In order not to freeze at home in winter, and to save costs on additional heating devices, you need to take care of insulating the room. Spray insulation is now gaining popularity.

It appeared back in 1937. It's not a new thing abroad for a long time. The active substance is called polyurethane foam. It is sold in large canisters and cylinders. It is obtained by mixing a polyol and a polyisocyanate. They react to form a significant amount of foam.

Apply to the surface by spraying. Has a bubbly texture. After drying it hardens. 80% consists of air. The insulation thickness of 5 cm is comparable in its characteristics to a 35 cm expanded clay layer.

Pros and cons of sprayed insulation

Any insulation material has its advantages and disadvantages. It is important to familiarize yourself with them before starting work. This will allow you to make the right choice and avoid unpleasant situations.

Positive characteristics:

- harmless to humans - the composition does not contain hazardous substances;

- penetration into hard-to-reach places - every small crack will be filled;

- low thermal conductivity - the room temperature will not decrease;

- absence of joints - forms a single canvas;

- excellent sound insulation - no more noise;

- resistance to temperature fluctuations - will not collapse under the influence of atmospheric phenomena;

- durability of the material – will last 30–50 years;

- reliable adhesion to surfaces - firmly attached to any objects;

- water-repellent properties - it is not afraid of moisture;

- versatility of use - used almost everywhere;

- ease of application - even a beginner can handle it;

- resistance to fungi, mold, pests, chemicals;

- light weight – almost weightless;

- resistant to ignition - stops burning without a fire source.

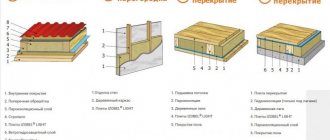

Figure 1. The insulation does not leave “cold bridges”.

Many problems are solved that other types of insulation cannot cope with.

But there are disadvantages:

- possibility of deformation of the spraying surface - preliminary leveling will be required;

- poor tolerance to exposure to sunlight - it is worth protecting it from them, otherwise a gradual loss of beneficial qualities occurs;

- the need to use additional equipment - a bulky unit will be required;

- work in a protective suit - vapors generated during work should not enter the lungs;

- vapor permeability of the finished coating - there will be a need to ventilate the room;

- high price - high cost compared to other types of insulation.

The presented type of thermal protection contains a small number of unpleasant moments. But you shouldn't ignore them. When choosing an insulation method, you need to carefully study them and draw the appropriate conclusions.

Minuses

When deciding to use polyurethane foam in cylinders for thermal insulation of your home, you must also take into account its disadvantages:

- Low resistance to sunlight . It is recommended to paint, plaster or panel the finished surface, thereby protecting it from the damaging effects of ultraviolet radiation.

- The need for special protection . You need to work with the material wearing waterproof gloves and a respirator.

- Expensive . Such insulation is an order of magnitude more expensive than conventional roll or slab materials.

- Ability to smolder . Although polyurethane foam is a fireproof material, it is better to avoid direct exposure to open flames. During smoldering, the substance emits carbon monoxide, which is dangerous to humans.

- Low mechanical stability . The frozen layer must be protected from impacts and sharp tools. Almost all popular insulation materials have a similar disadvantage.

Types of insulation for spraying

This is a universal material. It has two completely different types:

- Lightweight (open - cellular structure). Reminds me of cotton wool. It produces foam rubber. Has excellent elasticity. Soft. During operation, there is less material consumption than with rigid material. Provides better sound insulation compared to its rigid form, but the ability to absorb liquid is higher. Therefore it is suitable for internal insulation. Used in the creation of decorative elements. Its use requires adequate ventilation. Density 8–20 kg/m3.

- Hard (closed - cellular structure). Sufficiently dense material - from 25–300 kg/m3. Similar to foam. The price is higher than the light type. Suitable for outdoor use. Excellent insulation of the foundation. Ideally protects the walls of the bathhouse - vapor barrier is almost zero. Has a positive rating when working with a roof.

The use of any type depends on the tasks being solved and the conditions of use. All of them will retain their qualities for 25 years.

There is a classification by components:

- one-component - to acquire hardness you will need humidity from the air and building materials. Can be used outdoors and with sufficient ventilation;

- two-component - hardens due to a reaction between substances. Can be used in rooms without access to fresh air.

There are several types of sprayed PU - difficult to burn and poorly flammable. The fire safety class is indicated on the packaging.

