Recirculation of hot water through the boiler.

The water pressure in the boiler itself may be insufficient to provide the cottage with hot water. To recirculate hot water through the boiler, it is necessary to properly install the DHW system with the installation of a circulation pump.

In large country houses, experts recommend installing a hot water supply (DHW) system using a centralized method of heating water, through a gas and electric water heater (you can also use a single-circuit gas boiler). In this case, in order to provide the necessary supply of hot water, an indirect heating boiler must be installed in this system.

The volume of the boiler is calculated taking into account all the people living in the house (for a family of 4 people, a boiler of 100-150 liters will be enough). The water in the DHW system is heated using a heat exchanger, which is connected to a heating source (boiler, water heater).

The DHW system boiler has several inputs and outputs. The design feature of indirect heating boilers is that a coil in the form of a spiral-shaped metal tube is mounted into it, through which hot water from the boiler passes. Due to heat exchange between hot water in the coil and cold water in the boiler, the liquid inside the boiler is heated. This creates a preliminary supply of hot water for human needs.

The entire DHW system has a closed operating cycle. If hot water is not used for a long time, it begins to cool down. When a person wants to use hot water, he will probably face the problem of initial lack. When you turn on the tap, the system itself is activated and water heating begins. But it may take several minutes until it heats up to the desired temperature.

In order to be able to use hot water immediately after opening the tap, a circulation pump is installed in the system, which ensures water recirculation throughout the circuit constantly, regardless of whether a person uses hot water or not.

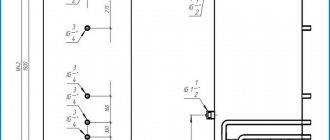

Uninterrupted recirculation of water through the boiler is carried out by installing additional equipment: an expansion tank, check and safety valves, and an air drain valve.

Thus, hot water is recirculated through the boiler using a circulation pump, a heat exchanger and additional equipment, which is mounted into a single DHW system. As a result, a person will not have to wait for the water to heat up by running water for some time.

How to refuse water meters?

So how can you get rid of unnecessary water meters? You need to write an application to the Housing and Communal Services (Housing and Communal Services) or management company; the details and address are written in the receipt that arrives every month in your mailbox, so it won’t be difficult to find them.

Interesting materials:

How are the houses on the street numbered? How should you care for small snails? How about a proposal against a wall? How to combine graphs in Excel? How to merge calls on iPhone? How to explain patience and labor will grind everything down? How to declare a variable in VBA? How to exchange points for Beeline minutes? How to exchange Tele2 minutes? How to exchange a skin for CS money?

What elements does the water supply scheme of an apartment building include?

The water metering unit, which organizes the supply of water to the house, is responsible for several functions:

- It takes into account the consumption of cold water supply, that is, it acts as a water meter;

- It can shut off the supply of cold water to the house in emergency situations or when it is necessary to repair components and parts, as well as to eliminate leaks;

- Serves as a filter for coarse water purification: any hot water supply scheme for an apartment building should contain such a mud filter.

The device itself consists of the following components:

- A set of shut-off valves (taps, valves and valves) at the inlet and outlet of the device. Standardly these are gate valves, ball valves, valves;

- Mechanical water meter, which is installed on one of the risers;

- Mud filter (filter for coarse water purification from large solid particles). This could be a metal mesh in the housing, or a container in which solid debris settles to the bottom;

- Pressure gauge or adapter for inserting a pressure gauge into a water supply circuit;

- Bypass (bypass from a section of pipe), which serves to turn off the water meter during repairs or for data verification. The bypass is equipped with shut-off valves in the form of a ball valve or valve.

Heating point

It is also an elevator unit that performs the following functions:

- Ensures full and continuous operation of the heating system in an apartment building, and also regulates its parameters;

- It delivers hot water to the house, that is, it provides hot water supply (hot water supply). The coolant itself in the heating system enters the hot water supply system of the apartment building directly from the centralized heating main;

- The heating point can switch the hot water supply between return and supply. This may be necessary during severe frosts, since at this time the temperature of the coolant on the supply pipe can rise to 130-1500C, and this despite the fact that the standard supply temperature should not exceed 750C.

The main element of a heating point is a water-jet elevator, where hot water from the working fluid supply pipeline circuit in the house is mixed in a mixing chamber with the return coolant by injection through a special nozzle. Thus, the elevator allows a larger volume of low-temperature coolant to pass through the heating circuit, and, since injection is carried out through a nozzle, the supply volume is small.

Adapters for connecting DHW can be inserted between the valves at the inlet of the route and the heating station - this is the most common connection scheme. The number of inserts is two or four (one or two each on the supply and return). Two inserts are typical for old houses; in new buildings, four adapters are practiced.

