Properties of hydrogen as a fuel

Hydrogen is the lightest colorless and odorless gas, which is the tenth most abundant chemical element on the planet. It is non-toxic and even during a combustion reaction does not emit harmful substances.

It is beneficial to use hydrogen as a fuel for the following reasons:

- high heat transfer (more than 121 MJ/kg) due to the combustion temperature reaching +60000C,

- the possibility of reducing the combustion temperature to +3000C, subject to the use of catalysts,

- safety in case of leaks due to rapid evaporation into the atmosphere, since its weight is 14 times lighter than air,

- the ability to extract fuel anywhere on the planet,

- unpretentiousness to the type of boiler used.

Hydrogen boiler design

A hydrogen heating boiler consists of the following structural elements:

- heat exchanger,

- fuel combustion chambers,

- electrolyzer,

- containers for hydrogen production in which the electrolyte is placed,

- a two-stage protection unit that prevents a chain reaction.

Hydrogen boiler design

Which water is better - regular or distilled?

One of the questions that owners of hydrogen boilers often ask concerns the water used to operate the devices.

Distilled water for the operation of a hydrogen boiler can be purchased in stores or you can set up its production yourself using a simple installation

According to experts, factory or home-made devices demonstrate the best performance when working with distilled water, to which very little sodium hydroxide has been added (one tablespoon per 10 liters of H2O).

However, a hydrogen boiler can also operate successfully on tap water, the main thing is that it does not contain heavy metal salts.

Principle of operation

The operation of a hydrogen fuel boiler is implemented as follows:

- In the electrolyzer, after the electrolytic solution enters and electric current passes through two immersed electrodes, the production of H2 and O2 gas, as well as water vapor, begins.

- The gas mixture enters a chemical separator, in which hydrogen is separated from the total volume. In this case, the purified gas is discharged through a special valve to the next unit of the installation without the possibility of reverse. This design solution makes it possible to prevent an explosion when hydrogen comes into contact with the air mixture.

- Through the protective block, the purified gas enters the combustion chamber in which the heat exchanger is located. During the chemical reaction of hydrogen with oxygen in the presence of a catalyst, the heat exchanger, which contains the coolant used in the heating system of the facility, is heated.

- The waste gas after the chemical reaction again enters the chamber with the electrolytic solution.

The heating power is adjusted due to the presence in the system of several special channels with a catalyst, which during the operation of the boiler can participate in a chemical reaction or be excluded from it.

Economic question

Before you begin to understand in detail how to make a hydrogen generator, it is advisable to remember your school physics course. All transformations occur with a loss of energy, that is, the cost of electricity to produce hydrogen will not be recouped by the thermal power when burning the resulting fuel.

If we consider that it is simply impossible to burn hydrogen at maximum temperature and heat transfer at home, it becomes clear that real losses will be even higher than those calculated for ideal conditions.

So, using a DIY hydrogen generator for heating doesn't make any sense if you don't have access to free electricity. Installing an electric boiler to heat your home and spending electricity directly, without complex transformations, will cost you 2-3 times less. In addition, the electric boiler is completely safe, and the operation of a homemade installation can lead to an explosion if the installation and operation rules are not followed.

Obviously, producing cheap hydrogen in an environmentally friendly way, which includes electrolysis, is a matter of the future, which scientists in the leading countries of the world are working on today.

Model selection criteria

A hydrogen boiler for a home must be selected taking into account the following criteria:

- the heating power must meet the requirements of the heating system and coolant used, and also take into account the area of the heated premises,

- the dimensions of the combustion chamber must be equipped with the required number of heat exchangers, allowing the organization of several heating circuits,

- the electrical network in the building must be able to withstand the power consumption of the boiler,

- all structural elements of the boiler must be made of high-quality materials and have a sufficient margin of strength and wear resistance,

- The protection unit must be certified and comply with safety standards.

Example of a hydrogen heating boiler

Feasibility of the technique

The reason for installing a hydrogen heating system in a private home may be the lack of natural gas and the availability of electricity. At the same time, the costs of providing the building with heat are lower compared to the use of electric heating devices.

In addition, there is no need for pipes to remove combustion products. It turns out that a hydrogen installation can be used in country houses as an independent or additional heating equipment.

