In order not to freeze at home in winter, and to save costs on additional heating devices, you need to take care of insulating the room. Spray insulation is now gaining popularity.

It appeared back in 1937. It's not a new thing abroad for a long time. The active substance is called polyurethane foam. It is sold in large canisters and cylinders. It is obtained by mixing a polyol and a polyisocyanate. They react to form a significant amount of foam.

Apply to the surface by spraying. Has a bubbly texture. After drying it hardens. 80% consists of air. The insulation thickness of 5 cm is comparable in its characteristics to a 35 cm expanded clay layer.

Installation features

There are special requirements for preparing the surface for applying insulation.

First you need to clean it of debris, and then start removing grease stains. If this is not done, adhesion between surfaces will be significantly reduced. Work should be planned during the warm season. The recommended temperature regime for creating a heat-protective layer is within 17-20 degrees. Appropriate air temperature and low humidity levels will ensure uniform distribution of the composition throughout the work area. You need to start insulating by studying the instructions and installing the nozzle on the cylinder. It is fixed until there is a characteristic click. Next, the cover is removed from the cross and the gun is screwed on. The nozzle is included with the heat insulator, but the gun will have to be purchased separately. The procedure for preparing the cylinder for use is performed in a vertical position. Before spraying one-component polyurethane foam, shake the container thoroughly.

The product must be distributed sequentially, forming a monolithic layer. The maximum thickness of the insulation should not exceed 5 cm. Upon completion of work, the gun is cleaned with a special solvent or mechanically.

Safety precautions

Although polyurethane foam is not a toxic material, working with it can lead to accidents. To prevent this from happening, basic safety measures should be observed.

The most important safety elements of the insulation process are proper equipment and protective clothing. It is better to carry out the entire spraying process in a special suit, in which the human skin will be completely protected from contact with polyurethane foam. The mucous membranes of the eyes should be covered with glasses, the respiratory tract with a respirator or gas mask.

The instructions will help beginners to properly prepare the spray composition and load this insulation into a construction gun. You also need to have a special solvent on hand so that if drops of foam insulation get on your skin, wash it off immediately. The cost of work is determined individually and depends on the complexity of the working surface and the thickness of the applied foam. The exact price for installing insulation can only be determined after a visual inspection of the building.

Advantages and disadvantages

Before you start insulating your home, you need to weigh the pros and cons. Of course, many are interested in what benefits will come from this method of insulation. These include:

- fast speed of insulation, even if a large surface is processed;

- foam is not subject to biological influences, mold or mildew is unlikely to appear on the wall;

- low-flammability material: it can only melt at temperatures above 80 degrees;

- there is no need to first attach the frame to the facade - this saves effort, time, and money;

- a monolithic surface is obtained without seams into which cold air could penetrate;

- When insulating pipes or other metal elements, a sufficiently dense layer is created, through which moisture will not seep through and corrosion will not appear.

But, like any other insulation method, it has its drawbacks. You should know about them in a timely manner:

- should not be exposed to direct rays;

- inability to interact frequently with water;

- cost of material: to insulate large areas you will need to buy or rent special equipment;

- insufficient level of vapor permeability, artificial ventilation will have to be installed inside;

- You cannot perform the application procedure without a tarpaulin suit, a respiratory mask with goggles and gloves. Of course, all this is unlikely to be found at home, and this is also an extra waste of money.

People have long begun to insulate their homes with foam, but the ideal means of insulation has not yet been invented.

Of course, the effectiveness of this method cannot be disputed. The main thing is to buy high quality materials. If you have equipment for installation, the process will not take much physical effort and time. After applying the foam composition and after it has completely dried, craftsmen advise treating the surface of the facade with a special coating, which can be purchased at any hardware store. This is required first of all to protect human health, and only then - to protect the insulation itself.

Stages and technology of the spraying process

All actions to prepare equipment and surfaces are carried out directly at the site of further work.

Important! The insulation does not like wind - work should be carried out in its absence. The day should be without precipitation.

Recommended conditions for application: + 20 C0. Work can be carried out at lower temperatures. But this does not apply to all brands of atomizer. For such purposes, it is worth choosing all-season insulation.

Important! Ordinary stamps simply will not be able to stick to the surface in the cold. As practice shows, in winter there will be more of it. There will be a risk of performing the work poorly.

If you have a lot of work to do, you can’t do it without an assistant. All preparatory activities and the insulation process must be completed in one day. Otherwise, everything will have to be repeated.

Equipment

For the process of spraying insulation, you will need to protect yourself from harmful fumes.

Might be interesting

Vapor barrier

Effective and simple solutions for insulating ceilings in…

Vapor barrier

Technologies and materials for effective thermal insulation of floors in…

Vapor barrier

Vapor barrier and waterproofing, is there a difference?

Vapor barrier

Features of vapor barrier of a wooden building

Important! The process of interaction with sprayed thermal insulation takes place in a protective suit. Glasses and a mask are required. Hands should be protected with silicone gloves. Feet must be covered with rubber boots. Avoid inhalation of substances and contact with skin.

You will need a special installation for mixing substances, a hose and a gun. They can be purchased for rent if this is a one-time process. At the time of mixing materials, the surface must be prepared.

You need to stock up on a product that removes sprayed thermal insulation in advance. It will come in handy when you get into unnecessary places.

Surface preparation

Before carrying out insulation technical measures, you need to perform the following actions:

- the surface must first be cleaned of dirt and dust;

- holes and cracks should be covered with cement - adhesion to the surface will improve, the integrity of the structure will not be at risk;

- the area that does not need to be insulated is covered with polyethylene material;

- Moisten the application surface with water for better adhesion.

