General characteristics of AOGV boilers

The abbreviation AOGV stands for Gas Water Heating Unit.

Different manufacturers in the instructions for this technique allow for minor nuances and differences in the decoding of its name, but this does not affect the overall meaning.

If the letters of the name are followed by numbers, they indicate the power of the device.

Efficiency and temperature

If you plan to choose a heating boiler that guarantees maximum efficiency, then purchasing an AOGV is an absolutely justified step. It produces about 92% of maximum efficiency, which was achieved thanks to the special design of the heat exchanger.

These devices are used in heating systems operating using forced or natural movement of coolants. The main condition for the normal functioning of AOGV gas boilers is atmospheric pressure in the system, which does not exceed 1.4 atm. The operating temperature range of these heating devices is from 40 to 90 degrees.

Power

Modern boilers of the AOGV type have been known on the Russian market for about 15 years. As a rule, they are designed to heat rooms with a total area of about 200 square meters. and have a power of up to 30 kW. It is not practical to use such devices for heating rooms with a small area (less than 100 sq. m.).

These heating boilers are considered energy-independent and operate exclusively on the basis of natural gas.

Most often they are produced in a floor-standing version. The following models are most widespread on the domestic market:

- comfort;

- station wagon;

- economy

The choice of type of heating device depends on its price category and the size of the room.

Boiler AOGV

AGV boiler - design, models, parameters

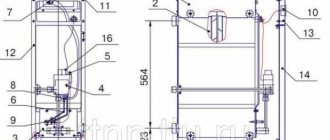

Of the older models, you can find two variations, while the design of the AGV 80 and AGV 120 is almost identical.

The design has a cylindrical tank, inside of which there is a flame tube with a tube wound in the form of a spiral, which allows you to extract the maximum amount of heat from the burning fuel. Next, the exhaust gases are removed outside the premises through a chimney or hood for AGV. The differences between these two models were the thermal power, i.e. the area of the house that they could heat, and different automation units. On the AGV 80, the automation is represented by an electromagnetic valve on the gas pipeline, a fusible valve made of Wood's alloy built into the lid of the device, the melting point of which is 105 ° C, and the membrane thickness is 0.04-0.05 mm, which protects the unit from significant differences in temperature and pressure . When the membrane breaks or melts, the liquid goes into the drain, and do-it-yourself repair of the AOGV in such an incident involved replacing the valve, of course, while eliminating the cause of overheating. In turn, the 120 model has a cylinder filled with kerosene and a bellows thermostat in the automation unit.

There is no need to argue about which AOGV is better: despite all the reliability in the eightieth, there was no adjustment of the coolant temperature or the ability to use external thermostatic sensors, so the improvements made in the design of the 120th device were necessary.

What is AOGV: decoding

Mechanical automation.

AOGV (interpretation: gas hot water heating apparatus) is a gas boiler that does not contain a single volatile element. That is, the unit can operate autonomously without electricity. They are usually installed where there is a central gas pipeline, but even in the absence of gas, you can change the burner, which will run on propane-butane. In the heater marking there are always numbers after the abbreviation - this is the maximum power. For example, AOGV 17 means that the maximum thermal power of the unit is 17 kW.

Main elements of the heater:

- automation;

- thermocouple;

- combustion chamber;

- heat exchanger;

- chimney.

The operation of the AOGV boiler is controlled by mechanical automation. Domestic heaters can be equipped with automatic equipment of their own (in cheaper models), European or American production. This is the heart of the heater; without automation, the boiler cannot operate. The second important element of the heater is a copper thermocouple. It is responsible for activating the solenoid valve, which shuts off the gas supply if the burner wick goes out.

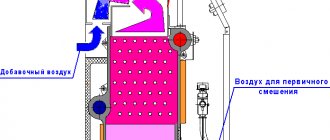

Unlike modern parapet heaters, AOGV gas boilers are equipped with an open combustion chamber. The disadvantage of such chambers is that they take air from the room in which they are located to maintain the fire. The advantage is the ability to exhaust smoke through a regular chimney with natural draft; there is no need for an energy-dependent fan.

The heat exchanger is located at the top of the combustion chamber, directly above the burner. Each circuit has its own heat exchanger; the fluids in them do not intersect. That is, if the heater is intended not only for heating the room, but also for preparing hot water, then there will be two heat exchangers.

General characteristics of AOGV boilers

The abbreviation AOGV stands for Gas Water Heating Unit.

Different manufacturers in the instructions for this technique allow for minor nuances and differences in the decoding of its name, but this does not affect the overall meaning.

If the letters of the name are followed by numbers, they indicate the power of the device.

Efficiency and temperature

If you plan to choose a heating boiler that guarantees maximum efficiency, then purchasing an AOGV is an absolutely justified step. It produces about 92% of maximum efficiency, which was achieved thanks to the special design of the heat exchanger.

These devices are used in heating systems operating using forced or natural movement of coolants. The main condition for the normal functioning of AOGV gas boilers is atmospheric pressure in the system, which does not exceed 1.4 atm. The operating temperature range of these heating devices is from 40 to 90 degrees.

Power

Modern boilers of the AOGV type have been known on the Russian market for about 15 years. As a rule, they are designed to heat rooms with a total area of about 200 square meters. and have a power of up to 30 kW. It is not practical to use such devices for heating rooms with a small area (less than 100 sq. m.).

These heating boilers are considered energy-independent and operate exclusively on the basis of natural gas.

Most often they are produced in a floor-standing version. The following models are most widespread on the domestic market:

The choice of type of heating device depends on its price category and the size of the room.

Properties of AOGV

Boilers of this type have become popular due to the fact that they have the following advantages, which were highly appreciated by consumers:

- The easy operation of this gas appliance allows you to safely and easily set the temperature within certain limits.

- The use of modern nanotechnologies in production guarantees high precision and error-free operation reliability.

- The boiler is considered non-volatile and does not require any connection to the electrical network.

- The equipment is compatible with polypropylene, cast iron, steel and other materials.