Possibility of using foam fillers

Balloon thermal insulation , although better than its analogues in all respects, was not widely used in the past due to its high cost. And the use of such insulation was limited by the need to use special equipment, which, due to its price and complexity of development, is practically inaccessible outside the professional sphere. Much simpler and more profitable, although not always more convenient, was the use of mineral wool and polystyrene boards, which are made by extrusion.

Then manufacturers began to produce sprayed insulation in compact-sized cylinders, which led to a reduction in the cost of the method. To spray such a mixture of steel, complex installations and specialists in thermal insulation finishing are not needed, since the material itself is filled into small containers and the possibility of manual spraying is provided. Each cylinder is designed to cover one square meter of base (layer up to 60 mm thick). One person can process up to one hundred square meters per day.

As a result, calculations showed that working with insulation such as Polyno r is much more profitable in terms of labor costs , costs for the materials themselves and surface preparation. If a professional team of workers charges up to one and a half thousand rubles for insulating one square of wall, then using Polinor insulation with the same amount of material, you need to spend only about 500 rubles. You can work independently, which eliminates the need to look for experienced workers, reduces finishing time, and saves money.

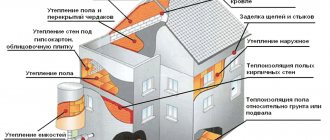

The choice of thermal insulation of this type remains the only optimal option that is available to people without special training. Foam can be used to create insulation for foundations, basements, walls inside and outside buildings made of brick, stone, concrete, and blocks. This option is also suitable for thermal insulation of non-load-bearing coatings, including floors on joists, as well as pitched roofs and attic floors.

Since Polinor is suitable for application to bases made of almost any material, it can be used as thermal insulation for plumbing fixtures and sewer pipes or fittings. In such cases, foam insulation in cylinders can be used indoors or in open areas. There is only one limitation on the use of balloon thermal insulation, which is that the material cannot be used to foam voids. It can only be applied to a dense base.

Popular manufacturers of sprayed polyurethane foam

There are not many manufacturers of sprayed PU - this type of insulation is only gaining momentum. There are 5 most famous ones:

- Polynor – country of origin – Russia. Designed for thermal insulation of rooms, surfaces of various shapes, eliminating the penetration of street noise. Polinor insulation is used to protect windows and balconies from drafts. Used to fill gaps when installing doors. Sold ready-made. All you need is a nozzle. Density 19 – 25 kg/m³. The cost of covering for 2 m2 is 450 rubles. Advantages: convenience, versatility. Disadvantage: high cost;

- Ecotermix are two-component spray systems. Produced in Russia. Available in 220 kg barrels. The price starts from 167 rubles per kg. Available types of insulation with an open-cellular structure. They are intended for interior use only. Density 7–14 kg/m3. There are polyurethane foam sprayers with a closed cell structure. Their density is higher - from 20–25 kg/m3; there are representatives with a density of 40–45 kg/m3. There are types of insulation based on water and freon. The latter are all-season. Suitable for tanks and pipes, providing complete heat and sound insulation. Can be used for outdoor work. 1.5 kg of insulation with a density of 20 m3 per 1 m2 of area is consumed. The advantage is the absence of excess waste. The disadvantage is the large dimensions, the need to mix components, and the need to independently purchase additional equipment;

- Tytan Professional Thermospray – Russian production. Its density is 20–25 kg/m3. Contains 1 component. Used for insulation of garages, basements, private houses. Fills voids and reliably glues surfaces. A can worth 612 rubles is enough for 2 m2. Pistol included. The advantage is ease of application. Disadvantage: it does not stick to polyethylene.

- Teplis – country of origin – Russia. The contents of 1 container cover up to 3m2. Material density 20–25 kg/m3. The price starts from 365 rubles per jar. Designed for sealing rooms, eliminating noise, and patching cracks. The advantage is the absence of a protective suit, the kit includes a rotating spray tube, a more affordable price category. The downside is the fragility of the included device;

- Foam Kit is a company that sells components made in Russia, the USA and other countries. Here you can purchase a ready-made kit to get started. It includes containers with components, gloves, a gun, nozzles, an installation key, and hoses. Everything is packed in a cardboard box with a carrying handle. The density of the resulting material is 28–30 kg/m3. Covered area up to 23 m2. The price of one set is 29,900 rubles. Designed for external and internal work. Able to close holes, insulate walls, and eliminate noise interference. The advantage is the elimination of the search for additional equipment and the low price compared to other brands.

