from moisture penetration.

average price

The caulking of log walls depends on the length of the inter-crown connections in linear meters, the design of the house, the configuration of the log section, so rounded logs are more expensive than standard ones.

In addition, the final cost is influenced by the shape and number of corner joints; “in a bowl” is more expensive than “in a paw”. As well as the type of sealant, installation of high-tech modern insulation costs much more.

Average costs for caulking log walls per 1 linear meter:

- in a simple wooden frame - from 90 rubles;

- in a house made of rounded logs - from 105 rubles;

- from chopped logs - from 90 rubles;

- dismantling old tow - from 35 rubles;

- laying decorative rope - from 30 rubles;

- punching of old tow - from 40 rubles;

- decorating cracks with flax rope - 40 rubles;

- finishing seams with varnish - from 15 rubles.

Protection of the upper floors should begin with sealing the seams

The reputation of panel houses suffers greatly due to poor waterproofing, especially on the top floors. In most cases, the space between the slabs in such buildings is not filled with anything, and this is a fact proven by practice and experience. In addition, the roofing material of balconies and loggias does not meet the waterproofing requirements.

The technical floor becomes a place where rainwater steadily accumulates after every rain, which penetrates into the apartments through drainage channels and empty seams, and the upper floors are the first to suffer.

To free your apartment from the constant penetration of dampness, drafts and cold from the roof, it is enough to properly insulate the joints and repair the roof on the loggia. To do this, craftsmen remove the old material and lay in a new one that has good strength and elasticity. Additionally, the work uses a burner and special modern waterproofing materials. Next, waterproofing of vertical joints in the area of the customer’s apartment is carried out on all floors. Afterwards, the joints between the panels are cleaned, where vilatherm and polyurethane foam are laid. Afterwards, the seam must be thoroughly coated with waterproofing material – mastic. Only compliance with this technology can guarantee a high result of waterproofing work and provide dry and warm walls in the premises.

The edge of a concrete wall with joints is often jagged and uneven, so if the joints are not sealed carefully, they begin to leak. The problem is that the seams on the inside of the slab are inaccessible for work, so the only solution is to carefully waterproof the joints on the outside.

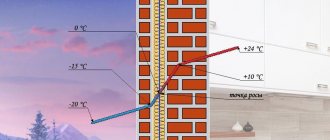

Thermal insulation of corner vertical joints in external wall panels

Particular attention should be paid to thermal insulation of corner vertical joints

of external walls

, where

heat loss is maximum

. For this purpose, the following measures are applied:

- install insulating liners

(Fig. 4, item 2), - perform an internal bevel of the corner

, - install external insulating pilasters

, - They supply additional heat

at the junction between the panels from a monolithic or freely installed

additional heating riser

.

In buildings with transverse load-bearing walls, insulation of external corners

thickened end external walls,

characteristic of such buildings , or

the installation of an additional internal panel

(Fig. 4).

The implementation of insulation and insulation

of corner joints

in

external wall panels

is shown in Fig. 4

10 mm

and of the same depth

is removed along the edges of the joints In addition, it is RECOMMENDED to arrange a smooth frame

at least

10 mm

.

Sealing seams in different types of houses

Sealing technology is selected for each home and case individually, since there are many factors that must first be calculated and taken into account. At the same time, craftsmen also consider the economic feasibility of using one or another sealing method.

Our company uses the “warm seam” technology for its work; today this is perhaps the only reliable, proven method that gives high results. The secret of our company is that we use our own, improved and time-tested technology for waterproofing seams. We use Vilaterm as a sealant, a material characterized by high wear resistance, Macroflex sealant and Oxyplast mastic.

Previously, houses of the KOPE type were built from sandwich panels that were empty inside. The tightness of the adhesion of such panels was simply terrible; as a result, the houses were not distinguished by good thermal insulation and airtightness.

Let us say right away that sealing seams using foam does not bring the desired result due to the specifics of the material; the foam did not linger in the seams after filling, but spread throughout the interpanel space. To achieve good tightness, a vilatherm seal is used. This material has already proven its effectiveness in ensuring tight sealing of seams and sealing.

In houses of the p.44 and p.44t series, problems periodically arise associated with chips on the slabs or with the formation of large seams between the panels, through which heat leaves the house, a draft penetrates from the street and condensation forms. In winter, such walls are not protected from the cold, as a result, fungus and mold become permanent residents in such apartments, and drafts also add to the dampness.

