Residents of the private sector, owners of country houses and cottages today are showing increased interest in heating devices running on solid fuel. There may be several reasons for such attention to solid fuel boilers, starting with the desire to achieve independence from a centralized energy supply and, conversely, due to the lack of it. The pace of suburban housing construction today is significantly faster than the speed of work on gasification of populated areas, so the only way out of this situation is cast iron heating boilers using solid fuel.

Why cast iron boilers when there is a wide selection of models of steel solid fuel boilers? We suggest that you familiarize yourself with the design features of solid fuel cast iron boilers and answer the question accordingly.

Long-burning pyrolysis boilers with a water circuit

Long-burning pyrolysis boilers with a water circuit are an excellent alternative source of energy in private homes in conditions of frequent gas supply interruptions.

A long-burning solid fuel boiler with a water circuit can operate on wood and other types of solid fuel: coal, wood waste, etc.

The main disadvantage of this type of boiler is the high price. In addition, unlike many other types of boiler equipment, a long-burning pyrolysis boiler with a water circuit is most often energy-dependent.

Not only the circulation pump and control devices are powered by electricity, but also the built-in fan: this equipment, as a rule, does not work on natural draft.

Solid fuel wood and coal boilers are second only to gas boilers in popularity. However, they have one serious drawback - fuel must be loaded several times a day.

During normal combustion of wood, the efficiency of boilers does not exceed 75%, and some of the flammable substances simply fly away into the chimney.

Long-burning pyrolysis boilers with a water circuit are much more practical and efficient.

It will not be a secret to anyone that pyrolysis heating boilers are currently very necessary and in demand heating system devices. It is for this reason that many of our people have become interested in these particular units.

A pyrolysis boiler is a special heating boiler that can use pallets, coal, wood, and other materials as fuel.

One of the main criteria, depending on which heating boilers are divided, is the type of fuel on which they operate. Thus, in today’s market you can find boilers based on pallets, coal, and wood. You can also find so-called universal boilers for yourself.

The most common at the moment are wood-burning solid fuel boilers, which have many advantages. The first is that fuel is considered the most affordable. It should also be noted that such boilers are sold at reasonable prices.

A distinctive feature of pyrolysis boilers is control of the oxygen level in the combustion chamber, and accordingly control of the temperature and rate of fuel combustion. A solid fuel pyrolysis boiler will ensure your independence from gas and electricity, since the costs of these energy sources significantly exceed the cost of solid fuel.

Let's sum it up

Solid fuel appliances steadily occupy one of the consumer niches among heating equipment. The wide technological capabilities possessed by the new models have brought heating devices made of cast iron to a new level.

Today, solid fuel units made of cast iron are becoming a mandatory attribute of a country house. The omnivorous nature of heating devices in terms of fuel, unpretentiousness in maintenance, and simplicity of design make these devices competitive products in the heating equipment market. The high cost of products should not confuse the consumer. The invested funds will pay off in full, taking into account the service life of the boiler equipment.

Design Features

Pyrolysis boilers are one of the types of solid fuel boilers, which have recently been in increased demand due to constantly rising prices for gas and electricity; they are also called gas generator boilers.

The main fuel for a pyrolysis solid fuel boiler is:

- wood;

- briquettes;

- wood chips;

- wood waste.

Very rarely, coal or coke is used as fuel. Pyrolysis boilers are easy to use, reliable and have a long service life. Before buying a pyrolysis boiler, you need to study the possibility of meeting strict requirements for the quality of the fuel used.

In the vast majority of cases, it is allowed to use wood with a moisture content of no more than 20%. When using wood with a large amount of moisture, efficiency decreases sharply.

The pyrolysis boiler operates on the principle of dry distillation of fuel.

With a lack of oxygen, under the influence of high temperature, dry wood decomposes into a solid residue and a volatile part (pyrolysis gas, which is subsequently mixed with hot air).

This air-gas mixture, which was formed during the pyrolysis process, is the fuel of the pyrolysis boiler. The pyrolysis combustion process is exothermic (accompanied by the release of heat).

It occurs at temperatures from 200 to 800 °C and provides heating of the air entering the combustion chamber. In this case, the fuel in the unit chamber is heated and dried, thereby minimizing the release of soot and ash.

A pyrolysis or gas generator boiler is characterized by a higher efficiency compared to traditional solid fuel equipment.

When burning high-quality fuel, the efficiency of a pyrolysis boiler is at the level of pellet boilers and long-burning boilers and reaches 90%.

Pyrolysis solid fuel boilers are used both in private houses and apartments, and for heating industrial premises.

Pyrolysis boilers are a very cost-effective type of heating equipment. The fairly high price of a pyrolysis boiler is covered by low fuel consumption.

