For reliable and proper functioning of heating radiators, it is recommended to install special shut-off valves, which allow you to regulate the pressure and flow of the coolant, increasing or decreasing its volume. Heating efficiency very much depends on the correct choice of this technical equipment.

Currently, special ball valves for radiators are used to solve such problems. The tap is an indispensable part of any heating system, because they can, for example, completely turn off the heating in the summer or turn off the water to flush pipes and networks and regulate the temperature.

Cranes are installed to save energy and save money. Also, with the help of such simple devices you can get rid of air that may be present inside the pipes.

Selecting a specific radiator model

Once you have decided on the type and type of heating radiators you need, it’s time to calculate and select specific models of these radiators that will have the necessary technical parameters.

Calculating thermal power

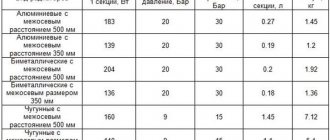

How to choose the right heating radiators to achieve the proper level of warmth and comfort? To do this, you need to calculate the thermal power of the radiators you plan to purchase. For certain standard conditions, a thermal power of 0.09 to 0.125 kilowatts per square meter of room is required. This is exactly the power that should be enough to create optimal climatic conditions in the room.

Now about what is meant by standard conditions. Everything is simple, this is a room in which there is a window with a wooden frame and three-meter (no higher) ceilings, as well as an entrance door. At the same time, hot water at a temperature of seventy degrees flows through the heating pipes. If you have the same conditions, then multiplying 0.125 by the area of the room you will get the power of the radiator or radiators (if several are required) required for the room. Next, all that remains is to look at the passport of specific radiators and, having found out there the thermal power of one section or the entire radiator, select the required model.

But this is a simple calculation; in fact, it is necessary to take into account some other factors that will have an impact in this case:

- You can reduce the power of radiators by 10 - 20% if you have plastic energy-saving double-glazed windows installed in your room, because they reduce heat loss in the room by approximately that amount.

- If there are not one, but two windows in the room, then you need to place a radiator under each of them. Their combined capacity should be 70% higher than the standard value. We will do the same in the case of a corner room.

- When the hot water temperature increases or decreases for every 10 degrees, we also increase (or decrease) the power of the device by 15-18%. The thing is that if the temperature of the coolant decreases, then the power of the heating radiators decreases.

- If the ceilings are higher than three meters, the heating power must again be increased. The increase must be made as many times as the 3-meter ceilings in the room are higher. If the ceilings are lower, then you need to make a reduction.

When making calculations, we will take into account how our radiators will be connected. Here are some recommendations on this matter:

- If the coolant enters the radiator from the bottom and comes out from the top, then a fair amount of heat will be lost - from 7 to 10%.

- The lateral one-sided supply makes it unreasonable to install radiators longer than 10 sections. Otherwise, the last sections of the pipe will remain practically cold.

- Gluing a special reflective insulating material to the wall behind the radiator increases heat transfer by 10 to 15 percent. For example, it could be a material such as Penofol.

Determine the required dimensions

When buying a radiator, you need to know exactly the following points:

- What type of eyeliner do you have - hidden or open?

- How are the pipes connected to the radiator, from the floor, from the wall, from above, from the side, etc.;

- Diameter of heating pipes;

- Distance between pipes (center distance).

We also provide for placing the radiator in such a way that air can flow freely around it - otherwise the room will not receive 10 to 15% of heat. The standards for placing radiators are as follows:

- The radiator distance from the floor is from 7 to 10 cm;

- distance from the wall – from 3 to 5 cm;

- distance from the window sill – from 10 to 15 cm.

Basic standards for the placement of radiators.

The final stage of purchasing radiators

Now, if you have autonomous heating, you can, taking these calculations with you, feel free to go to the store to buy heating appliances. But for residents of a high-rise building with a centralized heating system, it makes sense to first go to the emergency room after finding out what the operating pressure is in your heating system. We will build on this parameter when deciding which heating radiator is better to choose. The pressure indicated in the device passport must be higher than that indicated by the DEZ employees in order to obtain a certain reserve. After all, do not forget that in each new season, heating devices are tested with pressure testing, which is 1.5 times greater than the working one.

Frequent errors and problems during installation

The fittings are placed in a limited space, there is poor access to it, and the crane handle cannot be fully deployed.

The tap is installed incorrectly in relation to the direction of coolant flow.

