For efficient operation of the chimney, a special device is provided, which is mounted on its head.

The chimney deflector is designed to improve the draft created in the structure. It also provides reliable protection of the pipe from the penetration of precipitation and various contaminants.

There are various types of deflectors on the market, some of which you can make yourself.

Volpert Grigorovich deflector

This type of device is the most effective and popular.

Therefore, we will talk about it in more detail. This deflector is often installed on the chimneys of gas boilers. The key feature of this design is the presence of an inverted cone under the umbrella. Therefore, during side blowing, a reduced pressure occurs in the channel, and combustion products rush out of the flue.

In case of strong wind “from top to bottom”, the pressure in the deflector area can, on the contrary, increase. This point must be taken into account when designing and installing a smoke exhaust system. But in most cases, the airflow occurs from the side. Therefore, the type of product under consideration is suitable for most gas ducts.

They look like this:

- diffuser diameter: bottom - 2*D, top - 1.5*D;

- diffuser height - 1.5*D;

- immersion of the channel into the diffuser - 0.15*D;

- the height of both cones of the umbrella is 0.25*D;

- the distance between the diffuser and the cap is 0.25*D.

Can it be installed on a chimney?

By installing a deflector, unlucky homeowners are trying to solve the problem of lack of draft. This happens when the chimney pipe is made incorrectly - the head falls into the zone of wind support of the roof, is raised to a low height, or a neighbor has built a tall building nearby.

The best solution for insufficient draft is to raise the chimney to the required height. Why is it undesirable to jam various attachments onto the head:

- It is prohibited to place umbrellas and other exhaust devices on pipes that discharge combustion products from gas boilers. These are safety requirements.

- When burning, stoves and solid fuel boilers emit soot that settles on the internal surfaces of chimneys and caps. The deflector will have to be cleaned, especially the rotating one.

- At the bottom of a properly constructed smoke channel there is a pocket for collecting condensation and excess moisture. There is no point in covering the pipe from precipitation; it is enough to attach a nozzle at the end that protects the insulation of the sandwich.

The heads of stove flues can be equipped with umbrellas, but a turbo deflector is definitely not needed there. The topic of installing hoods on smoke exhaust ducts is covered in detail in a separate material.

How to build a deflector yourself

The deflector has its own parameters. So, its height should be 1.6-1.7 from the internal diameter of the chimney duct, and its width should be 1.7-1.9. Diffuser width – 1.2-1.3. But first, let's decide on the material from which it will be made:

If your chimney has a hole, birds often find it tempting to get inside. Small brownish black birds with a penchant for building nest in chimneys. Having these birds in your chimney can be quite annoying - they are vocal little buggers!

When you find yourself in difficulty with smokestacks, which are classified as an endangered species, there is little that can be done legally. The Migratory Bird Treaty Act, a federal regulation, prevents the removal of swift eggs and chimney chicks. The best thing you can do with quickies is to clean up after they leave. Technicians can be called in later to clean and remove nest residue from the chimney.

- Copper;

- Galvanized iron;

- Stainless steel.

Why copper if it is such an expensive material? The fact is that the deflector is located in one of the most inaccessible places in the bathhouse, and therefore, so that it does not have to be repaired, it is better to make it as resistant to atmospheric conditions as possible. And copper is the best in this regard.

Chimneys and most other birds are less likely to return to a nesting site if the nest has been removed. Several animals can get into your chimney, including squirrels and bats. Raccoons, usually females, enter chimneys to give birth and care for the pups. Terrible as they are, mother raccoons sometimes manage not only to get inside the chimney, but to pass through the smoke shelf or directly above the fireplace. If they have gotten this far, there is a good chance they will eventually break into your home. If not, you'll probably have to at least deal with various animal odors.

And here's how to make a deflector:

- Draw on cardboard an outline of all the main parts, such as the cap, diffuser and outer cylinder.

- Transfer everything to metal and cut using metal scissors according to these patterns.

- Connect the parts to each other using rivets, bolts or welding.

- Make brackets from a strip of metal - you will use them to secure the cap to the surface.

- Attach a reverse cone to the cap.

The deflector itself must first be assembled, and only then installed on the roof. We first install the lower cylinder and secure it with bolts and nuts. Using clamps, we attach the diffuser to the lower cylinder, and on it - a cap with a reverse cone.

A raccoon is an animal you never want to hang as they are known for carrying various diseases. Raccoons are home to bugs like fleas and ticks that you or your pets can get, as well as diseases like rabies and roundworm.

Luckily, there are ways to remove mom and her babies from the chimney. If you don't mind the smell, items such as predator urine can get rid of raccoons. A humane method of removal is a live trap. You'll probably want to catch the mother while she's going through or even trying to scare her in some way. The babies still can't handle most of the fighting, so it's fairly easy to reach the fireplaces and grab them.

Purpose and use of deflectors

As a rule, chimney systems are considered the most important element of the entire heating system, because it is the operation of the chimney that affects the process of fuel combustion and the removal of all combustion products from the system and the house in particular.

The entire process of operation of a heating boiler depends on a high-quality air flow and on the complete removal of smoke from the system. Without the proper amount of oxygen, the combustion process is impossible, and food residues in a living space can seriously harm the health of residents.