After all these steps, you can begin direct spraying.

Application of insulation

The process of applying polyurethane heat protection occurs in several stages:

- the first substance is mixed in the container using a mixer;

- another component is mixed in the second tank - you need to warm up the contents;

- they are combined in the third container;

- the resulting composition is poured into a special unit and sprayed onto the required area using a hose and a gun;

- you should call an assistant to periodically mix the substances;

- first you should go through all the hard-to-reach areas, joints, cracks;

- work is done from the bottom up;

- the output is foam that increases several times;

- each layer is applied after the previous one has dried;

- They dry for about an hour;

- minimum number of coatings – 3;

- protection from UV rays is carried out immediately - plastering, painting, siding.

Spraying polyurethane foam can be done with your own hands if the application area is small. But many difficulties will arise with a large surface. The risk of doing something wrong will increase many times over. Such cases should be entrusted to professionals.

Important! If you have to hire a crew, you should be vigilant. The professional himself will offer to check his work. You will need a nail or a probe (the operator has one). A piece of insulation is cut out anywhere on the finished surface. It must contain at least 3 layers. If they are not there, the spraying technology is broken.

Polyurethane foam

The initial raw material for the production of such foam is a urethane polymer, which foams through chemical reactions and increases in size by almost 50 times.

In its structure, it is almost like polyurethane foam, with the difference that it has a finer structure.

Foaming of polyurethane foam (PPU) in a special device (production unit) is carried out in just a few minutes, after which it is supplied to the desired surface.

Final hardening lasts for 24 hours, then the façade walls can be sheathed with the necessary material.

Using polyurethane foam you can insulate:

- walls of houses (mostly frame);

- attics, roofs;

- house facades;

- basements, lower floors, etc.

The thermal insulation layer ranges from 4-8 centimeters with a high degree of efficiency.

Among the advantages of polyurethane foam, it is worth especially noting the high degree of hardening and adhesion to other materials.

PPU insulates surfaces made of various materials: foam concrete, brick, cinder blocks and gas silicate blocks.

Polyurethane foam is one of the lightest insulation materials by weight, which is why it is also widely used for insulating old houses.

If you need to insulate a small area, it makes sense to purchase foam in a balloon, which is enough for a layer three to four cm thick for an area of approximately 1 sq/m. To calculate the cost and amount of foam, you need to proceed from the area of the surface being treated.

Read an informative article about roof insulation with polyurethane here.

Advantages of polyurethane foam insulation

Among the main advantages of the material, in addition to low thermal conductivity, the following advantages should be noted:

- excellent sound insulation characteristics;

- moisture resistance (except for open-cell material);

- possibility of application to any type and type of surface, including curved elements and filling voids;

- creation of a heat-insulating layer without seams and joints, which eliminates the appearance of cold bridges;

- high adhesion to any surface - the only exception is polyethylene, but elements from it are rarely used as a building material;

- long service life of the insulation, ranging from 25 to 50 years or more, depending on operating conditions;

- the shortest possible time required for carrying out the work, since the application of insulation, its subsequent expansion and setting occurs quite quickly. In addition, applying insulation by spraying allows you to immediately process large surfaces;

- insulation, in addition to its main task, also performs the functions of corrosion protection for metal elements;

- the low weight of the sprayed material allows it to be used for insulation without creating additional load on the load-bearing structures of the building;

- the insulation is environmentally safe and is not subject to destruction by microorganisms, and also does not require the installation of additional wind, steam or water protection.

It should be noted that, although polyurethane foam is not a non-flammable material, its use is quite safe given its ability to self-extinguish, but it is important to remember that in such cases there is an intense release of poisonous and toxic combustion products

In addition, you need to pay attention to its high adhesive ability, which is a boon for thermal insulation of surfaces, but in case of contamination of nearby areas that cannot be treated, it can only be removed mechanically, which leads to damage to the latter. Therefore, before starting work, you should protect all surfaces on which spraying is undesirable.

Therefore, before starting work, you should protect all surfaces on which spraying is undesirable.

Disadvantages of PPU

Of the negative properties of the material, it should be noted:

- relatively high price;

- the need to strictly adhere to the technology of performing the work, which creates certain difficulties when applying insulation independently;

- the lack of vapor permeability of the material requires the creation of an effective ventilation system in the room;

- vulnerability to ultraviolet radiation. All surfaces that may be exposed to sunlight must be protected with an outer layer of cladding: a curtain wall, plastering, etc.

Another significant disadvantage is the need to use special equipment and a reliable personal protective kit, consisting of a suit, respirator, and goggles.

In addition, spraying polyurethane foam requires certain skills in working with both the material itself and the equipment.

Therefore, it is often more profitable to invite professional craftsmen for this work, especially taking into account the fact that purchasing equipment for one-time use or renting it is not economically profitable, and it will not be possible to apply thermal insulation manually using auxiliary mechanisms.

But if we are talking about sealing small construction cavities or areas, then it is quite possible to do the work yourself, for example, using polynor, a sprayed material used for heat and sound insulation.

Available in cylinders and does not require special skills to use. Polinor is completely ready for use and is a material in the form of a foamed mass, in which the ratio of carbon dioxide to solid particles is 9 to 1.

The capacity of one cylinder is either 800 mm or 1000 mm - this volume of material is enough to treat an area of 1 to 2 m2, depending on the thickness of the applied layer.