Before installation, you must follow the direction of the arrow on the device body.

A protective screen is installed next to the thermostatic valve. In this case, the readings of the thermal valve relative to the air temperature in the room will always be inaccurate, since it is located in the warmer part of it.

Types of cranes

Conventionally, the reinforcement can be divided as follows:

- semi-rotary ball valve;

- balancing valve;

- thermostatic valve;

- flush tap;

- Mayevsky's bleeding valve.

Cranes differ in price, design and application features, which determine where and for what purpose the device is installed.

There are valves with manual and automatic adjustment methods; here the difference is also noticeable in the price of the valve. A system with automatic temperature control works like this: the controller receives a signal from a temperature sensor and sends a command to the servos, as a result of which the size of the flow hole in the tap is adjusted depending on the set mode.

Ball valve

The name of the tap is due to the spherical shape of the valve, which has a through hole. The valve is designed for only two positions - open or closed; it is not intended for quarter-turn operation. When you turn the handle of the faucet, the valve also rotates, and the hole in it is located either parallel or perpendicular to the pipeline.

The body of the device is made of steel, brass, bronze or silumin. Steel is the leader in terms of strength, but it is susceptible to corrosion, so products made of bronze and brass are preferable as they are more durable.

A good choice would be a brass half-turn with thick walls and an American - this is the name of the union nut, which allows you to connect pipes and the radiator without rotating them and quickly.

Balancing valve

The difference between a balancing valve and a ball valve is the ability to smoothly adjust the position of the valve by several turns of the knob. To prevent the valve settings from being lost or someone accidentally knocking them down, it can be fixed in its current position. It is placed on the outlet pipe of the battery, and makes it possible to smoothly regulate the flow of coolant.

Valve with thermostat

The most expensive, but also the highest quality, are thermostatic valves. The thermal head is adjusted to a certain room temperature and affects the valve stem.

Under its influence, the valve increases or decreases the cross-section of the hole for the passage of coolant, thereby regulating the temperature of the radiator. A valve with a thermal head is installed on the inlet pipe, and a balancing valve is placed on the outlet pipe.

Flushing tap

As the name suggests, it is designed to drain water or other coolant from the radiator in order to flush it. It consists of a metal body and a long rod, equipped with a rubber gasket. Opens with pliers or a wrench. The disadvantage of the design is the rapid wear of the rubber gasket and the need to replace it.

Mayevsky's air crane

Modern radiators provide for the installation of Mayevsky taps; some models are supplied with already built-in valves. The Mayevsky valve is mounted at the top of the battery, since compressed air accumulates at the top.

The valve is usually activated by a flat screwdriver or wrench. The air is released until the hissing stops and water begins to ooze from the tap.

Useful tips for choosing

Several features are described below in order to decide which products are best to use.

Locking mechanism

Thermostats have two types of locking mechanisms: a valve and a valve with a cone (rod). The latter is preferred, it allows for smooth adjustment. The temperature is set manually using a mechanical limiting ring. There are also electronic mechanisms, they are more autonomous.

It is better to install ball valves than gate valves, which have a number of disadvantages: the seal wears out faster, becomes overgrown with deposits, and takes a long time to close. Disadvantages of the Mayevsky crane: low maneuverability, it requires a special key or screwdriver, which is inconvenient to use. If its rod is accidentally unscrewed, it is very difficult to screw it back, overcoming the water pressure. Instead, it is recommended to install a regular valve or special automatic radiator air vents. The optimal and affordable option if temperature control is required is a faucet with a thermal head.

Housing and connections

It is better to install not standard ball valves on batteries, but full bore ones. In residential buildings and apartments, such mechanisms with a coupling connection are used.

It is better to choose taps for heating radiators with a steel or bronze body, but most often they use brass ones, since they are cheaper. An imitation of brass is silumin. You should not buy a product made from it; it is a very soft metal. Polymer ones are no less reliable, but they have large dimensions. To replace them, you need to cut out a piece of pipe.

Products with polymer rather than rubber gaskets are more durable. The taps for adjusting the coolant on heating radiators make it impossible to change them without draining the water; this can be done with straight-through taps or with an American valve installed (towards the battery).

Products from Itap (Italy) and Danfoss are considered to be of the highest quality. Approximate price range 700–2000 rub. In the middle price range there are Oventrop brand products - 550–950 rubles. For a limited budget, Luxor is suitable - 450–800 rubles, Chinese or Turkish brands.