In order to organize the correct level of draft in the system, you need to know some features of the chimney, the design and organization of which must be correct. First of all, it is worth considering the required cross-section of the pipe intended for air inflow and outlet. Important factors include the height of the chimney and its configuration. Now let's look at these requirements in more detail.

The choice of the required cross-section directly depends on the power of the thermal energy generator. The smoke exhaust duct or passage itself must be of a vertical type and straight enough so that no air pockets are created during operation.

In the event that compliance with these requirements does not produce a tangible result, it is worth resorting to the use of a deflector, which is mounted on the top of the chimney pipe.

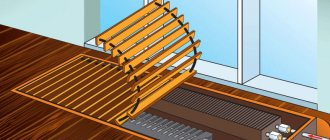

The principle of operation of the deflector is to use the wind as an additional tool in leveling or increasing the level of draft in the system. Externally it looks like this. At the end of the pipe, a part of the system is installed that has a larger internal diameter than the chimney itself.

A strong wind allows you to create a rarefied space in the deflector, into which all combustion products remaining in the chimney move.

Among other things, the deflector has additional useful functions that have a positive effect on the entire operation of the chimney duct. With the help of such an element, you can protect the system from rainwater and snow getting into it in winter. As a rule, this helps the system function efficiently in any weather.

Area of use

Where exactly can turbo deflectors be used? The products have proven themselves excellent in rooms and facilities where air exchange is extremely necessary. Scope of use:

- For private and apartment buildings. In addition, it should be noted that increased demands are placed on the operation of ventilation ducts in a high-rise building. Often in such houses the quality of ventilation is not the best, since they were made in the Soviet Union. But thanks to the use of a deflector, this problem is solved.

- Turbo deflectors are good for livestock farms and agricultural buildings such as stables, poultry houses, granaries and haylofts. They help ventilation more effectively remove odors, fumes and gases generated when keeping livestock. In addition, the humidity in the room is controlled, it is optimal.

- For processing enterprises. Since the turbo deflector does not require electricity to operate, the savings on the device are corresponding. The exception is enterprises that produce or process substances hazardous to humans.

- Public buildings such as sports complexes, swimming pools, shopping centers and cinemas.

Important! The turbo deflector is also used to ventilate the under-roof space.

But how to make turbo ventilation deflectors with your own hands? Let's find out.

Self-production of the device

To work you will need:

- galvanized or stainless steel sheet 0.5-1 mm thick;

- metal scissors;

- riveter;

- drill;

- a sheet of thick paper or cardboard.

The most important stage is drawing up a drawing. To do this, you need to measure the internal diameter of the chimney and calculate the product parameters according to the table.

If the internal diameter of your chimney differs from the parameters given in the table, calculations are performed as follows:

- the diffuser width is 1.2 d;

- width of the protective umbrella – 1.7-1.9 d;

- the total height of the structure is 1.7 d.

Both measurements and calculations must be as accurate as possible so that there are no difficulties during the installation of the structure and its subsequent operation. If the pipe has a square cross-section, then the deflector must be made square, although the angularity of the body slightly reduces the efficiency of the device.

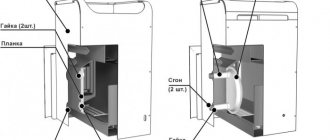

| Step, No. | Description | Illustration |

| Step 1. | A life-size drawing of the deflector parts is made on paper and cut out. | |

| Step 2. | The blanks are fastened and fitted to each other. If all the elements match, you can begin cutting the galvanized sheet. | |

| Step 3. | The templates are laid out on galvanized sheets, carefully outlined with a marker, and cut out with metal scissors. On the cuts, the metal is bent 5 mm with pliers and tapped with a hammer. | |

| Step 4. | In places of bends, the metal must be riveted with a hammer to make the edges thinner. | |

| Step 5. | The diffuser blank is rolled into a cylinder, holes for fasteners are drilled and connected with bolts or rivets. You can also use welding, but not arc welding, but semi-automatic, so as not to burn through the metal. | |

| Step 6. | The outer cylinder is made in the same way. Next, the cap blank is rolled into a cone and also connected with rivets or welding. | |

| Step 7 | 3-4 strips 6 cm wide and up to 20 cm long are cut out of galvanized steel. The strips are folded along both sides and tapped with a hammer along the entire length. From the inside of the cap, stepping back about 5 cm from the edge, drill the required number of holes for the bolts around the circumference. Fasten the galvanized strips to the cap and give them a U-shape. | |

| Step 8 | Using these homemade brackets, the cap is attached to the diffuser, and then the entire structure is inserted into the shell. |

If the design must have a reverse cone (Grigorovich deflector), the diameter of the protective umbrella is made 3-4 cm larger than the diameter of the cone. After assembling both elements, the cone is applied to the inside of the umbrella and outlined around the perimeter with a marker. Then make two cuts on the protruding part of the umbrella and bend the resulting strip inward. In the same way, make another 6-8 strips at an equal distance from each other, bend them inward and securely fix the reverse cone without additional fasteners or welding.