- Some models provide the ability to turn off the gas manually, which will ensure safety in an emergency or in the event of failure of automatic elements.

- The AOGV device from some manufacturers may be equipped with a circuit water heating system.

- The heat exchanger of heating devices of this type is durable and reliable.

- AOGV is not afraid of natural gas fluctuations.

- The coolant temperature can be adjusted manually.

These boilers have an optimal level of thermal protection, which ensures the most complete use of the energy of the used gas.

An attractive factor for the modern consumer, which helps to choose the right heating equipment, is environmental friendliness. Minimizing the emission of harmful substances after complete combustion of gas is due to the design of the micro-flare burner.

An important advantage is the adaptability of the gas device to the conditions of the Russian climate.

Cons of boilers

The high cost of a gas unit compared to some types of similar equipment is the main disadvantage of such a boiler. There are others:

- Certain difficulties in finding spare parts.

- Automation of outdated configurations on selected models.

- Bulky design.

- Aesthetic imperfection (the unit looks like an industrial-type device, which may not suit some users).

Model overview

Any AOGV is a single-circuit floor-standing device designed for heating a room. There is no second circuit in them. If you need hot water supply, you must connect an indirect heating boiler. Based on AOGV, AKGV is produced - they have a built-in heat exchanger for hot water supply.

The burner is designed for natural gas. To convert the device to liquefied gas, you will need to change it and need a special nozzle. The manufacturer produces heaters with power from 11 to 29 kW. You can choose a modification for heating an area from 45 to 250 m². The estimated cost of ZhMZ boilers is 18-23,000 rubles.

AOGV-11.6 Economy

Floor-standing version. Household versions - 11-29 kW. Features of version 11.6:

- Efficiency 90%

- Open camera.

- Heats 100 m².

- 11,600 W.

- One circuit.

- Mechanical control.

- Convection type.

- Weight - 45 kg.

AOGV-23.2-3 Comfort

- Efficiency 88%

- Open firebox.

- Heats 200 m².

- 23.2 kW.

- One circuit.

- Mechanical control.

- Convection type.

- Weight - 52 kg.

But 23 Universal can be made in two variations: single-circuit and double-circuit. The non-volatile device is equipped with imported automatic equipment. Works on any type of gas. Modest dimensions, light weight - an ideal solution for creating autonomous heating.

AOGV-17.4-3 Universal

AOGV 17 belongs to the convection type. Floor-standing version. Open firebox.

- Efficiency 88%

- Area - 140 m².

- Power - 17.4 kW.

- Weighs 49 kg.

The abbreviation stands for “Gas Water Heating Apparatus”. The Zhukovsky plant is not their only producer. They are released:

- JSC "Borinskoe" (Moscow region). It produces devices in an expanded power range; there are models for 5, 6, 7, 9 and 11 kW. Next: from 11 to 23 kW.

- CJSC "Rostovgazoapparat" Produces options 11.6-35 kW.

- There are also imported versions - Beretta (Italy).

Zhukovsky MZ does not produce parapet boilers, but they can be found from other domestic manufacturers, for example, a device from the ROSS company. Parapet models have a closed combustion chamber, so they can be installed in an apartment. They do not require a separate room.

Example of a parapet device: ROSS AOGV-13P. This is a 2-circuit option. Heats up to 130 m². 13 kW. Efficiency - 90%.

Advantages and disadvantages

AGV heating using boilers of this type can significantly increase the comfort of living. Like any technology, they have their own set of advantages and disadvantages.

pros

- Energy independence. The boiler does not require a connection to electrical networks; it will work all the time as long as there is gas in the pipe.

- Simplicity. Pipe, burner, tank. Operation is possible by unqualified personnel, which reduces its cost.

- Optimal efficiency - at higher values, condensate will flow through the pipe, at lower values, heating costs will increase.

- Relatively small in size.

- Acceptable price.

Minuses

- Outdated design.

- Condensation of moisture from the atmospheric air on the bottom mirror of the boiler and a leak, which can extinguish the burner. The effect is observed until the coolant reaches a temperature of 25-30 C.

- To completely interrupt the gas supply, the thermocouple must cool down. This takes up to a minute, which can be fatal in an accident.

- Ergonomics are not very good - pipelines and controls are open. It is difficult to coordinate the boiler with the interior design.

- To ignite the burner, you need to handle an open flame, which in itself is dangerous.

Automation of the new AGV

It completely controls the entire process of heating water. And the automation unit itself consists of:

- a temperature sensor that controls the water temperature;

- an electromagnet, which is responsible for controlling the main gas supply valve;

- thermocouple, which is mounted near the igniter. Heated by a constantly burning torch, it creates an electric current in the circuit;

- traction sensor. It is mounted in the chimney and controls the optimal draft of the pipe.

Automation of the new AGV

The automation unit will not allow you to turn on the heating of the AOGV if even the slightest breakdown occurs or the indicator of the boiler’s efficient operation is lost. The main thing is to properly adjust the automation and then the equipment will serve for a long time.

After which they became quite widespread throughout the Soviet Union, and proved themselves to be good. That is, AGV heating in an apartment has been tested over decades of use in the private sector and fits quite well into modern life, especially after it has been modernized and improved.

It is only necessary to observe absolutely all precautions when working with this type of boiler, follow documents such as the AGV heating instructions, and not engage in amateur activities - and then it will serve faithfully for many years, bringing warmth and comfort to the house. https://www.youtube.com/embed/QQkkUWbu-Yg

Moreover, this heating system is quite economical and allows you to use boilers both for heating the room and for a source of hot water, which is also very convenient and economical, both in terms of saving money and saving space in the occupied room. And taking into account the automation of equipment operation, this entire system is safe and easy to manage. The only thing is, after choosing AGV heating and installing it, you need to configure the automation correctly and then you can sleep peacefully.

Design features and equipment characteristics

The tanks are equipped with a reliable automatic gas supply control system.