In a conventional long-burning solid fuel unit, the coolant is heated by the heat released during fuel combustion, but pyrolysis boilers operate on a different principle.

When burning organic fuel (wood, pellets, wood briquettes and even coal) at a temperature of 400-800°C, gas is released, burning which can produce much more heat than when burning fuel.

The process of gas formation from solid fuel and subsequent combustion of the resulting gas is called pyrolysis, and units using this operating principle are called pyrolysis, or gas generator boilers.

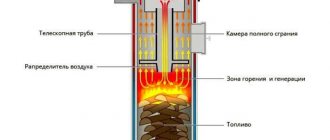

There are two chambers in the pyrolysis boiler, and combustion takes place in both:

- Combustion chamber – wood or other fuel is burned (charred).

- Afterburner – the gas emitted by the fuel is burned.

Fuel is located and ignited in the combustion chamber. Primary air is supplied to the combustion zone. When the fuel warms up to a certain temperature, gas evolution begins.

Using a smoke exhauster, gas, together with secondary air, is sucked into the afterburner chamber (it is located below the fuel level) and burns there, releasing heat.

Combustion products enter the smoke duct (flue) and enter the chimney, passing through the water jacket of the unit and heating the coolant.

As a result, firewood turns into charcoal, burning almost completely, and the smoke is cleared of unpleasant odors and carbon monoxide.

Which chimney is better

When calculating the mass, do not forget to calculate the weight of the chimney. For cast iron boilers, you can install a sandwich pipe, or you can install a ceramic chimney. It is not recommended to install a brick chimney on pyrolysis boilers - due to the low temperatures of the smoke at the outlet of the furnace, it takes a long time to heat up (the heat capacity of brick is large), so condensation forms abundantly. It's difficult to fight him. And one more thing: for a brick chimney in combination with a cast-iron stove, you definitely need a separate foundation, and a fairly solid one at that.

As for the ceramic chimney, this is a very corrosion-resistant and durable type of chimney, but it is expensive and, due to its heavy weight, also requires a separate base. Therefore, as in most cases, the most acceptable option is a sandwich chimney.

Advantages and disadvantages

Advantages of use:

- when burning firewood, it is impossible to obtain such a high temperature as during the combustion of pyrolysis gas (especially if the firewood contains a lot of moisture);

- With the help of a control controller, we can automate the operation of a pyrolysis boiler without much difficulty, since the combustion process of pyrolysis gas is easy to control and regulate;

- burning wood or coal requires much more secondary air than burning wood gas. Therefore, with the same volume of secondary air, the combustion efficiency of wood gas, the duration and temperature of combustion will be greater;

- the emission of harmful substances from pyrolysis boilers into the atmosphere is reduced to a minimum, therefore a pyrolysis boiler is an almost environmentally friendly source of heat;

- solid fuel pyrolysis combustion boilers need to be cleaned from ash extremely rarely;

- pyrolysis boilers can operate for a very long time (up to 15 hours) on one load of firewood, while conventional solid fuel boilers need to be reloaded every 3-4 hours.

If we talk about the disadvantages of this type of unit, then, in addition to the price, which is the price for increased efficiency, and a more complex design, because pyrolysis boilers are 30-35% heavier than conventional ones, since more metal is required for their manufacture, other “disadvantages” insignificant.

For maximum operating efficiency, the moisture content of firewood should be no more than 20%. If the wood is wet, when it burns, steam is generated, which reduces gas emissions and leads to the deposition of tar and soot. As a result, the efficiency of the boiler decreases, and there is a need to clean it.

Most pyrolysis units are electronically controlled.

Consequently, it becomes necessary to use electricity to operate the controller, which controls the fan and smoke exhauster.

Pyrolysis boilers with natural draft exist, but they require a very high and powerful chimney, so such models are unpopular.

The need to fill the firebox by 50-100% - only in this case will the high efficiency of the boiler be maintained.

Long-burning pyrolysis solid fuel boilers, although twice as expensive as a conventional solid fuel boiler, are distinguished by the possibility of economical use of fuel with maximum efficiency, which is significantly higher than from the combustion of coal and wood in conventional units.

Disadvantages of solid fuel boilers

- To store fuel, you will need additional space.

- If you purchase a cheap boiler model, you will have to clean it more often to remove soot and soot.

- You must load fuel into any type of boiler manually.

- If a long-burning boiler is installed, it differs from other models in its low efficiency.

- Boilers will need to be maintained regularly.

- It will be necessary to install additional devices, for example, a heat accumulator or a forced draft device.

Types of pyrolysis boilers with a water circuit

There are many models on the market that can be divided into groups.

- The location of the chamber in which the contents are burned.