It is more convenient to attach a cap with a reverse cone to the diffuser with construction pins. To do this, before installing the cone on the umbrella, three holes are drilled around its circumference, the ends of the studs are inserted and the nuts are tightened. Then put the umbrella on top and fix the cone in the manner described above. At the top of the diffuser, on the outside, hinges made of tin or aluminum are riveted and the lower ends of the pins are inserted into them. This design withstands strong gusts of wind, serves for a long time and reliably.

In a similar way, you can assemble a deflector of any type, the main thing is to draw up the correct drawing. The only difference will be in the number and shape of parts. The finished device only needs to be mounted on the chimney.

Objective assessment

Like any technical device, the TsAGI design has its pros and cons.

- Effective protection against the penetration of dust, precipitation, small birds, insects, and rodents inside the ventilation duct.

- Protecting the head of the outlet pipe from destruction.

- The cylinder-shaped screen prevents the occurrence of back draft in the air outlet of even the largest cross-section.

- Manufacturing material options allow you to replace a more expensive one with a cheaper one. Thus, affordable plastic can be installed instead of stainless metal on ventilation streams with cold air escaping.

Difficulties in operation are observed during severe frosts, when ice forms on the inner walls of the outer cylinder. Its layer can completely cover the flow area. The TsAGI deflector is sensitive to the direction of the wind: it creates resistance to traction when there is complete calm or a slight blow of wind.

How much does a deflector cost?

Ventilation devices are calculated together with the entire system. Deflectors of a specific model can be purchased for the required pipe diameter.

Table. Prices for deflectors

| Name | Model | Type of steel | Channel diameter, mm | Price, y. e. |

| "Vent-Class" D-120 | Khanzhenkov deflector | galvanizing | 120 | 18 |

| "Vent-Class" D-250 | Khanzhenkov deflector | galvanizing | 250 | 42 |

| "Fireplace Stoves" TsAGI-100 | TsAGI deflector | galvanizing | 100 | 17 |

| "Fireplace Stoves" TsAGI-220 | TsAGI deflector | galvanizing | 220 | 40 |

| Turbovent "Stabil 120" | Volpert-Grigorovich | galvanizing | 120 | 21 |

| Turbovent "Stabil 260" | Volpert-Grigorovich | stainless steel | 260 | 46 |

| Turbovent "Dragon" Dr-150-CH-A | Turning | stainless steel | 150 | 100 |

| Turbovent "Dragon" Dr-200-CH-A | Turning | stainless steel | 200 | 115 |

| Turbovent "Dragon" Dr-300-CH-A | Turning | stainless steel | 300 | 140 |

Deflectors are often made in artisanal workshops and small workshops (in this case, the product may not have a specific name or connection to the model). An indicator of the quality of the company’s work will be the product passport indicating the dimensions of the parts, steel grade and other details.

TsAGI deflector – “classic of the genre”

The design of old residential buildings was necessarily carried out taking into account the installation of ventilation systems with natural stimulation of air movement. This explains the dependence of natural air exchange on the vagaries of nature. The TsAGI deflector is a simple ventilation shaped device with an open flow path, developed by the Central Aerohydrodynamic Institute. He uses natural factors of weather changes in his work, but sometimes he works in a system and with mechanical motivation. It works for both ventilation and heating (used in chimneys). Installation options – hidden (in the channel), external.

Making your own weather vane deflector

The weather vane allows you to reduce the height of the pipe by increasing traction, since it is always in the right relationship with respect to the wind, prevents precipitation from entering the pipe and decorates the roof.

Tools and consumables for work

To make one of the options for a weather vane on a chimney pipe with your own hands, you need to add to the above tools and materials:

- set of wrenches;

- pipe section;

- a metal (preferably stainless steel) rod or a ready-made pin;

- die for cutting threads on the rod;

- tap for cutting threads for fixing bolts;

- bolts for fixing bearings in the pipe;

- 8 nuts that will need to be screwed onto the rod to secure the bearings and secure the deflector housing.

- two bearings, the size of which is selected according to the diameter of the rod and the internal diameter of the pipe.

Step-by-step instructions and important notes

Operating procedure:

- Initially, a drawing is made, according to which patterns for parts are then made from a sheet of galvanized steel.

- Using patterns, apply the contours of the deflector elements onto a steel sheet with a special chalk or marker.

- Metal scissors are used to cut out parts from a metal sheet.

- The deflector body is assembled from the prepared elements by drilling holes and fastening them with rivets. You must remember to make brackets with which the body will be mounted on the rod.

- Cut off a rod or pin of the required length so that it is enough to secure the bearings and fix the deflector body.

- If a rod is used, the thread is cut using a die.

- Next, two bearings are attached to the stud with the distance between them necessary to create sufficient support when the deflector-vane rotates. To secure each bearing, first screw on the first nut, then put the bearing on the axle, then screw on the second nut and tighten the nuts until the bearing is well secured.

- Cut the pipe to the required length.

- Holes are made in the pipe where the bearings are located. Use a tap to cut the threads for the bolts that will secure the bearings in the pipe. Holes are also prepared for attaching supports that secure the entire device.

- A ring is made from a steel strip to secure the deflector to the chimney.