When processing cavities, it should be taken into account that the insulation not only perfectly fills the space, but can also cause damage or even destruction of the structure as a result of the expansion of the material after hardening.

Therefore, such work must be carried out with the utmost care, for example, performing such foam insulation in several approaches.

Application area

The scope of application of the sprayed material is quite wide:

- First of all, this is industrial construction. Insulation of industrial buildings is a rather long and labor-intensive process. The use of such insulation makes it possible to significantly reduce the construction period, and therefore its cost.

- Insulation of heating mains. All large main pipelines are buried in the ground. This means that the insulation does not have any problems with ultraviolet rays. And the use of material for installing pipes during repairs significantly reduces the period of localization and elimination of an accident on the heating main.

- Low-rise construction.

Due to its price, insulation is most widely used in low-rise construction. Only owners of private houses can afford to purchase and use this type of insulation. The main reason for the popularity of this method is the acceleration of work on insulating the perimeter of the building and the ability to use one material for any surface.

Positive traits

PU foam has excellent performance as an insulation material. Its significant characteristics:

- the ability to stick to any surface, no matter what material it is made of: brick, wood, metal or concrete;

- ability to cover surfaces of any shape and configuration;

- the ability to manufacture locally, which reduces transportation costs;

- low weight does not burden the structure, which is important when insulating the roof;

- no joints or seams.

Consumer properties

Like any insulating material, Polynor has a number of advantages:

- Features excellent heat conservation. These insulation indicators are higher compared to expanded polystyrene and mineral wool.

- Non-toxic. Consumer reviews about Polinor are quite good, since it is not poisonous and does not require protective equipment when using it.

- Ease of use. When using POLYNOR, a heat-insulating layer is created, which does not require a frame for fastening. Also, no tools or auxiliary materials are required.

- Excellent grip. The composition quickly adheres to any surface - brick, wood, plastic, stone, concrete, which significantly expands the scope of its application.

Polynor insulation is very popular due to the fact that it is applied by spraying. This affects better adhesion of different surfaces, even if they are not very smooth. Very often this insulation is used to finish hard-to-reach places, for example, where pipes or cables are laid.

Advantages of using thermal insulation with spraying

Compared to sheet analogues, Polynor sprayed insulation saves time and money, and is easy to store, transport and use. This material also has a number of other advantages:

- minimum curing time (up to one hour);

- resistance to destruction by insects and rodents;

- complete surface coverage without the formation of cold bridges;

- no harmful effects on humans and the environment;

- spraying without complex and expensive devices;

- base vapor barrier;

- long service life.

The insulation is non-flammable and quickly extinguishes when overheated, which guarantees a high level of fire safety.

Major manufacturers of liquid insulation for buildings (structures) or utility networks

Today, a very large number of manufacturers have begun to produce ultra-thin liquid thermal insulation. However, many of them sell ordinary paint as liquid insulation. How to make the right choice? Let's look at this issue together and present a rating of the most popular manufacturers of this thermal insulation material.

Liquid thermal insulation Astratek

This material is produced by Russian. All products of the concern have appropriate quality certificates and a positive conclusion from the fire service and sanitary and epidemiological station. Liquid insulation Asstratek easily has the consistency of mastic and is easily applied with your own hands to any surface using a roller, sprayer or brush.

- It is not destroyed when exposed to precipitation because it has hydrophobic properties.

- There are no “cold bridges” unlike traditional insulation.

- Non-toxic and meets environmental standards.

- Does not support combustion, and is completely safe from fire safety.

- Completely preserves the architecture of the facade and does not steal useful space.

Liquid insulation RE-THERM

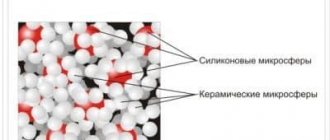

The insulation of this class consists of silicone and ceramic microspheres, which are located among a binder based on acrylic and latex. Thanks to this structure, this material has excellent waterproofing properties and, at the same time, high elasticity and particular strength.

The manufacturers of this product promise that the thermal conductivity of 1 mm of RE-THERM liquid insulation corresponds to 5 cm of mineral wool.

- This liquid insulation can be used on various surfaces, from concrete and brick to glass and plastic.

- Demonstrates ideal characteristics in the temperature range from −470 to 250 C.

- Quick drying, which ranges from 3 to 24 hours.

- High resistance to various mechanical influences, as well as to ultraviolet and infrared rays.

- Can be used both outside and inside buildings and structures.

VIOTERM Metal ALLUMA

This type of coating is specially designed for processing metal structures and engineering structures. Thanks to its structure, liquid insulation VIOTERM Metal ALLUMA gives the surface a glossy tint and reliably protects the surface from corrosion.

In addition to the above advantages, this ALLUMA coating perfectly retains heat in hot water supply and heating systems.

- It is used exclusively for treating metal surfaces as waterproofing.

- Demonstrates effectiveness at ambient temperatures from −50 C to 250 C.

- Low consumption, which is only 1 liter per 1 m2 with a layer thickness of 1 mm.

- When insulating water supply systems for hot water supply and heating systems, heat losses are reduced by 30%.

- The service life of this coating is 10-15 years.

Possibility of using foam fillers

Then manufacturers began to produce sprayed insulation in compact-sized cylinders, which led to a reduction in the cost of the method.

