Autonomous heating systems have become increasingly popular in recent years and this is due to the enormous savings. The boiler is an asset in your budget, because it will pay for itself in 2-3 seasons, depending on the price. And you shouldn’t skimp on it, because the price affects how long it will last and whether it will be safe. Therefore, a good choice would be a floor-standing gas boiler from Vaillant, a company that has been known to consumers for many years. However, there are no perfect products, so let's look at all the advantages and disadvantages of the device so that you can decide whether it is worth the money.

Description of the Vaillant floor standing boiler

This is not the first year that Vaillant floor-standing gas boilers have conquered the market, and all thanks to the high quality of the products. The company's most popular product is dual-circuit devices; their advantage is that they are capable of delivering greater power, providing heat from two floors or more.

However, it is definitely worth making an extension or a separate boiler room for such a boiler, because placing devices with a power of over 60 kW in the kitchen is prohibited according to fire safety rules. But if you don’t want to spend additional resources on rebuilding a new building, the company also has a number of wall heaters - from 24 to 34 kW.

To figure out why it’s worth paying a little extra for the brand, let’s look at the characteristics of the Vaillant atmovit gas floor-standing boiler.

Prices: summary table

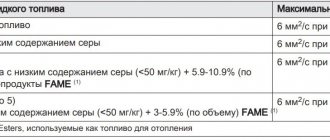

| Model | power, kWt | Efficiency, % | Gas consumption, m³/hour | DHW capacity, l/min | price, rub. |

| atmoTEC pro VUW 240/5-3 | 24 | 91 | 2,8 | 11,4 | 71 000—79 000 |

| atmoTEC plus VUW 240/5-5 | 24 | 91 | 2,9 | 11,5 | 79 000—90 000 |

| turboTEC pro VUW 242/5-3 | 25 | 91 | 2,9 | 11,5 | 76 000—82 000 |

| turboTEC plus VUW INT 242/5-5 | 25 | 91 | 2,9 | 11,5 | 97 000—103 000 |

| ecoTEC plus VU INT IV 346/5-5 | 34 | 107 | 3,7 | — | 125 000—182 000 |

| atmoVIT VK INT 254/1-5 | 25 | 92 | 2,9 | — | 117 000—153 000 |

| ecoCOMPACT VSC INT 266/4-5 150 | 25 | 104 | 3,24 | 12,3 | 190 000—315 000 |

Vaillant boilers are considered the standard of heating equipment. Indeed, for many years they continue to be leaders in their field. If you are looking for a reliable and comfortable boiler, then Vaillant is ideal for you.

Gas boilersBoilersGerman boilersReviewBoiler manufacturers

Specifications

One can argue for a long time about the superiority of double-circuit and single-circuit boilers, but it all depends solely on the volumes that need to be heated. The company has several series for different purposes, but they all have one thing in common:

- Highly economical gas consumption. The efficiency of boilers is approaching record levels, with a difference of 5 percent, depending on the chosen model.

- There are also series with mechanical and digital control. It is not worth mentioning that the second type is more reliable, but it makes you dependent on electricity, and if the power goes out in the area, you can freeze in your own home.

- The water heating speed is standard; it is difficult to speed up this process in any way, and almost all double-circuit boilers in the mid-price category produce the same performance.

- Additional purification of combustion products. Some may consider this unnecessary, but those who have ever dealt with a clogged chimney will immediately understand why such functionality is needed. In fact, this saves the user from unnecessary headaches.

- The user has immediate access to control of all systems, without the need to go into the boiler hardware and change anything. The PRO series also has an electronic display and remote control capabilities.

- The screen displays absolutely everything. If an error occurs, it will display its code and explanation, allowing the user to quickly find the cause of the failure.

The consumer is given a standard choice, from wall-mounted versions with 24 and 34 kW of power, to floor-mounted versions with 2-3 times more power. This solution allows you to operate the company’s equipment in all premises, from small apartments to multi-storey private houses. You do not need to give up your favorite brand because of the scarcity of the product line.

In addition to the standard circulation pump with expansion tanks, you will find many safety features in the boiler, which are extremely important. Some will consider such pedantry unnecessary and only inflating the price, but in reality it is better to be safe, especially if you want to install an autonomous heating system directly in a living space.