Most boilers are designed so that this compartment is located at the bottom. This is more convenient for laying the material, but after its combustion, the ash enters the chamber where the resulting gas burns.

This obliges the owner to frequently clean the equipment. The top location of the camera eliminates this need, but has a number of disadvantages. The main disadvantages of such a system include the inconvenience of placing the chimney and the larger amount of materials for its manufacture.

- Traction type.

It can be carried out either by force or by supercharging. Boilers in which the draft power can be manually adjusted require the installation of a reinforced chimney and do not depend on the power supply. Such models are few and far between.

Devices of the second type are equipped with automatic systems that determine the blowing time. Maintaining power requires the energy dependence of the unit, but the rate of pyrolysis output in it is quite high. These models are the most popular.

- Type of fuel.

When determining the possibility of using a particular type of fuel, one should start from the moisture level of the material. If it is higher than 20%, then the first operating time of the boiler will be spent drying the material, which leads to a decrease in the efficiency of the device.

If the humidity of the fuel used is initially high, then the pyrolysis process will take no more than 1/5 of the entire combustion cycle. This is extremely ineffective and irrational.

It will be difficult to recoup the high cost of the boiler. Therefore, the conclusion is obvious: the best material for combustion in pyrolysis boilers is firewood, coal or briquettes, the moisture level of which is minimal.

Each material has its own burning time. The smoldering time determines the quality and uniformity of heating of a living space. The best option is dry wood with a moisture level of no more than 10–15%.

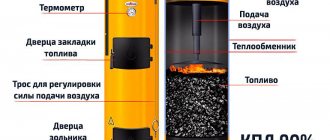

Today, there are two main types of pyrolysis units, differing in design.

- Boilers with forced air supply.

In the first version of the boiler design, the primary combustion chamber, where solid fuel is placed, is located above the secondary combustion chamber, where afterburning of pyrolysis gases is organized. A special nozzle is installed between the chambers, having a straight cross-section and made of a refractory composition similar to fireclay bricks.

In this design, air is forced into the main firebox using an installed fan, and partly enters the firebox with solid fuel, and partly into the afterburning chamber of the released gases.

In this case, it is obvious that the principle of pyrolysis is violated initially, since the fan creates an excess of oxygen instead of limiting it.

But, despite this, efficient and complete combustion of firewood occurs, with virtually no residue of even fine ash, since dry wood or products based on it burn to fine ash, and it is easily blown out through the nozzle by a fan into the chimney pipe.

Knowing the features of this design, it can be called a “top blowing device”, since the air pumped by the fan enters mainly into the upper main combustion chamber.

Due to the influx of oxygen, the temperature during combustion increases and gas production increases, but it burns quite quickly, escaping through the nozzle.

In this regard, firewood quickly burns out, and it has to be added quite often in the process of heating the house. This principle of boiler operation cannot be called pyrolysis in the full sense of the word, although similar devices are sold quite often under this name.

It’s another matter if the fan standing on the outlet pipe (often called a “smoke exhauster”) creates air movement, which is proportionally divided into primary and main - secondary using the usual mechanical method or using automation.

In this case, the primary air damper is located so that it is supplied precisely to the lower part of the fuel filler.

The smoldering of firewood occurs from below, and the temperature released during this process promotes heating - in the middle layers of the stack, and final drying - in the upper ones.

The main air flow will be supplied only to the nozzle area, so that the final combustion of the pyrolysis gases with the maximum amount of heat generated takes place in the lower chamber. Such a boiler can rightfully be classified as a long-burning pyrolysis boiler.

- Boiler with natural air supply.

In such a boiler design, the combustion chamber for storing firewood is located in the lower part of the device, and the combustion section of the pyrolysis gases released by the fuel is in the upper area of the body.

A fan is not installed in this design, and the air for lighting the boiler and afterburning pyrolysis gases is supplied naturally through dampers for primary and secondary air.

In this version of the arrangement of the chambers and the dosed supply of air flows, the pyrolysis process is carried out properly, since instead of intense combustion, with the primary air supply damper closed, wood smoldering occurs in the combustion chamber with the release of a large amount of pyrolysis gases.

However, this design also has its own problem. And it lies in the fact that the correct debugging of the combustion process is extremely important.

When the main chamber damper is completely closed, the temperature in it decreases, as well as the formation of gases. The concentration and temperature of the gases becomes insufficient for their complete afterburning and the upper chamber turns into a regular gas outlet.

The combustion products that rise into it do not burn out, but simply give off heat to the walls of the water circuit and go into the chimney. The efficiency of the boiler during such operation is sharply reduced. If the damper is opened more than required to create the conditions necessary for pyrolysis, then the intensity of combustion in the main firebox will increase, which leads to completely irrational fuel consumption and the need for frequent refills.