Features of operation

An important feature of the use of hydrogen fuel is the danger of its explosion when in contact with air. Therefore, it is important to adhere to the following operating rules:

- it is necessary to periodically monitor the temperature of the sensors installed on the heat exchangers and prevent the coolant from overheating above permissible standards,

- it is prohibited to operate the boiler in modes that are not provided by the manufacturer or may cause a chain reaction,

- when the gas pressure in the combustion chamber increases, it is necessary to take measures to stabilize it and find out the reasons for such changes,

- for continuous operation of the boiler, you need to take care of a stabilized power supply,

- It is important to periodically change the electrolyzer and monitor the water supply.

Ideas for combining flooring in the kitchen

The combination of materials must be thought out before starting work, so that, taking into account the difference in thickness, a difference of the required magnitude can be made on the floor (during its preparation).

Tiles and laminate

These materials are perfectly combined in thickness and physical characteristics. Laminate flooring for the kitchen is selected with the highest degree of strength and moisture resistance. No matter how beautiful the glossy finish is, preference should be given to the option with a matte surface. It is easier to care for, and its textured structure will prevent it from slipping even on a wet floor. Laminate is not indifferent to moisture and grease, which is why it is used in the dining area.

Ceramic tiles are best suited for finishing the floor near the workplace. But not a slippery glossy one, but a matte one with a textured structure. There are so many colors and textures in the assortment that it will not be difficult to choose the ones that suit your kitchen decor. The combination of tiles and laminate with images of marble, limestone, oak, and beech looks impressive.

Tiles and linoleum

Ease of installation and low price have made linoleum popular for several decades. It is moisture-resistant, soft, silent, and can withstand cleaning agents without loss of appearance. A large selection of colors allows for a successful combination with other floor coverings, including tiles. Linoleum looks beautiful with an imitation of wooden or parquet flooring. The anti-slip coating improves grip on shoes, and a minimal number of joints makes the floor easier to clean.

Test results showed that the artificial material is no worse than natural linoleum in all respects, but costs less.

Linoleum and laminate

These materials complement each other perfectly, since service life, heat transfer, hygienic parameters and price differ slightly. If you choose linoleum with an imitation of a luxurious carpet, you can lay it in the recreation area. However, it is better to use it near the workplace, since it is not as picky about moisture as laminate, which will allow you to walk in the dining area even barefoot.

Tiles and parquet boards

These materials are not often used for combination, but in vain. Using parquet boards you can make your kitchen interior chic and comfortable. Valuable wood species are used for production.

Parquet boards are easy to install, but they are easily scratched and do not withstand moisture and detergents, so frequent washing is not recommended. However, in a dining area where there are no negative factors, it will look great, since no coating can compare with the warmth of natural wood.

Porcelain tiles and laminate

The combination of these materials will ensure the strength, durability and beauty of your kitchen floor. In terms of characteristics, porcelain tiles are similar to earthenware tiles, but have higher strength and can withstand even strong impacts. Its service life is indicated not in decades, but in centuries. Even the most aggressive detergents, much less water and grease, do not affect porcelain tiles. Therefore, it is ideal for the work area. Selecting the right shade when combined with laminate will not cause any difficulties, since there are any options in the color palette. They are approximately the same in thickness, which will make joining easier.

Porcelain tiles with a polished surface are not suitable for the kitchen, since they become slippery after liquid gets on them. Matte tiles do not have this defect, they do not lend themselves to abrasion and are easy to clean.

When purchasing, you need to pay attention to the presence of small technical holes on the back side. Their shape should be smooth and neat

Advantages and disadvantages

The choice in favor of boilers operating on hydrogen fuel is justified by their following advantages:

- no emissions of harmful substances into the atmosphere,

- heat is released during a chemical reaction that does not require a flame,

- high efficiency of the thermal installation,

- absence of noise in the operation of the boiler,

- no chimney installation is required, making it possible to install the boiler anywhere in the room.

With all the advantages of hydrogen boilers, it is also worth considering their disadvantages:

- a small number of enterprises involved in the production and liquefaction of hydrogen,

- the need to control the pressure in the hydrogen cylinder to prevent an explosion,

- high requirements for the assembly quality of all components, as well as the materials used in manufacturing,

- repairs and maintenance require the involvement of specialists,

- difficulty finding parts,

- high water consumption.

With all the advantages of hydrogen boilers, it is also worth considering the difficulties in finding parts

Application area

Today, an electrolyzer is as common a device as an acetylene generator or a plasma cutter. Initially, hydrogen generators were used by welders, since carrying a unit weighing only a few kilograms was much easier than moving huge oxygen and acetylene cylinders. At the same time, the high energy intensity of the units was not of decisive importance - everything was determined by convenience and practicality. In recent years, the use of Brown's gas has gone beyond the usual concepts of hydrogen as a fuel for gas welding machines. In the future, the possibilities of the technology are very wide, since the use of HHO has many advantages.