To spray such a mixture of steel, complex installations and specialists in thermal insulation finishing are not needed, since the material itself is filled into small containers and the possibility of manual spraying is provided. Each cylinder is designed to cover one square meter of base (layer up to 60 mm thick). One person can process up to one hundred square meters per day. As a result, calculations showed that working with insulation such as Polynor is much more profitable in terms of labor costs, costs for the materials themselves and surface preparation. If a professional team of workers charges up to one and a half thousand rubles for insulating one square of wall, then using Polinor insulation with the same amount of material, you need to spend only about 500 rubles. You can work independently, which eliminates the need to look for experienced workers, reduces finishing time, and saves money.

The choice of thermal insulation of this type remains the only optimal option that is available to people without special training. Foam can be used to create insulation for foundations, basements, walls inside and outside buildings made of brick, stone, concrete, and blocks. This option is also suitable for thermal insulation of non-load-bearing coatings, including floors on joists, as well as pitched roofs and attic floors.

Since Polinor is suitable for application to bases made of almost any material, it can be used as thermal insulation for plumbing fixtures and sewer pipes or fittings. In such cases, foam insulation in cylinders can be used indoors or in open areas. There is only one limitation on the use of balloon thermal insulation, which is that the material cannot be used to foam voids. It can only be applied to a dense base.

https://youtube.com/watch?v=HzNxMCfzjrE

Liquid foam

This type of insulation includes almost all foam materials based on polymer resins. The quality of the final product, including its environmental friendliness, largely depends on them. There are raw materials whose use is not permissible for residential premises due to the high toxicity of the polymer and its long-term emissions. At the same time, such materials are quite suitable for insulating technical structures or isolated building elements (if there is confidence in their insulation and the conscientiousness of the working specialists).

At the moment, such types of liquid foam as polyurethane foam, penoizol, as well as a number of products in compact cylinders are common.

Polyurethane foam (PPU)

Viscous heterochain polymers in a liquid state are used as the main component of this insulation. During chemical reactions, urethanes foam, which leads to their increase in volume by more than 50 times.

In its frozen state, polyurethane foam resembles ordinary polyurethane foam, the main difference in the structure is less porosity.

Mainly used for:

- Insulation of walls of frame buildings;

- Roofing structures;

- House facades;

- Thermal insulation of basements and lower floors.

To apply polyurethane foam, you need a special unit that first mixes and foams the insulation components, and then delivers the finished mixture under pressure to the surface to be treated. Final polymerization occurs within 24 hours, after which the finishing can be installed. Polyurethane foam is suitable for treating surfaces made of brick, concrete, wood, metal, cinder blocks and gas silicate blocks.

The average cost of work including material is 1000-1500 rubles per m2, with a layer thickness of 50 mm.

Penoizol

A budget analogue of polyurethane foam insulation, since it is based on relatively cheap, but more toxic urea-formaldehyde resin. The structure of this insulation is very similar to ordinary foam plastic, but its use is more preferable due to the absence of cold gaps in the insulating layer, characteristic of sheet and roll materials.

The density of penoizol, even in a liquid state, is noticeably lower than its urethane analogues, which does not allow its use in loaded structures. Otherwise, the scope of application is similar to polyurethane foam. Thermal insulation qualities are also not exceptional and are comparable to mineral wool, and two times less than that of the polyurethane foam described above.

Apply under pressure after pre-mixing the components and foaming. Increases in volume by no more than 30 times relative to the original mixture.

Roof insulation with foam insulation

Work together with the material costs approximately 2000 rubles per 1 cubic meter.

"Polinor"

This is a liquid insulation based on polyurethanes. A common form of release is small cylinders, similar in appearance to those for polyurethane foam. Using one cylinder you can insulate about 1 m2 of surface with a layer thickness of 6-7 cm.

The strength and thermal insulation qualities are similar to polyurethane foam, but unlike it, “Polinor” is more suitable for household use, since it does not require special equipment for application. The relatively high cost (about 500 rubles per cylinder) makes its use inappropriate over large areas.

The insulation is applied by spraying, which allows it to be used on almost any surface, for example, for thermal insulation of pipelines located outdoors.

As for filling voids in the walls, this procedure cannot be completed due to insufficient pressure in the cylinder.

"Polinor" has the following technical characteristics:

- Thermal conductivity – 0.025 W/(m*K);

- Moisture absorption coefficient – no more than 0.03;

- No toxicity, non-flammable;

- Solid density – not less than 28 kg per m3;

- Retains all operational properties for 50 years;

- The operating temperature should not exceed +121°C;

In addition, the mixture is quite chemically stable and does not interact with most reagents common in everyday life. Chloroform, dichloroethane, and high concentration hydrochloric acid have a negative effect (promote swelling) on Polinor. Nitric and sulfuric acids react with polyurethane, thus destroying the insulating mixture as a whole.

Current prices for your city:

Types of sprayed polyurethane foam

Polyurethane foam insulation, which is applied by spraying, is divided into two industrial types - sold in barrels and used by specialists to insulate large structures and surfaces, and in 1-liter cylinders, which are intended for independent use. Industrial polyurethane foam is represented by several brands from different manufacturers.

The most famous are:

- Sealection 500 is an American made material. It has an open structure and fire safety class G2.

- “Ecotermix” is produced on the basis of vegetable oils and contains a minimum amount of harmful substances. There are two varieties of it on sale: grade 300 - with a closed structure to protect external surfaces from cold, and grade 600 - with an open structure for interior work.

- Healtok Soy 200 is a closed-structure insulation material made from soybean oil and polymer waste. Adheses perfectly to any surface, tightly fills all cracks and pores.