ZhMZ products now represent about 30 types of boilers. Among them are modifications with a power from 11 kW to 68 kW - AOGV, KOV, AKGV. Certified devices that have permission to manufacture and use are capable of heating up to 610 m² of area.

Operating principle of AGV

In the AGV-80 and AGV-120 devices, a turbulator was placed inside, which slightly increased the efficiency of the installation.

The heating system is a network of rising pipes, radiators, expansion tank and return pipe.

This system provides a full cycle of operation of the device, which includes:

- heating the coolant - water;

- lifting the heated coolant through the ascending pipeline to heating devices - radiators;

- heat transfer;

- return of water to the device for subsequent heating.

The thermosyphon heating system (or a system with natural circulation) does not require additional installation of pumps, and compensation for water losses occurs from the expansion tank. Waste gas combustion products enter the chimney and are released into the atmosphere.

When the coolant temperature decreases, the automatic sensor is triggered, turning on the gas supply to the burner.

The new generation AGV devices have a more efficient design, but all heat and water heating systems operate in the mode of a conventional gas boiler. The design differences lie in the division of the flame tube into separate sections. A coil for preparing hot water is also mounted in the water jacket.

Technical parameters of the first and one of the latest modifications of AGV boilers are presented below:

The right choice and purchase of a boiler

If an old AGV 80 burns out and repairing it is impractical, there is a need to select a new boiler that must meet modern safety and efficiency standards. First, it’s worth understanding the kilowatts - what power boiler should you buy for optimal heating? With this characteristic, everything couldn’t be simpler: 1 kW corresponds to 10 square meters of heated area. This is an average figure, for example, AOGV Zhukovsky 29 is intended for premises up to 280 sq.m. You should also not lose sight of the heat losses at home, and if you have old windows and doors, from which there is a lot of cold in the winter, then it is better to choose a boiler “with a reserve”. In order to accurately take into account everything, they use thermal imaging monitoring of heat loss - read more here.

Next, you should pay attention to the Sit and Honeywell automation unit - two types of imported equipment at the comfort and station wagon levels. But good boilers with domestic production automation work no worse, but their cost is an order of magnitude lower

After the purchase, a mandatory point that the instructions for the Zhukovsky AOGV insists on is installation, and especially connection to the gas main, by gas service workers. They will simultaneously register the system. These requirements cannot be neglected, since incorrect installation can lead to a decrease in power or even premature equipment failure.

Loading …

Instructions AGV 80

agv80_instrukzia.pdf

345.1 KiB 44129 Downloads

AUTOMATIC GAS WATER HEATER AGV-80 GOST 11032-69

| Date of: | 03.04.2014 |

AOGV-11, 6-3, AKGV-11, 6-3 Instructions

aogv-11, 6-3, akgv-11, 6-3_instrukzia.pdf

553.5 KiB 20998 Downloads

HOUSEHOLD GAS HEATING APPARATUS AOGV-11.6-3 AND COMBINED HOUSEHOLD GAS HEATING APPARATUS AKGV-11.6-3 “ECONOMY” OPERATING MANUAL

| Date of: | 03.04.2014 |

Operating principle of AGV

The main structural element of the AGV is the container in which the coolant is heated. When gas burns, a heat exchanger, made in the form of a pipe and installed inside the AGV housing, heats up. The heat from the heated pipe is transferred to the coolant, which is subsequently sent to the heating circuit.

Gas combustion products are discharged through a chimney built into the boiler design. All automation is a valve that opens the gas burner. Thanks to the operation of the valve, the required temperature is constantly maintained in the tank.

AOGV boilers also have an automation unit that turns off the device in case of a number of problems:

- Traction disorder;

- Significant reduction in gas supply pressure;

- The igniter stops burning.

- Expansion tank;

- Heating devices located in each room requiring heating;

- Main pipeline providing distribution of heated coolant;

- Upper pipe distribution;

- Return pipe.

To know how an AOGV gas boiler works, you need to imagine the physical laws that arise in the heating system during its operation. The heated coolant has a lower density, which allows it to independently rise above the cold liquid. The coolant enters the main pipeline, is carried through the heating devices, gives off heat to them, and returns to repeat the heating cycle.

In AOGV boilers, the liquid moves by gravity, without any additional effort. If during the heating process the coolant expands too much, then its excess is drained into the expansion tank. This element is installed on the uppermost section of the heating circuit. When the temperature in the circuit decreases, the coolant returns to the OGV gas boiler.

To increase the efficiency of the system and make it more stable, you can supplement the AGV with a circulation pump, which forces the coolant to move forcibly and ensures more uniform heating of all sections of the circuit. It must be remembered that the pump requires electricity to operate - and the main advantage of the AGV is its independence from electricity.

Manufacturers

If you want to purchase a higher quality and more expensive AGV, you can pay attention to the products of foreign companies:

- BAXI and FERROLI. These devices have a good design and an electronic control unit.

- RINNAI. Devices of this brand are distinguished by quality, reliability and ease of use.

- ANIERIA. Relatively inexpensive, but very reliable boilers made in Korea.

Imported devices outperform domestic ones in efficiency, but lose due to their dependence on electricity. Before you turn on a foreign-made AGV, you need to connect it to the power grid. Considering that there are often power outages in the domestic space, this factor cannot be ignored when choosing a suitable device.

The choice of AGV is often based on the cost of equipment and operation. Domestic-made boilers are cheaper on their own, and they are much more profitable to operate. The total savings are approximately a third, based on similar indicators of imported devices.

Design Features

- Fire adjustment is made in two ways: automatically and manually. The models differ not only in power, each of them has a certain range of capabilities.

- Some models have a pump to circulate water in the pipes. This allows you to effectively heat the room due to uniform heat distribution. Cheaper modifications do not have pumps, and water circulates according to the laws of physics. Therefore, when installing such boilers, the pipes are mounted at an angle.

- All modifications have an expansion tank. It allows you to achieve optimal pressure in the system, and if the liquid expands due to strong heating, it stores its excess.