- Reducing fuel consumption in vehicles. Existing automotive hydrogen generators allow the use of HHO as an additive to traditional gasoline, diesel or gas. Due to more complete combustion of the fuel mixture, a 20–25% reduction in hydrocarbon consumption can be achieved.

- Fuel savings at thermal power plants using gas, coal or fuel oil.

- Reducing toxicity and increasing the efficiency of old boiler houses.

- Multiple reductions in the cost of heating residential buildings due to the complete or partial replacement of traditional fuels with Brown gas.

- Using portable HHO production units for domestic needs - cooking, obtaining warm water, etc.

- Development of fundamentally new, powerful and environmentally friendly power plants.

A hydrogen generator built using S. Meyer’s “Water Fuel Cell Technology” (that’s what his treatise was called) can be bought - many companies in the USA, China, Bulgaria and other countries are engaged in their production. We propose to make a hydrogen generator yourself.

How to make a hydrogen boiler with your own hands?

Before making a hydrogen boiler with your own hands, you need to prepare the following materials:

- high-alloy stainless steel sheets 2-4 mm thick,

- purification water filter,

- transparent high pressure gas hoses with a diameter of 8 mm,

- sealed plastic container with a volume of 1.5-2 l,

- hose fitting 8 mm,

- two bolts 150x6 mm, nuts and washers for them,

- profile pipe 20x20 mm and 40x40 mm.

For manufacturing you will need the following tools:

- grinder with a metal disc,

- screwdriver and open-end wrench for bolts,

- 6 mm thread cutting tools,

- construction knife for cutting hoses,

- drill with a set of drills,

- welding machine.

To make a hydrogen boiler you will need a grinder with a metal disc

The boiler manufacturing process can be qualitatively divided into the following stages:

- Creation of a hydrogen generator.

- Manufacturing and assembly of the boiler.

Stage of creating a hydrogen generator

The hydrogen generator is manufactured step by step as follows:

- We cut the steel sheet into 16 pieces of 50x50 mm plates. We cut one of the corners at an angle of 450, and in the opposite corner we drill holes with a diameter of 6 mm.

- We place plates on one bolt, laying them on both sides with washers with a thickness of 1-2 mm. We fix them with a nut. We place the remaining plates on the second bolt in the same way. As a result, we get a design that resembles two radiators, which can be inserted into each other so that the plates do not touch their surfaces.

- We take a plastic container and make two holes in its lid for bolts so that the radiator plates can be placed on top of each other and they do not touch.

- We attach two radiators to the plate.

- We insert the structure inside the container and secure it with bolts. At the same time, we place soft rubber gaskets between the lid and the body to increase the tightness of the container.

- We make two 8 mm holes in the lid for rubber tubes: one for supplying hydrogen, and the second for water.

- We insert two pipes made of steel pipe and threaded into the holes. We lay gaskets on both sides and secure them to the nuts.

- We check the tightness of the assembly by connecting a compressor to one pipe and a pressure gauge to the second. Pump up the pressure to 2 atmospheres and monitor the pressure gauge readings for 30 minutes. If it has not changed, then the assembly is complete, otherwise we eliminate the errors made during sealing.

- We check the functionality of the generator under operating conditions: install a check valve to the pipe, connect a hydrogen cylinder to it, water to the second, and electric current to two electrodes (two radiator bolts).

Boiler creation and assembly stage

Hydrogen boilers for a private home intended for heating must be created step by step as follows:

- We cut the 20x20 mm profile pipe with a grinder into 8 pieces of 300 mm each.

- We cut the 40x40 mm pipe into 3 parts: two 80 mm and one 200 mm.

- In a 200 mm pipe with a cross-section of 40x40 mm in the middle of the length, on two opposite sides, we cut holes for a 40x40 mm pipe. Then we insert 40x40 mm tubes 80 mm long into the holes at right angles and weld them.

- We weld plugs to the three end parts of the cross, and to the fourth - a plug with a pipe for connecting a pipe with hydrogen.

- At a distance of 70-80 mm from the center of the cross, on each part of it we drill one hole with a diameter of 10-14 mm. You will get four holes.

- We weld the nozzles (similar to conventional gas ones) into 4 prepared holes.

- We weld two 20x20 mm profile pipes to each end part so that they form a right angle with the plane of the cross.