Valve selection

When choosing a valve, it is recommended to determine:

- device type;

- valve material;

- installation method;

- specifications.

Types of valves

The following is installed on heating systems:

- ball valves. The device serves to completely shut off the coolant in the system;

- needle valves. The devices can be used to completely or partially shut off water in the system.

The ball valve body contains a metal ball that has a hole. If the hole in the shut-off ball is located perpendicular to the flow of coolant, then the valve is in the closed position. If the hole in the ball is located in the direction of flow of the coolant, then the valve is open. To seal the free space in the valve, a special gasket is provided.

Ball valve device

A ball valve can be:

- direct. Installation of such a device is carried out on a flat section of the pipeline;

- corner. The corner valve is installed on the pipe bend.

Valve for installation on a pipeline bend

The advantages of a ball valve are:

- high tightness of the device;

- low cost.

The main disadvantage of a ball valve is the inability to regulate the fluid flow in the system. The device can only serve as a shut-off valve.

The needle valve belongs to the shut-off and control valves. The element that limits the flow of liquid in the system is a special conical tip that moves along the thread.

Control valves for heating

The choice of valve type depends on the purpose of the device.

Any control valve is equipped with:

- manual control. To adjust the heat in the room, you need to independently set the desired position each time;

- automatic thermostat. When installing automation, constant system adjustment is not required. It is enough to set the desired temperature once.

Control valve with automatic control system

Materials from which devices are made

Valves can be manufactured:

- made of bronze;

- of steel;

- made of brass;

- from silumin;

- from polymers.

The most reliable and durable devices are those made of bronze or steel. However, the cost of such valves is quite high.

The most reliable valve for heating

Most often, brass valves are installed on household pipelines, which are distinguished by excellent characteristics, high reliability, and low cost.

Silumin valves are analogues of brass. The main disadvantage of this material is its fragility, since silumin is too soft a material.

Polymer products are mainly installed on similar pipes. The valves are durable and reliable, but can only be installed on similar pipelines.

Valve for polymer pipeline

Types of valves depending on the installation method

The valve for the heating system can be installed:

- coupling method using threaded connections;

- flange method;

- welding method.

The most suitable method for domestic pipelines is the coupling method of connecting the valve to the pipes. This method is detachable and allows you to replace devices several times if necessary.

Threaded valve

Installation using flanges is carried out mainly on industrial pipelines, since installation of the device requires special skills, and the valve itself is large in size.

Industrial pipeline device

The welding method has practically not been used recently, as it causes installation problems. However, the weld is still considered the most airtight.

Welding valve

Experts recommend installing coupling valves in household pipelines

When choosing a device, you need to pay attention to the size of the existing thread.

It is important that it fully matches the threads on the pipes

Valve technical parameters

Which heating valve to choose based on the technical parameters of the system? The standard parameters of a home heating system are:

- temperature – no more than 200ºС;

- pressure – up to 40 bar.

In addition, the valve must be:

- resistant to mechanical stress;

- not to be subject to corrosion;

- completely match the diameter of the installed pipeline.

Differences between a faucet and a valve

Radiator shut-off devices differ from valves in their compactness and ease of use. In them, just turn the handle and the valve will be closed.

In addition, valves break quickly and constantly require maintenance and replacement of seals.

It is difficult to imagine their use in a home heating network. Due to their low cost, they are used in central heating pipelines where the pipe cross-section is greater than 100 mm.

Stopcocks

The simplest device that can change the temperature of radiators is a shut-off valve. It can, at the most primitive level, control the supply of hot water from the heating system of the house. The shut-off valve has the form of a ball valve, which has only two positions:

- “closed” – the movement of hot liquid is stopped, the battery cools down;

- “open” – the maximum volume of coolant passes through the radiator.

A significant disadvantage of adjusting the heating of the battery using a shut-off valve is the need for constant manipulation. It is impossible to create a constant temperature regime using a tap.

