Diffuser for ventilation

For more efficient ventilation in the room, the supply air should not flow in a stream, but should be evenly distributed throughout the entire space of the room.

After all, when the air flows in one stream, drafts are created, and they negatively affect people’s health. In addition, with a jet air flow, only a certain part of the room is ventilated. Therefore, in order to ventilate the space as efficiently as possible, ventilation diffusers are installed. Ventilation diffuser - what is it? This is part of the ventilation system, the purpose of which is to disperse input/output air flows throughout the room.

What does the deflector consist of and what tasks does it perform?

The effective operation of the ventilation system is primarily influenced by the strength of the wind, its direction, and air temperature. For example, in summer it is very hot outside, and due to the fact that the air heats up, draft decreases and, accordingly, air circulation decreases. To reduce the impact of such negative impacts, devices such as deflectors are installed. The use of structures is considered mandatory when organizing a chimney, because the deflector is, first of all, a device that normalizes the operation of the ventilation system.

A dome, ball or other structure that is installed on the roof and acts as a deflector.

On a note! To understand what a deflector is, you should refer to the images of ventilation pipe outlets.

It is the dome, ball or any other structure located on the roof that is the deflector. The main task of the device is to ensure normal ventilation of various types of premises by using wind loads. By and large, the deflector is a fairly simple device, which was previously used only when equipping chimneys, but is now the crown of the ventilation system. However, one should not think that the only role of the device is protective.

Chimney cap: how to choose a chimney cap for a chimney pipe (read more)

In essence, deflectors are aerodynamic devices that reduce the negative impact of weather factors on ventilation operation. Functioning occurs according to the principle of the Bernoulli effect. The main task of ventilation deflectors is to provide better draft within the system by regulating the air flow.

That is why the devices are installed at the highest point of the pipe. You can see the fixtures on most garages, which are topped with pipes coming out of basements or basements. In addition, deflectors are located almost everywhere on the roofs of houses.

The main task of deflectors is to provide better draft inside the ventilation system.

What is a diffuser?

A diffuser for a ventilation system is a device that has the shape of a lattice on the outside. The purpose of this unit is to uniformly distribute the incoming and outgoing air masses of the room. There are three types of devices that help dissipate air flows:

Diffusers in air conditioning

The purpose of such devices is to uniformly distribute air flows from an air conditioner or fan through air ducts into the room.

Difference between diffuser and vent grille

The difference between these devices is only in the design and intensity of air movement.

During the calculation and design of air flow dispersion equipment, air circulation is taken into account. Therefore, the arrangement of the blades and partitions of the structure is carried out so that the air flows are mixed as efficiently as possible and evenly distributed throughout the space of the room.

A diffuser, like ventilation grilles, promotes a more intense flow of air to the air ducts from the air conditioner, but does so in a slower and smoother manner.

Application and principle of operation of a diffuser for ventilation

The air distributor can be used for ventilation systems for premises of any purpose - residential buildings, offices, production facilities. With these devices you can:

Eliminate drafts

Drafts have a negative impact on people's health. People with weak immune systems are especially susceptible to their influence. They arise as a result of the fact that air mass flows form a single stream. This phenomenon is eliminated by the supply air distributor. It promotes divergence and dispersion of air flow.

Effective ventilation

If the ventilation system does not have units that can be used to disperse the flow of air masses, only the area of the room in which the air circulates is ventilated, since the air flow is carried out using the jet method. When ventilating using an air diffuser, the jet air flow is evenly dispersed throughout the entire space of the room. Dispersion is mainly carried out according to the vortex principle. And ventilation deflectors help reduce the intensity of air movement through a flexible air duct, or speed up the movement of air masses entering the exhaust system.

Modernize the exhaust system

To modernize the exhaust system, outflow (exhaust) diffusers are used. They are installed in the ventilation system. Without an air distributor, although the exhaust structure discharges the air masses, jets of air flows are still formed. This factor negatively affects the atmosphere of the room. Plus, the volume of exhaust air entering the exhaust opening directly depends on changes in the direction of its flow - the greater the change, the lower the throughput. Using an air diffuser this problem can be solved.

Control air flow

You can control the inflow/outflow of air flow using a diffuser using a specially configured control panel. In this way, you can provide additional comfort and prevent the formation of drafts or poor ventilation. Another advantage of this device is sound insulation. Using this unit, you can eliminate the noise of air flows “walking” around the room.

Classification

Types of diffusers for ventilation

The ventilation equipment market has a fairly wide range of diffusers. They are divided into several types according to the following characteristics:

According to case material

Plastic diffusers for ventilation.