To achieve ideal operation of a pyrolysis boiler of this design, it is necessary to correctly adjust the supply of primary and secondary air, which is quite difficult to do, since this requires practical experience.

Modern models have automated process monitoring and control systems, and if the automatic fuel loading system works correctly, it lasts for 12-14 hours of operation at maximum heat transfer.

Advantages of solid fuel boilers

- They are easy to work with.

- Installation does not take much time and effort.

- They are small in size.

- Minimal maintenance - fuel is easy to load, the firebox is cleaned once every 2 months.

- Economical.

- Environmentally friendly - the fuel used does not harm the environment.

- Simple technology of use - boilers serve for a long period and without failure.

- Lots of fuel options. This can be firewood, peat, coal, briquettes or solid waste.

- They are autonomous - the supply of heat to the house will not depend on gas or light.

- Installation and operation are cheaper than installing gas equipment.

- Wide range of boiler models to choose from.

- They are easy to install in any home.

- Suitable for heating private houses located far from the gas pipeline.

Fuel for pyrolysis boiler

Solid fuel pyrolysis boilers are practically omnivorous. Various types of solid fuel can be used as fuel: from ordinary firewood to peat.

Based on this, a boiler can be heated with any type of solid fuel, but still each type has its own inherent qualities and properties, so the operation of the boiler will also differ.

Therefore, fuel selection is a very important process.

- Using regular firewood.

Firewood for solid fuel pyrolysis boilers must be dry (it is allowed to use firewood with a moisture content of no more than 20%). The heat transfer of the boiler depends on dryness.

When loading logs into the firebox, they should be placed tightly together, and a free space of at least 20 cm should be left at the top. It is worth noting that unsplit firewood can also be used.

When loading for the first time, it is necessary to use approximately half of the portion of firewood, the rest is placed as it burns out in the boiler. Firewood burns unevenly - it must be carefully laid out on the surface of the firebox all the time, while preventing the solid fuel pyrolysis boiler from cooling.

The disadvantage of using firewood is that heating with this type of fuel cannot be automated. An advantage is the fact that this is a very environmentally friendly way of heating a room.

- Use of peat.

When using peat as fuel for a solid fuel pyrolysis boiler, certain rules must be followed. Firstly, the firebox must always be cleared of ash, and secondly, the ash door must be closed.

Peat should be placed on a grate. For better kindling, you can put some firewood on this layer and cover it all with another layer of peat. Then open the chimney valve and start lighting.

During operation of solid fuel heating equipment, it is necessary to ensure that the peat always lies in an even layer. This arrangement of peat will ensure maximum heat transfer.

- Use of coal.

To obtain the best level of heat using coal as fuel, it is necessary to use a special firebox - a shaft with a grate and vertical walls.

The firebox must be high enough, the distance between the arch and the grate must be at least 50 cm. The combustion and ash doors must be made of cast iron, the optimal distance between the doors is 21 cm.

In addition, it is recommended to strictly seal the doors. It should be remembered that when using coal, a new portion of fuel should be added only when the first one has flared up well. In this case, you need to constantly maintain an even layer and prevent the coal from burning to the grate.

- Use of fuel briquettes.

Today, fuel briquettes are the most optimal means for heating solid fuel pyrolysis boilers. You can use both coal and peat briquettes.

Thanks to the use of briquettes, you will receive high calorific value, an even combustion process (no need to interfere with the combustion process itself and adjust the layers), high density of the burning layer, a small amount of flame and a minimal amount of smoke.

Another advantage is the combustion of the briquette without any residue and the convenience of packing the briquettes. The combustion chamber of a solid fuel pyrolysis boiler is carried out until the fuel briquettes are completely burned. If unburned briquettes remain, they are reused.

The dimensions of a standard boiler firebox regulate the dimensions of the fuel used (dimensions of firewood or briquettes). As a rule, logs with a length of 400 mm and a diameter of up to 200 mm are used for fuel in gas generator boilers. The size of fuel briquettes is 300x30.

Along with firewood or briquettes, sawdust can also be used as fuel. But they should be taken no more than a third of the main part of the fuel by volume.

The operating instructions stipulate that the fuel moisture content should not be higher than 45%. The lower the moisture content of the wood, the greater the power of the boiler and the longer it can operate without repair.

For example, a kilogram of wood with 20% humidity when burned produces heat equivalent to 4 kWh, and firewood with 50% humidity produces only 2 kWh. In addition to the fact that with an increase in moisture content in the fuel, the specific heat of combustion decreases, fuel consumption increases significantly.