Important! The ball valve must not be left in an intermediate position, since the shut-off ball is damaged by solid particles in the water of the heating system

Flow regulator

Having installed energy metering devices, the question naturally arises of how you can regulate and control the supply of coolant, limit or add its flow. For this purpose, there are all kinds of automatic regulators, the use of which allows you to save money; they operate from outside air temperature sensors and return pipeline sensors. Another advantage of temperature controllers is that they control the temperature directly at the radiator installation site, unlike other devices. This advantage gives priority in obtaining a uniform temperature background for a comfortable stay in the room. The regulator will prevent overheating of the air in the room, which sensors on centralized automation cannot always track. It is possible to adjust the temperature for each room separately. Sometimes, when solving the adjustment issue, ordinary taps are installed. Of course, this solution reduces financial costs, but deprives a number of useful advantages. The faucet has limited functionality to open and close. There is a danger of stopping or airing the riser. By adjusting the heating using taps it is impossible to achieve the required temperature. Using automatic regulators, you can adjust the system accurately and efficiently.

Theme Options

Search by topic

Types of locking elements

Any check valve (the outdated name is non-return) performs a simple task - it does not allow the coolant flow to change direction, passing liquid only in one direction. In water heating schemes, this function is not always needed and is implemented as needed.

The following types of check valves are used in heating systems of private houses and apartments:

- petal;

- disc-shaped;

- ball

Industrial models are installed in large boiler houses and production facilities

Let us analyze the device and operating principle of each type of valve separately. In the future, this will help you understand which product is best to select and install in a specific heating system.

Reed valves

The element, made of brass or stainless steel, consists of the following parts:

- body in the form of a tee with a unscrewing top plug (for maintenance);

- a butterfly valve mounted on an axis by means of a rotary lever;

- a seat with a seal into which the disc fits when closed.

The general design of a reed check valve is shown in the detailed drawing. The principle of operation of the element is as follows: the coolant moving in the indicated direction deflects the locking disc and freely passes further along the pipe. When the direction of water flow is reversed, the valve, under the influence of gravity (or a spring), automatically slams shut and blocks the passage.

Typical gravity seal design

We list the important characteristics of petal check valves installed in heating systems of private houses:

- internal passage diameter – from 15 to 50 mm (½—2 inches);

- maximum working pressure – 16 Bar;

- low hydraulic resistance;

- There is a screw on the side of the body for disassembling and adjusting the shutter axis;

- The gravity version without spring can only work normally in a horizontal position.

The design and operating principle of the rotary valve is shown in detail in the video:

Poppet valves

The principle of operation of a poppet check valve is clear from its design, shown in the drawing:

- Inside the cylindrical brass body there is a platform with a round hole - a saddle.

- On the other side of the part there is a partition with a hole in the center.

- A rod with a disc-type valve at the end equipped with a seal is inserted into the hole in the partition.

- A spring is installed between the partition and the “plate”, pressing the disk to the seat.

Water flowing in the right direction overcomes the elastic force of the spring, opens the valve and moves on. Flow in the opposite direction is impossible - the duct instantly closes. What properties of a check valve are important for heating systems:

- ability to function in any orientation of the body in space;

- working pressure – not less than 10 Bar, diameters DN15 – DN100 (internal);

- type of connection – coupling (internal pipe thread);

- spring lock creates increased hydraulic resistance to fluid flow;

- The seal loses its tightness if solid particles, such as sand, enter.

In the utility networks of private houses and apartments, valves with coupling connections are used

Disc locks are also used in water supply networks, for example, in conjunction with submersible pumps. The valve prevents water from the pipelines from flowing back into the well or borehole.

Ball valves

This is a check valve of the simplest design, operating on the following principle:

- Inside the cylindrical brass body there is a ball made of rubber, less often aluminum.

- The ball is prevented from jumping out by 2 partitions with holes made along the edges.

- The coolant flow presses the rubber ball against the partition with ribs. These protrusions form a gap where water flows freely.

- If the coolant moves in the opposite direction, the ball will press against the second jumper - the seat. Since there are no ribs, the body of the ball will completely cover the passage hole.

The advantages of a ball check valve are low price, low hydraulic resistance and operation without any springs in any position, although vertical is preferable. The disadvantage is the loss of tightness when the pressure increases to 6-7 bar, which does not happen in individual heating networks.

To take a closer look at the ball valve, watch the following video:

Air valves and radiator fittings

Almost all modern radiators provide the possibility of installing Mayevsky manual valves for air discharge. Some manufacturers even complete their products with them. If desired, instead of a manual air vent, you can install an automatic one, but in practice it does not look very presentable.