Such devices are made of plastic and are resistant to corrosion and rotting processes. These air diffusers are very lightweight and come in different shapes and colors.

Metal diffusers for ventilation

Such air distributors are made of aluminum or steel. The advantage of these products is their high strength. They are reliable in operation and have an optimal design. Metal diffusers are much heavier than plastic ones. Also, sometimes problems with their installation may arise.

Do not confuse a metal supply anemostat and a diffuser. Unlike a diffuser, using an anemostat you can control the volume of circulating air flows (this is not possible with diffusers). Also, the body of the device is made only in a round shape, and the diffuser can have various shapes (both round and rectangular).

The price of the device depends on the material from which the diffuser body is made. Steel fixtures are much more expensive than plastic ones.

By shape

Round (swirl) diffusers for ventilation

Such models are divided into:

Slot diffusers for ventilation

The boxes for installing such devices are very compact and almost invisible on the surface. Due to their shape, they allow you to adjust the direction and angle of air flow.

Installation of such units will not require much effort. It is done using brackets.

By purpose

Supply diffusers

Devices for supply ventilation are designed to draw and quickly deliver a flow of fresh air masses from the outside into the room or ventilation unit and their uniform distribution.

Exhaust diffusers

They are used for prompt removal of exhaust air from the premises. At the same time, they promote uniform distribution of air throughout the room and ventilation of its maximum area.

Universal (supply and exhaust) diffusers

Such units are used for the influx and outflow of air into the room, as well as for circulation through the ventilation system.

Nozzle diffusers

Such units are used to create jet air streams of narrow direction.

At the installation location

Ceiling diffusers for ventilation

Since the mixing of air flows in the room is carried out at the top (under the ceiling), such air distributors are very common in operation - 95%. They are used for both supply and exhaust ventilation systems.

Floor diffusers for ventilation

This type of device is used for rooms in which supply ventilation is carried out through the basement.

Wall diffusers for ventilation

Such diffusers for ventilation are quite rare in operation, since ventilation grilles are mainly used for walls.

Basically, such units are installed when it is necessary to install ventilation through a hole in the wall.

Design features

Vortex

The external design of such distributors for air flows consists of partitions and grilles, which are located in such a way as to create turbulence in the air masses. This allows you to speed up the movement of air masses and increase the efficiency of such a system.

Often in swirl diffusers the placement of jumpers is radial. They are used in rooms with large areas and high ceilings. Also, such units are well suited for rooms that require rapid air change (bathroom, toilet, etc.).

From the inside, such a unit has the shape of a cylinder. The grille for it can be of various shapes. In this case, its holes should be located only around the circumference.

Vortex air mass distributors for the supply ventilation system have an additional impeller. It is located behind bars, in the device body. This part can be movable or stationary, controlled or uncontrolled. The controlled impeller can have several operating speeds.

Swirl diffusers can have a static pressure chamber. With its help, too active movement of air flows is eliminated, thus preventing the occurrence of drafts.

Slotted

The shape of such diffusers resembles slits. Since the distribution of air mass flows directly depends on the position of the partitions, their shape, size and direction, the design of such units is specially developed and calculated.

Such devices are used for rooms in which the ventilation system has low or medium performance.

Slot devices for dispersing air flows can be adjustable and change the direction of the supplied air masses (similar to air conditioner blinds). Such diffusers may contain a static pressure chamber.

The design of slot diffusers and grilles for them can be of various shapes.

Adjustable

These ventilation diffusers are equipped with adjustable sliding plates. This is a regulatory element of the design, through which the throughput of the device is controlled.

Such devices are called anemostats. The flow of air masses is regulated by moving the central part of the unit clockwise or counterclockwise. The slats in the device are movably fixed. This allows them to change position and open or close the gap to generate air masses.

There are anemostats equipped with presence sensors and air mass composition analyzers. Such units are connected to the room climate control system. This system operates automatically. Its task is to maintain a given room microclimate.

What are turbo deflectors and weather vanes?

The designs can be safely combined into one group, because they are not only similar to each other, but also have a similar operating principle. If we look at the drawings of turbo deflectors, we can pay attention to the fact that a distinctive feature of the devices is the spherical shape of the rotary devices with blades in the form of semicircles that rotate under the influence of wind force. In this case, rarefied air, which increases the efficiency of the hood, is formed inside the sphere above the head of the pipe.

