Pedagogical development

Author:

Prosochkina Natalya Aleksandrovna

Position:

teacher of special disciplines

Educational institution:

Baiknur Electrical and Radio Engineering College

Locality:

Baikonur

Name of material:

Laboratory work

Topic:

“Calculation of heating elements”

Section:

secondary vocational

Calculation of heating elements

General education –

Consolidation of knowledge on the topic “Heating elements”

Developmental —

Development of cognitive activity of students.

Educational

– Test your ability to introspect.

Theoretical information about the calculation of heating elements

The main task when calculating an electric heating device with separate

heaters comes down to the following.

It is required to heat a given amount of material of known heat capacity with a certain

starting temperature to a certain final temperature at a given time. Based

These conditions determine the cross-section and length of the heaters powered by a current of known voltage.

The calculation begins with determining the useful amount of heat, kJ, required for the increase -

changing the temperature of the heated material to a given value without taking into account thermal effects -

), where m is the mass of the heating material, kg; t

- final temperature of the material,

WITH; c is the specific heat capacity of the material.

Table 1. Specific heat capacity of some materials in the temperature range 0-

Source

Electric heating element device

The design of heating elements includes the following components:

- metal tube;

- spiral;

- filler;

- ceramic insulator;

- contact rod.

The spiral is completely sealed in a metal tube and connected to a contact rod, the outer edge of which has the necessary projections for connection with the element that supplies the electric current. This design of heating elements eliminates the possibility of short circuits and ensures uniform distribution of heat over the entire surface of the metal tube.

The insulating filler of the spiral from the heating element tube is periclase, a mineral consisting of magnesium oxide sometimes with admixtures of iron oxide, manganese oxide and zinc oxide.

The metal tube of the heater is made of alloys:

- pure brass (Fig. 1) and copper (Fig. 2). These heating element tube materials are necessarily used with coatings;

- become. The steel can be either stainless (Fig. 3) or carbon (Fig. 4), it depends on the design features and operation of the heating element;

- aluminum (Fig. 5)

It can have different diameters, from 6 to 19 mm. The design of the block heating element can be equipped with a temperature sensor and an overheating fuse.

The choice of metals and their alloys depends on the working environment of the heating element. These can be alkalis and acids, air with low and high concentrations of active gases, various metal surfaces that will come into contact with the heating element, fatty compounds and aqueous solutions.

A conductive fechral or nichrome spiral acts as a heating element. Fechral spiral is an iron alloy with additions of copper, manganese, aluminum, titanium and other metals. The main advantages of a spiral made of fechral or its varieties (eurofechral, superfechral) are low price, high resistivity and heat resistance.

A nichrome spiral is an alloy of nickel and chromium and has the same characteristics as fechral, but the main difference between fechral and nichrome spirals is the specific operating temperature when open: a fechral spiral can withstand maximum heating up to +1400 °C, and nichrome spirals up to 1200 °C.

The contact rod can have a cartridge or single-end shape. Depending on the area of operation, air, water or oil heating elements are often distinguished. Heating elements that are used in various gaseous spheres are also classified as air.

Introduction

With the onset of golden autumn, when utility workers have not yet woken up, the temperature in our apartments sometimes drops to indecent levels. In such an extremely unpleasant situation, it is necessary to act somehow. Which home heater is the most economical and inexpensive?

But what to do if electricity bills are getting higher every year, as are prices in stores, how can you escape from this terrible cold? The only option left is to choose the most economical, inexpensive, efficient heater with the highest efficiency, and we will try to help you in this matter.

EFFICIENCY COEFFICIENT (Efficiency)

Gas stove

For a standard gas stove, the maximum burning power of the burner is 2 kW. The efficiency of such a burner is only 50 - 60%. When a burner is lit, a significant portion of the power is spent on heating the air in the kitchen, then heating the pan, and only then begins to heat the liquid in the tank, but without ceasing to waste energy on heating your kitchen.

Electric stove

For an electric stove, the maximum burner of 20 centimeters has a power of 2 kW. The efficiency of an electric stove with a glass-ceramic coating is ± 50%, the efficiency of classic electric stoves is 30 - 40%. When you turn on the electric burner, for some time all the power is spent on heating the heating element of the stove itself, then part of the power is also spent on heating the air in the kitchen, then heating the pan, and only then it begins to heat the liquid in the tank.