In such cases, interpanel joints are sealed using the “warm seam” technology. If the width of the joint does not allow the use of Vilaterm insulation, the seam is reliably foamed and covered with sealant on top. Construction foam has good resistance to environmental influences and can perform its functions for a long time.

To be fair, it should be noted that blown seams are not only a drawback of panel houses. Monolithic brick buildings also face this problem; poor sealing is especially often observed at the junction between the brickwork and the concrete monolithic floor. Similar problems also often arise at the junction of brickwork and windows. From personal experience, we can say that such seams must be sealed very carefully, using not only foam, but also sealed plaster.

How often should this procedure be done?

In the old days, only experienced craftsmen were involved in caulking log cabins. If the house was built from its own timber, which was dried in natural conditions, then the caulking was done twice: rough - during the construction of the walls, and completely - after the construction of the log house was completed.

In the case where the timber was purchased externally, it was impossible to accurately predict the shrinkage of the logs, so the house was caulked three times. This technology has remained effective to this day.

First time

It is performed during the assembly of the log house. Linen, jute, and hemp are used as insulation, and it is spread over the upper surface of the installed log. Today, for the convenience of the caulking process, tape felt is used.

When constructing a log building, I use the “stretched” and “set” method of protecting seams. The most popular is the “stretch” option. The free edges are wrapped with a roller no more than 2 cm wide and pressed into the seam between the logs.

When using wet, loose insulation in the form of moss and tow, when twisting the roller, you need to completely select the adjacent ends , all the time twisting them with the previous ones in order to obtain an even and strong seam.

The “set” method is used mainly for the 2nd caulking, when the ends of the heat-insulating material are short to create a full-fledged roller or the house has wide crown joints. A bundle of selected insulation is prepared for it.

It is allowed to use ready-made jute rope of the required thickness. If the seams are oversized in width, loops are made from it, which are then driven into the inter-log area until the required level of compaction is achieved.

The process invariably starts from the bottom row and is carried out along the full contour of the seam. First, the outer side of the log joint is sealed, and then the inner side.

The next crown is started only when the previous one is completely caulked.

The tourniquet is secured in the seam using a special caulking tool . They first tap the top of the joint, then the bottom and finally the middle. If necessary, additionally take a mallet, striking at the end of the caulking handle.

Important! In the process of caulking the seams of a log house, it is necessary to systematically control the horizontalness of the logs and the vertical level of the wall structures.

Despite its apparent simplicity, this process can change the position of the logs and cause a displacement of the structural elements of the house: move them away from their initial position or raise them.

Second

This mandatory process of protecting log seams is carried out after the building has settled , usually within 12-18 months after the log house has been erected.

Currently, the procedure is technically more advanced, since in addition to traditional caulking, it provides sealing by creating a warm seam. This provides users of wooden houses with additional advantages :

- plastic connection;

- durable wall structures due to the absence of moisture on internal surfaces;

- ultraviolet resistance of the seam;

- the highest heat-protective characteristics;

- vapor permeability;

- biological stability of compounds.

Sealing of seams between logs is carried out using the following technology:

- Preparing the insulated seam area. For this purpose, logs in the work area are cleaned of all types of dirt and grease stains. After thorough cleaning, a test is carried out to determine the adhesion of the sealant and the surface of the log.

- Install the sealing cord. Modern material can be made of extruded polyethylene. In this case, it is not allowed to be glued into the seam, but only loosely inserted into it.

- Before coating the cord and the seam surface of the logs with sealant, it is moistened. It is allowed to stick paint tape on both sides of the seam in order to guarantee equal width of the joints.

- The sealant is applied depending on its brand with a spatula or a construction gun.

- The layer size is at least 4 mm, but it should not exceed 10 mm.

- The seam is smoothed and formed with a construction spatula no later than 15 minutes after completion of its application.

- Remove the adhesive tapes, and clean the excess with a wet rag or sponge.

This is painstaking work, but its careful implementation will be fully justified by the high wear resistance of the structure and a warm house, which significantly reduces the cost of heating it in winter.

Third

The third time the filling is done after 5-6 years . In this case, the technology corresponds to the second caulking machine. The process starts from the bottom up along the contour of the log house, first the external protection is installed, and then the internal one.