Foam cost

If you buy a cylinder at retail, then on average you can pay 300-500 rubles per piece. But this type of insulation is rarely purchased separately. Usually its cost is included in the cost of work:

- polyurethane foam - about 100 rubles per linear meter;

- penoizol - 700−2000 rubles per cubic meter;

- polyurethane - 3000−5000 per cubic meter.

The price of the material also plays a big role in its selection. But you shouldn’t skimp on high-quality thermal insulation if you need to insulate your home for a long time for a comfortable stay.

Foam insulation is suitable for most walls , including panel, block and aerated concrete. Therefore, they can be safely used as insulation for apartments and private houses. What type of foam to choose is a purely personal matter for everyone. But first, it still doesn’t hurt to find out more about the selected composition, read reviews, and get advice from a salesperson at a hardware store. It is not recommended to use loose-fill insulation, which easily catches fire, unlike the foam fireproof version. And it is not the most convenient to use, the only exception being the floor surface.

Insulation with liquid foam is a better solution , because if desired, this procedure can be carried out independently, without the help of specialists. If you do everything correctly and are careful, you will be able to quickly insulate any surface that needs it.

Application area

Sprayed polyurethane foam has found its place in almost every area:

- large-scale and individual construction - creation of a heat-insulating and waterproof layer (roofing work, blocking the access of cold air through walls, windows, doors, balconies, basements, bathhouses, foundation);

- prefabricated structures - creation of sandwich panels;

- furniture production - the use of an elastic urethane foam layer (foam rubber) in the creation of mattresses, upholstery, seats;

- freezing units – protection against cold leakage for household and industrial appliances;

- pipeline transport – insulation of pipes for various purposes (petroleum products);

- heating networks – preventing hot water supply from cooling down;

- automotive industry - application in the arrangement of car interiors, creation of bumpers;

- equipment – vibration protection of electrical devices, waterproofing of contact connections;

- aircraft construction – protection against heat loss, noise insulation;

- carriage building – fire-resistant materials, noise reduction, thermal insulation properties;

- transport refrigeration equipment – microclimate support;

- design – creation of decorative products, jewelry, stucco moldings.

This material has conquered the whole world. Its ability to stick to almost any surface, even pipes, has come in handy for many. People sleep on it, sit on it, without knowing it.

Stages and technology of the spraying process

All actions to prepare equipment and surfaces are carried out directly at the site of further work.

Important! The insulation does not like wind - work should be carried out in its absence. The day should be without precipitation.

Recommended conditions for application: + 20 C0. Work can be carried out at lower temperatures. But this does not apply to all brands of atomizer. For such purposes, it is worth choosing all-season insulation.

Important! Ordinary stamps simply will not be able to stick to the surface in the cold. As practice shows, in winter there will be more of it. There will be a risk of performing the work poorly.

If you have a lot of work to do, you can’t do it without an assistant. All preparatory activities and the insulation process must be completed in one day. Otherwise, everything will have to be repeated.

Equipment

For the process of spraying insulation, you will need to protect yourself from harmful fumes.

Might be interesting

Vapor barrier

Effective and simple solutions for insulating ceilings in…

Vapor barrier

Technologies and materials for effective thermal insulation of floors in…

Vapor barrier

Vapor barrier and waterproofing, is there a difference?

Vapor barrier

Features of vapor barrier of a wooden building

Important! The process of interaction with sprayed thermal insulation takes place in a protective suit. Glasses and a mask are required. Hands should be protected with silicone gloves. Feet must be covered with rubber boots. Avoid inhalation of substances and contact with skin.

You will need a special installation for mixing substances, a hose and a gun. They can be purchased for rent if this is a one-time process. At the time of mixing materials, the surface must be prepared.

You need to stock up on a product that removes sprayed thermal insulation in advance. It will come in handy when you get into unnecessary places.

Surface preparation

Before carrying out insulation technical measures, you need to perform the following actions:

- the surface must first be cleaned of dirt and dust;

- holes and cracks should be covered with cement - adhesion to the surface will improve, the integrity of the structure will not be at risk;

- the area that does not need to be insulated is covered with polyethylene material;

- Moisten the application surface with water for better adhesion.