Varieties

All boilers at the Zhukovsky Plant are floor-standing. There are three modifications:

In the first case, automation manufactured in the Russian Federation was used, in the other two - foreign ones. The brand presents only single-circuit versions - for heating buildings; double-circuit versions are not produced at ZhMZ.

Device

The efficiency of the equipment is 89%, which is quite good for domestic products. This productivity can be achieved due to the original design of the heat exchanger. The cast iron heat exchanger is equipped with turbulators. The burner is atmospheric, air comes from the room. Thanks to automation, continuous operation for a long time is ensured.

Heaters from the Zhukovsky Plant have a number of innovations that increase their environmental friendliness. Developers are trying to keep up with global trends, but still, domestic products are far from achieving the indicators of European and some Asian competitors. But Russian products have an undeniable advantage - a low price that satisfies all consumers.

Generation of new AGV systems

Some units are produced at Russian factories. One of them is AOGV-23.2-1, which structurally looks like a household heating cylinder. It is used in houses with an area of 140-200 square meters. There is a unit with a lower heating power - approximately 100-140 square meters. Apart from power, these two devices are no different from each other.

Recently, a new system was released called AKGV (Combined Gas Water Heating Apparatus). According to the method of use, it is no different from AGV; it is used both for heating the house and for supplying hot water. But the design of the AKGV unit is different - instead of a pipe that goes inside the boiler, three steel sections are installed, which are stamped in a special way, they are mounted in a vertical position and connected into one chimney.

This device is rightly called “two in one”, because it initially heats the water using a coil, which is encircled along the entire contour of the boiler. The water flowing through the coil is used for domestic purposes, and in the boiler the water is heated for heating.

The newest models have an injection burner. It ensures gas combustion without residue and works even when the gas pressure drops.

Automation of the new AGV

Automation AKGV heating system

This irreplaceable item fully controls water heating and consists of:

- Thermal sensor, which gives the system an idea of the current temperature;

- Electromagnet - valve control device;

- Thermocouples, which are installed next to the igniter and are responsible for generating electric current when heated from the torch;

- Traction sensor. It is installed in the chimney to control draft.

With proper adjustment, the automation unit will prevent sudden shutdown of the AOGV in the event of a breakdown or failure in the boiler settings, and most importantly, will extend its service life.

If we talk about the origins, this type of heating equipment was developed back in the 50s, due to the lack of central heating in villages, villages and small towns. Since then, AGVs began to systematically gain popularity, and soon most houses in the USSR began to be heated with them. Thus, this system, of course, after modernization and modifications, fits well into modern realities

It is only important to know how to choose AGV heating, remember the rules for handling this system and follow them, then the boiler will serve you much longer than its declared service life. After all, the system in which hot water circulates does not tolerate jokes and amateur activities

In general, this system is quite economical both in terms of funds and in terms of space occupied. And with the introduction of ACS (Automated Control Systems), its operation and maintenance does not cause any trouble at all. After proper setup, according to the instructions or with the help of a specialist, the coefficient of intervention on your part becomes minimal and guarantees warmth to your home.

Features of installation of the AGV heating system

Installation and connection of AGV can only be carried out by specialists from the gas service of your locality. After installation, your gas water heater will be registered.

If you plan to install AGV heating, then you must provide for the following features:

- The heating boiler is installed in a separate room (boiler room);

- The pipe for exhaust gases must be installed outside, at a height not lower than the roof.

- The minimum diameter of the chimney pipe must be 135 mm;

- The outer part of the chimney must be insulated and insulated;

- The chimney is equipped with a special channel for collecting waste.

When using a system with natural heat circulation, it is necessary to ensure that the unit is located below the installation level of the radiators.

AGV system with natural circulation

If you already know how to choose AGV heating, then you should be aware that the diameter of the pipes is selected based on the technical documentation of the equipment.

When laying heating system pipes, it is necessary to lay them at a certain angle of inclination. The slope should be 10 millimeters per 1 meter of pipe. The condition with a slope is necessary in order to avoid the appearance of air locks in the system, as well as to improve water circulation. Plus, it’s convenient when draining water from the system.

When the temperature reaches 50 degrees C, gas condensate may appear on equipment elements. Because of this, the service life of some system components may be reduced. Also, at this temperature, the coolant itself stops circulating.

AGV heating scheme

Disadvantages of the AGV gas system

- The layout and installation of pipelines when using the AGV system requires strict adherence to the rules.

- It is not possible to automatically regulate and control the temperature in each individual room. This may be the reason for not the most efficient fuel consumption.

If the AGW system is used in a country house and you leave it in winter, then it is important not to forget to drain the water from the heating system. In principle, this can be avoided if you use special antifreezes that do not freeze even at sub-zero temperatures.

You should be careful when using such chemicals as they can be toxic.

It is possible to significantly improve the AGV heating system by installing a circulation pump, which will increase the efficiency of your heating system.

Advantages and disadvantages

Despite their apparent simplicity, AGV-80 boilers have such advantages as:

- Comparative ease of installation and ease of further management and maintenance. This concerns the safe regulation of water temperature within a predetermined range.

- The tank is made of metal, corrosion-resistant, strong and durable.

- Manufacturing of important components and parts using high-precision modern technologies. They are considered sensitive to the slightest changes in system operating parameters.

- Energy independence. The operation of AGV does not require stable network operation, costs for checking sockets and wiring, or adapting the system to increased load.

- Virtually silent operation. There is no circulation pump and fan.

Installing an AGV means that the pipework in the heating system can be made from any materials - cast iron, steel and heat-resistant metal-plastic.

The operation of the unit does not depend on gas pressure differences in the network. Well-thought-out protection allows you to turn off the system in time when the pressure drops.

Compared to models equipped with a circulation pump and fan, AGV has lower efficiency and does not have remote control.

There are technical features that lead to destruction of the device. For example, if the water temperature in the system drops below +50°C, abundant condensation begins. Unlike modern models, it is not used in any way in such boilers, but it is capable of extinguishing the flame.