The productivity of the weather vane is ensured by the fact that the blades of the device always turn their backs to the wind, thereby preventing air flows from entering the channel. A low-pressure zone, the so-called aerodynamic shadow, is formed behind the structure’s body, facilitating the rapid removal of polluted air from the vertical channel.

Among the advantages of the ventilation turbo deflector are:

- protection of the ventilation duct from overheating in the summer, which reduces the cost of cooling the room on hot days;

- preventing the formation of condensation under the roof by regulating the temperature in hot weather;

- no need to connect the device to the electrical network;

- ensuring efficient operation, because the productivity of the turboreflector is in some cases 200% higher than that of static models.

The main advantage of the turbo deflector is that there is no need to connect the device to the electrical network.

In addition, we can separately note the fact that the nozzle has an attractive appearance. Unlike other models, the device looks like an elegant spherical cap. After installing the deflector, excess heat, moisture, minor contaminants and carbon monoxide vapor are independently drawn out of the shaft and under-roof space. This increases the service life of important structural elements of the building.

Before purchasing a ventilation turbo deflector, you should familiarize yourself with the main negative aspects of the device:

- if there is no wind outside, the blades of the structure will not rotate and, accordingly, traction will not improve;

- the deflector rotation units require constant maintenance, at least regular lubrication;

- if you do not notice in time, complete or partial freezing of the nozzle is possible;

- design features do not allow the device to reliably protect ventilation from precipitation, especially on windy days;

- in strong winds, there is a possibility that a jammed weather vane will lose its integrity.

Relative disadvantages include the fact that the price of dynamic type deflectors is higher than the cost of static models. For example, the cost of umbrellas and deflectors for ventilation systems 5.904 51 does not exceed $20-30, while turbo-reflectors can be purchased for at least $35-40, and the equipment requires constant maintenance.

The productivity of the weather vane is ensured by the blades, which always turn the device “back” to the wind.

DIY diffuser installation

To avoid any problems during the installation of equipment, you need to prepare the hole for installation in advance. The opening must match the size and shape of the fixture.

The components for mounting the diffuser are always supplied with special fixing latches. With their help, the unit can be installed both in a flexible air duct and in a rigid duct.

Installing a diffuser in a hard channel

Installing a diffuser in a soft channel

Installing a diffuser in ductless exhaust ventilation (hole in the wall)

If the diffuser components do not include latches for fastening, they can be replaced with glue, anchors, sealant or self-tapping screws.

Source

Deflectors for ventilation: types, principle of operation, calculation of the required quantity and power

Since Soviet times, ventilation of a residential building or apartment has been ensured by insufficient tightness of building structures - the same chill from “breathing” wooden windows. But today, construction technologies have reached another level, in which random cracks are not provided. And therefore, the internal microclimate of apartments and houses began to be treated differently, for which today deflectors for ventilation are actively used - special devices that ensure an uninterrupted flow of fresh air.

We invite you to consider the most popular designs, their advantages, disadvantages and application features. This will help you choose the most suitable option that will ideally suit the characteristics of your area and the available area of the house. Fresh air is very important!

When is natural ventilation not enough?

Let's delve a little deeper into the question and define some concepts: natural ventilation is provided by open windows or hatches, but we will talk about forced ventilation. For this, the concept of traction is used. That is, something must pull air out of the house and bring in fresh air.

This is truly vital. After all, unfortunately, the pursuit of durable and practical finishing leads to the fact that housing turns into something similar to a “plastic cocoon”. Even furniture can sometimes be toxic to humans.

Be honest: do you always require environmental certificates from the selling company? And vinyl wallpaper and plastic interior elements gradually introduce unsafe chemical compounds into the room air. Yes, little by little, but in the aggregate and over time it has an adverse effect.

But how is this allowed? The thing is that the environmental safety of a particular thing or repair material is always assessed only from the point of view of how much harm it alone can cause. But in the CIS countries the accumulative moment is not taken into account. That, for example, in addition to a suspended ceiling, such a room may well also have linoleum laid, and the walls painted with paint without the Eco prefix. Sometimes it gets to the point where, with the help of special meters, it becomes clear that the air in the house is much more polluted than on the side of the open highway.

What to do then? The only normal way out of this situation is high-quality internal ventilation of the house. It is the active air exchange in the house that will create comfortable living conditions in it. And for this purpose it is not at all necessary to install a complex ventilation system connected to electricity. A well-chosen deflector that skillfully uses the free power of the wind will be enough:

If you want to understand the issue of ventilation even deeper, watch this entertaining episode:

By the way, for industrial facilities, ventilation deflectors are generally an irreplaceable thing, because this is the only way to get rid of unpleasant odors in poultry houses, stables or places where food supplies are stored for animals. In addition, fresh air with the required humidity is needed to create certain conditions for keeping animals and birds.