Features of operation of gas generator boilers

The operating efficiency of a pyrolysis boiler largely depends on the type and quality of fuel. Technically, not only wood, but also coal and even peat can be loaded into the firebox; most modern boiler models are designed to use several types of fuel.

Wood burns in about 5-6 hours, depending on the type. The harder the wood, the longer it burns.

Modern models of pyrolysis combustion boilers can operate on various types of wood fuel: firewood, briquettes, pellets, coal, peat, etc.

It will take about ten hours to burn black coal, and the same amount of brown coal will smolder for eight hours. In practice, pyrolysis technology demonstrates the highest heat transfer when loaded with dry wood. Firewood with a moisture content of no more than 20% and a length of about 45-65 cm is considered optimal.

If access to such fuel is not available, you can use coal or other organic fuel: special sawdust briquettes and wood pellets, waste obtained from wood processing, peat, materials with cellulose, etc.

Before starting to operate the boiler, you should carefully study the device manufacturer’s recommendations regarding fuel.

In pyrolysis combustion boilers, the air supply is regulated by conventional mechanical valves. The absence of complex electronics ensures high fault tolerance of the device

Too wet fuel in such devices is unacceptable. When it burns in the firebox, additional water vapor is formed, which contributes to the formation of by-products such as tar and soot.

The walls of the boiler become dirty, heat transfer decreases, and over time the boiler may even stop working and go out.

If you use wood with too high a humidity for a pyrolysis combustion boiler, conditions will arise inside the device for the formation of tar, which will worsen the heat transfer of the device and can lead to breakdowns

If dry fuel is placed in the firebox and the boiler is configured correctly, the pyrolysis gas produced as a result of the operation of the device will produce a yellow-white flame. Such combustion is accompanied by an insignificant release of by-products of fuel combustion.

If the color of the flame is different, it makes sense to check the quality of the fuel, as well as the settings of the device.

Pyrolysis gases mixed with air burn with an even yellow-white flame. If the color of the flame has changed, you may need to check the boiler settings or fuel quality

Unlike conventional solid fuel devices, before loading firewood into pyrolysis boilers running on solid fuel, the firebox must be preheated.

To do this, perform the following steps:

- Load small dry kindling (paper, wood chips, etc.) onto the bottom of the firebox.

- They set it on fire using a torch made of similar materials.

- Close the combustion chamber door.

- The loading chamber door is left slightly open.

- Add portions of kindling as it burns.

- The process is repeated until a layer of smoldering coals forms at the bottom.

By this moment, the firebox has already warmed up to approximately 500-800°C, creating conditions for loading the main fuel. Do not use gasoline, kerosene or any other similar liquid substances to light the kindling. Before warming up the furnace of a long-burning boiler, you should make sure that the device is ready for use.

A characteristic feature of pyrolysis combustion boilers is a small amount of ash and ash, which facilitates the process of cleaning the device and its maintenance

To do this, check the presence of draft, the tightness of the doors, the serviceability of locking mechanisms and control equipment, the presence of coolant in the heating system, etc.

Then you should turn on the thermostat to make sure that voltage is supplied to the device. After this, open the direct draft damper and ventilate the boiler for 5-10 minutes.

Why is it better to choose a pyrolysis boiler and the basic rules for its operation

- Firstly, during the combustion of firewood it is impossible to reach such a high temperature as during the combustion of the gas obtained from them.

- Secondly, to maintain the combustion of gas, less secondary air is required than for burning wood; accordingly, the combustion temperature will be higher, and with it the efficiency.

- Thirdly, the procedure for burning pyrolysis gas is easier to control, thus, the operation of a gas generator boiler is automated in the same way as a liquid fuel or gas boiler.

This equipment is based on pyrolysis fuel combustion technology. Its essence lies in the fact that under the influence of elevated temperature and in conditions of lack of oxygen, wood begins to decompose into a solid residue and a volatile part - pyrolysis gas.

Pyrolysis occurs at temperatures ranging from 270 – 700 degrees. This process is exothermic, in other words, it is characterized by the release of heat, which increases the drying and heating of the fuel in the boiler.

Subsequently, the mixing of oxygen with pyrolysis gas at a high temperature leads to combustion of the latter, which is used to obtain thermal energy.

Pyrolysis gas actively interacts with carbon, due to which the flue gases leaving the boiler almost do not include harmful impurities, being considered, to a greater extent, a mixture of water vapor and carbon dioxide.

Numerous studies have shown that carbon dioxide will be released into the environment up to three times less than from an ordinary wood-burning and, even more so, coal-fired boiler.

The pyrolysis combustion procedure is characterized by the formation of a small amount of ash and soot, which is why this equipment rarely requires cleaning.

