Insulation of floors in a private house is a necessary part of construction work. Up to 15% of the heat goes through the flooring into the ground. An unheated basement under a building leads to heat loss of 5-10%.

Floor insulation is an effective way to avoid heat loss Source giropark.ru

What measures need to be taken to protect your home from cooling during the cold season? How to insulate floors in a private house to reduce heat loss and save on home heating? The use of modern thermal insulation materials will help solve this problem.

Types and properties of floor insulators

Materials used for insulating floor coverings are produced in the form of:

- granules - expanded clay, foam glass, perlite, vermiculite granulated slag;

- rolls with and without a reflective layer - mineral wool, glass, slag, polyethylene foam, polystyrene foam, cork;

- foil and non-foil boards - polystyrene foam, penoplex, polystyrene foam, chipboard, OSB, plywood, wood concrete, basalt wool;

- liquids and foam - special insulating paints, polyurethane foam, ecowool;

- mixtures - foam concrete, polystyrene concrete, expanded clay concrete, slag concrete, sawdust concrete.

Mineral wool is an affordable material for insulation. Source giropark.ru

They have general technical characteristics that allow the materials to be widely used for thermal insulation:

- Fire resistance - do not support combustion.

- Low thermal conductivity coefficient - retains heat well in the room.

- Environmentally friendly, safe for use inside a residential building.

- Durability - with proper installation, materials retain their properties for at least 20 years.

- Simplicity of the installation of the thermal insulation layer - no highly professional knowledge or complex operations are required.

- Resistant to rot, mold, fungi.

- Lightweight - does not additionally load load-bearing structures.

- Low water absorption - they do not absorb or retain moisture in capillaries and pores.

- Vapor permeability - air exchange is ensured in the room, a favorable microclimate is maintained.

- Strength is especially important when constructing concrete pavements, where the load is transferred directly to the insulation.

Foam glass is another material for thermal insulation Source giropark.ru

Modern thermal insulation materials are inexpensive and effectively cope with floor insulation in a private house.

Choosing insulation material

The floor is insulated with materials with high thermal insulation properties, which prevent heat from escaping outside the room. For these purposes, the most popular are:

- Bulk materials (expanded clay, wood concrete, shavings) - have good thermal insulation qualities and are relatively inexpensive;

- Mineral wool and glass wool are effective in terms of heat and sound insulation, fireproof, not susceptible to infection by fungi and rodent attacks, hygroscopic (require mandatory vapor barrier);

- Polystyrene foam and expanded polystyrene are moisture-resistant materials, not subject to deformation, do not ignite, conduct heat poorly, and dampen sound noise.

It is impossible to say which of these materials is the best. You need to choose based on your financial capabilities and the functionality of the insulated room.

Features of the use of insulation

Today, the buyer is offered a wide range of thermal insulators for floors. To select the most suitable material, you need to take into account the features of their installation and use.

Bulk insulators

Used for insulating wooden, concrete, tiled floors in a private home.

Expanded clay is one of the options for bulk insulator Source stroyfora.ru

The material is poured between the lags or onto a prepared surface protected from below from moisture penetration. The insulator is compacted and a leveling screed is placed under the final coating. The minimum layer thickness is 5-15 cm.

Roll insulation

Place it on a flat surface, insulated from moisture, and cover it with a layer of vapor barrier.

Roofing felt is easy to install and inexpensive Source th.decorexpro.com

Install the flooring from boards or plywood and the finishing coating. For concrete floors, polystyrene foam is used; wooden floors are better insulated with mineral wool. When installing foil materials, make sure that the metallized layer is on the surface. This will allow heat to radiate into the room without loss.

Slab heat insulators

The mats are laid in the spaces between the joists or in a checkerboard pattern on concrete foundations. Protection from moisture below and steam from above is required. Before final finishing, it is recommended to reinforce the insulation surface.

Liquid thermal insulation

Used to protect wooden, concrete and plastic floors from heat loss.

Liquid insulation retains heat well despite the thin ball Source remtra.ru

What tools and materials will be needed

First of all, you will need fine gravel screenings, sand and an entrenching tool, with which you can backfill the base on the ground, level it and compact it. To do this, you can use ordinary shovels, a garden wheelbarrow and a hand tamper. If possible, it is best to work with a motorized rammer. The process of preparing the soil for the floor will require a lot of physical strength, so there is no need to skimp.

On dry soils, you can insulate the floor by laying EPS directly on the sand, but with the obligatory sealing of the seams

We purchase the rest according to the list:

- The road surface is high-density agrotextile, polyethylene film 0.5 mm thick;

- Perforated polyethylene pipes with a diameter of 50 mm;

- Insulation in slabs;

- Polyurethane foam;

- Cement-sand mortar.

If the floor insulation is planned to be laid on a pre-filled leveling screed, then the amount of solution will need to be increased by 2.5 times and an additional reinforcing mesh will need to be purchased. To insulate with backfill materials, you will need a set of leveling slats made of galvanized profile.

In addition, you will need to stock up on measuring tools - a building level, preferably a two-beam laser, a tape measure, a meter ruler and a carpenter's square.

Heated floor systems

Underfloor heating systems have proven themselves in creating a comfortable microclimate in the house. They are satisfied:

- based on water heating;

- with connection to a power source.

Insulation with a metallized coating is used, on top of which small-diameter pipelines, electrical mats, cables or infrared emitters are laid. The reflective layer directs thermal radiation into the room, preventing heat loss. The structure is covered from above with a screed or flooring material.

Warm floors for comfortable living Source utepleniedoma.com

Advantages of the systems:

- Ease of installation.

- Economical in operation.

- Small thickness of structures.