- Cut sections used as supports for attaching the block with bearings to the ring securing the product to the chimney.

- The final assembly of the product is carried out using rivets and fixing bolts.

There are many options on how to make a deflector for a pipe with your own hands. Everyone chooses for themselves what type of device is best suited. It is only necessary to note that such a design, placed on a pipe to remove combustion products, performs several useful functions - it increases draft when removing gases, protects the chimney from debris and precipitation getting inside. After installing the deflector on the chimney, the heating efficiency in the house increases significantly.

Types of turbo deflectors

Varieties of deflectors by shape Many types of deflectors have been developed to select a rotary head model that works effectively in specific conditions. All devices differ in technical characteristics, despite the fact that the commercially available options are almost the same in appearance.

Rotary turbine models vary:

- according to spare parts material;

- according to the size of the connecting ring.

Moving parts of equipment require periodic maintenance. The cost of turbo deflectors is quite high, so many owners can make and install the structure themselves.

According to the material of manufacture

Turbo deflectors made of stainless galvanized steel and polymer-coated The choice of material depends on the preferences and budget of the buyer. Some parts of the turbocharged device are made of plastic. Organic material based on natural or synthetic polymers does not react to humidity or acid precipitation.

The main materials are:

- thin sheets of chrome or galvanized steel with a matte finish are available in budget options;

- Stainless steel has double the cost compared to the previous material and is powder-coated in standard roofing colors;

- Structural metal with a polymer coating does not differ in color from the facade or roof of the building.

Chromium plating saturates the surface of steel with chromium molecules under conditions of electric current or in an electrolyte bath. Processing increases the metal’s resistance to destruction and improves the appearance of products. Stainless steel is used without coating or with a decorative layer; it actively resists corrosion due to the addition of chromium, phosphorus, nickel, and copper during production.

According to the diameter of the connecting ring

The turbo deflector is selected according to the size of the base. The size of the seat is indicated in the labeling and product passport. The diameter increment is 5 mm; sizes are available from 100 to 200 mm. More than 200 mm, sizes are made 250, 300, 315, 355, 400, 500, 600, 680 and 800 mm. Turbine diameters for exhaust 1000 mm and others are manufactured upon request.

The deflector is installed on the outlet section of the ventilation pipe, which can have a cross-section of different shapes. The devices are available with a round or square base. There are turbo deflectors with a box-shaped transition type base. They are installed on ventilation ducts made of bricks or blocks.

Grigorovich deflector manufacturing stages

The simplest product is the Grigorovich device, which is easy for most people to make.

Calculations and preparation of drawings

When drawing drawings and sizing this product, the following ratio applies:

- the height of the structure is approximately 1.7d;

- the cap must be made with a width of 2d;

- The diffuser width should be about 1.3d.

The symbol d refers to the diameter of the smoke channel. If a different size ratio is used during manufacturing, this will negatively affect the efficiency of the created device.

Based on the drawn drawings, patterns are prepared that are used when cutting galvanized iron into elements, from which the product is then assembled. To do this, transfer the outline of the elements in expanded form and in full size onto the cardboard, using a ruler, tape measure and pencil. When making a deflector for a chimney pipe designed by Grigorovich, prepare patterns for the outer cylinder, diffuser and cap.

Stages and nuances of making a deflector

Next, the following work with metal is performed:

- Using prepared patterns, outlines of the necessary parts are applied to sheets of metal, outlining cardboard figures with special chalk. If special chalk is not available, you can use a simple pencil. Add 20 mm to the contour of the parts in places where they overlap, which will allow you to maintain the required configuration of the finished elements during assembly.

- Using metal shears, the elements necessary for assembly are cut out of galvanized metal, thereby preparing the expanded outer cylinder, diffuser, and both parts of the cap - the umbrella cap along with the reverse cone.

- Then, using a hacksaw, metal strips or a corner are cut into pieces of the required length, through which all the elements will be connected into the finished product.

- The parts are given the required shape by folding and bending them in a certain way.

- The next operation is assembling the product. The elements are placed on top of each other and, using an electric drill, the necessary holes are drilled. Using rivets placed in prepared holes, the parts are fastened together.

- To install the Grigorovich device on a chimney, you can use two options - in the first case, through holes are drilled at the mounting location, through which the structure is fixed with fasteners on the chimney, and in the second option, a clamp is made from a strip, through which the deflector is fixed to the pipe.

What is a diffuser

A diffuser is a part of a ventilation system designed to introduce/exit air into a room and mix it effectively. It also performs decorative functions - it closes the entrance/exit to the ventilation duct. Outwardly it looks like a regular ventilation grille, but has a slightly more complex structure and may have additional devices - an impeller and a static pressure chamber.

Diffusers are designed for rapid air mixing

The difference between a diffuser and a ventilation grille

What is the difference between a diffuser and a ventilation grille? Yes, actually, nothing. The ventilation grille is simply the simplest of diffusers. Why is the price so different? There are reasons for this.

When developing diffusers, manufacturers calculate the movement of air, position the blades and partitions in such a way that the air in the room is mixed in the best possible way. Therefore, the air is mixed, evenly distributed throughout the room.