When combustion products mix with condensate, sulfuric and nitric acids are formed. The latter are harmful to human health and equipment because they lead to corrosion.

About old-style boilers

AOGV is a later modification of the AGV brand. They, like their predecessors, do not have particularly high efficiency and do not have thermostat control. When gas was cheap, no one paid attention to low performance; today efficiency is one of the most important characteristics when choosing heating equipment. AGV models were distinguished by low-quality automation, which broke after one or two seasons of operation.

AGV and AOGV can work without automation: if it breaks down or is turned off on purpose, it will not interfere. When buying a heating boiler, you need to take care of a sufficient number of pipes - their diameter should not be less than two inches. If you take a smaller diameter, the circulation of the coolant may deteriorate - there will be additional costs for heating it.

What is the improvement?

The developers have made a number of improvements to the design:

- Glass thermometers were replaced with Italian, more modernized ones.

- German automation from Honeywell was installed.

- Piezo ignition.

- The appearance has improved thanks to the high-quality coating. The design has changed: the body can be round or rectangular. White color. Painting: powder.

AGV design

The AOGV gas boiler has a gas-tube design with a vertical flame tube and is installed on the floor. The round burner is located at the bottom. The air required for combustion enters through the lower holes in the casing. Removal of combustion products occurs naturally, through the chimney pipe at the top, at the base of which there is a draft breaker cap with a door.

Design of the AGV-80 gas unit

The flame tube is divided into sections by so-called turbulators, which provoke turbulence in the flow of exhaust gases, reduce its speed and increase the efficiency of the device.

The connection pipe for the direct line of the heating system is mounted on the top cover of the boiler. Returns are on the side. The AGV-80 gas boiler differs from the AGV-120 in that the fuel line with shut-off valves is located on the outside and does not have a casing.

In combined models (with the letter “K”) there is a coil that wraps around the flame tube from the inside. It supplies hot water to the water supply system.

The boiler automation stops the gas supply in three cases:

- When traction drops.

- Pressure drop in the fuel line.

- Flame breakout or arbitrary cessation of combustion.

No connection to electrical networks is required, the device is completely autonomous. The boiler casing is made round or square, which depends on the type of design - “Economy”, “Universal” or “Comfort”.

Advantages and disadvantages of AGV

The list of positive qualities of AGV is as follows:

- Independence from electricity. This quality is often fundamental when choosing an AGV. The equipment in question does not require electricity at all to operate, so it will fit perfectly in situations where there are problems with electricity, or if there is a desire to save money on it.

- Cheapness. Compared to any foreign analogues, AGV wins in everything related to the cost of equipment. This advantage remains such even taking into account the extremely low efficiency of autonomous gas water heaters.

- Economical. AGVs are rightfully considered one of the most economical types of gas heating equipment.

The disadvantages of AGV come down to the following list:

- Big sizes. To install an AGV, about 1 m3 of space is required - which is quite a lot. Often a separate room is allocated for the installation of such equipment.

- Appearance. From a visual point of view, AGV is a purely utilitarian thing that does not have the slightest aesthetic value. In addition to the unpresentable appearance of the heater itself, the heating system is necessarily supplemented by large pipes and radiators, so you have to be sophisticated to create a good interior.

Advantages and disadvantages of Zhukovsky gas boilers

The popularity of AOGV gas boilers for private houses and apartments is due to a number of advantages that users appreciate.

Advantages of Russian technology:

- Easy controls that provide safe and simple temperature settings within certain limits.

- The use of innovative technologies ensures maximum accuracy and error-free operation reliability.

- The boiler is energy independent and therefore does not need to be connected to the power supply network.

- The equipment is compatible with polypropylene, cast iron, steel and other materials.

- There are modifications in which it is possible to turn off the gas yourself, this increases safety in the event of an accident or failure of automatic devices.

- The heat exchanger is durable and reliable.

- The AOGV gas boiler is not afraid of natural gas fluctuations.

- The coolant temperature can be adjusted manually.

- Service life is 14 years or more.

- Manufacturer's warranty for 36 months.

All gas boilers from the Zhukovsky plant have one circuit and are intended only for heating. However, please note: some similar models from other manufacturers may be equipped with a second circuit for heating water for domestic needs.

These units have high-quality thermal protection, ensuring the most complete recycling of the energy of the used gas.

AOGV gas boilers are environmentally friendly. They emit a minimum of harmful substances into the atmosphere after complete combustion of the gas, all thanks to the design of the micro-flare burner.

Another important fact is that such units are adapted to the climate conditions in Russia.

Disadvantages of units:

- Considerable cost of these boilers in comparison with some analogues.

- Certain difficulties when finding spare parts.

- Automation of outdated configurations on some modifications.

- Large boiler dimensions.

- Some people may find the external design of the boiler equipment casing unattractive.

Operating principle of AGV

The main structural element of the AGV is the container in which the coolant is heated. When gas burns, a heat exchanger, made in the form of a pipe and installed inside the AGV housing, heats up. The heat from the heated pipe is transferred to the coolant, which is subsequently sent to the heating circuit.

Gas combustion products are discharged through a chimney built into the boiler design. All automation is a valve that opens the gas burner. Thanks to the operation of the valve, the required temperature is constantly maintained in the tank.

AOGV boilers also have an automation unit that turns off the device in case of a number of problems:

- Traction disorder;

- Significant reduction in gas supply pressure;

- The igniter stops burning.

Immediately behind the AGV, the following elements of the heating system are installed sequentially:

- Expansion tank;

- Heating devices located in each room requiring heating;

- Main pipeline providing distribution of heated coolant;

- Upper pipe distribution;

- Return pipe.

To know how an AOGV gas boiler works, you need to imagine the physical laws that arise in the heating system during its operation. The heated coolant has a lower density, which allows it to independently rise above the cold liquid. The coolant enters the main pipeline, is carried through the heating devices, gives off heat to them, and returns to repeat the heating cycle.