Electric induction cooker

Everything is much better here; the tested electric induction cooker has a maximum heating power of the burner of the same 2 kW. The efficiency of such a burner is ± 90%. When you turn on the induction cooker, an electromagnetic field is formed in the burner, which, in turn, creates eddy currents in special cookware made of ferromagnetic materials. The bottom of moonshine stills is made of ferromagnetic stainless steel AISI 430. Accordingly, all the power of the stove goes only to heating the bottom of the tank itself, and the bottom itself begins to heat the liquid in the tank. At the same time, the stove burner remains cold, and the energy of the stove is not wasted on heating the air in the kitchen.

Ten

As I said at the beginning, almost all manufacturers of modern moonshine stills produce devices with a flange for connecting a heating element. Well, or this useful option (weld a flange on the tank) can be ordered in stores selling moonshine stills.

For a comparable comparison, let’s take a heating element with a power of 2 kW. The efficiency of operation on heating elements is 99%. Everything is as good as possible here. Heating elements do not heat the air in the kitchen, they do not waste energy heating the dishes, all the energy supplied to the heating element heats it in a matter of seconds, the heating element gives off the energy immediately and all directly to the liquid in the tank.

Types of heaters

Today on the market there are a great variety of different electric heating systems, from simple small heaters to complex systems of heated floors, walls or ceilings with remote control coupled with smart home systems, but all of them can be divided into just a few types:

- Electric (fan heaters)

- Electric fireplaces

- Oil radiators

- Convectors or convection heaters

- Quartz panels

- Infrared. They differ by type of heating element: halogen, carbon, quartz, micathermic (best efficiency)

OPERATION SAFETY DURING DISTILLATION

This is where the biggest pros and cons start.

The technological process of moonshine distillation itself (FIRE HAZARDOUS, EXPLOSIVE)

Let's consider the following situations:

You put the moonshine still with mash on the stove, connected the water to the device for condensing the moonshine, turned on the stove at full power, the mash heated up to operating temperature and now the moonshine dripped into the jar. The distillation process is not fast, you begin to be distracted by other things. And here anything can happen: the water was turned off, the water supply hose burst, the mother-in-law walked by and accidentally pulled the hose out of the tap (by the way, the situation with the mother-in-law is real, from my experience) and what happens next. No water flows into the refrigerator of the moonshine still, condensation of the moonshine does not occur, and sharp alcohol vapors begin to whistle out of the spout instead of moonshine. They fill the kitchen, the concentration of alcohol vapor becomes critical, and your GAS is on and the flame is burning. You yourself understand what happens next.

Or such a situation, moonshine fills a jar, you wanted to measure the alcohol content of the moonshine coming out, or your wife came into the kitchen, a child ran in, a dog ran in and one awkward move and your jar of moonshine falls on the table, splashes fly around the kitchen, fall on the stove where the gas is burning, and the alcohol content of moonshine even from the simplest moonshine still is 60°, such an alcohol-containing liquid burns very well (like gasoline), you yourself understand what happens next.

Now let's return to the issue of job security. Here it essentially comes down to two questions: what type of energy, open fire or electricity, and does the burner heat up or not? During distillation, the tank of the moonshine still, due to the liquid inside, will not heat up to more than 100 C°, but the electric burner heats up to 300 C°, and if all the liquid has boiled away from the tank, it can heat up to 500 C°, which is also moderately dangerous.

Gas stove DANGER! (Open fire)

Electric stove is MODERATELY DANGEROUS! (The burner gets very hot up to 300-500 C°)

Electric induction cooker is SAFE! (Stove is cold)

TEN SAFE! (The heating element is located inside the tank with liquid)

Principle of operation

First, you need to remember the principle of operation of heaters. Fan heaters are considered the simplest devices; heating occurs due to the distribution of hot air by a fan through an incandescent lamp; the efficiency is quite low.

The principle of electric fireplaces is similar to fan heaters; as a rule, such devices are stationary and have rather a decorative component; the efficiency of such devices is at an average level.

In oil radiators, heat is distributed by heating the oil inside the heater using heating elements. Heating takes quite a long time, but cooling is noticeably slower. Due to the smooth heating of the oil inside the radiator grille, such batteries cannot be called economical, and later you will find out why, the efficiency is low. Even in some European countries they are assigned class C for energy efficiency.

Convectors operate on the principle of convection by circulating air inside the room through the heater. Heavy cold air falls down, is captured by the convector, heats up and rises, and as it rises it displaces the cold air. The efficiency of such devices is quite high.

Quartz panels are an electric heating element enclosed between artificial stone panels; the efficiency is average. First, energy is expended on heating the plates and further slow heat transfer occurs from these plates.