On the cold water supply route, a dead-end tie-in scheme with two connections is usually used: the water metering unit is connected to the bottling, and the bottling itself is connected to the risers through which pipes are routed to apartments. Water will move in such a cold water supply system only during disassembly, that is, when opening any mixers, taps, valves or valves.

Disadvantages of this connection:

- If there is no water supply to a particular riser for a long time, the water will remain cold for a long time when drained;

- Heated towel rails embedded in the DHW inlets from the boiler rooms, which simultaneously heat the bathroom or toilet, will only be hot when the DHW is drawn from a specific riser in the apartment. That is, they will almost always be cold, which will cause the appearance of moisture on the walls, mold or fungal diseases of the building materials of the room.

A heating station with four hot water connections in the house makes the circulation of hot water continuous, and this happens through two bottlings and risers connected to each other by jumpers.

Important: if mechanical water meters are installed on the hot water taps, then the water supply consumption will be taken into account without taking into account the water temperature, which is incorrect, since you will have to overpay for hot water that was not used.

Hot water supply can operate in three ways:

- From the supply pipe to the return pipe to the boiler room. Such a hot water system is effective only in the warm season when the heating system is turned off;

- From supply pipe to supply pipe. Such a connection will bring maximum benefits in the demi-season - autumn and spring, when the coolant temperature is low and far from maximum;

- From the return pipe to the return pipe. This DHW scheme is most efficient in extreme cold, when the temperature at the supply pipe rises to ≥ 750C.

For continuous movement of water, a pressure difference is required between the starting and ending points of insertion into one circuit, and this difference is ensured by limiting the flow. This limiter is a special retaining washer - a steel pancake with a hole in the middle. Thus, the water that is transported from the inlet to the elevator encounters an obstacle in the form of a washer body, and this obstacle is regulated by a rotation that opens or closes the retaining hole.

But too much restriction of the movement of water in the pipeline route will disrupt the operation of the heat station, so the retaining washer should have a diameter 1 mm larger than the diameter of the heat station nozzle. This size is calculated by representatives of the heat supplier so that the temperature at the return heating pipe of the elevator unit lies within the standard temperature limits.

What is pipe filling and riser

These are pipes laid horizontally and carried through the basement of a residential building, which connect the risers to the heating station and water meter. Bottling of cold water supply is done in single copies, bottling of hot water supply - in duplicate.

The diameter of the DHW or cold water filling pipes can be 32-100 mm, and depends on the number of connected consumers. For any water supply scheme, ø 100 mm is too large, but this size is taken taking into account not only the actual condition of the route, but also taking into account the size of salt deposits and rust on the inner walls of metal pipes.

A vertical pipe riser distributes water to the apartments located above it. The standard layout of such wiring includes several risers - for cold and hot water supply, and sometimes separately for heated towel rails. More wiring options:

- Several groups of risers passing through one apartment and providing water to water points located at a great distance from each other;

- A group of risers in one apartment that supplies water to a neighboring apartment or several apartments;

- When organizing hot water supply, pipe jumpers can be used to connect up to seven groups of risers across apartments. The lintels are equipped with Mayevsky taps. This is called a circulation pipeline, or CTP.

The standard diameter of cold and hot water supply pipes for risers is 25-40 mm. Racks for heated towel rails and single risers are mounted from ø 20 mm pipes. Such risers provide both one-pipe and two-pipe home heating systems.

Closed hot water system

The constant circulation of water in a closed hot water supply system is based on the principle of taking cold water from the pipeline and supplying it to the heat exchanger. After heating, the water is supplied to the distribution system throughout the apartment. The working fluid in the heating system and hot water for the technical needs of consumers are separated, since the coolant may have toxic inclusions to improve its heat transfer qualities. In addition, hot water pipes rust faster. Such a scheme is called closed because the consumer uses the heat, and not the coolant itself.

Pipe liner

The main function of the connections is to distribute water to the water collection points in the apartment. The standard diameter of the supply pipes is 15 mm, the grade of pipes is DU15, the material is steel. For PVC or metal-plastic pipes, the diameter should be the same. When repairing or replacing the liner, it is not recommended to use a smaller diameter so as not to change the design pressure parameters that the hot or cold water supply circulation system must comply with.

To organize the correct wiring, tees are most often used; for more complex wiring schemes, manifolds are used. The collector supply requires hidden installation, so the collector should be installed when servicing a large number of rooms in the house. After 10-15 years, metal pipes become overgrown from the inside with salt mineral deposits and rust, so preventive work to restore the system’s functionality consists of cleaning the pipes with steel wire, or replacing old pipes with new ones.