But the price segment varies greatly. The quality of the equipment allows you to buy used boilers, but it is better to choose series that are a maximum of 2 years old, so that there are no problems. A new device will cost you from 60 to 150 thousand rubles, depending on the series and configuration. Here everyone makes an individual choice, because you are unlikely to need a powerful floor-standing boiler in an apartment or a weak wall-mounted one in a two-story house.

The main thing is not to forget that, even after calculating the required power for the specific dimensions of the building, it is better to add 10 kW on top as a reserve. Otherwise, you will encounter “cold zones” in the pipes, and the room temperature will constantly change within 5 degrees.

Price range

German gas equipment is a model of quality, and the price matches it. Boilers of this class cost at least 45,000 rubles. And these are the lowest-power versions, more powerful ones are twice as expensive. How much a boiler costs depends on several factors:

- Burner type.

- Smoke removal method.

- Level of automation and configuration.

- Power.

Installing Vailant devices allows you to save 30-40% of gas, so it will fully pay for itself within 2-3 heating seasons.

Distinctive features

But all of the above can be found in other brands. So what's the point of buying these particular boilers? It's all about several features of the equipment produced by Vailent:

- High build quality. It is to him that the price of the goods is due. Nothing will stick together or fall apart during installation, as in Chinese crafts, and the company’s name is known throughout the world, because the brand is more than 100 years old. The experience of Vaillent engineers is difficult to overestimate, which is why their products are famous for their high level of safety, because there is nothing more important in gas boilers.

- Often, “German technology” is just a marketing ploy, and not all goods produced in Germany are worthy of praise. But it is thanks to companies like Vilent that users still value European quality.

- Diverse product range. Having one quality standard, the company manages to produce cheap wall-mounted and expensive floor-mounted double-circuit gas boilers. This way you can choose what you need specifically in your case.

- The high efficiency of all boilers is one of the highest on the market, and is combined with the German safety standard.

About company

Vaillant is a brand of the famous concern Vaillant Group. The history of the company began in 1874, when its founder Johann Vaillant began manufacturing sanitary equipment. Today, the Vaillant Group is a large company that manufactures heating devices, ventilation and air conditioning systems and occupies a leading position in the global market in this area. The company has branches in 20 countries and exports products throughout the world. Vailant also has offices and service centers in Russia.

The concern is constantly working on its product range, has many developments in the field of using renewable energy sources, considering this direction one of the main ones in its activities in the future. However, the production of gas boilers still comes first and is a priority in the company's work.

Vaillant has several scientific laboratories that study and implement innovative technologies developed by company specialists. The Vaillant Group is currently building a large research center to create the devices of the future.

The company produces energy-saving heating systems and gas equipment. Vaillant's main strategy is to follow the principles of an environmentally friendly lifestyle. All gas boilers of this company are made taking into account advanced eco-technologies. The devices have a very low noise level and CO2 emissions into the atmosphere, saving resources. Vailant boilers use the resulting energy with maximum efficiency and provide high efficiency of the heating and hot water system.

Installation features

Installation of double-circuit boilers should always be carried out with caution. Don't forget that the body heats up just like the water. Accordingly, you should worry about the fire-resistant wall and its coating. It is best not to place flammable objects near the boiler at all.

And leave half a meter around the case on the sides and a meter in front so that you can easily service the device if necessary. With branded boilers it is much easier to obtain permission to connect to the gas main, but if you do not follow all safety precautions, then even the most expensive device will be lying around in the garage without use.

TurboTec Pro device

Double-circuit devices are equipped with two heat exchangers. The first is made of copper - it heats the coolant, the second is made of stainless steel - for heating running water. A copper heat exchanger has a large number of plates.

The gas burner modulates the flame within 40-100% of power. There is a built-in hydraulic unit - a secondary heat exchanger, a security system, a circulation pump, as well as various sensors are installed there.

The brand's main competitors are German Viessmann boilers. Vailant has an undeniable advantage - the water-gas elements are made of high-quality copper, while its competitors are made of composite material.

The device uses gas and electricity economically. Thanks to the use of low-voltage equipment, less electricity is consumed.

Prevention recommendations

If you want the boiler to last several times longer than the warranty period, worry about its cleanliness. Don’t forget to wipe it off from any accumulation of dust, call a technician to check the equipment once a year, and don’t touch it with dirty hands.