Advantages and disadvantages

To increase draft, an electric fan is additionally installed in the ventilation duct.

A ventilation deflector to increase draft effectively protects the ventilation system from dirt and precipitation. If the deflector was calculated correctly, the ventilation efficiency increases by 20%.

If there are weak winds in the area, it is best to install a device on the system to enhance the exhaust and inflow of air. In this case, the effect of thrust overturning will be completely eliminated.

The device has a number of disadvantages:

- If the wind direction is vertical, the flow will come into contact with the top of the structure. This will result in the air not being able to be properly vented outside.

- In winter, ice forms on the base of the pipe. To avoid problems with the functioning of ventilation, you need to regularly arrange preventive examinations.

To combat the first disadvantage, designs were invented that are equipped with two cones.

Operating principle of ventilation deflectors

Let's move on. A deflector is a special round cylindrical cap for a ventilation or chimney pipe. It is usually made of aluminum or galvanized or stainless steel; occasionally there are also copper deflectors. By the way, you can even find plastic structures on the market, which are especially convenient to match the color of the roofing. True, they cannot boast of durability.

But how is a deflector different from a regular umbrella? This one, in all its modifications, is always static, does not spin or turn, and its main task is to protect the pipe from precipitation and birds. But the deflector already takes an active part in organizing the air flow, namely creating thrust.

And in most models without electricity! It's all about the special design of the deflectors, which use the force of the wind to their advantage, rarefy the air and, thanks to the laws of physics, create a pressure difference. In this case, fresh air enters the house or apartment and exits through a deflector like this.

This is where the so-called Bernoulli effect comes into play. Its essence is that air flows create reduced pressure in the process of bending around an obstacle, and this increases draft in the ventilation duct itself. This process is ensured by an internal cone in a special shape. This is why a real deflector is always cylindrical:

By the way, if you think that the shape and dimensions of the deflector are designed based on design considerations, then you are very mistaken. In fact, to manufacture one type or another, quite complex aerodynamic calculations are carried out and experiments are carried out. Therefore, all popular species were developed by searching for those ideal proportions.

And such an element decorates the roof of the house in its own way.

How to assemble a turbo deflector yourself?

Turbo deflectors themselves today are relatively inexpensive when compared with other roofing elements. And during operation they do not require any additional costs.

But, if you still want to craft and make such a product with your own hands, we will tell you in detail and show you in practice how to do it.

Step 1. Design and drawing

If we are talking about an ordinary country house, then a turbo deflector with a standard diameter of 315 mm is quite suitable for you. This can serve a house with an area of 80 square meters.

But it’s better to focus on these numbers:

- for ventilation of small rooms such as a basement, garage or room, a turbine with a base diameter of 110-116 mm will be sufficient;

- if the room has an area of more than 40 square meters, then make the base with dimensions from 200 to 600 mm. The same applies to a room in which up to four people are constantly present;

- if you need to provide fresh air to a warehouse or even an entire farm, then you need a turbo deflector with a base from 400 to 680 mm;

- but for ventilation of the under-roof space, a 315 mm turbo deflector is ideal, because it is designed to ventilate 50-80 square meters of roof. Just keep in mind: the smaller the angle, the larger the turbo deflector will have to be installed;

- in rooms where air pollution is high, a turbo deflector cannot be used as the only means (although it is effective).

In total, the outer dimensions of the deflector itself will be equal to the diameter of the pipe plus from 80 to 120 mm. And in order to make your own product, it is better to take as a basis a drawing from an industrial turbo deflector:

But it is also important to understand how exactly the durability of such a device is ensured. Thus, the industrial model uses special bearings that can withstand significant temperature changes from -50 to +50. Whether it will be possible to install them at home is another question, of course.

Step 2. Selecting materials

For each element of the turbo deflector, manufacturers carefully select the material according to certain technical requirements, which are calculated depending on the loads.

For example, for all external elements, special grades of aluminum alloy are used, always electropolished, or, at a minimum, galvanized or laminated sheet metal, or stainless steel. Stainless steel, of course, is better because it has a certain property of self-healing, in which a special film of chromium oxide helps it:

The main requirement for the materials themselves is to provide the deflector with strength, wear resistance and durability. After all, remember that such roofing elements always work in conditions of high humidity, under pressure from wind and rain.

That is why all working parts of the turbo deflector are made either of metal painted in a special way, or galvanized or stainless steel. But, if galvanized metal is used, it is important to carefully check all products for scratches, which will not turn into rust in the future.