Recently, laying heating lines below floor level and using radiators with bottom connections has become increasingly popular. Then there remains a small gap between the battery and the floor, where it is not always possible to place any fittings. For this case, there is a special connection headset with built-in taps, shown in the picture (left):

On the right is a headset for the bottom connection of a conventional radiator with side plugs; it also has valves plus the ability to connect a thermal head. Such solutions look very aesthetically pleasing, but will require maximum financial costs. More information about the headset is shown in the video:

How to choose the right one

It is important to know which taps to install on heating radiators. To do this you need to know their main characteristics.

The valve, designed for installation on a radiator, is most often presented in the ball type, which ensures regulation of the coolant flow and its temperature. It is also due to this element that the radiator is connected to pipes, which can be made of different materials.

The installation can be in different parts of the battery, which include the riser or the upper part. Can be mounted on bypass. Areas where air accumulates are selected so that, if necessary, it can be vented.

When selecting an element, you need to consider the following features:

- what diameter are the pipes for which the tap is purchased;

- at what operating pressure the product will be operated;

- what type of connection will be used to attach the tap, since individual elements may have threads;

- what is the purpose of the fittings itself;

- where should it be installed;

- what parameters and characteristics does the work environment have?

- properties of the valve input and output in a specific radiator.

Cranes themselves may have certain characteristics. These include:

The Mayevsky crane is considered the most popular choice because it is widely used, has an affordable price and excellent efficiency; The plug valve is considered an excellent choice because it can be installed in an intermediate position

It is important to regularly return this element to its original position, so you need to constantly review its condition; A thermostat equipped with automation is considered an effective and reliable element, but its price is quite high.

When choosing, you need to pay attention to the following parts of the taps:

- What locking mechanism is the faucet equipped with? Thermostats are equipped with two mechanisms at once: one is a valve, and the other is a valve with a special rod. The second option is considered the most optimal, since with its use the adjustment will be smooth and effective. The required temperature is set manually using a restrictive ring. However, there may also be thermostats with electronic mechanisms, but their price will be higher. The Mayevsky crane has many disadvantages in this regard. This is due to low traffic and the need to use a specialized wrench to use the crane.

- Crane body. The optimal products are those whose body is made of steel or bronze. The most popular are brass structures because they have an affordable price. You can often find faucets made of silumin, which is considered an analogue of brass. However, such options are considered unsuitable because this material is too soft. Polymer products are reliable, but they are usually produced in oversized sizes, so to install them you have to cut out too much of the pipeline. Also considered durable are taps in which gaskets are installed not from rubber, but from suitable polymers.

There are many types of taps that are installed on radiators of the heating system.

They differ in the ability to adjust the temperature, installation method, and various additional elements and parameters.

With the correct selection and proper installation of a tap on a heating radiator, you can increase the comfort of using the system, as well as its safety and efficiency.

Useful tips for choosing

Several features are described below in order to decide which products are best to use.

Locking mechanism

Thermostats have two types of locking mechanisms: a valve and a valve with a cone (rod). The latter is preferred, it allows for smooth adjustment. The temperature is set manually using a mechanical limiting ring. There are also electronic mechanisms, they are more autonomous.

It is better to install ball valves than gate valves, which have a number of disadvantages: the seal wears out faster, becomes overgrown with deposits, and takes a long time to close. Disadvantages of the Mayevsky crane: low maneuverability, it requires a special key or screwdriver, which is inconvenient to use. If its rod is accidentally unscrewed, it is very difficult to screw it back, overcoming the water pressure. Instead, it is recommended to install a regular valve or special automatic radiator air vents. The optimal and affordable option if temperature control is required is a faucet with a thermal head.

Housing and connections

It is better to install not standard ball valves on batteries, but full bore ones. In residential buildings and apartments, such mechanisms with a coupling connection are used.

It is better to choose taps for heating radiators with a steel or bronze body, but most often they use brass ones, since they are cheaper. An imitation of brass is silumin. You should not buy a product made from it; it is a very soft metal. Polymer ones are no less reliable, but they have large dimensions. To replace them, you need to cut out a piece of pipe.

Products with polymer rather than rubber gaskets are more durable. The taps for adjusting the coolant on heating radiators make it impossible to change them without draining the water; this can be done with straight-through taps or with an American valve installed (towards the battery).

Products from Itap (Italy) and Danfoss are considered to be of the highest quality. Approximate price range 700–2000 rub. In the middle price range there are Oventrop brand products - 550–950 rubles. For a limited budget, Luxor is suitable - 450–800 rubles. Chinese or Turkish brands.