Valant's standard of protection is high, but it's not worth playing with fire, so follow all safety rules as if you had no room for error.

Nowadays, double-circuit gas boilers are quite often used for heating residential premises. Let's imagine the following situation: you buy a heating unit, study the instructions for its operation, and then start using it. However, you do not know what the boiler consists of and how it works. It seems that there is no need to explain that there can always be unforeseen failures in the operation of any device, and in order to at least independently determine their causes, it would not hurt to study the principle of operation of a double-circuit gas boiler designed for heating and supplying hot water to the house.

Official website: where to view all models and operating instructions

A snapshot of the official Vaillant website in Russia.

In Russia, the official website of the manufacturer is located at https://www.vaillant.ru/

By going to the “Equipment” → “Gas boilers” section, you can see all available models and their descriptions. Each model is accompanied by electronic copies of full instructions for use, installation, configuration, technical data sheets and certificates. The manuals for each model describe the characteristics, installation diagram, algorithm for switching on and adjusting the operation, maintenance features, and contain clear schematic images.

How does a double-circuit gas boiler work?

The base of any boiler is the body; it can be round or rectangular. There is a combustion chamber inside, and its outside walls are covered with heat-insulating material. At the bottom there is a gas burner device with an igniter.

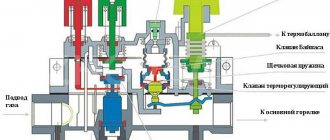

In the upper part there is a main heat exchanger made of cast iron or heat-resistant steel, through which the coolant flows. The secondary heat exchanger for providing hot water is located outside the combustion chamber. An automatic element is installed in front of the burner, which includes a gas valve and a thermostatic regulator with a heating sensor (thermocouple).

A three-way valve is used to distribute coolant flows and admixture in the circuit. The general structure of a double-circuit gas boiler can be considered using the example of a wall-mounted gas unit with an open chamber of the VAILLANT brand, made in Germany.

In addition to the main equipment, high-tech gas boilers are equipped with a circulation pump, a fan for forced air supply and an expansion tank. The most expensive versions have a second expansion tank for hot water or a built-in boiler.

The flame of the gas burner heats the main heat exchanger, in which the coolant circulates using a pump, this is the principle of operation of a gas boiler. The coolant temperature is measured by a sensor and maintained at a certain level by an electronic control unit. It goes like this:

- The coolant circulates in a small circle through the main heat exchanger, three-way valve and pump.

- The temperature sensor detects the heating of water to a certain value and transmits an impulse to the control unit, which sends a command to the electric drive of the three-way valve.

- The three-way valve begins to open the flow of coolant from the outside, from the system, mixing it with the heated water. The more it heats up, the more the valve opens the external flow. Thus, the outlet temperature is always constant.

- When the temperature of all water in the system reaches the set value, the electronic control unit acts on the gas valve and it shuts off the fuel supply, the burner turns off. The flame remains only on the igniter.

- As soon as the coolant cools down, the controller issues a command and opens the gas valve, after which the burner is automatically ignited by the igniter.

Types of heating equipment

Heating equipment can be manufactured in floor or wall-mounted versions. The first type of structures are characterized by large dimensions. They can have a single-circuit or double-circuit device, different configurations and power.

The power of wall-mounted models does not exceed 36 kW. Most often, for heating individual buildings, heating structures with a power of 24 kW are purchased. Exhausted air masses can be removed by forced and natural means. In some cases, gas heating equipment is installed together with a central heating system. This allows you to depend less on the work of utilities and better regulate the indoor microclimate.

Single-circuit devices are marked “VU”. They can only be used for heating. In order to heat the water, you will need to purchase additional equipment. The Vaillant double-circuit wall-mounted gas boiler is marked “VUW”. Such models are used not only for heating air, but also for creating a hot water supply system.

Dual-circuit and single-circuit devices include a liquid crystal display. Its presence greatly simplifies the operation of the heating unit. The automation control system includes temperature sensors.

Single-circuit models

The most common models of single-circuit heating devices are:

- The power of Atmo Tec plus units does not exceed 28 kW. To adjust this parameter, a modulating burner is used. In some cases, the boiler is equipped with a chimney and a water heater. Therefore it can be used to heat water;

- The power range of Turbo Tec plus units is wider. This parameter can reach 36 kW. Such devices can operate in dusty conditions.