- Even heat distribution.

- Environmentally friendly.

- Reliability.

- Safety.

A warm floor can be the main or additional element of the heating system of a private home.

Three main ways to insulate floors in a private home

The base is a reinforced concrete slab, a wooden subfloor on joists or soil. Warming is carried out in a certain order. It is advisable to entrust the process to professionals, but to understand what is happening, you can familiarize yourself with the algorithms.

Thermal insulation device for the floor on a reinforced concrete slab

- The surface is cleaned, leveled, and the seams are sealed with mortar.

- Lay a vapor barrier film with sizing of joints if mineral-based insulation is used. Polystyrenes do not need protection from moisture.

- Place thermal insulation - slab, roll, bulk.

- Reinforce the surface with mesh.

- Fill the cement-sand screed.

- In damp rooms, waterproofing is installed to protect the insulation from moisture.

- Install the covering - laminate; tiles; parquet; board.

Thermal insulation of floors on joists

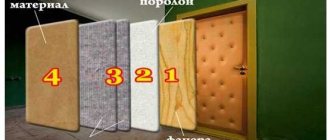

- Logs—beams with a special cross-section—are laid on the support columns.

- A galvanized mesh or board is attached to the bottom of the beams.

- A wind and moisture protective membrane is spread, the joints are glued, and secured with a stapler to the beam.

- Insulation is laid - slabs, rolled materials with a thickness no less than that calculated for a given climatic zone.

- The top is insulated from moisture with steam and waterproofing, securing it to the joists and gluing the joints.

- Plywood or boards are placed along the top of the structure and fixed to the sheathing. This is the base for the finished floor.

Sometimes thermal insulation is laid in two layers. In this case, the bars of the second level are installed perpendicular to the first.

Thermal insulation of floors laid on the ground

- Prepare the base - cut off the soil, fill it with sand and crushed stone, and compact it.

- Concrete is poured and the surface is leveled.

- A hydro-vapor barrier made of film or roofing material is laid on top.

- Thermal insulation is installed - extruded polystyrene foam, it is not afraid of moisture.

- Reinforced with mesh and fiberglass.

- A finishing screed is arranged in which a heated floor system can be placed.

- Finishing the surface.

How to insulate the floor underneath the board

If the floor covering is already lying down and you don’t want to lift it, but you need to insulate the ceiling, you can use one of two technologies. The main thing is that there is access to the surface from the basement or plinth. The first type is liquid polyurethane foam. It will not be cheap, the technology has the following features:

- The composition is applied using a machine that foams it and distributes it evenly. You can make any layer, which is very convenient. But only a specialist in special equipment can carry out the work, so you will have to pay for his services.

- After drying, a durable coating without voids is formed, which retains heat well and does not collapse over time if it is not exposed to sunlight. The composition adheres perfectly to all substrates; they do not need to be prepared.

Extruded polystyrene foam is also suitable for insulation on the bottom side. Dense sheets do not collapse under the influence of dampness and temperature changes, so they can be used in this case. It is worth following several recommendations when carrying out work:

- Take measurements and cut pieces of the desired size in advance. Buy a special adhesive foam, which is applied with a gun, this will improve the quality of insulation and significantly speed up the process.

- Apply a small amount of glue around the perimeter and in the middle, then press the element and hold for a few seconds until it is fixed. You should act carefully so as not to get dirty with foam - it is not easy to wash it off your clothes and hands.

- Fill the cracks around the perimeter and voids with the same glue or buy polyurethane foam - it will cost less if you need to fill many joints.

Advice!

If foam does get on your hands or clothes, you can wash it with a gun cleaner or buy the drug “Dimexide” at the pharmacy; it removes even dried composition well.

If during construction you insulate the foundation from the inside and fill the space under the house with sand, protection from the cold will be much better. The preferred option is to insulate the floor during the construction of a house or during its major renovation, when there is good access to the surface.

Features of floating floor insulation

A flooring structure that is not fixed to the base is called floating. It consists of layers of sound and heat insulation laid on the surface of the slab. The absence of a rigid connection to the base and walls significantly reduces the noise level in the premises.

The process of insulating a floating floor Source polonest.ru

Insulation of a floating floor is carried out taking into account the following features:

- Insulation - bulk or slab (polystyrene, mineral wool) is placed on the screed or slab and carefully leveled.

- An edge is laid around the perimeter to create a gap between the wall and the floor structure.

- A hydro-vapor barrier is laid on top.

- The screed is poured over it and the floor covering is installed.

The screed can be replaced with moisture-resistant gypsum fiber sheets laid in two layers and glued together. It is important to move at least 10 mm away from the wall.

Insulation of the concrete base

Insulation of concrete floors is carried out using dense and rigid materials. The optimal choice is extruded polystyrene foam (penoplex) of hard grades. The technology is simple:

- the surface of the concrete subfloor is freed from the finishing coating and all intermediate layers

- the insulation is laid tightly, without gaps or gaps

- A protective layer of screed is poured over the insulator . Its thickness must be at least 3 cm.

The disadvantage of this method is the change in floor level. If this option is not possible for some reason, then another insulation option should be used.

How to insulate floors in an old house

The first step is to inspect the remaining parts of the floor structure. They disassemble the covering, inspect the wooden elements for the presence of rot and fungi. All destroyed boards and bars are removed.

Insulating the floor in an old house will help make it cozy again Source giropark.ru

If the load-bearing beams are well preserved, insulation is carried out along the joists. Otherwise, they need to be replaced with healthy wood. All structural parts are treated with antiseptics. The thermal insulation material is protected from above and below with vapor and waterproofing. The work is completed by laying the flooring.