It is extremely important that the internal elements do not rust over time. Therefore, usually when making a turbo deflector yourself, its central axis is made of durable stainless steel, but the vertical supports and radial elements are made of aluminum in order to significantly reduce the weight of the structure.

Remember also that complex assembly jigs and even laser cutting are used to produce industrial models. The entire production line takes up a lot of space in the workshop, so try to make a high-quality deflector, but do not demand much from it in the end, especially in terms of durability.

But for this homemade deflector they used the most unusual materials:

Indeed, quite often when making a turbo deflector yourself, plastic is used as a cheaper material.

The only thing is that in severe frosts, ice can form on the inner walls of the cylinder, which impedes its movement. But since you are already doing everything yourself, you can play with the shape of the deflector. After all, even on sale they are found not only in spherical shapes, but also in conical and cylindrical shapes.

Step 3: Making individual parts

Next, you will need to cut out all the elements of the future design from a metal sheet using metal scissors, a jigsaw or a chisel. Process them using an electric sharpener or a file.

Here are careful measurements of a standard industrial turbo deflector to guide you:

The next step is to use a lathe to turn the top fairing using the same technology used to make table bowls. At the same time, make sure that there are minimal gaps where air passage is not desirable.

Important note: be sure to make the upper disk a little larger in diameter than the pipe.

Popular types of ventilation deflectors

The modern market provides several types of aerodynamic deflectors for ventilation. And each of the designs used today is designed for its own tasks, which we will consider.

So, all deflectors are divided into the following main types according to their operating principle:

Also, all chimney deflectors are divided into two groups: rotary turbines and static structures. Only a rotating deflector, or in other words a turbo deflector, is classified as rotating. The rest are static.

Weather vane deflector: resisting the wind

Such a deflector is valuable when the ventilation duct usually lacks draft or air vortices often occur, and also if the winds in your area are quite strong and like to change direction. This is what the weather vane design looks like:

The most common deflector attachment is called a dragon. This is exactly what you see in the illustration above. This is a pipe cap with its own unique bearing system, which rotates only in the desired direction. Here the air jets enter the space between the bent canopies, change their vector and go upward. This creates the necessary rarefaction of air in the chimney, due to which draft occurs.

A structure called the “Hood” or “Net” also performs the function of a deflector. This is a semicircular wind catcher trough, which is installed inside the channel on a rotating rod.

But the weather vane has a small problem - in winter it can freeze. Therefore, the bearings in it must be constantly lubricated. That is why weather vanes are more justified in warm southern regions where winters are less severe.

TsAGI deflector: a finely thought out mechanism

The TsAGI deflector is a unique development of the Zhukovsky Institute. Its operating principle is that draft increases not only due to the pressure drop at a height of two meters from the roof, but also due to air and thermal pressure. Moreover, such a deflector is allowed to be installed directly into the ventilation duct in a hidden way.

The wide side of the diffuser is directed upward, and the cover is made in the shape of a cone. Basically, such a deflector is designed for air vents with a cross-section from 10 to 125 cm, and they come in a variety of sizes.

Look how complex the design really is here:

The main advantage of the TsAGI deflector is that it blocks reverse draft even in strong winds.

Grigorovich deflector: as simple as shelling pears

The simplest design is Grigorovich. In this device, the cone expands downward, and a reverse cone is arranged under the hood to create additional air flow. It looks like a plate of two umbrellas, which is located above the flowing wall.

In this model, air does not accumulate under the hood at all, which has a good effect on the properties of this roofing element. Moreover, home craftsmen like to rivet such a deflector themselves:

It is also called the Volperg-Grigorovich deflector.

Exhaust deflectors for complex systems

But deflectors of this type already operate on electricity:

Typically, ventilation, which is based on electricity, is not a simple pipe in the house, but rather a whole complex of devices that not only purifies the air, but also heats it. And so that the air can change, a special aerodynamic mechanism is installed at the top point of the ventilation pipe.

Turbo deflector: aesthetics and practicality - at their best!

The turbo deflector also does not require the installation of additional equipment or electrical energy.

Let's take a closer look at how exactly this roofing element works. So, it has a moving part - an impeller. It will always move in only one direction, no matter which way the wind is blowing. This will create a vacuum in the pipe, affecting air entrapment. Thanks to movement along only one axis, there will be no backdraft in the room. In addition, due to the special shape of the cap, sediment or debris is excluded from the pipe.