Given the apparent functionality and durability of PVC or metal-plastic pipes, it is recommended to use steel products for liners - they withstand water shocks and temperature changes well. Such deviations in the DHW operating mode can often be observed when the heating system is turned on or turned off in an emergency. Pipe material should be included in the plan for the water supply scheme of a residential building at the stage of drawing up the project and estimate.

What pipe products are recommended for use in cold and hot water supply schemes with constant water circulation:

- Galvanized metal pipes - they have been used for many decades, and they have proven themselves to be the best. The zinc layer on the metal prevents corrosion from developing and does not retain salt deposits. When purchasing galvanized products, you should remember that welding work is not carried out on such a surface, since the weld seam will remain unprotected by zinc - all connections must be made on threads;

- Pipe connections on fittings for soldering copper connections last much longer than steel and even galvanized pipes. Such connections with a solder connection do not need to be maintained, and they can be laid in both open and hidden ways;

- Corrugated pipe line for cold or hot water supply made of stainless steel. Such products are simply and quickly mounted on threaded connections or compression fittings. No special equipment other than two adjustable wrenches is required for this. The guaranteed service life of stainless steel is not limited by the manufacturer. The only thing that will have to be changed over time is the silicone seals.

Where should the boiler room be located?

A very serious issue is the correct location of the boiler room. Most often, in apartment buildings, boiler rooms are installed either on the roof or in the basement. Projects of private houses with a boiler room provide for the presence of the latter only in the basement or ground floor.

True, sometimes you can also see boiler rooms located in small buildings located a few tens of meters from the house. This can be a good solution: there is no need to lift and install equipment on the roof of the building, but at the same time there is no threat of explosion due to fuel leakage and its accumulation in the basement of the building.

But still, this method is not very popular: the need for additional construction, pouring the foundation and carrying out a large amount of earthwork scares off many potential owners of autonomous heating boilers. Therefore, only two options are usually considered - a boiler on the roof and in the basement. And it’s worth talking about them in a little more detail.

This is what a boiler room looks like on the roof

What is a boiler

A boiler is an electric water heating device that is installed in private or apartment buildings for autonomous supply of hot water. Boilers are especially common among high-rise residents, since centralized hot water supply often works intermittently and solely at the wishes of utility workers.

In order to understand the principle of operation of the boiler, you first need to understand it

device. The device consists of the following parts:

- Bracket. Used to mount the device to the wall.

- Water supply pipes. There are two of them: the first supplies cold water inside the device, and the second removes hot water. The supply and output of fluid is limited by valves.

- Thermal insulation layer. Prevents heat loss when the heater is not active. Helps save energy.

- Storage tank. Actually, the place where water is collected.

- Thermal sensor. Used to limit heating and also provide information about the current temperature in the tank.

- heating element. Element that heats water.

- Magnesium anode. A device used to protect heating elements from corrosion.

As you can see, the set of parts in the boiler is relatively small, but each of them performs an important function. Next, let's talk about how they interact and how the boiler operates.

The municipality installed a boiler room in the house and handed it over to the maintenance authority

One of the management organizations of Magnitogorsk found itself in a difficult situation, under a contract it was engaged in the maintenance and repair of common property in an apartment building with direct management. In this house several years ago, the administration installed a boiler room and transferred it under the right of economic management to a heat supply organization.

After 13 years, RSO informed the city administration that it would no longer service the boiler room, and the local government excluded the equipment from the register of municipal property in accordance with Part 2 of Art. 36 Housing Code of the Russian Federation. The compulsory medical insurance department sent copies of the inspection and transfer certificates of the ITP, as well as test reports, and all the technical documentation for the boiler installation to the Administration, considering that this is now part of the property of the owners in the house.

But the owners of the premises at the general meeting refused to accept the equipment as part of the common property, and therefore, to include boiler room maintenance in the fee under the agreement with the management company. The company did not do this, including conducting hydraulic tests of input units and heating systems, flushing them and adjusting the ITP. This was recorded by the State Housing Authority after an unscheduled inspection of the company’s activities and demanded that the violations be eliminated.

The management authority appealed to the court to declare the order of the supervisory department illegal: it cannot service equipment that is not included in the common property of the apartment building and in the agreement with the owners. However, courts of all instances, including the Supreme Court of the Russian Federation, rejected the company’s claim (case No. A76-39409/2019). Let's figure out why.

Is it possible to alienate common property in an apartment building?