The best modern option is jute - an environmentally friendly natural high-strength fiber that is highly resistant to moisture and wear.

Provides an even, protected outer seam. This material does not require re-caulking.

It is easy to install and fix; therefore, installation can be done with your own hands without the involvement of expensive specialists.

For energy efficiency, it is advisable to apply acrylic sealant on top of the jute seal. It is a new and safe building material with high reliability and environmental safety, and also has the ability to be quickly and easily installed.

Sealing joints that were previously plastered

Often, instead of sealing, utility workers simply plaster the walls and seams, but these actions do not solve the problem, the void between the seams remains, water and cold air constantly penetrate into apartments, as a result, the home is cold and uncomfortable, fungus and mold develop, which not only allows you to create comfortable living conditions, but also negatively affects the health of residents. Over time, dampness destroys the plaster layer and cracks open.

Of course, it is not always necessary to open the seam completely. Such measures are taken if the joint between the panels is narrow or the plaster is held tightly, then construction foam is used. Holes are made in the plastered seam, every 20-30 cm, foam is released through them, which penetrates into all the cracks and fills the entire space. Afterwards, a layer of sealant – mastic – is applied to the plaster; this coating will provide additional protection against moisture penetration.

Execution steps

Regardless of the technology used and the type of insulation, work begins only after preparatory measures have been carried out. All materials are purchased in advance, and subsequent actions are carried out strictly according to the instructions.

Installation of insulation

The glue is spread over the cleaned surface in several layers. If the wall is curved, it can be leveled with an adhesive mixture, but not more than 2 cm.

Then, in the direction from bottom to top, you need to fix the foam plates. After fixing the material, strengthen the fastening with dowels. To do this, holes are made in the slab, an expansion hood is installed and the fasteners are hammered in.

Glue and insulation are distributed over the surface.

Reinforcement

Unlike mineral wool, foam plastic does not require the use of panel materials. However, since it is quite fragile, it needs to be additionally reinforced using iron mesh.

In multi-storey buildings this is done end-to-end. If you overlap the reinforcement, the plaster layer will begin to delaminate.

Padding

The primer composition is distributed before puttingtying the reinforced coating. It is better to apply it in 3 layers, and plastering only after drying.

Plaster

Finishing with a plaster base and painting allows you to disguise the foam under the facade. In this case, people will not be able to notice the joints between panels or insulating sheets, and the appearance of the room will be refreshed.

Plaster allows you to disguise the insulation.

Painting

Waterproof compounds are used to paint plastered surfaces. If there are no financial restrictions, it is better to purchase insulating paint to consolidate the results.

Sealing seams at the joints of loggias and windows

The design of loggias and balconies implies the presence of joints between the slabs and walls, through which water can penetrate during rain. Constant dampness negatively affects materials, destroys them, develops fungus in them, and mold appears on the walls and ceiling. If the loggia is also blown out, then the furniture and materials on them begin to deteriorate, and there is nothing to say about comfort.

To eliminate drafts and moisture penetration inside, you need to provide sealing. Before starting work, the loggia must be carefully examined by employees of the sealing company, which will allow you to first draw up a competent work plan and select the necessary materials.

Step-by-step pattern for embroidering a rose

Starting is always difficult. However, it is not for nothing that they say: “If you are afraid of wolves, do not go into the forest.” If a student does not practice mastering the acquired knowledge, then he will never become a real master. Therefore, learning to embroider in the Rococo style and master class on embroidering a rose is one of the most important steps in mastering this craft.

Having prepared everything necessary, novice craftsmen can begin to implement a simple embroidery pattern for their first flower:

- Choose the color of the future rose and thread the needle, tying a knot at the end.

- Thread the needle from the inside out at the place of the first stitch.

- Make a stitch of 5-6 turns.

- Then the remaining stitches are made, forming the petals of the future flower. Formation principle: from the center, each new petal is slightly longer.

- Make the final stitches of the flower for 15-18 turns.

- Thread the needle with a thread of the color of the stem and leaves.

- Thread from the inside out at the location of the leaves or stem. Preliminarily outline the location of the elements with a pencil.

- Make the corresponding stitches according to the drawing.

By following simple instructions, future craftsmen will be able to master all the secrets of craftsmanship and in the future embroider the most incredible compositions and ornaments.