Several supply ceiling deflectors with air distribution patterns

Manufacturers of cheap ventilation grilles are unlikely to conduct any research, copying external features and not caring about efficiency. The air enters a certain point, and obvious zones with different temperatures are observed. So much for the price difference.

When to install a diffuser

Where and when can ventilation grilles be used, and where are diffusers needed? In ordinary old apartment buildings there are only exhaust ventilation ducts that operate due to pressure differences. The exits of the ventilation shafts are located in the walls. In this case, you can install ventilation grilles, since installing a more complex device has practically no effect on the situation.

But, if you have made a suspended ceiling behind which you have hidden an air duct connected to this duct, it is advisable to install diffusers. They work more efficiently. Since the presence of a suspended/tensioned structure impedes the movement of air, more efficient devices are needed for the normal operation of the ventilation system.

A deflector is installed in any type of suspended or suspended ceiling

If the ventilation system was specially designed, you will most likely be given precise recommendations as to what, where, and what type should be installed. In such a situation, any replacement may have a negative impact on system performance.

Application of deflectors

The main quality of deflectors for which they are used is the ability to increase traction by diverting external air flows. Regardless of the design, any deflector works on a single principle - the air bypassing the obstacle creates a low-pressure zone, due to which the draft in the chimney increases. A good deflector can increase the efficiency of a smoke exhaust system by 20%.

In addition, the deflector has an additional function that occurs indirectly - an obstacle installed on the chimney pipe prevents precipitation and various debris from entering it.

A simple deflector consists of two cylinders, one at the bottom and one at the top, and a protective cone, also called an umbrella. The bottom cylinder is usually part of a chimney made of metal or asbestos cement. Galvanized metal is used to make the deflectors themselves.

There are several standard options for deflectors:

- TsAGI deflector;

- "Volper" with a round body;

- Grigorovich deflector;

- Open deflector Astato;

- H-shaped;

- Star-shaped "Shenard".

Different types of deflectors are used in the following types of structures:

- Collective and private ventilation shafts;

- Collective and private chimneys;

- Systems for the removal of gases and combustion products;

- Garbage chutes.

Features of installing a turbo deflector for ventilation

In the operation of any ventilation system, it is important to ensure not only the flow of fresh air, but also the removal of exhaust air. In some cases, the ventilation shaft does not cope with its task and needs to be “helped”

Electric hoods are not the only solution in this situation. Another option is to install a turbo deflector.

Design and principle of operation of a turbo deflector

Structurally, the product consists of 2 parts:

- The turbine head is a round moving part consisting of a large number of thin bent plates, “assembled” with small gaps between each other. The plate material is metal (usually galvanized steel or aluminum), up to 1 mm thick. The head is fixed on top of the supporting part, on bearings.

- Supporting part - needed for fastening to the ventilation shaft exit. May have a rectangular, square or round cross-section. The nozzle (transition) for installation can have different sizes - from small (about 10 cm) to large (more than 50 cm).

The turbo deflector, installed on top of the ventilation shaft, is located in an open place and is blown by the wind.

The air flow hitting the blades (plates) sets them in motion - the head begins to rotate.

Even a light wind of 0.5 m/s is enough to rotate. The turbine rotates only in one direction.

Due to the rotation of the plates in the ventilation duct, draft increases and the operation of natural ventilation improves: air is removed from the premises more efficiently.

Errors and problems with the device

With the deflector, as with all devices, troubles can arise. One, the biggest and completely preventable one is incorrect work. This happens if the device was selected the wrong size. It can simply fall inside the chimney pipe, closing the path for combustion products to escape.

To avoid this situation, you need to pay attention that the diameter of the deflector pipe must be equal to the diameter of the internal chimney pipe. If the chimney is brick, and the installed device has a round cross-section, then you cannot do without the appropriate adapters

If the chimney is made of brick, and the installed device has a round cross-section, then you cannot do without the appropriate adapters.

The second mistake when installing a deflector is choosing a rotating model for areas with cold and snowy winters. Such a solution is fraught with icing of the device, and after a few days it will be covered with snow and not only stop rotating, but will also significantly interfere with the normal operation of the chimney.

To clean everything by removing snow and ice, you will have to climb onto the roof, and this is not the most pleasant activity on a cold and snowy day.

The third problem is the ineffectiveness of the deflector.

The problem may arise if the installation location or model is incorrectly selected:

- the body of the device is poorly blown by winds from different directions;

- in areas with gusty winds, an H-shaped deflector will be more effective;

- you should avoid installing the device in the aerodynamic shadow zone of trees and taller structures located nearby;

- the device must be located above the roof ridge and above other structures if they are present near the chimney.

If the deflector turns out to be ineffective, then it is necessary to look for the reasons for the backdraft of the chimney.

The fourth problem is the breakdown of rotating models. The fact is that the mechanisms that ensure rotation require maintenance. More precisely, you must not forget to periodically carry out maintenance on individual parts of the deflector and lubricate the bearings on time.

If the device was made by hand, and the material used turned out to be cheap and of poor quality, then everything can rust very quickly. In this case, you will soon have to replace it with a new deflector.