The advantages of long-burning pyrolysis boilers with a water circuit are environmental friendliness.

The efficiency declared by the manufacturers is only 4–10% higher than the productivity of a conventional solid fuel boiler. Obviously, the choice should be based on taking into account the individual characteristics of the heating system and the preferences of the owners.

The main features of a quality model that is worth purchasing:

- Good, neat welds and sufficient material thickness (at least 4 mm). Thin metal in cheap boilers burns out quickly and is more susceptible to corrosion. Buying such products is a bad decision!

- Ceramic nozzle and gas combustion chamber lining (this model will last longer). This material has excellent fire-resistant properties. Make sure that ceramics is used, as the most reliable material for these parts of the boiler.

- Two working chambers with the ability to smoothly adjust the air supply. Two chambers are the main feature of an effective pyrolysis model! If you need high-performance and at the same time economical long-burning boilers, choose long-burning pyrolysis boilers with a water circuit.

- The coolant is in contact only with the chimney and gas combustion chamber. If this technical point is not observed, the boiler will lose heat, since the main combustion chamber has a lower temperature (the coolant cools on contact).

- Availability of an automatic control unit and a corresponding warranty for it. Repairing this very important unit for regulating the air supply in some cases costs up to 50% of the total cost of the equipment. Take this part of the boiler seriously.

Some more tips for choosing a boiler:

- The required power can be calculated based on the area of the room and the degree of insulation. Approximately you need to take 1 kW per 10 m2, while adding a few kW, also taking into account the functions of the boiler as a boiler. So, if you have an area of 80 m2, then a 10 kW option is suitable, but if the area is 100 m2 and the walls are not insulated, then 10 kW will not be enough;

- The size of the firebox is important, if you burn with wood, the larger it is, the larger the size of firewood that can be placed there;

- Burning time without additional loading is usually indicated taking into account excellent quality fuel, so take 2/3 of these data. For example, if 10 hours are stated, you can count on 6;

- Energy independence is very important when choosing a boiler for a dacha or a place remote from electricity; in addition, it also saves electricity.

For normal operation of the equipment, it is necessary to maintain a certain range of fuel combustion temperatures. This range is from 2000 to 8000 C.

It is necessary to configure the device quite accurately. To prevent emergency situations at high temperatures, the water circuit of the unit is used.

The housing plays the role of a heat exchanger; water passes between its walls. This feature and the built-in coil in one of the walls prevents the creation of prohibitive temperatures.

When the water temperature is insufficient, the formation of pyrolysis gas stops, air is supplied to the combustion chamber and the boiler operates like a conventional solid fuel stove. It is not allowed to cool the water below a temperature below 600 C. In this case, the combustion process without oxygen stops in any type of pyrolysis boilers.

To ensure a small water circuit and transfer the equipment to an operating state, an additional jumper (bypass) is installed in the water circuit. The bypass is adjusted manually; temperature sensors are installed to control the temperature.

This type of equipment can work on all types of firewood, briquettes, pallets.

In reality, a type of fuel such as coal can be used. Provision is made for the processing of flammable household and industrial waste. But this can backfire due to their high polymer and rubber content.

Pyrolysis boilers are produced only as single-circuit boilers and cannot be used for heating water. But, in the absence of natural gas, to create comfortable conditions in the building, this type of equipment is the best solution to the problem.

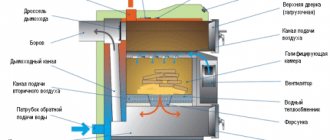

Top combustion boilers

One of the options for a pyrolysis device is an upper combustion boiler. The operating principle of these two units is very similar.

In the same way, a large amount of low-humidity solid fuel is loaded into the firebox, air is forced in and the fuel is allowed to smolder with a reduced amount of oxygen. The valve that regulates the flow of oxygen is installed in the desired position.

Diagram of a top combustion boiler. The firebox of such a boiler has a solid bottom, particles of combustion products are removed through the chimney (+)

But long-burning boilers have neither an ash pan nor a grate. The bottom is a blank metal plate. Such boilers are designed so that the wood burns completely, and the small amount of ash remaining in the firebox is blown out with air.

Such devices are characterized by high efficiency and also operate at temperatures above 1000°C.

The main feature of such devices is that they really provide a long service life when fully loaded. The fuel chamber in such devices is usually made in the shape of a cylinder.

Fuel is loaded into it from above, and the air necessary for combustion is pumped from above, in the center.

In top-burning boilers, the air injection device is a movable element that moves down as the wood burns out.

This ensures slow smoldering of the top layer of fuel. The fuel gradually burns, its level in the firebox decreases. At the same time, the position of the device for supplying air to the firebox changes; this element in such models is movable and it practically lies on the top layer of firewood.