Double-circuit gas heaters

Vaillant wall-mounted gas boilers have a reputation for quality heating equipment. Its distinctive characteristics include the following features:

- heating units are manufactured in Germany. The entire model range is characterized by high build quality;

- the devices have a long service life and are easy to maintain;

- devices have different power and different functional purposes;

- heating devices have increased efficiency;

- boilers have a reliable protection system;

- double-circuit design allows you to simultaneously provide your home with heat and hot water;

- heaters can have a condensing or convection design. The former have a more complex structure and increased efficiency.

One of the main disadvantages of Vaillant equipment is its high cost.

Gas boiler automation

In budget boiler configurations, the burner control functions are performed by an automatic gas valve, combined into one unit with a thermostat. A simpler operating principle of the gas boiler thermostat is used, in which the gas valve drive is connected to the thermostat rod. The rod moves under the influence of a thermocouple connected to it by a capillary tube. The movement of the rod is limited by the handle, which is used to set the desired temperature on the boiler.

There are two types of thermocouples. The first uses the principle of an expanding liquid placed in a closed space of a housing. When the thermocouple heats up, the liquid begins to expand and, through the capillary tube, acts on the thermostat rod. Another principle of operation of a thermocouple in gas boilers is based on the following phenomenon: if you heat the junction of two different metals, a small voltage of up to 50 mV appears on the wires soldered to these metals. In this case, the gas valve drive is equipped with an electromagnet, which turns off when the thermocouple cools and shuts off the gas. The diagram of the automatic valve is shown in the figure.

Automatic valve diagram

When igniting using a piezoelectric element, the operating principle of a gas boiler automation is as follows:

- The adjustment wheel is pressed by hand, and gas is supplied to the igniter.

- With the other hand, the piezo ignition button is pressed, a spark jumps from the igniter and it ignites.

- The wheel is held for 10-30 seconds. This is necessary for the thermocouple to heat up and lock the gas valve in the open position.

- The wheel is released and turned to the required position. Gas is supplied to the main burner and it is ignited by the igniter.

- If the gas suddenly turns off, the gas burner and igniter go out. It takes a few seconds for the thermocouple to cool down and release the gas valve drive, which immediately shuts off the gas.

This is the simplest security automation that does not require connection to an electrical outlet. However, it is inertial, that is, for it to operate, it takes time for the thermocouple to heat up or cool down. However, in accordance with regulatory documents, this automation should be installed on every boiler, since it is reliable and does not require electricity. Electronic elements and sensors controlled by a controller are devoid of inertia, but still they can only be used in conjunction with basic automation.

List of first level problems

Let’s first consider what the owner can “fight” on his own, without fear of the product becoming completely unsuitable and voiding the warranty.

The list of situations available for correction includes two options:

- The boiler doesn't work at all. Those. the device does not heat the coolant if it is a single-circuit model, and does not heat either the coolant or sanitary water if it is a double-circuit model.

- The boiler heats sanitary water, but does not heat the coolant. This problem is typical only for dual-circuit units.

Both of these positions have a number of completely removable reasons and several solutions that a prudent owner should familiarize himself with. However, before a detailed study of the situation, you should check whether the boiler is connected to the network at all and whether one of the functions is disabled: heating or DHW.

Image gallery

Photo from

Heating system of a large private house

Safety group with pressure gauge

Display showing operating parameters

Checking taps and connections

Now let’s look at the typical causes and methods for eliminating them in the case when the boiler does not heat at all:

- The gas valve is closed. Both shut-off devices installed by gas workers on the inlet gas pipe must be opened.

- The supply of cold water is cut off. This can be solved by opening the shut-off valve on the water pipe.

- Power supply disruptions. The heating unit will stop operating if there is no power supply. If the electricity supply is restored, the boiler will start itself.

- Temperature set too low. The owner of the boiler corrects an oversight made when making settings by simply switching the unit to the required temperature regime.

- Water pressure drop (F22). The encoding will indicate a lack of pressure in the system for normal operation of the boiler. Its appearance means that you need to bleed the air from the batteries and open the make-up valve located at the bottom of the device.

- Refusal to ignite (F28). If the third attempt to ignite the gas heating equipment does not lead to the desired result, you need to find the fault reset button on the control panel, press it and hold the position for at least a second. Failure again? Call the gas workers.