A turbo deflector for the ventilation pipe is also used for gas boilers with electric ignition. The turbine itself can rotate either under the influence of wind or with supply current. But most often, a self-spinning turbine is found, for which a light breeze is enough.

And now about the shortcomings. This device is more expensive than conventional models. Its price is mainly influenced by the material used - whether it is galvanized steel or whether there is a polymer coating. Also, some unfavorable conditions can lead to its stop, be it complete calm or high humidity combined with negative temperatures. Of course, manufacturers are working on this, and modern turbo deflectors are becoming less susceptible to icing.

Khanzhenkov deflector

This unusual design is a raincoat plate that acts as an exhaust umbrella, immersed at the required distance inside the circumferential wall.

Low pressure deflectors

And finally, low-pressure deflectors Vilpe and Alipai are gaining popularity today, which until now were installed mainly only in attics. And today they cope well with the task of air exchange in attic floors.

Installation of a chimney on the roof

There are two options for installing the deflector: connecting directly to the smoke duct and mounting it on a piece of pipe, which is later put on the chimney. The second method is considered the best in terms of convenience and safety, because the most troublesome stage of the work is performed on the ground, and not on the roof.

Standards according to GOST

Excerpts from current regulatory documents regarding the installation of a deflector on a pipe inform about the following:

- any nozzles on the smoke channel must be mounted in such a way that they do not block the path of fuel combustion products;

- on a flat roof, the mouth of the pipe should be placed above the fence;

There should be free space around the mouth of the pipe

- on a roof with slopes, the chimney head must be located above the ridge, if the space between them is less than one and a half meters, or at the level of the ridge, when the gap from the pipe to the highest point of the roof varies within three meters;

- the deflector must not be installed in an area where an aerodynamic shadow is created due to neighboring buildings;

- the device body must be well ventilated regardless of the wind direction;

- rotating deflectors are not suitable for chimneys of stoves located in houses built in areas with cold winters;

- installation of a round deflector on a brick chimney involves the use of special transition pipes.

Required Tools

To install the deflector on the smoke duct, you need to find some tools and fasteners:

- electric drill;

- open-end wrenches;

- threaded rods;

- nuts;

- clamps;

- two ladders (one for climbing to the roof, and the other for moving along the roof).

In addition, to install the device on the chimney you will need a piece of pipe. Its diameter should be slightly larger than the size of the smoke channel.

Deflector mounting

The chimney is connected to the pipe, performing certain tasks:

- On the prepared section of pipe, 10 cm from the edge, mark the points where you need to drill holes for fasteners. Similar marks are left on a wide area of the diffuser.

- Holes are made in the pipe section and diffuser with a drill. The parts are temporarily connected to each other, checking that the upper and lower holes match. If this is not observed, then the product is considered defective, because the fastening elements cannot be inserted smoothly.

- Pins are inserted into the holes. On both sides, both on the diffuser and on the piece of pipe, the fasteners are secured with nuts. They are twisted evenly to protect the product from deformation.

- With the manufactured device they are sent to the roof. The structure is placed on the smoke duct and tightened with clamps.

If you install a deflector on a brick chimney, you will have to arm yourself with nails and a hammer

Proceeding as described above, you can mount any device except the weather vane deflector, since its design is rather non-standard.

In the case of using a device with a compass rose, 3 holes are created in the smoke channel with a drill. The holes are made at the same level so that bolts can be inserted into them a little later. These fasteners are immersed in the holes when the ring part of the deflector-vane is placed into the cut of the chimney. An axle is inserted into a bearing in the form of a ring, and a cylinder, a device blade and a cap are alternately attached to it. The elements of the weather vane deflector are combined with brackets or rivets.

The deflector can confidently be called a useful device that has a positive effect on the draft force in the chimney and the functioning of heating equipment. It is relatively simple to make and connect the device to the pipe; you just need to be “savvy” in choosing the type of deflector.

How to calculate the power and number of deflectors?

So, you already understand that there is no way to live without fresh air in a living space, and what solutions there are for this. And the fact that your house or apartment will be gradually ventilated is already good, but it is important to create a truly high-quality microclimate. Moreover, each room has its own requirements. Let's look at this calculation using the example of a turbo deflector:

The number of ventilation deflectors is calculated using a special formula:

According to all rules, air exchange in any room should occur in three cycles in one hour.

What kind of deflector for the ventilation pipe did you decide to install?

Source

Installation of wind hoods

Installation of hoods

When installing the deflector, it is necessary to take into account SNiP standards.