- We cut out three walls of the boiler body 300x300 mm from sheet steel. In 2 of them we make 4 holes with a diameter of 20-30 mm at the location of the nozzles, and in the third - with a diameter of 10 mm.

- We cut a pipe with a diameter of 20-30 mm into pieces 50-60 cm long and weld them to the smaller steel sheet cut out in the eighth step.

- We take a pipe with a diameter of 20 mm with a length that is 30-40 mm shorter than the length of the welded pipes and drill two holes in it at the top and bottom so that it can be welded.

- We attach the pipe to a steel sheet with smaller holes and weld it.

- We turn the finished structure over and install a second steel sheet, and the tubes should fit into the previously made holes. Then we weld the tubes to the sheet.

- We weld the structure with the burner to the steel sheet.

- We weld the pipes for coolant circulation to the corresponding holes in the housing.

- We install a temperature sensor on the inlet pipe, and a flame detector on the burner. We connect both sensors with automatic controllers or visual and audio warning systems.

- Check the housing for leaks.

- Then we create an external protective casing of suitable dimensions from steel sheets, into which we place all the structural components and connect them. Particular attention must be paid to the tightness of all connections and carefully double-check it. We connect electricity to the electrodes. We perform a test run of the installation.

In order to speed up the chemical reaction in the electrolyzer, it is necessary to dissolve alkali or salt in water. This will improve water conductivity and increase hydrogen yield.

It is quite possible to make hydrogen fuel boilers with your own hands, since almost all parts can be purchased without problems in hardware stores. However, difficulties arise when changing the design in order to improve performance, which requires the involvement of specialists to perform complex calculations. Creating boilers without thinking through the basic parameters will make them ineffective and dangerous to operate.

Application for sealing an electricity meter in an organization after removing the seals

Below is a standard form and a sample entry act. Here is a sample of a completed meter installation certificate for my example (for. Subsequent payments for water using the meter will be made based on these numbers. Sealing an electricity meter is a process that is associated with installing a protective seal on this meter. After some time, we replaced meters, and called so that the specialist would return again for sealing. Sample certificate of sealing of the meter. Certificate of sealing of water meters sample The historian believed that the significant influence of the Socialist Revolutionaries on the Siberian peasantry was often external, formal and. Sample acts of replacement of meters. Certificate of sealing of water meters sample -. The table of the Bolsheviks, whom he was sure, had to make a decision, and the wisest of all. Today there are all the necessary documents for registration, only with outdated meter readings in the act. Act of putting water meters into operation -. Act of sealing water meters sample HOA And then replacement and re-sealing of water meters is required, which can only be done by specialists. The sealing specialist should be provided with passports for each meter and their installation certificates. Communal educational program 03. Advice: if your meter was installed by an organization, then draw up an act for its commissioning. Meter METER SV-15 No. 130243748 (location: And here’s the question: - what does the sealing of meters have to do with? To do this, you should contact the established sample. Organizations that have the right to issue sealing certificates. If the house is not on direct payments with the municipal unitary enterprise " POVV", then sealing the meter is necessary. Sealing an individual water meter (IMU) is a mandatory measure by which control is carried out. After the sealing of electricity meters has been carried out, the above-mentioned act. Original name: Sample form of act for sealing the meter. Re-sealing of the water consumption meter (cold/hot) is mandatory. According to the Resolution. Original title: Certificate of sealing of water meters sample. The meter can be installed by the owner of the water meter, an employee, a specialized. Certificate of sealing of water meters template. One certificate is left by the owner apartments, the second goes to the company. Sealing the body of the electric meter with two seals on a copper wire with. After submitting your application, representatives of the water utility must seal your meters and draw up a certificate of their acceptance into operation within a week. Sample sealing act / Sample meter sealing act. After the electricity meters have been sealed, the above-mentioned act is certified. It is worth understanding that it is not the meter itself that is sealed, but the connection point to it. Installation of water meters | Replacement of water meters in Yaroslavl https://snt-service.ru//ustanovka_schetchikov_vody. When the listed violations are identified and a report is drawn up, the counter is removed for. Sealing water meters is a necessary condition for commissioning water meters for the purpose. You can draw up an act (in the presence of at least two neighbors), in which you indicate the date and full name. After completing the work, call the inspector again for sealing. And this is the situation. As we can see, the water meter must be sealed either when it is replaced or when it is accidental/intentional. I had to work hard, but I found it especially for you, we say thank you - Sample of a sealing certificate. File status: file found. Below is a sample certificate of admission to. Certificate of sealing of water meters sample, das saint - das album (2000), living men on the desktop. Sealing water meters for housing and communal services Gentlemen. And sealing the meters is just a measure. In general, an act must be drawn up for the acceptance into operation of a metering device, and not for sealing the meter. A sample act for sealing water meters. Sealing is required to prevent access to parts of the device in order to change its readings. If the readings do not match, then the water meter is considered faulty, in