How to increase the efficiency of a heater

In order to increase the efficiency of the heater, various technologies are used in production.

In oil heaters, higher efficiency can be achieved due to the larger surface of the device itself. Thus, a larger volume of air masses comes into contact with the heated body, which slightly increases the rate of heating of the room.

Operating principles of various heaters

IR heaters and fan heaters focus their work on a specific area of the room. This type of zone heating allows you to provide heat only where it is needed.

Convectors increase productivity due to the special design of the device itself and its heating element.

Efficiency of the main types of home heaters

Everyone knows what efficiency is, this is the difference between the energy expended and the energy produced. When calculating the coefficient, we tried to provide the most detailed answer in tabular form . Since, in addition to the energy component, there are also financial costs for the purchase of the device itself, electricity costs, the calculation is made taking into account these factors.

The table shows the average values obtained from tests of various types of heaters (thanks to one well-known store for providing testing equipment). The cost for 1 kW of energy is 4 rubles. Heating took place for 1 hour in a furnished room of 18 square meters with an initial temperature of 22 degrees C. Heater power 1500 W. Control type – electronic.

| View | Average price, r | Declared maximum power, W | Temperature change over 1 hour, gr. WITH | KW consumed according to the meter | Cost of consumed electricity, p |

| Fan heater | 1250 | 1500 | +3,9 | 1,69 | 6,76 |

| Oil | 3200 | 1500 | +5,1 | 1,74 | 6,96 |

| Convector | 3540 | 1500 | +6,2 | 1,52 | 6,08 |

| Infrared | 3580 | 1500 | +6,1 | 1,22 | 4,88 |

| Micathermic | 7800 | 1500 | +7,0 | 1,24 | 4,96 |

The obtained figures are approximate, since many important factors influencing the result are not taken into account, such as: a single brand of the manufacturer, humidity in the room, the model of the heater itself, direction, voltage in the electrical circuit, etc.

But nevertheless, the figures turned out to be the following; the highest efficiency was obtained from convectors, infrared, and micathermic heaters. The fan heater was barely able to heat the room by 4 degrees.

The oil radiator heated the room quite well; after the end of the experiment, the room continued to heat up and remained heated longer than others, so it should not be written off due to high power consumption.

In addition to the electronic type of control, there are also mechanical (outdated) and inverter (the most modern and economical). If we compare the electricity consumption of similar heaters with different control modules, the following figures come out:

mechanical - 0% savings, the electronic unit allows you to save 30% in contrast to the mechanical one, the inverter control unit is the most economical, this method of thermoregulation allows you to save up to 80% of electricity compared to mechanical regulators.

The cost of heaters with inverter units can vary from 8,000 to 30,000 rubles. In the long term, as a rule, such costs pay off. More details in the video:

Method for calculating the heating element heater spiral

The easiest way to calculate a spiral is using a table of current loads. If this method cannot be used for some reason, then you should refer to the formula for the permissible specific power, which is the ratio of the heating power of the coil in W to the surface area of the coil. The calculation is performed depending on the temperature of the heater surface and the rate of heat removal from it.

In most cases, the power of the heating element coil is set by manufacturers in the range from 0.01 to 12 kW. The maximum possible power is selected depending on the following indicators:

- heating element shell diameter

- shell material heating element

- operating environment

- expanded length of the heating element tube

- heating part length

Violations of the specific power of the heating element

In order for the heating element to operate within the operating parameters, it is necessary that the power density meets acceptable standards. A significant excess or reduction in power density can lead to malfunctions of the element. If, when the power is reduced, the heating element cannot provide the necessary heat transfer, then in the event of a significant increase in power, it may burn out and will need to be replaced.

The best inexpensive, economical heaters according to experts, TOP-15

When choosing a heater, it is often difficult to understand just by looking at it in a store whether it is good or not, and testing for functionality is also not enough. Before going to the store, it is important to know exactly which of the heaters will actually cope with its task, and which one should not be considered. For this purpose, we have compiled a rating of the best and inexpensive heaters, suitable for a home, cottage or apartment, for a room of 20 square meters, with a power of 1000 to 2000 W. This rating is based on expert opinion and experience of use by other users. When choosing, also pay additional attention to reviews from other users and the cost in retail stores.