165470

Using what criteria to choose

There are 3 main criteria for this process:

- Volume. You should not set the device to the maximum value for this value. This may lead to financial difficulties in the future. Since a container of sufficient volume will use more water, the bill for its consumption will be higher. It is worth remembering that the larger the volume of the installation, the more it will come into contact with the coil, which can lead to heating of the coolant.

- Power. This criterion affects water heating. For a full heating process, a water heater with an indicator of 8-12 kW is suitable.

- Diameter. This criterion depends on the area of the room where the device is installed.

We disassemble the boiler “to the bones”

You can understand the principle of operation of a storage water heater only by understanding how it works.

With all the modern variety of boilers, they all consist of the same elements:

Electric boiler device.

- outer casing (can be made of steel or plastic, determines the “appearance” of the device);

- internal tank (it can be made of glass porcelain, stainless steel, and can also be equipped with titanium coating);

- thermal insulation (located between the inside and outside of the boiler; usually made of polyurethane foam);

- heating element (is a heating element that converts electrical energy into heat);

- system for fastening to the wall (plate with holes);

- hot water supply and cold water extraction pipes;

- adjustable thermostat (automatically ensures heating of water and maintaining its temperature);

- thermometer (shows the temperature of the liquid);

- magnesium anode (prevents corrosion of the internal tank);

- indicator light (lights up during active operation of the device).

Depending on the type of water heater, there may be some subtleties in its design. For example, today storage heaters with “dry heating elements” are becoming popular, where the heating element is enclosed in a special flask that prevents the formation of scale. The heating element does not come into contact with water, hence the name of this type of heater. A floor-standing boiler will not have a mounting system, unlike a wall-mounted one.

How does a boiler differ from an instantaneous water heater?

Comparing it with a flow-through water heater will help you fully understand the operating principle of a storage water heater. If a certain amount of water is heated in a storage device, equal to the volume of the tank, then during operation of the flow-through apparatus, as much water will be heated as the consumer consumes at a time. Water heating occurs in real time.

A boiler, compared to a flow-through device, will consume less electricity to heat the same amount of water. This is the most significant advantage of a storage water heater. Among the advantages of a flow-through water heater, it is worth noting its compactness.

Thus, the essence of the operation of modern boilers is quite simple, which allows them to be quite productive and economical. The newest models have fully electronic controls. This makes it possible to effectively “communicate” with the unit even for people who are far from knowledgeable about technology.

Single pipe heating system

Single-pipe heat supply to an apartment building has a lot of disadvantages, the main one being significant heat losses during the transportation of hot water. In this circuit, the coolant is supplied from the bottom up, after which it enters the batteries, gives off heat and returns back to the same pipe. Hot water first reaches the end consumers living on the upper floors in a barely warm state. There are cases when a single-pipe system is further simplified, trying to increase the temperature of the coolant in the radiators. To do this, the battery is cut directly into the pipe. As a result, it seems that the radiator is its continuation. But only the first users of the system receive more heat from such a connection, and the water reaches the last consumers almost cold (about

Breakdowns in the hot or cold water distribution system

You can fix the following emergency situations with your own hands:

The valve or faucet is leaking. This happens most often due to wear of the oil seal or seal. To eliminate the malfunction, it is necessary to open the valve completely and with force so that the raised oil seal stops the leak. This technique will help for a while; in the future, the valve must be rebuilt and worn parts replaced.

Noise and vibration of a valve or faucet when opening in a hot water supply system (less often cold). The cause of noise is most often wear, deformation or crushing of the gasket in the gearbox of the mechanism. Noises appear if the tap is not opened all the way. This fault can cause a series of water hammers in the pipes, so its elimination is of utmost importance. The faucet valve is capable of closing the valve seat in the faucet or valve body in a few milliseconds, if it is not a ball valve, but a screw valve. Why is the risk of water hammer higher in hot water supply systems? Because in hot water pipes the operating pressure is higher.

How to fix the problem:

- Shut off the water at the inlet;

- Unscrew the valve housing of the noisy faucet;

- Replace the gasket, but before installing, chamfer the new gasket so that the valve does not vibrate when opening under high pressure.

The heated towel rail does not heat up. The cause of the breakdown may be the presence of air in the water supply system with constant coolant circulation. Typically, air accumulates in a pipe jumper, which is installed between adjacent risers, after an emergency or scheduled drain of water. The problem is eliminated by bleeding the air plugs. To do this you need:

- Vent the air at the highest point of the system - on the top floor;

- Shut off the hot water supply riser located in the apartment (the riser is closed in the basement of the house);

- Open all hot water taps in the apartment;

- After bleeding air through taps and mixers, you need to close them. And open the shut-off valve on the riser.