Another problem is when a simple cap is installed instead of a deflector. It may become icy and covered in snow. This will have to be fixed. It is dangerous if this situation occurs at night and all combustion products remain in the house. This is fraught with death for all household members.

Therefore, you need to install the deflector right away and not experiment with different canopies. If you don’t want to build an amplifier from scrap materials, you can always buy the model you like and install it on the chimney yourself.

It is necessary to take care of the normal operation of the boiler and the effective removal of combustion products at the heating design stage. Useful information on chimney construction is presented in this article.

Area of use

Where exactly can turbo deflectors be used? The products have proven themselves excellent in rooms and facilities where air exchange is extremely necessary. Scope of use:

- For private and apartment buildings. In addition, it should be noted that increased demands are placed on the operation of ventilation ducts in a high-rise building. Often in such houses the quality of ventilation is not the best, since they were made in the Soviet Union. But thanks to the use of a deflector, this problem is solved.

- Turbo deflectors are good for livestock farms and agricultural buildings such as stables, poultry houses, granaries and haylofts. They help ventilation more effectively remove odors, fumes and gases generated when keeping livestock. In addition, the humidity in the room is controlled, it is optimal.

- For processing enterprises. Since the turbo deflector does not require electricity to operate, the savings on the device are corresponding. The exception is enterprises that produce or process substances hazardous to humans.

- Public buildings such as sports complexes, swimming pools, shopping centers and cinemas.

Important! The turbo deflector is also used to ventilate the under-roof space. Number of blocks: 18 | Total number of characters: 23820 Number of donors used: 6 Information on each donor:

Number of blocks: 18 | Total number of characters: 23820 Number of donors used: 6 Information on each donor:

Number of blocks: 18 | Total number of characters: 23820 Number of donors used: 6 Information on each donor:

- https://ventkam.ru/ventilyatsiya/rotatsionnyj-deflektor: 3 blocks out of 7 were used, number of characters 2861 (12%)

- https://trubanet.ru/sistemy-ventilyacii/deflektor-na-vytyazhnuyu-trubu-princip-raboty.html: 3 blocks out of 6 used, number of characters 2191 (9%)

- https://oventilyacii.ru/ventilyaciya/deflektor.html: 4 blocks out of 6 were used, number of characters 6964 (29%)

- https://www.stroy-podskazka.ru/ventilyaciya/montazh-turbodeflektora/: 3 blocks out of 5 were used, number of characters 6282 (26%)

- https://proventilation.ru/ventilyatsiya/turbodeflektor-svoimi-rukami: 1 blocks out of 5 used, number of characters 2510 (11%)

- https://ProRoofer.ru/aksessuary/turbodeflektor-dlya-ventilyacii-svoimi-rukami.html: 3 blocks out of 8 were used, number of characters 3012 (13%)

Installation of a deflector with a wind protection device

The deflector with wind protection is mounted as follows:

- Two bearings and a vertical axis are fixed in the chimney at two levels;

- A semi-cylindrical screen, a weather vane and a roof of the structure are successively installed on the axis.

The operating principle of this type of system is as follows:

- When the wind direction changes, the weather vane rotates and pulls a curtain behind it, covering the chimney from the wind. As a result, smoke can escape from the leeward side of the chimney at any time.

- Air flows pass tangentially over the semi-cylindrical screen and pull smoke behind them, increasing draft in the system.

To increase the efficiency of the structure, it is necessary to periodically lubricate the deflector bearings, and in the cold season, also remove ice that forms in the structure due to condensation. Taking into account the last nuance, we can say that such a nozzle on the chimney pipe from the wind can effectively protect only those structures that are located in warm regions.

Turbo deflector performance

There are quite a large number of estimates of the efficiency and performance of a turbocharged deflector, from advertising statements about increasing pipe thrust by 4-6 times, to minimalist estimates of 20-30%.

In reality, the increase in thrust using a turbo deflector in ideal conditions and with average winds is 150-250%.

As can be seen from the graph, the theoretical performance of the device increases almost linearly with increasing wind speed over the pipe. In practice, such growth is only possible if it is possible to place the turbo deflector in the most favorable location on the roof.

Types and principles of design and operation of deflectors

Deflectors can be made in several generally accepted configurations and designs:

- TsAGI type deflectors;

- round type deflector (Volper);

- deflector designed by Grigorovich;

- open and H-shaped deflector.

The deflector itself has a design consisting of several separate parts. These parts include the lower type cylinder, diffuser and umbrella. The diffuser has the form of a cylinder located at the top of the element, and the umbrella protects the chimney from rain and snow getting into it. As a rule, deflectors are made from galvanized steel, which eliminates the possibility of metal corrosion by such debris.

The operation of the deflector does not have any features in its concept that even a novice master is not able to master. The wind flow goes around the entire deflector, colliding with it. This allows air to penetrate the upper cylinder of the deflector, increasing the draft in the chimney and drawing out all the smoke stagnant in the system. Due to the intensive movement of air inside the deflector, the traction force increases several times.

The design of this element allows you to increase thrust even when the wind flow moves in a vertical direction. For this purpose, there are special gaps in the upper part of the cylinder through which air penetrates into the ventilation and chimney systems.