Requirements for the height of the ventilation pipe and nozzle:

- if the ventilation duct is located less than 1.5 m from the top of the roof, then the height above the ridge should be more than 50 cm;

- if the distance is from 1.5 to 3 m, then on a par with the roof;

- at a distance of more than 3 meters, the nozzle should be no lower than a line drawn at an angle of 10 degrees, from the top point downwards;

- if the roof is flat, then the height of the nozzle is at least 50 cm.

Do not install deflectors in areas of the aerodynamic shadow of neighboring buildings.

Ventilation deflector: 7 popular models

To ensure a healthy indoor microclimate, fresh air is necessary. Natural ventilation is most often used for this. The caps that cover the end of the pipe create additional resistance to air flow.

To solve this problem, modern ventilation systems use a deflector. What are deflectors, what types are there, and which deflector is best to choose will be discussed in this article.

Why do you need a deflector?

Exhaust natural ventilation works due to the difference in pressure outside and inside the room, creating natural draft. Wind has a great influence on traction; it can either promote good traction or hinder it.

A deflector will help reduce the negative impact of weather conditions. It not only protects the ventilation duct from the influence of weather conditions, but also protects against the ingress of various objects, debris, and precipitation. The deflector also increases draft by 15-20% and protects against reverse draft.

The deflector is a nozzle that is mounted on the edge of the ventilation duct.

There can be no problems with traction

Ready-to-install rotary deflector

The purpose of any ventilation system is to remove polluted air and excess moisture from the premises, that is, to ensure normal air exchange. This will take place if the ventilation duct functions efficiently and correctly - the draft in it is excellent. If there are problems in this regard, they are often provoked by rain, snow, or wind masses entering the canal shaft.

What is a deflector: principle of operation

In order to better understand the purpose of the deflector and the principle of its operation, consider the diagram of the device.

The deflector consists of the following parts:

The operating principle of the nozzle is based on Bernoulli's law. The presence of a narrowing in the ventilation duct causes a drop in pressure, which in turn increases draft. It is used to enhance draft in the channel due to the Venturi effect: the higher the speed of air flow when the cross-section of the channel decreases, the lower the static pressure in this section. Deflectors increase draft in the duct and increase the efficiency of ventilation systems.

You may be interested in the article “How to properly connect an RCD: diagrams, options for connecting to a single-phase and three-phase network” Go>>

The principle of operation of the deflector:

For proper operation, it is necessary to calculate the deflector required for your ventilation system.

Let us next consider the classifications and models of wind nozzles.

Spark arrester for chimney

The device, called a spark arrester, consists of the following parts:

- body (cylindrical pipe);

- cap (protective cover);

- mesh that extinguishes sparks.

The simplest device is a pipe sealed at the top with holes in the walls.

The installation of a spark arrester usually requires a stove, fireplace or boiler where solid fuel is loaded. We are talking about firewood or wood products.

The main difference between the spark arrester is the walls made of mesh

Classification of wind nozzles

When choosing wind nozzles, you need to decide on a number of important points in order to make the best option for yourself. It is necessary to determine the following characteristics:

The first thing you need to pay attention to is the material from which the deflector is made. Stainless or galvanized steel, ceramics, plastic, copper are used in production.

You may be interested in the article “Sewerage for a private house: stages of construction, which septic tank to choose” Go>>

More often they choose steel or aluminum nozzles; they are not very expensive and are not inferior in quality. Copper models are used less frequently due to their high price. A good option for quality and decorativeness are metal attachments coated with plastic. When choosing a material and color for the deflector, it is advisable to match it to the facade of the house.

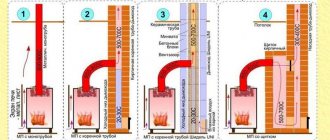

The next criterion for choosing a nozzle is the operating principle. Depending on the functionality, deflectors are divided into 4 types:

dimensions

Having selected the device according to the type of material and design features, you should calculate the dimensions of the deflector that will suit you. The table below shows the main ones using the TsAGI nozzle as an example.

Standard sizes of TsAGI nozzle

If there is no value above that corresponds to the parameters (diameter) of your ventilation duct, the deflector is calculated according to the following principle:

- Diffuser width = 2*channel diameter;

- Umbrella size (width) = 1.8*channel diameter;

- Total height of the device = 1.7 * channel diameter.

You can use the following scheme to calculate all elements depending on the selected pipe diameter:

Drawing of a deflector with calculations of element values

Popular models

Today there are a huge number of different models of deflectors. They vary in shape, there are closed and open types, with a cap or several cones.

If you choose a roof deflector, we suggest you familiarize yourself with the characteristics of the most popular models today.