The second stage of combustion takes place in the upper part of the firebox, which is separated from the lower compartment by a thick metal disk. Hot pyrolysis gases formed as a result of combustion of fuel below expand and move upward.

Here they mix with air and burn, additionally transferring a significant portion of thermal energy to the heat exchanger.

The beam holding the disk that divides the combustion chamber into two parts, like this disk itself, is constantly under the influence of high temperature during the operation of the top combustion boiler. Over time, these elements burn out and will have to be replaced periodically.

A draft regulator is usually installed at the outlet of the second part of the fuel chamber. This is an automatic device that determines the temperature of the coolant and, depending on the data received, regulates the intensity of movement of the combustible gas. It protects the device from possible overheating.

It is worth noting that the external heat exchanger in such boilers reacts to changes in the speed of liquid circulation in the heat exchanger, i.e. to temperature fluctuations. A layer of condensate immediately forms on the surface of the device, which causes corrosion, especially when it comes to steel boilers.

It is preferable to take a device made of cast iron, which resists such effects much better.

Although fuel in long-burning pyrolysis boilers should burn without residue, in practice this is not always the case. Sometimes the ash cakes, forming particles that are difficult to remove with a stream of air.

If a large amount of such residues accumulates in the firebox, a noticeable decrease in the heat output of the unit may be observed. Therefore, the top combustion boiler should still be cleaned periodically.

The peculiarity of devices of this type is that as the fuel burns, it can be reloaded without waiting for the entire fuel load to burn. This is convenient when you need to get rid of flammable household waste.

There are also varieties of top-burning boilers that run not only on wood fuel, but also on coal. There are no complex automatic control units in pyrolysis boilers of this type, so serious breakdowns are extremely rare.

The design of the top combustion boiler allows the firebox to be loaded only partially, if necessary. However, in this case, igniting the top layer of fuel may not be easy. The fuel itself must be dried; firewood from an open woodpile is not suitable for such a boiler.

Fuel of large fractions should also not be used for this type of equipment, i.e. The wood will have to be chopped into small pieces.

DIY pyrolysis boiler

Make a pyrolysis boiler with your own hands according to the drawings, or order production from specialists (which is still cheaper than buying a ready-made one).

To make such a complex device, you will need a fairly wide range of tools and materials.

Here is an approximate list of them:

- Plan diagram. Without an accurate calculation, you are unlikely to be able to do everything correctly. You don’t have to make the drawings yourself, if you don’t have the appropriate skills, you can simply download it on the Internet.

- Welding machine.

- Grinding machine.

- Metal pipes of different diameters and lengths (120, 130 and 150 centimeters, with a diameter of 50, 45 and 6-8 centimeters) and the boiler frame itself and the chimney will be made from the pipes.

- Sheet of metal for making a door.

- Hinges and handles for installing dampers.

Manufacturing a pyrolysis boiler includes the following steps:

- Making the frame.

The frame of the pyrolysis boiler consists of two parts: a casing and a firebox. A frame is made from two pipes of a larger and smaller diameter. One pipe is inserted into another and welded. In this case, the larger pipe acts as a casing, and the smaller one as a firebox.

The bottom and top of the pipes are welded in circles cut from a metal sheet. The space between the pipes is filled with a heat-conducting agent.

- The second stage is the division of the firebox by putting on the chambers.

Firewood will be loaded into one of them, and gas will burn out in the second. The air distributor acts as a separator. This is a pipe of the smallest diameter onto which a sheet of metal with blades is welded.

- Next, in the lower part of the frame - the firebox, you need to cut a hole-door; the door itself is made from a sheet of metal. It is very important that the door fits as tightly as possible to prevent excess air from entering the boiler.

- The last stage of manufacturing a pyrolysis boiler will be the installation of a chimney and an outlet pipe through which unburned gas will be discharged into the chimney and outside.

In addition to the fact that the pyrolysis boiler must be manufactured correctly, it must also be installed correctly:

- As a rule, a pyrolysis boiler is installed in a separate room - a boiler room; this is the safest option.

- Install the pyrolysis boiler at a distance of at least thirty centimeters from the walls.

- The floor on which the boiler will stand must be made of non-combustible materials.

- The boiler room must be equipped with good ventilation.

- The boiler chimney must be well insulated to avoid the release of combustion products into the room.

Recommendations:

- The fuel loading hole for home-made models is usually placed slightly higher than that of conventional solid fuel boilers.

- It is imperative to install a limiter that will allow you to control the amount of air entering the fuel chamber, as well as add firewood or briquettes in a timely manner.

- To make a limiter, you can use a pipe with a diameter of about 70 mm, slightly longer than the body of the device.