In AOGV boilers, the liquid moves by gravity, without any additional effort. If during the heating process the coolant expands too much, then its excess is drained into the expansion tank. This element is installed on the uppermost section of the heating circuit. When the temperature in the circuit decreases, the coolant returns to the OGV gas boiler.

To increase the efficiency of the system and make it more stable, you can supplement the AGV with a circulation pump, which forces the coolant to move forcibly and ensures more uniform heating of all sections of the circuit. It must be remembered that the pump requires electricity to operate - and the main advantage of the AGV is its independence from electricity.

Features of work

The heat exchanger is heated by gas. In this case, energy is transferred to the water that is in the container. Air comes from the room, combustion products are discharged through a specially constructed chimney.

Such boilers provide natural circulation of liquid due to differences in temperature and altitude. Hot water rises to the top, from there it enters the radiators. Thermal energy is used to heat the house, then the liquid cools and drops to return to the boiler.

To compensate for the difference in volumes, the system is equipped with an expansion tank. From the latter, the excess goes into a special overflow tube, which serves as protection against high pressure.

The gas boiler is equipped with a solenoid valve that is connected to a thermocouple. They are responsible for the safe operation of the unit. During normal operation of the installation, the igniter heats the thermocouple junction. Electric current appears in the circuit. The valve itself remains open, and at this time the gas flows to the main burner. When the pilot goes out, the thermocouple junction cools down. The valve itself blocks the access of fuel to the main burner.

The peculiarity of AGV is that the igniter can only be re-ignited manually, but not immediately, and not earlier than after 2 minutes. You can turn on the boiler after it is filled with water.

Gas boilers AOGV from JSC Borinskoe

The Borinsky plant produces rectangular heaters, with automation in the rear.

The second most popular manufacturer of AOGV is the Borinsky plant. It offers 7, 11, 17, 23 and 29 kW heaters. Such a wide range allows you to choose a boiler even for a small house up to 70 sq. m. This is convenient when there is no point in overpaying for a more powerful unit. At the same time, the Zhukovsky plant can offer customers gas boilers AOGV 11.6 - this is the minimum value.

The Borinsky plant produces two modifications of heaters:

- normal - single-circuit;

- combined - double-circuit.

Boiler burners are made of stainless steel. Copper DHW heat exchanger. The heater body is painted with polymer paint. The unit has built-in temperature regulators to prevent it from overheating, a thermocouple to control the gas supply, and a draft stabilizer. The latter smooths out differences during strong gusts of wind, and in the event of a complete lack of traction, it blocks the gas supply and, accordingly, the operation of the unit. Natural or liquefied gas is suitable as an energy carrier.

Operating principle of AOGV

All AOGV units are equipped with a built-in atmospheric burner. At the bottom of the structure, directly under the tank with a heat exchanger, a burner is installed, which is responsible for heating the water. When converting the device, it can be operated on bottled gas.

Construction of the AOGV gas boiler at the Zhukovsky Machine-Building Plant

The steel heat exchanger has a tubular design, which contributes to a high efficiency. At the back of the structure there are outlet and inlet fittings with a diameter of about 4 cm. They are necessary for connecting the coolant. The return line is located at the bottom, and the “direct” line at the top.

The chimney has a diameter of about 120 mm and is connected to the top of the boiler.

The boiler is controlled by a valve that has electromagnetic properties, as well as a thermostat lever. Units with piezo ignition or autostart are often produced. A thermocouple and a draft sensor are connected to the valve.

A copper thermocouple regulates the flame on the igniter and is one of the main elements of boiler equipment. The traction sensor shuts off the gas when the traction weakens.

Installation of AOGV in a heating system

AOGVs are installed in private homes.

Installing an AOGV in a private house will cost one and a half times less; on average, the cost of a heater is 20 thousand rubles. Such units can operate in both sealed and open systems. In the latter case, the circuit depends only on the gas supply; there are no energy-dependent devices in the boiler.

The do-it-yourself installation scheme for AOGV in a private house is standard. Consider a sealed circuit:

- the supply from the boiler goes straight to the radiators (air vents must be installed in them);

- a pump is placed on the return line in front of the boiler - installing a pump is allowed in any place, but on the return line it is more correct;

- A mud trap is placed in front of the pump along the coolant flow - this is mandatory;

- The expansion tank is also installed before the pump - this is necessary for the correct operation of the expansion machine.

In an open system, the expansion tank plays the role of an air vent. It can be placed on the supply, immediately above the boiler, or on the return. The main thing is that it is at the highest point. In gravity systems, certain slopes must be observed, then an electric pump is not needed. If the circulation in an open circuit is disrupted, then installing a pump will easily solve this problem; you can even not replace the expansion tank with a sealed one.

AGV modifications

Considering the variety of modifications of gas water heating devices on the market, it is worth understanding how the AOGV differs from a gas boiler. Looking ahead a little, there is no fundamental difference between the devices; all the differences lie in small nuances.

If we talk in detail, then everything that distinguishes an AOGV from a boiler comes down to the following points:

- Glass thermometers have been replaced with modern Italian components;

- Honeywell products began to be used as automation elements;

- The design is supplemented with a piezo ignition device;

- The last difference between the AOGV and the boiler is that the appearance of modern modifications has been slightly improved, for which a higher quality coating has been used.

Energy and energy equipment

Research Institutes of Energy Energy companies Energy saving technologies Sale of heating boilers Repair of heating boilers Cleaning of boilers and heat exchangers Design and construction of boiler houses Boiler equipment - production, sale, repair Construction of energy facilities Construction, repair and maintenance of energy facilities Power plants - equipment Diesel power plants, sale RusHydro Pipes and pipeline fittings Electrical installation work Cable industry enterprises Electrical products, sales Gas industry, gas equipment Oil and gas industry - enterprises in Moscow Sale and transportation of petroleum products Petrochemical enterprises Energy audit Energy equipment Air conditioners and fans, sales Electrical goods stores Leroy Merlin electrical goods

Boilers of these brands are produced

by the Zhukovsky Machine-Building Plant (ZhMZ)

, the largest enterprise in Russia producing household gas heating boilers.