Heating shut-off valves

This class is designed to regulate the flow of coolant volume in a certain section of the system or the entire pipeline as a whole. A shut-off needle valve for heating is installed in those sections of the pipeline where smooth adjustment of the volume of liquid is necessary - in underfloor heating manifolds, in radiators. Ball models are designed to quickly shut off liquid.

Ball valve

This type of valve appeared relatively recently - 20-30 years ago. Previously, the design used a needle rod, which did not provide prompt shutoff of water.

The design of a ball valve is simple - a ball with a through hole is used as a shut-off element. When it is rotated, the axis of the hole shifts, as a result of which the flow of coolant is partially or completely blocked. What is the difference between a needle valve for heating and a ball valve? In the latter, the diameter of the hole is always less than the cross-section of the pipe. Therefore, in this section of the highway there is an increase in hydraulic resistance.

- Radiator piping is in the bypass design;

- In key heating units where the likelihood of breakdown is high;

- In front of each radiator.

It must be remembered that the operating principle of a ball valve is not suitable for a control valve on a heating radiator. With its help, it is impossible to regulate the volume of coolant flow with proper accuracy.

In the vast majority of cases, a handle is provided to turn the ball in the valve. It moves 90° and should not touch walls or pipes.

Needle valve

Heating needle valve

Each thermostatic heating valve has a needle rod necessary to shut off the water in the pipes. It is located perpendicular to the plane of the pipe, and at its end there is a saddle that blocks the flow of coolant.

It can be installed not only as a valve for a heating radiator, but also in those areas of the system where smooth adjustment of the water volume is required. The shut-off needle rod rotates on the internal thread in the valve body, reducing (increasing) the flow capacity of the tap channel. Thanks to the simple principle of operation, the needle valve in the heating radiator can operate in several modes:

- Manual regulation;

- Installation of servomechanisms connected to a temperature sensor will allow you to automatically change the volume of coolant entering the radiator or a certain heating area;

- An additional block inside the radiator valve changes the position of the stem depending on the water temperature and the values set by the user.

In addition, needle valves for heating differ in the type of fastening - flanged or threaded. Also, when choosing, you should take into account the shape of the channel, which can be straight-line or angular. In autonomous heating systems of a private home, direct-flow models are most often used, since the pressure in the pipes does not exceed 5 bar. Angle valves are installed in pipelines where sudden pressure changes are possible and complete sealing of the passage is required in the event of a sharp jump in liquid or gas pressure.

One of the characteristics of a needle valve for heating systems is the pitch of the internal thread. The level of coolant flow regulation depends on this parameter.

Installation of ball valves on batteries

A conventional ball valve is designed only to switch to 2 positions: “open” and “closed”. It cannot be used to regulate the flow of coolant through the radiator, only shut it off. The figure below shows a simple connection diagram for a heating device with this type of fittings:

The proposed scheme is the best option for an unregulated connection of a radiator to the central heating risers in an apartment. You won’t have to balance it anyway, and installing a thermostatic valve is pointless due to the poor quality of the coolant. Instead of a ball valve at the outlet, it is also practiced to install a so-called shut-off valve; its difference is only in appearance.

Depending on the layout of appliances and heating pipes, you can choose an angle valve for a radiator with or without a decorative coating

Also, when choosing a product, it is recommended to pay attention to the operating pressure indicated on the product body or in its passport. It must correspond to the pressure in the heating network of the apartment building

Advice. For installation on the radiator, choose good taps made of thick-walled brass and a connection with an American union nut. It will allow you to quickly disconnect the connections without rotating the elements. On a single-pipe riser, do not forget to install the bypass with a slight offset away from the main pipe.

Control taps for heating radiators

This type of radiator fittings belongs to shut-off and control valves. But they very rarely seal the coolant tightly, so the presence of a control valve does not mean that a ball valve is not needed.

What is a control tap or radiator valve? This is a device with which you can change the amount of coolant flowing through the heating device. This way you can regulate the temperature in the room.

The control valve can only reduce the temperature

How does this device work? The coolant flow is regulated by a shut-off cone. You raise and lower this cone by turning the handle. Everything is very simple. Valves are made with direct or side connection, from brass or bronze, there are nickel plated (both brass and bronze). There are also stainless steel ones, but they are very rare, apparently due to their high cost.