It is worth taking into account such a thing as a downwind wind, which can make it difficult to remove smoke and reduce the level of draft in the chimney. Due to this wind flow, multi-directional wind flows are formed under the deflector umbrella, which clog the entire pipe.

Diffuser Body

The body diffuser is part of the car’s additional body kit, which performs the function of redistributing the oncoming air flow between the bottom and the road surface. Usually it is a tuning element or a structural part of a sports car. But it can be installed on a production car.

Why do you need a body diffuser?

The main purpose of the diffuser is to improve the aerodynamic characteristics of the car. It converts the kinetic energy of the oncoming air flow and creates a vacuum area under the bottom, which tends to press the car to the road. An increase in downforce improves the quality of tire adhesion to the road surface. Due to this, the car receives improved maneuverability, efficient acceleration, and safe braking. An additional function of the diffuser can be the distribution of air flow for additional cooling of the brake mechanisms.

Design and location of the body diffuser

Diffuser for the rear of the car

Most often, the diffuser is mounted under the bottom in the rear of the car. It can also be installed directly under the bumper.

The diffuser consists of several structural elements. Longitudinal ribs forming air channels that break up the flow and increase its speed. They also restrict airflow from the sides. Sometimes such ribs can also direct air to the discs and brake pads.

Modern diffusers are made of high-strength and lightweight carbon fiber plastic (carbon fiber). The diffuser, regardless of its design, contains voids that increase in volume along its entire length - for ease of construction.

How it works

The action of the body diffuser is based on Bernoulli's law. The volume of air passing through the narrow channels of the device is divided into several separate streams. In this case, the speed of the medium increases, which leads to a decrease in pressure. At the outlet of the diffuser, the pressure is compared with atmospheric pressure, and under the bottom it will be lower. Due to the resulting rarefaction of air, downforce increases. This effect increases overall downforce and reduces rear lift.

Of great importance is maintaining the correct angle of inclination of the diffuser walls, which should not change abruptly. The air flow should not be separated from the top and side planes. Vertical baffles help improve its efficiency and ensure that air escapes from underneath and does not affect the top of the vehicle.

Types of bumper diffusers

Depending on the design and location, there are several types of diffusers:

- a rear diffuser that ends under the car's bumper;

- a front diffuser or splitter that creates a low-pressure zone in the nose;

- rear two-level or secondary diffuser, which has an increased volume and allows you to draw more air from under the bottom.

Source

Types of chimney caps

Before you make a chimney cap with your own hands, you need to decide what shape it will have, and then make a drawing. The most common forms that a chimney cap can have:

Chimney caps differ in design features and the material used in the manufacture of the product, but they all serve to enhance draft and protect the chimney from atmospheric phenomena.

When choosing an option, you should take into account the overall architectural appearance of the house. Thus, a chimney cap with a flat copper top is usually installed on houses in the Art Nouveau style. For a European-style home, it is better to make a canopy over the chimney with semicircular finials. Wind vanes with a gable roof serve for effective ventilation and protect the structure from filling with snow.

In wind vanes with a built-in weather vane, you can place a special damper, which in windy weather allows combustion products to escape unhindered. Chimneys with an opening lid are very practical; they allow you to clean chimney channels without much effort (see).

Types and characteristics of pipe deflectors: main differences

If you look at the photo of the deflectors, you will notice that they all look different, but nevertheless perform the same functions

Therefore, before giving preference to one of the models, you should pay attention to the following criteria:

- material of manufacture;

- operating principle;

- design features.

Basically, all models are made from the following materials:

- aluminum;

- of stainless steel;

- galvanizing;

- copper;

- plastic;

- ceramics.

Note! Ventilation specialists believe that deflectors made of steel or aluminum are optimal in terms of price/quality ratio. Copper devices are also good, but due to their high cost they are used quite rarely. The deflector can be made of aluminum, stainless steel, galvanized, copper and plastic

Devices are divided into the following types:

- TsAGI, characterized by the presence of a ventacal expansion - diffuser;

- Volper cylindrical ventilation fungus;

- cap-weathervane, in common parlance - “sycophant”;

- H-shaped deflector made of pipes;

- turboreflector, which is a spherical rotary nozzle;

- static-dynamic device of open type Astato.

Some include in this list regular umbrellas installed at the top of the channel. It should be understood that this kind of device only helps to protect the ventilation from rain, but does not in any way affect the draft.

Open structures also differ in shape; the following devices are considered the main ones:

- flat;

- semicircular;

- with opening lid;

- gable.

In addition to the fact that devices are divided according to the type of weather vane, they are also classified according to the principle of operation:

- rotary;

- deflector;

- turbine

The operating principle of the device can be rotary, deflector or turbine.

Chimney deflectors are primarily installed to improve draft, which removes smoke and carbon monoxide outside. In addition, after installing the device, heat transfer increases, and the fuel burns better. Various photos of chimney deflectors also make it clear that with the help of the device the pipe is protected from precipitation and other debris brought from the outside.

Air conditioner deflectors, which differ in appearance from conventional devices, can be classified as a separate group. This design is a reflective screen that redistributes the air flow. Thanks to this, the beam of cool air is not directed directly, but parallel to the ceiling. Even though the air is dispersed, the pressure does not change.