- Chimney fault (F48). This signal indicates an increase in the temperature of the exhaust flue gases. They could have stagnated and overheated due to a clogged external chimney that needs to be cleaned.

Note that a drop in pressure will also be signaled by the S76 indicator. This code is from the boiler condition monitoring group. However, to restore operation, the same actions will be required as when fixing error F22.

For the sake of his own safety, health and the safety of his household, the boiler owner is obliged to monitor the smoke removal system. Complete removal of gases is necessary, since the products of blue fuel processing are extremely toxic

The second type of violation, determined by the operation of only the hot water supply without heating the coolant, is most often associated with errors made by the technician during the settings. You can change the temperature yourself. The manual supplied with the boiler describes in detail how to perform this operation.

Description of the operation of the DHW circuit

In heating systems with a DHW circuit, there is a secondary water-to-water heat exchanger. Cold tap water passes through its tubes and is heated by the coolant, which washes these tubes from the outside, while the flows move towards each other. To switch flows, the following operating diagram of a double-circuit gas boiler is used:

- In heating mode, the coolant moves from inlet to outlet along the route: circulation pump - main heat exchanger - switching valve - outlet.

- When you open a hot water tap in the house, the flow sensor detects the flow of water through the secondary heat exchanger and sends a signal to the controller.

- The electronic control unit switches the valve and the flow of hot coolant is directed to the secondary heat exchanger, heating the cold tap water.

- After leaving the secondary water heater, the coolant enters the heating supply line. After closing the tap, the valve switches the flows back and the direct movement of the coolant is restored.

Another diagram of the operation of the boiler with the preparation of domestic hot water is shown in the figure.

There is no secondary water heater; instead, the main heat exchanger of a complex design performs the function of heating tap water. For efficient heat transfer, it contains tubes of complex shapes placed in the flowing coolant. Water from the main passes inside the tubes, which is heated by the coolant, and its temperature increases due to the operation of the burner.

Service

I have often come across boilers that, with regular maintenance, have worked for over a decade without causing problems. Therefore, I advise everyone to call a specialist every year before the heating season. Or at least adhere to the following recommendations:

- Before switching to Winter mode, inspect all connections for leaks.

- Every 2-3 years, clean the combustion chamber, heat exchanger and ignition electrodes.

- Every 5 years, the heat exchangers should be cleaned of scale.

General characteristics and principles of operation

To make an intelligent decision on purchasing a certain standard size of such complex household appliances as a gas boiler, you need to focus on the following principles.

- Where the equipment will be installed. The Vaillant brand produces both floor-mounted and wall-mounted units. The former are in great demand because they do not require any special room for installation, are compact and are very easy to use. At the same time, if there is a technical room in individual houses with a significant heated area (more than 300-400 m2), installing floor-standing gas boilers is the best option.

- How is the flue gases generated during operation of the unit supposed to be removed? Where the installation of a special chimney can be carried out at the stage of building a house, it is possible to install a Vaillant gas boiler according to the instructions with natural removal of flue gases due to the difference in density. At the same time, in apartment buildings it is more expedient to install turbocharged, closed boilers, the removal of combustion products from which is carried out forcibly, using a specially mounted fan.

- Ensuring the greatest efficiency. The Vaillant company supplies a fundamentally new line of condensing-type gas boilers, which use so-called modulating burners. The peculiarity of these fuel-burning devices is that they are able to operate under conditions of gas supply varying over a wide range. At the same time, the final thermal power of the unit remains virtually unchanged due to the presence of a plate heat exchanger. Such equipment is installed in low-temperature individual heating systems.

Installation

The dimensions of the room in which the boiler will be located are determined in accordance with SNiP. There are no strict requirements for TurboTEC turbocharged models. The only rule is that the area must be at least 8 square meters. m. A device up to 60 kW can be installed in any room (kitchen, living room) and even built into furniture.

More powerful AtmoTEC atmospheric boilers are best installed in a separate room with good ventilation and air exchange. They are mounted on the outer wall of the building. The floor option requires a non-combustible base. Free access to equipment should be ensured.

Installing a boiler is a complex process (connecting a gas pipeline, heating system, hot water supply, chimney design, automation). Therefore, all work must be carried out by an accredited specialist, who usually performs installation and commissioning, and checks the electronic control.