What else do you need to know about these valves? By installing it on a radiator, you will greatly reduce the amount of coolant that will pass through it. Even when fully open there will be barely half the capacity. As you can see in the cross-sectional photo of the control valve, its seat is very small. Therefore, you can install such a device if it is really very hot in your area, or you can look for a device with a higher throughput. The second option is to install a tap with a larger cross-section.

Options for connecting and installing control valves. But to be able to repair the radiator without stopping the system, you need to install a ball valve before the regulator (click on the picture to enlarge its size)

Due to the small gap, the control valves often become clogged. It is advisable to carry out preventive maintenance on them before the heating season (as with all radiator fittings): remove and wash them. If it became clogged during the season, or you simply didn’t have time/forgot to wash it, and the battery began to heat poorly, you can try to remove the blockages without removing it. To do this, shut off the supply and return (with ball valves) and wait until the radiator cools down. Then, having previously placed the basin, remove one of the plugs on the battery (unscrew it with a key of the appropriate size). Water drains from the radiator, then alternately open the supply and return, trying to rinse the valve seat under pressure. This does not always give results, but if the pressure is high enough it can help. If there is no result, remove the control valve from the radiator and wash it in the removed state.

To prevent blockages, you can install a filter at the inlet. But this is only possible when the pressure allows: there will be a drop on both the filter and the tap. So this is not always possible.

Possibility of adjustment in different heating systems

Unfortunately, even in our time, it is not possible to regulate the temperature in the room everywhere, and, therefore, there is no point in installing special devices on batteries for this. This option is not available for those living in old apartment buildings, the heating system of which has a single-pipe distribution. In this case, the coolant is supplied from top to bottom, and it sequentially passes through all radiators before returning to the check valve. This heating system has many disadvantages:

- Uneven heating of rooms. Temperatures on upper floors may be higher than on lower floors.

- Temperature control is only possible for the whole house or a separate entrance using valves in the heating system.

A single-pipe heating system can be improved using a bypass, which is a jumper between the forward and return pipes. Then adjusting the heating batteries becomes possible.

Bypass for radiator

Nowadays, when designing apartment buildings, I rarely use a single-pipe wiring diagram. There is a two-pipe heating system; it does not have the disadvantages of the previous one. It also consists of distribution risers, but after each radiator the coolant immediately enters the return line. At the same time, the temperature at the entrances to the heating radiators on any floor is almost the same. Each battery can be equipped with a heat regulator, either manual or automatic.

A two-pipe heating system has an advantage over a single-pipe one.

Here you need to take into account that any changes to the heating system in an apartment building must be agreed upon with operating organizations and executive bodies.

If the home has an individual heating system, adjusting the temperature of the batteries is simplified. In this case it is necessary:

- Provide a powerful boiler in the heating system.

- Installation of forced pumping of coolant.

- Install a standard shut-off and adjustment or three-way valve on each battery.

Locking devices

The taps used for installation in the room heating system should be divided into two groups - shut-off and control. This division is largely arbitrary, since shut-off valves also allow you to regulate the movement of the coolant. Naturally, in this case the adjustment accuracy is quite low, but it is possible to cut off the battery from the water source.

Ball design diagram

The simplest and most commonly used type of valves are ball valves:

The ball valve is designed to shut off the radiator. Its design allows the device to be installed in either an open or closed position, so that the adjustment is carried out quite according to the principle “there is heat - there is no heat.”

Ball valves for heating radiators provide two-position adjustment

Note! In principle, it is possible to fix the valve in an intermediate position, but then the rate of its wear will increase many times due to the friction of particles suspended in water against the shut-off element. So it's better not to do this unless absolutely necessary.

- The coolant flow is blocked by the movement of a metal ball with a hole coaxial with the pipe clearance. When you turn the faucet handle, the rod comes into action, which rotates the sphere inside the body, aligning the hole in it with the lumen of the pipe.

- As a rule, faucet parts are made of steel, bronze or brass. PTFE gaskets are responsible for sealing the connections and the locking part, which, if necessary, can be replaced with your own hands.

- Connection to the radiator is carried out either using a regular nut or using an “American” one.

Ball design with American

Unlike ball valves, cone valves make it possible to regulate the coolant flow more smoothly. This is ensured by the features of their design:

Sectional view of the device

- The locking element is a conical rod, on the surface of which a thread is applied.

- When we rotate the flywheel, the rod moves along the thread, moving in a vertical plane.

- In the lowest position, the pipe lumen is completely blocked. The tightness of the overlap is ensured by elastic gaskets that fit onto the annular grooves of the rod.