Protection of deflectors from low winds

Due to the presence of this feature of wind flows, deflectors began to be equipped with special protective devices that help increase the level of draft in the pipe in any weather. To do this, an axis is installed inside the chimney on two bearings located at different levels.

A semi-cylindrical screen, a weathervane and a cover are installed on the axis. It is this design that protects the entire chimney from the effects of the lower wind flow.

After the direction of the wind flow changes, the weather vane rotates, thereby closing the chimney from the wrong wind flow. Thus, any direction and strength of the wind is not able to block the path of the exhaust smoke, and the draft in the chimney remains the same power.

Do not forget that the deflectors are designed for round pipes, which can become a problem if you have an old brick pipe with a square cross-section. In order to solve this problem, special pipes are used that act as adapters.

For chimneys with a large square cross-section, which are built for fireplace heating systems, it is necessary to use adapters in the form of spacer legs that connect the pipe and the deflector itself. These legs are made of metal strips that can be galvanized or high-quality painted.

Brick pipes require an appropriate transition with an inlet in the desired direction, which allows you to connect a round deflector and a square chimney. In other words, it is not difficult to secure this element of the chimney system in the presence of any type and shape of chimney structures.

You don’t have to buy a deflector at a hardware store, because you can make it extremely easily with your own hands. To do this, you need to calculate the size and shape of the element, after which you can begin the manufacturing process.

On galvanized steel sheet it is necessary to draw the upper and lower cylinders of the future deflector, which can be easily done using an ordinary pencil. You can cut out the necessary elements using metal scissors, which can easily cope with this task.

Once these two parts have been cut and filed, which is required to properly join the two edges of one part, you can begin to secure these edges. As a rule, a welding machine, bolts or rivets are used for this.

It’s worth noting right away that connecting a galvanized steel workpiece using a welding machine is extremely difficult, because it burns through thin metal quite quickly. It is for this reason that rivets or small bolts are most often used.

The finished cone cap must be secured to the upper cylinder of the deflector. This is done using small brackets made of the same sheet steel. The brackets are secured to the pipe using rivets. Do not forget that the brackets should be attached only to the outer side of the deflector, so as not to create additional interference in the internal part for proper air flow and smoke extraction.

A reverse type cone must be attached to the element umbrella. In addition, the assembly of all parts of the deflector must be carried out directly on the pipe itself, which will allow for high-quality installation and fastening of each individual part of the structure.

Otherwise, it is possible to connect two elements of the system poorly, which will subsequently cause a malfunction of the structure and the entire chimney as a whole. In some cases, it is simply impossible to make this design on your own.

As a rule, this happens with brick chimneys, which require high-quality adapters or stands. From this we can conclude that it is much easier, more profitable and faster to buy this inexpensive element of the system than to try to make it yourself.

It is worth recalling that only galvanized steel can be used to make the deflector, which successfully resists the formation of rust, which negatively affects the life and quality of service of such a system element.

Features of device installation and useful tips for proper installation

To correctly calculate the deflector, you need to measure the diameter of the exhaust shaft. If there is a rectangular exhaust shaft, you should select a device with a round cross-section, the value of which is equivalent to the size of the channel. That is, you need to calculate the cross section of the rectangle and take a circle with a similar area. It is also necessary to remember that in this case, an additional adapter will be required for installation.

As for the installation of the deflector, they are guided by SNIP standards governing installation rules

So, first of all, you need to pay attention to the height of the ventilation pipe and hood, which is determined depending on the location on the roof:

- The height is 50 cm, if the air duct is located closer than 1.5 meters from the edge of the roof.

- At the same level as the ridge or slightly higher, when the distance from the parapet to the ventilation shaft varies from 1.5 to 3 meters.

- If the pipe is more than 3 meters away, the height is selected so that the top of the deflector is not below the deviation line drawn from the ridge down to the edge of the roof at an angle of 10°.

It is optimal when the deflector is installed at the stage of roof installation.

Additional points to consider during installation:

- The deflector cannot be mounted in an area covered by the aerodynamic shadow of other buildings.

- The device must be mounted where there is free airflow. It is best when the cap is the highest point of the roof.

When organizing a ventilation system, you should also not forget how to install the ventilation grill correctly - up or down

Most craftsmen focus on the fact that if there is forced ventilation, air will somehow get into the shaft, so when installing it is better to focus on how the wall will look after installation and whether the grate gaps will be noticeable

Possible problems associated with system smoke

Most often, smoke in the chimney system occurs for the following reasons:

- strong wind gusts, as a result of which air under strong pressure penetrates into the pipe, which causes a decrease in traction force and smoke in the living room;

- the smoke passage is too narrow, which is not able to provide the system with the required level of draft;

- insufficient lifting height of the chimney pipe, which does not allow the formation of the required pressure and draft force in the pipe.

Statistical type deflectors are designed specifically to solve all these problems, allowing the chimney to work extremely correctly and efficiently. The use of this element of the system is relevant for private or collective ventilation and chimney systems. As a rule, there are no restrictions on the use of this auxiliary device if its location does not interfere with other functions of the chimney.