After all these steps, you can begin direct spraying.

Application of insulation

The process of applying polyurethane heat protection occurs in several stages:

- the first substance is mixed in the container using a mixer;

- another component is mixed in the second tank - you need to warm up the contents;

- they are combined in the third container;

- the resulting composition is poured into a special unit and sprayed onto the required area using a hose and a gun;

- you should call an assistant to periodically mix the substances;

- first you should go through all the hard-to-reach areas, joints, cracks;

- work is done from the bottom up;

- the output is foam that increases several times;

- each layer is applied after the previous one has dried;

- They dry for about an hour;

- minimum number of coatings – 3;

- protection from UV rays is carried out immediately - plastering, painting, siding.

Spraying polyurethane foam can be done with your own hands if the application area is small. But many difficulties will arise with a large surface. The risk of doing something wrong will increase many times over. Such cases should be entrusted to professionals.

Important! If you have to hire a crew, you should be vigilant. The professional himself will offer to check his work. You will need a nail or a probe (the operator has one). A piece of insulation is cut out anywhere on the finished surface. It must contain at least 3 layers. If they are not there, the spraying technology is broken.

Features of the material

Sprayed polyurethane thermal insulation refers to a substance formed by mixing two components ( polyol and isocyanate ). Filling or spraying can be used to lay the finished material . The first method is well suited for insulating large areas and filling voids inside engineering structures. The spraying method allows you to create a higher quality surface. In this case, the components are mixed under pressure inside special generators, and then supplied to the outside using a spray gun.

For use in everyday life and in local areas (inside cracks, gaps, openings), one-component polyurethane foam compositions , placed under pressure in liter cylinders. There is no need to pre-prepare the substance here: foaming and subsequent polymerization occurs during spraying. Polyurethane reacts with oxygen, resulting in a monolithic coating of microscopic cells. The liquid consistency helps the material reach hard-to-reach areas, ensuring their sealing and insulation.

Sprayed insulation in cylinders

It differs from a conventional sprayer - the finished substance is already in a convenient form. You just need to put on a special device (a pistol), and you can perform the necessary actions. The aerosol sprayer should be shaken periodically during application.

Analogue of construction foam. Quite a lot of it is consumed - on average, 1 spray bottle is needed for 2 m2.

Helpful Tips:

- the substance should be sprayed at a distance of 30 cm;

- It is worth adjusting the pressing force when working with sprayed thermal insulation in cylinders - it will be more economical;

- For the ceiling, a special corner attachment will be useful. It is more convenient to use;

- in winter, care must be taken to maintain heat in the container. You can wrap it in woolen cloth. Additionally, wrap the polyurethane foam in the balloons with cellophane;

- There is successful practical experience in using “heat islands” in winter - a movable shelter is built in which the temperature is maintained using heaters.

A protective suit will also be required. All other stages of working with it are exactly the same as with spraying systems.

Receiving PPU

When mixed, polyol and isocyanate produce foam, which increases in volume and then hardens. During the manufacturing process, it is necessary to adhere to a number of requirements: maintain the required temperature and mix all components well, which makes it possible to obtain a polyurethane output that does not have seals and large air cavities.

If you change the production method, you get polyurethane foams that differ in their basic characteristics. Some are better suited for insulating openings for doors and windows, others for brick and panel buildings or pipelines. By changing the proportions of the ingredients, when mixing them, polyurethane foam with different cell sizes is obtained.

Price for sprayed insulation

The cost is quite high. Starts from 350 rubles for 1 container. If you need to do work on the walls of the house or roof, the amount will be quite large.

Spraying systems cost around 200 rubles per 1 kg. Sold in barrels from 200 kg. The amount for one container is no less than 40,000 rubles. But this amount of spray, with a density of 20 m3, is enough for approximately 133 m2.

Calculation. Working with the foundation. For 1 m2 you will need 3.25 kg of components with a density of 45 m3. For the foundation, a density indicator from the presented figure and higher is suitable.

A density of 30 m3 or more will require 2 kg of the finished substance.

Calculation. Liquid insulation Polinor in cylinders. Protection of the walls of a house with an area of 375 m2. For 2 layers of coating, 406 pieces were required. The cost of one is from 400 rubles. The total amount is more than 150,000 rubles.