Classic Grigorovich cap

One of the most popular deflectors. Grigorovich's cap gained such popularity due to its simplicity and low price.

The cap consists of two umbrellas that are connected into one “plate”. Installation is carried out on round pipes. Can also be mounted on rectangular air ducts using an adapter plate.

Thanks to this design, the Grigorovich cap performs double air ejection. One in the direction of the diffuser, and the second in the direction of the return hood. Due to the narrowing of the channel cross-section under the lower cone, the air speed increases and the pressure decreases. As a result, the pressure difference increases.

TsAGI universal nozzle

This ventilation deflector was developed by a specialized research institute during the Soviet era.

This design consists of several parts:

Table of characteristics of TsAGI deflectors:

| Pipe diameter, mm | Performance | ||||

| 2 m/s | 2.5 m/s | 3 m/s | 3.5 m/s | 4 m/s | |

| 100 | 21 | 26 | 31 | 36 | 345 |

| 200 | 95 | 115 | 142 | 168 | 190 |

| 300 | 240 | 300 | 360 | 420 | 480 |

| 400 | 380 | 475 | 570 | 660 | 760 |

Performance is calculated without taking into account the resistance of ventilation ducts. The actual volume differs from the calculated one.

Despite the fact that the design was developed quite a long time ago, today the TsAGI deflector is considered to be a very effective existing stationary nozzle.

You might be interested in the article “Do-it-yourself greenhouse made from window frames: step-by-step instructions” Go>>

Let's list the advantages of the deflector:

The only disadvantage of the nozzle is its strong dependence on wind speed. However, almost all attachments have such a dependence.

Not effective in winds less than 2 m/s.

Stato-dynamic hood Astato

This nozzle was developed by the French company Astato. The deflector design includes two truncated cones. At the top there is an umbrella and an axial electric motor. The device is covered on the sides with a mesh to prevent birds from entering. The nozzle is used on any building, regardless of the number of floors.

Operating principle of the Astato deflector:

The moment the fan turns on can be adjusted independently.

The downside of this attachment is its very high cost. Depending on the configuration, the price for a 160 mm ventilation duct ranges from 1,400 to 4,000 euros.

DS series deflector

This attachment is very similar to the Astato deflector, with one difference, it does not have a fan. The body consists of three cones. The structure is protected from birds by a metal mesh.

In the upper part two of them are connected, in the lower part one is truncated.

Rotary turbine or turbo deflector

Such a deflector is mounted on the ventilation pipe of large industrial buildings, gyms, and retail premises.

The nozzle consists of two parts:

Due to its light weight, even with little wind, the drum begins to rotate. Inside the sphere, the pressure decreases and the thrust increases.

You may be interested in the article “Decorating the facade of a house: 14 cladding options, modern materials and design styles” Go>>

Disadvantages of a rotary turbine:

Turbo deflectors are produced in Russia, Ukraine, and Belarus.

Rotary weather vane type hood

I also call it a “net”. It is a rotating semicircular wind catcher. Thanks to the weather vane, the deflector constantly turns in the wind, thereby closing the blowing of the open ventilation duct.

Operating principle of the rotary vane:

The disadvantages of a hood-type rotary weather vane are the same as those of a turbo deflector; we list them:

H-type module

Such deflectors are used mainly for industrial premises. Used to increase draft in ventilation ducts and chimneys.

The main advantage of the H-type deflector is its ability to perform its functions in large gusts of wind.

Do-it-yourself production

We propose to explain the technology for assembling the cap using the example of a TsAGI type nozzle. The parts are cut out of galvanized steel 0.5 mm thick and fastened together with rivets or bolts with nuts. The design of the exhaust element is shown in the drawing.

To make it you will need a regular metalworking tool:

- hammer, mallet;

- metal scissors;

- electric drill;

- vice;

- marking equipment - scriber, tape measure, pencil.

The table below shows the dimensions of the deflector parts and the final weight of the product.

Reference. The most common diameters of ventilation ducts are 100 or 110 mm, when the hood is made of a plastic sewer pipe.

Pattern and drawing of an umbrella with a cap with a diameter of 100 mm

The assembly algorithm is as follows. Using scissors, we cut out the blanks of the umbrella, diffuser and shell using the developments, and fasten them together with rivets. Cutting the shell is not difficult; the development of the diffuser and umbrella is shown in the drawings.

The finished deflector is placed on the head, the lower pipe is tightened with a clamp. For a square shaft, you will have to make or buy an adapter, whose flange is attached to the end of the pipe.