Electric (fan heaters)

Electrolux EFH/S-1115 1500 W (1100 – 4000 RUR)

Zanussi ZFH/C-408 1500 W (1450 – 4000 RUR)

Ballu BFH/C-31 1500 W (790 – 3600 RUR)

Oil radiators

Ballu Classic BOH/CL-09 2000 W (2800 – 3300 RUR)

Electrolux EOH/M-6209 2000 W (3600 – 4900 RUR)

Timberk TOR 21.1507 BC/BCL 1500 W (3400 – 3950 RUR)

Convectors or convection heaters

Ballu Enzo BEC/EZER-1500 1500 W (4230 – 4560 RUR)

Electrolux ECH/AG2-1500 T 1500 W (3580 – 3950 RUR)

REFERENCE: the time it takes to reach operating temperature depends on the alcohol content of the mash

Gas stove

If the tank volume of your moonshine still is 20 liters, the power of the burner is 2 kW. when filling the tank 16 - 17 liters. mash, then to an operating temperature of 80 C° (when the first drops of moonshine are dripped in), the device will come out in ± 55 minutes, and the entire distillation process will take ± 2 hours

Electric stove

I won’t go into too much detail about the time it takes to distill mash on an electric stove. The performance is approximately the same as that of a gas stove, only slightly worse.

Electric induction cooker

Distillation time on an induction cooker is reduced due to higher efficiency. When filling the tank 16 - 17 liters. mash, the apparatus will reach an operating temperature of 80 C° in ± 40 minutes, and the entire process of distilling mash will take ± 1 hour 40 minutes.

Ten

Thanks to the highest efficiency, from 16 - 17l. mash, apparatus with heating element 2 kW. it will reach an operating temperature of 80 C° in ± 30 minutes, and the entire distillation process will take ± 1 hour 30 minutes.

Warm floor or heater, which is better and more economical? Video

Many people wonder what is better: an energy-saving heater or a heated floor system; this topic is especially relevant for owners of private houses or residents of the first floors of multi-story buildings.

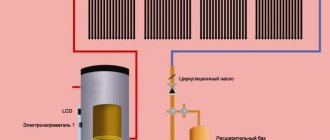

So, what is a heated floor ? It is a heating system that heats a room from bottom to top, from floor to ceiling. Electric panels (mats, films, amorphous tapes) or hydraulic systems are used as heaters; accordingly, the heating principle is also different, infrared and convection. The system is mounted under various floor coverings, tiles, laminate, linoleum, PVC tiles, concrete.

Like all heaters, heated floors have their advantages and disadvantages, which you should pay attention to in order to understand what is best for the room. If we compare it with convection, the heat from the radiator rises up, cools down at the ceiling and falls down, and so on in a circle, therefore, in the upper part of the room it is much warmer than in the lower part, and in order to increase the heat in the area of the feet, it is necessary to increase the power of the radiator.

Unlike radiators, heated floors distribute heat over a larger area of the room evenly on the lower surface, thanks to this arrangement, savings on coolant costs , the feeling of warmth in the house increases by an average of 2 - 3 degrees C, and energy savings reach 15-20% compared to radiators. in more detail .

The disadvantages of heated floors include a long heating and cooling period. As the outside temperature changes, the indoor temperature does not always have time to change quickly. In order to install heated floors, it is necessary to rebuild the floor covering or provide for it in advance when renovating or building a house.

So which is more economical? When choosing heaters, you should definitely pay attention to the underfloor heating system. The best use case is combined heating systems, heated floors where needed in conjunction with radiators.

In case of a long period of low temperatures outside the window, the use of heated floors is certainly more profitable than wall heaters and will, over time, pay for the costs of installation and screeding. During short-term cold snaps, a local expensive or cheap heater is better suited.

Advantages and disadvantages of heating elements

The popularity of electric heating elements of this type is due to their high reliability, variety of shapes, long service life, and the ability to work in a wide variety of conditions, both in household and industrial devices and installations.

- versatility - heating elements are used in almost all areas of industrial and national economy;

- wide choice of operating environments - due to a fairly significant range of operating temperatures, the upper limit of which can reach 650 degrees Celsius, heating elements can be used in infrared, conductive and convection heating installations;

- reliability - the design of heating elements, tested for more than a century, was brought by trial and error to the optimal proportions and parameters of alloys, sizes, ratios of all elements;

- service safety;

- low explosion hazard;

- are not afraid of vibrations, shocks, temperature and pressure changes;

- availability and wide range.

Flaws:

- when using alloys of nickel, copper, and other expensive metals as the material for the spiral and tube, the price of the heating element increases;

- impossibility of repair in case of failure. The operating principle of an electric heating element implies that after serious breakdowns, the structure is easier to replace than to repair;

- tendency to form plaque

- limited service life.