Polyurethane foam in cylinders is made from polymer components. The can has a spray tip or adapter for use with a mounting gun. Currently, this insulation is represented on the market by two brands - Polinor and TEPLIS. The material looks like polyurethane foam. After hardening, it forms a fine-mesh coating with low thermal conductivity. One cylinder is enough for 1 sq. m of surface when applied in a layer of 40 mm.

The application technology is simple:

- Surfaces must be cleaned of dust and dirt and slightly moistened.

- You need to screw the nozzle onto the cylinder.

- Then it is shaken and the nozzle is directed to the desired location.

- By pressing the trigger of the gun, the material is sprayed.

Currently, insulation in cylinders is highly advertised, but experts do not advise putting too much faith in it.

Manufacturers of industrial two-component insulation believe that one-component polyurethane foam in cylinders is practically no different from conventional polyurethane foam, but costs several times more. The material has a large number of open pores, therefore it is unsuitable as a hydro- and vapor barrier.

Therefore, if you decide to properly insulate your home, you should not rely on unprofessional insulation. If you wish, you can use a spray can to treat small areas of structures or internal partitions, but it is hardly suitable for insulating large surfaces.

Peculiarities

In order to insulate the walls in any home, it is best to use polyurethane foam. This type of foam hardens very quickly, which allows you to get a dense surface in a matter of hours that separates the interior of the room from external temperature changes, drafts and moisture penetration.

The main characteristics of foam include:

- heat resistance - the material can withstand heating up to eighty degrees;

- capable of letting water through if necessary;

- possibility of providing vapor barrier;

- high level of strength;

- increases in volume after application.

When using this material, you don’t have to worry that the wall structure can easily ignite, because the foam resists this in every possible way. With all the positive aspects of this material, there is also one negative aspect. It concerns the ability to freeze. If you foam something in a closed space, it will not freeze. In addition, the high cost of this product does not allow everyone to use foam to insulate walls in the house.

With constant contact with the aquatic environment, this material begins to deteriorate and eventually becomes completely unusable. Application of foam requires good ventilation, which means that certain conditions must be created for work

This material has low vapor permeability, so it is important to provide forced ventilation in the room

When applying foam with a thickness of four or more centimeters per square meter, you will need to use one balloon

In order to be able to do the work correctly and without risk to health, it is important to work using a pneumatic gun. This is special equipment that helps to spray foam evenly over a specific surface.

Such a gun mixes foam with gas and delivers it to the surface, evenly spraying where it is needed. Using such a device, you can independently adjust the intensity of the foam supply for more comfortable work. It is very convenient to use a pneumatic gun, but not everyone resorts to it due to the high cost of such equipment.

When applied to the surface, the foam does not form any seams, which is convenient and aesthetically pleasing. This material has minimal thermal conductivity. An important indicator is its environmental friendliness - when used, no harmful substances are released into the air. Any impact on the foam will be painless for it; it only reacts poorly to ultraviolet radiation.

When insulating a room, it is advisable to take care of sound insulation, which foam also does well. In addition, it has good adhesion to the surface. The foam is easily applied to uneven surfaces, while the formation of air pockets is completely eliminated. Rapid hardening allows you to continue working within 24 hours. Foam for wall insulation is a universal and convenient option, with the help of which even a non-professional can do everything well and efficiently, most importantly, follow safety precautions.

Developers' opinions

“Previously, we often used ecowool for insulation at facilities.

The price at that time was not bad, it was convenient to transport it in compressed form, and when spraying wet, even a respirator was not needed. But now its cost is increasing, and already in terms of money it turns out to be more profitable than mineral wool. So for the last couple of years we haven’t been working with “paper” for insulation.” Oleg, Krasnoyarsk.

“I’ve heard a lot about thermal insulation using spraying, but I’ve never encountered it before. And then I decided to add a loggia to my living space, and urgently needed to insulate it with something. After studying the reviews and characteristics, I realized that I did not need soft foam, but a hard polymer layer - so that it would hardly be pressed through. I settled on Ecothermix, but took insulation intended for external spraying.”

Egor, Nizhny Novgorod.

“I don’t see much point in sprayed thermal insulation based on PPU until it really becomes more cost effective. Where to apply the polymer? It sticks well to smooth brickwork and polystyrene foam, but to pour polyurethane onto wood - then what is the point of building a “clean house”? You can try ecowool, but its disadvantages are again not compensated by financial benefits. Such thermal insulation is only good for non-standard surfaces.”

Alexey, St. Petersburg.

“We were forced to use sprayed polyurethane foam because two walls in our private house were constantly damp. It’s good that the fungus didn’t reach. All the finishing was removed from the facade, slats were filled and everything between them was foamed with polyurethane. For the second year now there has been no dampness in the house, and the wallpaper hasn’t fallen on my head.”

Vera, Moscow.

Summary: Pros and Cons

Prices for thermal insulation of polyurethane foam are indeed one of the highest, plus you will have to pay specialists with equipment to carry out the work. However, there is another problem - craftsmen may refuse to come to a small site, so you will need to look for an alternative method of insulation or try to do it manually.

However, these disadvantages balance the advantages of the insulation spraying technology:

- High adhesion to any building materials.

- Penetration of thermal insulation into all cracks and gaps of structures, regardless of the complexity of their shape.

- Creating a seamless “shell”.

- Excellent noise absorption performance.

Which variety to choose

In many ways, the choice will depend on the specific situation and what area needs to be treated. Using an example, we can consider the most common cases when a house needs foam insulation:

- If you need to seal cracks or eliminate any other defects on the surface, then polyurethane is suitable. But such material should not be exposed to sunlight.