- By lifting the locking part, we open the gap slightly, and the coolant begins to flow into the radiator.

Note! The microclimate in the room can be adjusted only approximately by decreasing or increasing the amount of hot water in each battery

Model in polypropylene case

In practice, bronze or brass cone valves for heating radiators are most often used: only systems are equipped with polypropylene, some of the pipes in which are also made of plastic. This is explained by the relatively low strength and wear resistance of polymers compared to sanitary alloys.

On the other hand, polypropylene taps for heating radiators are somewhat cheaper, so in conditions of budget deficit they can be used.

Mayevsky crane

When you pour coolant into the heating system, air gets inside along with water or antifreeze.

To remove it, special devices are used - the so-called Mayevsky taps:

Air release device

- The design of such a product is quite simple: it is based on a shut-off rod installed in a housing with a thread for the radiator plug.

- The rod is driven either by a screwdriver or a special wrench, opening the lumen of the pipe in the saddle.

Note! If possible, buy valves for a screwdriver, since you will regularly lose the key, which is not surprising - you will have to use it once or twice a year. You need to keep in mind that the throughput of such a faucet is small, so, for example, you shouldn’t install it on an expansion tank: it will take about an hour to bleed off excess air

In such a situation, a regular valve or a water tap installed with the spout facing up is more suitable.

You need to keep in mind that the throughput of such a faucet is small, so, for example, you shouldn’t install it on an expansion tank: it will take about an hour to bleed off excess air. In such a situation, a regular valve or a water tap installed with the spout facing up is more suitable.

Photo of the installed valve

Advantages and disadvantages

This type of fittings has its pros and cons.

The advantages of a radiator shut-off, as well as a shut-off and control device include:

- cutting off the flow into this battery, which allows it to be dismantled, repaired and reinstalled without draining the contents from the pipeline;

- turning off the radiator and directing the coolant flow around it through the bypass, which makes it possible to remove the battery without stopping the operation of the entire heating system in the house;

- draining water from a specific heater, bleeding air from it;

- adjusting the amount of heat supplied to the heater.

If the single-pipe system is not equipped with a bypass, closing the valve in the battery will lead to the blocking of the entire pipeline, for example, in the entrance.

Ball valve: how to replace it with your own hands?

Due to the fact that it has a slightly different device, installing taps on radiators, as well as replacing them, can create minor difficulties. Although the repair itself does not take much time: after unscrewing the nut, a new oil seal or valve axle box is installed, and then the nut is returned to its place. However, even before repairing the ball valve, you need to prepare the necessary materials.

Materials

To repair a ball valve, you need to ensure you have the following tools:

- screwdrivers;

- pliers;

- hex wrench;

- gloves;

- used spare parts.

Expert advice

The diagonal connection scheme for radiators has already proven its best efficiency. The greatest heat loss is allowed when installing the bottom connection.

The thermoregulatory valve head should be placed perpendicular to the radiator screen so that the flow of warm air does not have a corrective effect on its readings.

Do not install the tap on the pipe connecting the expansion tank to the boiler. Unexpected overlap can lead to an explosion.

Installation

The location of valves with thermal heads is on the supply pipeline. Regulating taps do not require coiling; Unipak paste is used. Rubber gaskets fit tightly to the joint, ensuring complete tightness. If there is a defect at the edges of the faucet, water leakage is inevitable.

While their ball counterparts are responsible only for safety and are able to instantly shut off the water during an emergency, the purpose of control valves with a thermal head is to save energy and provide comfort. On cold winter evenings, on dull autumn days, on warm spring days, the house will be warm and cozy, and the numbers on your heating bills will pleasantly surprise you.

Reliable manufacturers

A high-quality faucet for a heating system is the key to its long-term operation. When choosing, you must also take into account the manufacturer of the device, since trusted brands will not risk their reputation and produce low-quality products.

First of all, you need to pay attention to the following brands:

- Oventrop (Italy).

- Danfos (Denmark).

- Luxor (Italy).

- Valtek (joint production of Russia and Italy).

Cheaper models are made of silumin. This alloy is quite brittle. For long-term operation of the heating system, it is better not to use these. Instead, quality products are made from brass, steel or bronze.

The world's largest faucet manufacturers use silicone gaskets instead of rubber ones. Silicone does not tend to crack, so such devices last a really long time. Rubber seals lose their elasticity at high temperatures and crumble over time.