Today this type of decorative and applied art is very popular. Many fashion designers use embroidered elements in their collections. Rococo embroidery on knitted items and items is especially in demand among modern fashionistas. Having learned the basics of embroidery, many decorate their personal wardrobe with patterns in the Rococo style.

Popular posts

- Chair for dressing table Chairs for dressing tables in Moscow - 189 Products Company from Moscow, delivery 29643 a In…

- Silicone sanitary sealant Silicone sanitary sealant white in Moscow - 1491 products Company from Moscow, delivery (tomorrow) 140...

- Shelf in the hallway Currently, there are a huge number of different options for shelves in the hallway, and this is directly ...

- TechnoNIKOL insulation characteristics TechnoNIKOL - technical characteristics of the material and its wise choice In the cold season, you want…

What advantage does sealant have over other building materials?

According to its technical characteristics, the sealant has good elasticity, which allows the material to adapt to external changes, slab shifts and other deformations that may occur as a result of the operation of the building. A high-quality sealant withstands exposure to sunlight well and is a reliable protection for foam, which can collapse under the influence of UV rays. At the same time, the sealant protects the foam not only from sunlight, but also from moisture, and prevents the formation of flax, mold, and fungus inside the seam.

Our specialists use only materials proven by experience and time, which provide long-term safety for the seam and the apartment (house) from moisture.

A question or request for work using the warm seam technology method for a panel building can be submitted to the contact phone +7 (495) 585-79-00 or sent right now: Order

Frequently asked questions about sealing seams: / How to properly seal internal seams between slabs / Who should I repair the interpanel seams in my house? / Sample application to the Management Company for the repair of interpanel seams / Secrets of correctly writing an application for interpanel seams in the management company / Reasons for the appearance of mold on the walls of an apartment / Walls freeze in a panel house, what should I do? / Typical mistakes in sealing seams between panels

Tools for the procedure

The basic tools for caulking seams are special blades called caulking tools and a mallet.

The first ones can be either wooden or steel. Here it is important to follow the rule that the caulking material is softer than that of logs, since otherwise marks will begin to form on the walls.

Over time, the working plane of the wooden spatula becomes frayed, in which case it will need to be replaced with a new one. Metal caulks , where it is very important to caulk the inner area of the bowl.

To carry out heat-protection operations during the construction of a log home, conventional or type-set caulking is used. The dimensions of a traditional spatula range from 16 to 25 cm in length, 5 cm in width and 5 mm in thickness. Its shape is flat and ends in a wedge shape.

It is designed for sealing ordinary seams of various thicknesses and makes it possible to easily push the protective material into a narrow gap. Based on the volume of the surface being treated, it is divided according to its dimensions into large, ordinary and narrowed.

The main types of tools for caulking a log house:

- The standard spatula is used for gaps of various sizes and additionally in corners and roundings of joints. The width of the working blade is from 5 to 6 cm and the thickness is 5 mm. It is preferable to use an iron spatula for processing fillet welds.

- A wedge-shaped or split blade allows you to move apart the inter-crown gaps to facilitate the installation of insulation. The width of its working blade is 3 cm.

- The road worker is a spatula with a wide working blade of 17 cm, up to 15 mm thick, has a longitudinal groove 1 cm wide. As a result, it twists the fibers well into a roller when sealing cracks using the “stretch” method. In the retail chain there are such blades in 3 sizes - for wide, medium and narrow cracks.

- A steel caulking chisel is produced with different working blade sizes, so it can be used for different types of wooden walls.

- A mallet or mushel - with a rubber or wooden working tip, promotes deeper penetration of the insulation into the inter-crown cracks.

Before choosing a caulk in a retail chain, the buyer should pay attention to the fact that the working blade of the tool is smooth and does not catch the insulation. Metal tools are more productive .

Despite the fact that steel blades have the highest wear resistance, an overly sharpened blade can damage the fiber of the log, leaving harmful marks on it.

Attention! For ease of use, the handle of the spatula is made of corrugated rubber. In order to cover all the uniform seams in a log building, three types of caulk are purchased: two with a wide working blade, and one with a narrow one.

During the caulking process, consumable materials include the insulation itself and various impregnations, usually antiseptics. Currently, artificial insulation for caulking is becoming increasingly popular : inter-crown sealants, mineral wool fiber and polyurethane foam.

They have high elasticity, good heat-shielding characteristics, as well as moisture and bioresistance. The use of self-expanding sealing cords can perfectly seal the seam.