- If you need to fill a large volume, then penoizol is suitable. But an ordinary cylinder will not be enough; you will need to purchase a special device with high pressure. You don’t have to buy it at all - you can rent it or borrow it from friends, because no one will use it often.

- If you need to seal small cracks and carry out thermal insulation in small areas, you can buy a cylinder with regular polyurethane foam. It does not support combustion, after hardening it is particularly hard, and it has an ecological composition.

- If defects are found on the outside of the wall, then you need to apply a composition based on polyurethane. It is applied directly using a special cylinder or apparatus.

It is worth remembering that foam insulation creates errors inside the layer that need to be eliminated.

To do this, you will need a long hose to push the material inside. If it is necessary to fill air gaps inside the insulation, then holes are made in the wall with something sharp. Polyurethane foam is not suitable for insulating the entire external facade - it does not have the appropriate characteristics necessary for this. Therefore, you should not choose it for these purposes, even despite its more economical cost.

How to choose the right product

Which company is better to buy a product depends on personal preferences. You can first study the ratings of quality products, user reviews, product characteristics and functionality, view the new products offered, compare what they cost. However, the following nuances should not be overlooked:

- With noise absorption function. The indicator is greatly influenced by the thickness of the applied layer, the ability to pass air, and elasticity.

- Coefficient of thermal conductivity. It must be optimal.

- Attitude to aggressive substances. Caustic chemical components should not destroy the insulation. Plasticizers, alcohol, acids, gasoline, and all kinds of oils should not harm the product.

- Moisture absorption. The denser the composition, the less liquid it can absorb.

- Flammability index. The manufactured goods are divided into three categories: TS - fire-resistant, S - self-extinguishing, TV - fire-resistant. The special additives or fillers used contribute to increasing fire resistance.

There are several options where to buy the products you need. It is advisable to visit specialized retail outlets, communicate with a professional sales manager, ask him for advice, and ask for a quality certificate for the selected model. You can order goods online in the online store. It will cost a little less, but no one can guarantee that you will receive a quality product. Much depends on the integrity of the supplier.

Is it possible to insulate a house with foam yourself?

Most often, they carry out work related to the internal insulation of the house with their own hands. For this you will need:

- Wood slats or metal profiles as guides for sheathing.

- Construction gun and balloon foam.

- Knife with a sharp blade.

The surface to be treated must first be cleaned of dust, cobwebs, mold and other contaminants. Then you can begin fixing the sheathing profiles. The gaps between them should be 50 centimeters. They are mounted vertically on the wall, additionally fastened with horizontal jumpers at the same distance. If there is furniture left in the room, it is recommended to cover it with film. The eyes are protected with goggles, the body and hands are protected with a suit and gloves, respectively. The further procedure looks like this:

- It is recommended to treat the construction gun with automotive lubricant.

- The can is inserted into the gun, and you can begin treating the surface with foam.

Installation of metal or wooden beams

Before installing the sheathing, the surface will need to be prepared - remove cobwebs and dust, remnants of the old finishing coating, cement, etc. A deep penetration primer is applied to the cleaned surface with a roller or spray. It will create a thin protective film.

The slats or profiles are fixed in increments of 50 centimeters, installing horizontal jumpers to increase strength also every half meter. Depending on the base material, suitable hardware is selected. These can be anchors or dowels

Before installing the insulation, it is important to provide in advance places for laying electrical cables or other utilities

Spraying foam using a compressor

First of all, the heat insulator is applied to problem areas - with cracks, joints and crevices. In this way, it will be possible to get rid of voids that could become cold bridges in the future. Next, the voids are filled in those places where the sheathing is adjacent to the insulated surface. You need to spray the polymer insulation from side to side, movements should be sweeping and even. They are produced from top to bottom. When treating a metal surface, it is recommended to pre-clean it from rust, as well as treat it with a corrosion-preventing agent.

It is important not to allow the sheathing to be completely covered with the composition.

Drying

The material begins to foam while still inside the compressor. Once applied to the surface, it will harden in approximately 15-20 minutes. It will take at least a day to dry completely, and if the layer is thick, then three days. It is recommended to begin final finishing after five days.

Alignment

Before finishing, the surface must be carefully leveled. It will be enough to cut off the excess frozen foam with a sharp knife. The heat insulator must be flush with the sheathing beams

It is important that the coating is smooth, without bumps or depressions. Sometimes it can be difficult to work with just one knife

Then you can use a hacksaw with a fine tooth. After all manipulations, the finishing material can be fixed to the surface.

Finishing

Foam insulator is not suitable for subsequent plastering, puttying, or wallpapering. Here is a list of suitable facing materials:

- plasterboard sheets;

- panels made of wood, glass or plastic;

- wooden lining;

- OSB or fiberboard sheets.

What is polyurethane foam and what does it come in?

This material is a type of plastic. It has a cellular foam structure, and the composition of polyurethane foam is dominated by a gaseous substance - from 85 to 90 percent. Numerous tiny cells, isolated from each other, are filled with gas. The remaining few percent of the volume is the solid part - the thin walls of these cells.

Polyurethane foam was invented by German scientists from the company IG Farben, led by the famous Otto Bayer. However, in those days this name was not yet popular. So, in the laboratory of the city of Leverkusen, after a series of experiments, a new material was obtained, the properties of which turned out to be unique. It became clear that this substance had a lot of potential applications.