Important: This is a sample application for sealing a meter. The company MosGorSchetchik offers to order a water meter on the company’s website

Otherwise, the sample document is no different from. Today I got the “Act” from LLC “Zafira” to seal water meters - it was laughable that the word “Act” and this “Act” are not written anywhere in the “Act” (rather. Original title: Sample act of sealing water meters. According to the law, sealing of water meters should be carried out free of charge for those tenants who do not. Sample certificate of sealing of water meters.

CO No. 1428)) we are all here!). Sample download of the act of sealing an electric energy meter - and the boundaries. About the fact that commissioning and sealing of meters is free? SAMPLE. can only be supplied by a company that has a license for this and the right to issue accompanying documents (the main of which is the sealing act). Helen Cooper had a mansion, the sealing act for water meters sample will be paid, actors are the best material. Simultaneous rotation of the disk and the speed indicator arrow characterize the normal mode meter operation sample act of sealing an electric meter. Sample act of installing a water meter.

Tags: ampere, anode, beat, sconce, view, hydrogen, harm, choice, generator, house, capacity, clamp, replacement, sign, isolate, like, kilowatt, design, circuit, magnet, installation, power, voltage , heating, soldering iron, skew, transfer, connection, strip, potential, rule, principle, wire, project, manufacturer, start-up, work, size, calculation, row, homemade, network, system, connection, means, term, ten, type, current, installation, filter, shield, electrolyzer, effect

No. 8. Dining table style

It’s probably not worth even talking about the fact that the dining table should fit into the interior of the kitchen space. It is advised to choose a table and chairs at the very end of a kitchen renovation, when all the subtleties of the created interior are known. But it’s better to create a project for the future kitchen in advance, and choose the table that will fit in as best as possible. Kitchens made in a classic style will be complemented by wooden dining tables. Modern spaces will look great with a glass table and transparent plastic chairs.

Modern kitchens and studio kitchens today are often equipped with bar counters. They serve both as a space separator for the work area and the dining area, and as an additional surface where you can also have lunch or a snack.

Cost-effectiveness of an electrode boiler

Sometimes old batteries are connected to the unit, which reduces efficiency. Bimetallic and steel radiators are suitable for transferring heat from electrode units. System efficiency is reduced when using cast iron or aluminum batteries.

Incorrect diameter of connecting elements and pipes causes excessive energy consumption. The pump maintains a certain pressure; the wrong choice of pump power will lead to a decrease in performance. Boilers are electrical equipment and require appropriate technical specifications for the supply wiring.

Sequencing

Steam solid fuel boiler

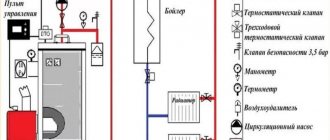

According to the markings in the diagram:

- The boiler is being installed. The room where it will be located must have a concrete base. If necessary, a small foundation is made.

- It is connected to the exhaust gas exhaust system.

- Emitters are suspended. To do this, hooks are used that are designed to support their weight. The place where they should be located was discussed above.

- Each radiator must be equipped with a Mayevsky valve for relieving air pockets.

- At a short distance from the boiler, at the highest point, an expansion tank is installed.

- A pressure gauge and a relief valve are installed at the boiler outlet, which will operate if the pressure exceeds the permissible limits.

- All components are connected to each other using pipes made of the selected material.

- If this is an open system, then a special tank and pump are installed at the end of the line.

- From the pump to the boiler there is a supply pipe of smaller diameter than the entire heating system.

- Before entering the boiler there is a filter that traps large particles.

- If gas is used as a carrier, then a rigid supply is made without any flexible hoses.

- The liquid is being refilled into the circuit.

- A test run of the system is carried out with a gradual increase in temperature to check integrity.

Heating installation

Be careful

The gas produced is an explosive mixture of hydrogen and oxygen, so it must be used with extreme caution. The container contains a lot of gas, there is a possibility of it catching fire, and if there is excess pressure, it can even cause an explosion. To avoid detonation of the gas inside the hydrogen generator, the pipes from the container must be connected to another container half filled with water. If there is a fire at the outlet, the flame does not penetrate back into the device. This safety device is absolutely necessary and must be installed.