Therefore, these boilers are often called Zhukovsky

.

ZhMZ is located in Zhukovsky, Moscow region. Since 1967, the plant began producing household heating boilers AGV-120, widely known in all regions of Russia and the CIS countries. Currently, the plant produces more than 30 types of AOGV, AKGV and KOV with power from 11 to 68 kW. Zhukovsky boilers are used in electrically independent autonomous water heating and water supply systems. New modern equipment and highly qualified personnel allow us to produce competitive products and the plant to be the Russian leader in the production of gas equipment for autonomous heating and water supply systems. Boiler AOGV-17.4 Gas floor-standing boilers AOGV

are used for heating residential buildings and domestic premises in heating systems with natural or forced water circulation.

The boilers are single-circuit and are used only for heating. For hot water supply, a double-circuit analogue is used - AKGV boilers

.

The abbreviation “AOGV”

stands for

“Gas Heating Unit”, “AKGV - “Combined Gas Unit”.

Those. The AOGV boiler is used only for heating, while the AKGV boiler allows for the selection of hot water for domestic needs. The boilers operate on natural gas, and when replacing nozzles (on the main burner and igniter) - on liquefied (cylindered) gas. The boiler heat exchanger is steel. It has a special design that allows achieving a boiler efficiency of at least 89%. The model range of AOGV boilers includes devices with a power from 7 to 23.2 kW and allows you to heat rooms with an area of 25 to 200 m2. The AKGV boiler range includes devices with a power from 11.6 to 23.2 kW and allows you to heat rooms with an area of 50 to 200 m2. The distinctive qualities of boilers of these brands are simplicity and reliability of design, unpretentiousness, and ease of use. These qualities allowed the AOGV and AKGV boilers to gain popularity in Russia. The AOGV boiler can be found in many country houses and in houses with apartment heating. Gas heating boilers AOGV and AKGV can be used both in systems with natural circulation of coolant (open system), without connection to the electrical network, and in systems with forced circulation of coolant (closed system) with the installation of a circulation pump. Based on serial boilers AOGV and AKGV, it is possible produce modular boiler houses of various capacities When AOGV and AKGV boilers operate in the heating system, low-freezing liquids recommended for use in heating systems can be used as a coolant

About the production of ZHMZ

Zhukovsky Machine-Building Plant is a large industrial Russian enterprise that has been successfully operating for more than seven decades. Even before the war, the main focus of the company was the production of metal devices for general purposes, and during wartime the plant supplied equipment for the needs of the front. After the war, the organization produced ground equipment that was intended to serve aviation.

It must be said that ZhMZ still supplies such equipment to the domestic and foreign markets. The equipment of the Zhukovsky plant is available on Russian territory, in Asian countries, and even in Cuba.

In the 1970s, the company began producing components and various components for the space sector. Among other things, the plant produced shock absorbers, seats and backpacks for astronauts.

The 1990s were remembered for the partial production of fire-fighting mobile equipment. We can conclude that ZHMZ is an organization with extensive experience and a serious material and technical base.

Currently, the main direction of the plant’s work is the development and production of heating equipment. Moreover, the company’s specialists can prove serious achievements in this area - today more than thirty modifications of gas boilers such as AOGV, KOV and AKGV are available to consumers. Power characteristics vary from 11-68 kW. The buyer can choose the optimal technology to create comfort in his home or apartment. There are modifications that can be installed in non-residential premises.

The manufacturer supplies the market with excellent heating boilers at a budget price. Cost reduction is the result of an integrated approach to the production process. Various workshops operate specifically for the organization: foundry, electric welding, painting, etc.

Currently, the factory structure consists of 50 divisions, employing more than 1,200 specialists. Such capacities make it possible for the Zhukovsky Machine-Building Plant to create projects, improve and bring to the market modern heating boilers that meet state standards.

In order not to doubt the seriousness of ZhMZ as a large manufacturer of high-quality equipment, it is enough to take a closer look at floor-standing gas boilers AOGV, as the main engines of sales.

Insertion of AOGV into heating

Since it is not difficult to include AGV in home heating, you can do it yourself, but you will first need permission from the utility services. The insert involves connecting the unit to the heating pipes, as well as to the gas main. To prevent scale particles and dirt from getting inside the boiler, coarse filters must be installed on the inlet pipes. All threaded connections are sealed using tow and O-rings.

Shut-off valves are installed on water pipes. Only a person who has permission to do this type of work can connect the boiler to the main gas line. The gas pipe is also connected with additional sealing. When connecting, copper products or corrugated hoses are used.

Rubber parts are not used because over time they crack and can leak gas, which, if accumulated in the room, will lead to disastrous consequences. A union nut is used to secure the corrugated hose.

Main operational characteristics of the AOGV and AKGV boilers

Boiler brandThermal power, kWAutomationHeating square, m2Weight, kgAOGV-7-3 AOGV (AKGV) -11.6-1 AOGV (AKGV) -11.6-1 SIT AOGV (AKGV) -17.4-1 AOGV (AKGV) -17.4-1 SIT AOGV (AKGV) -23.2-1 AOGV (AKGV) -23.2-1 SIT AOGV (AKGV) -23.2-1 SIT with Zhukovsky connection AOGV (AKGV) -29-1

| 7 | EUROSIT | 25-60 | 40 |

| 11,6 | Orion | 40-90 | 45 |

| 11,6 | EUROSIT | 40-90 | 45 |

| 17,4 | Orion | 70-140 | 50 |

| 17,4 | EUROSIT | 70-140 | 59 |

| 23,2 | Orion | 90-200 | 54 |

| 23,2 | EUROSIT | 90-200 | 54 |

| 23,2 | EUROSIT | 90-200 | 54 |

| 29 | Nova SIT | up to 250 | 58 |

Manufacturers of boilers AOGV and AKGV

.