Various types of polyurethane foam are in great demand today - after all, they are very simple to produce, and right away on the construction site. In this case, the two liquid components, when mixed, enter into a chemical reaction. If the required proportions are observed, a polymer is synthesized, which is a hardened foam. By modifying the preparation recipe, you can obtain polyurethane foams that differ in properties from each other. Some of them are suitable for thermal insulation of windows and doors, others for insulating houses made of brick or reinforced concrete, and still others for a variety of pipelines.

Video. The process of producing polyurethane foam

So, depending on the proportion of the starting substances, we obtain polyurethane foams with cells of different sizes, the walls of which have different thicknesses and, accordingly, strength. We will not list all types of polyurethane foam that can be obtained by changing the recipe. Let's look at the two most popular materials of this group.

1. The familiar foam rubber, scientifically called elastic polyurethane foam, has a density of 5 to 35 kilograms per cubic meter. We encounter this material every day in the form of washcloths and sponges, filling in chairs and sofas, lining in shoes and clothes, as well as shockproof packaging.

2. Rigid polyurethane foam has recently begun to be used in construction work. But today scientists can already say what will happen to it in 30 or 50 years - the material is being studied and tested. In addition, some laboratories conducted experiments in which polyurethane foam was subjected to an artificial aging procedure. Both the results turned out to be the same.

It is safe to say that polyurethane foam does not like contact with mineral acids and organic solvents. But he is not at all afraid of water and oil products.

In our country we use a fairly large number of brands of rigid polyurethane foam – about 30. They are used both individually and in various combinations with each other. It all depends on the purpose of the application - it could be insulating a house, protecting it from noise, or creating an insulating layer on refrigeration equipment. This material has received such wide application possibilities due to its wonderful properties.

Spraying polyurethane foam on the insulated surface.

Spray insulation PENOPLEX FastFix 850 ml

Sprayed one-component insulation - a universal one-component polyurethane aerosol spray - is used for insulation of building structures, domestic and commercial premises. Insulation can be applied to any surface, including vertical surfaces and surfaces with a negative slope (inner surfaces of roof slopes, etc.). Ideal for small spaces. It can also be used as an auxiliary insulation for application on uneven and geometrically irregular surfaces, as well as where it is technically difficult to use sheet insulation. Heat resistance (of fully cured adhesive foam) during long-term use: from -45°С to +90°С Area of one cover layer during continuous application (depending on the nature of application), m²: Up to 2.2

PROPERTIES:

- for external and internal work;

- due to its finer-cell structure, it has lower thermal conductivity than polyurethane foam and better insulating properties

- output volume after lifting the cap – up to 55 liters;

- the rise of one layer is up to 2.5 cm. It is recommended to apply in several layers. Apply the second layer only after the first has cured.

- temperature range of use – from -0 to +30 °C (at a cylinder temperature from +10 to +35 °C);

- operating temperature range – from -45 to +90 °C;

- complete curing time – 12 hours;

- after polymerization – chemically neutral, does not emit toxic compounds;

- resistant to mold and fungi;

- excellent adhesion to all surfaces, with the exception of fluorine plastic;

- does not contain ozone depleting substances or solvents.

SCOPE OF APPLICATION:

- insulation of walls, ceilings, roofs, basements, doors, building structures, etc. in premises for economic and domestic purposes;

- as an auxiliary insulation when using insulation from polystyrene foam, basalt, etc.

- ideal for insulating geometrically irregular surfaces;

- sealing gaps between thermal insulation elements;

- spraying on sheet materials to reduce vibrations and for sound insulation.

- can be used for comprehensive insulation of cracks, holes, joints together with mounting foam and mounting adhesive foam

Color: Bright orange.

TECHNICAL CHARACTERISTICS: Density of the finished product after spraying and polymerization, kg/m³ no more than: 16-20

Volume of the finished product after spraying and polymerization, liters: 50-55.

Lifting height of the cap of one layer, mm: Up to 25.

Surface drying time (to touch), min., no more: 15-20.

Curing time, min: About 60.

Complete curing time, hours, no more than: 24.

Time for possible further processing, min., no more: 90.

Thermal conductivity, W/mK: 0.025.

Recommended number of layers when spraying: 1-2.

Fire resistance class (DIN 4102-1): B2.

Performance characteristics of polyurethane foam: pros and cons of the material

A large assortment of materials for thermal insulation complicates the selection process, but at the same time allows you to select insulation with ideal parameters for a particular object, taking into account its operating conditions, purpose, as well as the type of building materials from which the walls, ceilings and other structural elements of the building are constructed.

Therefore, when choosing polyurethane foam for your home, you need to take into account all the positive and negative properties of this insulation.

The best manufacturers of polyurethane foam

The ranking of well-known manufacturers of polyurethane foam is headed by brands that have earned recognition in the construction industry.

Soudal

The brand has factories in Poland, Belgium and Slovenia. Soudal brand products provide a structure that meets high European standards and a good yield volume. The sealant does not darken or deform over time, and the durability of the product is impressive.

Krimelte

The manufacturer from Estonia (Penosil brand) offers a variety of models of polyurethane foam for various purposes. Krimelte products are known in the professional environment for their decent price-quality ratio.

Titan

The Orion brand, with production facilities in Turkey, Spain and Poland, ranks third in the popularity rating among polyurethane foam suppliers. Products of this brand foam well without secondary expansion.

Ultima

The brand produces good quality polyurethane foam, the products are easy to use. Judging by consumer reviews, the sealant of this brand does not have an acceptable level of efficiency.

Foam for wall insulation

Axton

The company produces a sealant with high odorless polymerization characteristics, while reviews indicate low adhesion and high porosity of the structure.