- A steel disk should be welded to the bottom of the limiter, forming a gap of about 40 mm with the pipe walls.

- To install the limiter, a corresponding hole must be made in the boiler lid.

- The loading hole for firewood should be made rectangular. This hole is closed with a door with a special steel plate that ensures a secure fit.

- Below you need to make a hole to remove ash.

- The pipe through which the coolant moves inside the boiler must be bent to maximize heat transfer. The amount of coolant entering the boiler can be adjusted using a valve installed outside.

- If after the first start-up of the boiler there is no carbon monoxide in the combustion products, it means that the design is made accurately and functions correctly. In the future, you should regularly monitor the condition of the boiler welds and promptly clean it of accumulated ash and soot.

Popular manufacturers

Among the existing Belarusian companies that are popular in the CIS markets for climate control equipment are:

- Belkomin produces units of the popular TIS brand.

- OJSC Mozyrselmash, which produces solid fuel boilers.

- Minsk Electric Plant provides Raton units.

There are no significant differences between the presented Belarusian-made units. These are boilers made of cast iron and steel, single-circuit and double-circuit varieties of devices. In the first version, the devices are produced only for the heating load, and in the second - with additional DHW heating.

There are also other boiler manufacturers in the republic: Teplopribor and Brestselmash. However, they offer a much smaller range of products.

Products of the Brestselmash company

In addition, most companies not only produce ready-made heating systems, but also offer customers repair and installation services, which is practical.

Reasons for purchasing domestic and Belarusian boilers

If the buyer is confused by the small range of models presented by a domestic manufacturer, you can consider in detail the model range offered by Belarusian ones.

These devices are not much inferior in quality to Russian models, and in some respects they even surpass them.

If we compare Belarusian-made boilers with European ones, the latter may be somewhat superior in terms of ease of use, but Belarusian-made models will differ not only in decent quality and long service life (compared to European models that are adapted to other conditions), but also in versatility. They can be used in almost any conditions (there are models adapted for working in rooms where the temperature will be too low for the normal functioning of European analogues).

Solid fuel boilers

In addition, Belarusian solid fuel boilers are not at all capricious in terms of fuel quality, which cannot be said about European devices, for which fuel quality is not only a guarantee of high-quality work with high efficiency, but also a guarantee of no breakdowns. In other words, using low quality fuel in European boilers can lead to breakdowns.

Mozyrselmash

The last brand that will be considered is Mozyrselmash (boiler price from $140 ). Boilers from this manufacturer are distinguished by reasonable prices and simple design. These boilers can be called the simplest of installations, based on the principle of direct combustion of solid fuel and with a power in the range of 20-80 kW. Prices from this manufacturer are probably the lowest on the market for similar products.

The principle of their operation is the same as that of the previously discussed boilers. At the same time, the specificity of the installations from Mozyrselmash differs in that the air is supplied due to the principle of natural draft. The intensity of work can be adjusted manually or with a thermostatic regulator. Boilers of the brand in question can be classified by power:

- up to 50 kW: the units have a wall thickness of 3 mm and are designed for an operating pressure of 1 bar;

- more than 50 kW: wall thickness – 5 mm; pressure 3 bar.

According to the manufacturer, all devices of this brand have an efficiency of 80% .

Boilers from Belarusian manufacturers are known in our country not only because of the geographical proximity of the country of production, but also because of their quality, simplicity of design and reasonable prices.

Raton boilers and their features

A distinctive feature of Raton boilers is a wide range of models adapted to any room area and to work with different types of fuel (there are models adapted to work with fuel such as firewood, and also intended as heating equipment for large or small rooms).

Thermal insulation of boilers is made of purely environmentally friendly materials. In addition, all boiler elements are made of high-quality, durable materials, due to which the service life of boilers of this production is no less than 15 years.

A separate advantage is that all Raton models are produced on modern equipment, and as a result, they are not much different from their European counterparts. Due to the specifics of the territory in which solid fuel boilers are sold, their functionality and capabilities are simple, although there are models with advanced, supplemented functions.

These boilers can be called universal based on the type of application - they can be used as a closed heating system, or as a gravity-fed one.

Boilers Raton

The design of the devices is also extremely interesting - just the design, the appearance of boilers produced by Raton is not much inferior to their European counterparts, or the appearance of the device is even closer and more pleasant for buyers from the CIS countries than any other models from European, Russian and Belarusian manufacturers.

The combination of good quality, original design and affordable cost makes the models of this production desirable for purchase and popular in the market.

Recently, the company has been updating its product range, intending to release to the market solid fuel boilers of greater capacity and power, adapted for use in industrial premises, as well as boilers of minimal sizes, which will be more convenient for use in a residential building.