The Boiler Equipment Plant OJSC Borinskoye

has been producing AOGV boilers for more than 15 years and during this time has made a number of significant changes to the basic design of the boilers. Improvements such as: •modern design of the heat exchanger and gas burner device, •increased efficiency, •possibility of installing a copper circuit, •use of imported automation, •polymer painting,

New generation of AGV devices

Russian factories produce AOGV - 23.2 - 1. This is a household heating gas cylinder. It is intended for heating houses with an area of 140 - 200 square meters. meters. There is also a device with slightly less power for heating an area of 100 - 140 square meters. m. Otherwise, these two types of heaters are practically no different from each other.

Recently, a more modern model AKGV - 23.2 - 1 with a water circuit has appeared. It can also be used to heat a home and supply hot water. And instead of a pipe running inside the boiler, three steel sections are installed, which are made using a special stamping method and are hollow inside. The sections are mounted vertically and are connected into one chimney, through which gas combustion products flow into a separate chimney pipe.

How to choose gas heating boilers?

New generation of AGV devices

Water is heated using a special coil, which encircles the entire circuit inside the boiler and the water that is used for everyday life flows through it. And in the boiler the water for heating is also heated. That is, it turns out that this device is two in one.

The new model includes an injection burner, which ensures efficient combustion of gas without residue. This type of burner works perfectly even when the gas pressure in the pipeline is low.

Automation of the new AGV

It completely controls the entire process of heating water. And the automation unit itself consists of:

- a temperature sensor that controls the water temperature;

- an electromagnet, which is responsible for controlling the main gas supply valve;

- thermocouple, which is mounted near the igniter. Heated by a constantly burning torch, it creates an electric current in the circuit;

- traction sensor. It is mounted in the chimney and controls the optimal draft of the pipe.

Modernization of AGV boilers by the manufacturer

The boiler manufacturer AGV was in no hurry to discontinue them due to obvious advantages.

However, taking into account that this equipment needed a thorough modernization, the following design changes were made:

- Fragile glass thermometers have been replaced with more reliable instruments made in Italy;

- The new systems were equipped with automation from the American company Honeywell;

- To turn on the device with a handle, a piezo ignition system was used;

- New coating technology has made the appearance of the unit more aesthetically pleasing.

Boiler diagram AOGV - 23

Rules for handling the heating system

The unit is installed in a separate room. It is advisable that this room be soundproofed, since when the boiler burner is turned on, a rather loud bang occurs.

In some new modifications (AOGV-23.2-1-U), this drawback has been largely eliminated, since when the water overheats, the automation does not turn off the burner completely, but switches it to a mode in which the flame is minimal.

A chimney (with a diameter of 140 mm) for combustion products is installed outside residential premises. Below the junction of the pipe from the heating tank with the chimney, there is a garbage container - a “pocket” for foreign objects and waste that accidentally fell into the channel.

Option for a chimney for AGV in a private house

Note! You should not connect the unit yourself. It must be carried out by gas service workers. In this case, the device is registered.

For the unit, a room should be allocated in the lower part of the building. The ascending pipeline needs insulation. The return line should not be insulated.

The installation instructions for heat transfer devices (radiators, convectors and heating panels) provide for their installation at the highest possible height from the unit itself. To circulate layers of air, such devices should be installed under windows. The return pipeline is laid under the floor of the room.

If the return line is laid above the door jambs, airing of the system may occur.

General view of a fragment of the pipe layout of a heating system with AGV

Two-inch network pipes do not look very aesthetically pleasing, however, when replacing them with pipes of smaller diameter, it is necessary to take into account that as the diameter of the pipe decreases, hydrodynamic resistance increases, which weakens the water pressure in the system. This, of course, can seriously impair the performance of such a unit.

AOGV connection: rear view

During installation, pipelines are installed with a slope of 1 cm for each meter of pipe length. This avoids the appearance of air locks in the system, facilitates water circulation and allows water to be drained from the system.

This video examines some practical issues of installing AGV in a private home:

Some Caveats

- When the water temperature in the system drops below 55-50°C, condensate begins to release abundantly. If it accumulates, it can extinguish burners;

- Combustion products, when mixed with condensate, form nitric and sulfuric acids, which cause corrosion of equipment;

- If the water temperature in the system drops below 50°, then its circulation in the system almost completely stops;

- If the room is not heated in winter, the water from the system must be drained, but in this case corrosion increases significantly;

- To get hot water without heating the entire system, you can use a tap that shuts off the circulation in the heating system. And if you connect the forward and return lines, you can maintain turnover.

Have a warm winter!

Technical characteristics of AGV-120 boilers

From a design point, the gas apparatus of this model includes only a heat exchanger, an expansion tank, a cast iron burner and simple automation. Boilers can be installed where the facility cannot be connected to a centralized heating system.

Such a device, operating on gas, was the AGV-80 boiler. The AGV-120 unit appeared later, then several more modifications were developed. The devices are in demand. They have such advantages as reliability, versatility (the unit is used to heat a room and provide hot water supply), and are also characterized by fuel economy. At the same time, the main components have been modified.

The cylindrical tank is made of galvanized steel, which is resistant to corrosion. Its volume is 120 liters. At the same time, the device is equipped with a piezoelectric element and imported automation, which can increase operational safety. There is an improved ignition system.

The thermal power of the device is 14 kW (however, the heating output is lower - 11 kW). The water does not heat up too quickly: it takes an hour to raise the temperature to 90 °C. The efficiency of modern units is about 85%.

The casing of the device is made of steel sheet. There remains a space between the tank and it, which is filled with slag, which acts as thermal insulation. The device is equipped with a cast iron burner. Cold water is supplied from below. The selection of hot liquid that will circulate inside the heating system occurs from above. The return line must be connected to the water supply fitting.

There is a thermostat to change the temperature of the liquid. Its element is located directly inside the tank. To control the burner, a thermocouple and a solenoid valve are installed. There is a fire tube inside the tank, designed to allow combustion products to be discharged outside. This design increases the heating area and improves the heat transfer process.