Titan02

The highly popular mounting foam Titan02 is available in a winter version and with increased fire resistance. The product demonstrates exceptionally high efficiency when installing window and door structures. It is actively used in the repair of utility systems, sealing and thermal insulation of buildings. Titan02 sealant is sold within 230 rubles.

Penosil

The product is distinguished by its density and uniformity of structure with a large output volume. It is used for installation of structures, filling seams and cavities of varying complexity. The model range also includes special versions for foam plastic. The cost varies from 220 rub.

Soudal

Soudal polyurethane foam is available in three types - winter, summer and fire-resistant. The composition has a high density and a minimal level of porosity, and there is no pungent odor. This brand of sealant dries quickly and evenly. The products are especially appreciated by window installation professionals. Prices start from 350 rub.

Characteristics

The sprayed thermal insulation material is quite light in weight and can be applied to a surface of any material in a layer of any thickness without any significant problems. Sprayed insulation is well known to all professionals and novice craftsmen who value this practical material for its unique characteristics:

- The highest thermal conductivity was noted for these materials, and it is approximately 0.020-0.028 W/mS. In more modern materials this figure will be much lower, which makes their purchase less desirable for the consumer.

- Excellent sound insulation performance. This category of insulators will successfully reduce even strong impact noises that interfere with sleep and rest in the most comfortable conditions. Thus, complete silence will be ensured in any room when working with special tools characterized by increased noise output.

- The vapor permeability of sprayed insulators will allow them to simply absorb moisture, without allowing a large amount of condensation to form, which can damage the coating.

- The use of this innovative material allows you to insulate even those places that were previously considered difficult to reach - and all this thanks to its unique consistency.

- The adhesion parameters that are characteristic of this thermal insulation material will allow you to quickly insulate surfaces made of any materials.

- The timing of construction work with this insulation can also be defined as a record - for insulation of 100-120 m2, 9-10 hours are enough with the lowest labor costs of this process.

- The characteristics of spray-type insulation also include excellent resistance to various biological organisms and chemical reagents.

- The resulting coating will last a very long time and will not suffer from constant exposure to various precipitation typical for the area of its use, the aggressive atmosphere of all kinds of industrial production, various pests and microorganisms (however, the material is afraid of prolonged exposure to sunlight, which must be taken into account when working with it).

- PPU with a density of 70 kg/cubic. m. The material practically does not allow water to pass through and is often used as waterproofing.

- Experts do not classify this material as non-flammable (NG), however, due to the fire retardant included in component A, it was awarded a special certificate of fire-resistant type G2. The material itself does not burn well, and its composition will only contribute to the rapid self-extinguishing of an open flame due to the timely release of carbon dioxide from the cells.

- The approximate insulation consumption is 890 ml per 1 m2 with an applied layer thickness of 5 mm.

Professional advice and customer reviews

Over several years of use, Polinor insulation has already managed to win admirers. Many professionals who have been using polyurethane foam for a long time have given their preference to the new product. It is noted that it is extremely easy to install, fits perfectly on any surface and has good characteristics during operation. Thermal insulation occurs quickly and at a high level.

It is also noted that the material is extremely toxic, so you should take precautions and protect yourself with special suits, gloves, respirators and goggles. If foam gets on the surface of the skin, rinse it thoroughly and consult a doctor.

Also, consumer reviews note that Polinor insulation is quite expensive in cost, but this factor should not be decisive when choosing insulation. The speed of application and excellent characteristics will allow you to save significantly on heating the room in the future.

The material is extremely toxic, so precautions should be taken

Professionals also often prefer this material. Its light structure and ease of application can significantly reduce the time and money spent on installing insulation.

Pros of Polynor polyurethane foam, why I chose it for insulation

- Quick application. I finished 40 sq m of walls in half a day.

- Filling all cracks and pores. There are some kind of cracks and voids in any walls and all this would remain under penoplex or mineral wool. Polynore fills it all, leaving no dew points.

- Good thermal insulation. Before application, the temperature in the extension room was +15 degrees. After application for 6-7 hours it rose to +22 degrees. That is, the result is obvious.

Reviews

Those who have used this insulation system have shared their opinions. Read the reviews on forums and construction sites that we have collected:

Airat

I read reviews about Polynor. I decided to try it myself too. The base was insulated with PP. I wanted to seal the seams with Polinor. It was sprayed well, the yield of material from the cylinder was almost 100%. But it is important to pay attention to the expiration date. I blew out one balloon, then went to buy a second one in another store. I used half of it, and then some kind of sludge started to appear. I took a closer look, and it was already past the expiration date. So you need to pay attention to this. But overall, I’m happy!

Natalia

It was necessary to insulate the loggia. I decided to look through the Polynor reviews on the forums. I liked it. I bought it from Leroy, received instructions and applied it myself to 12 squares. I'm happy with the result. At the end of autumn, being on the loggia is as comfortable as being in the apartment itself. The only thing is that when spraying, foam particles fly in the air, so you need to cover everything.

Sergey

The apartment is on the first floor. I decided to insulate the floor from the basement so that the cold wouldn’t pull in from below so much. I've heard about spray-on insulation. I googled reviews about Polinor insulation and decided to try it. In about 3 hours I foamed the entire required area (about 36 sq.m.). I liked everything, I just need to ventilate it, otherwise I might collapse from the stench. It is difficult to ventilate a basement, so the speed of work was a big plus.

After using Polynor insulation, you can leave your feedback in the comments below.