Why do you need to insulate your house? Most likely, this question will cause confusion among many ordinary people.

A residential building must be insulated. If you reliably insulate a residential building, you will be able to create a stable internal microclimate at any time of the year. Thus, how comfortable the homeowner and all members of his family will live will not depend on temperature changes and the vagaries of nature. By also insulating the house, you will ensure reliability of all elements of the structure and increase their durability.

Before starting to build a private house, it is worthwhile to think through the issue regarding the insulation of not only the walls and ceiling, but also the entire structure. These activities can be carried out not only at the construction stage, but also during the operation of the building (this is best done in the warm season).

If a residential building has unsatisfactory thermal insulation performance, this will negatively affect not only the people living in the house, but also the building itself.

All members of your family will be susceptible to frequent colds. Life in cold rooms will not be comfortable. The walls of the house will be subject to freezing, and then the appearance of mold and mildew on them.

If all structural components of a building have increased thermal conductivity, this will cause self-destruction of building materials.

From the above, one conclusion suggests itself: a residential building needs to be insulated . And how this can be done must be decided by each homeowner individually.

You can insulate your house with one of these materials:

- mineral wool;

- Styrofoam;

- extruded polystyrene foam;

- penoplex;

- penofol;

- penoizol;

- polyurethane foam.

Foam for wall insulation: types and features

To insulate walls, modern craftsmen use various materials and technologies. They have significant differences among themselves, but they are all designed for the same purpose - to make the thermal insulation of the house as productive as possible.

IMPORTANT!

Polyurethane foam is considered one of the most effective materials used for insulation . This material will best protect against cold air entering the building.

Liquid foam for wall insulation is called polyurethane foam (PPU).

All the necessary ingredients are mixed at the factory and the composition required for polymerization is kept under high pressure in cylinders. In order for the foaming and hardening reaction to occur, contact of this composition with oxygen is necessary.

Insulation with polyurethane foam

Is it worth insulating walls with foam? Of course, it’s worth it for one simple reason - polyurethane foam is an ideal material for this purpose, and besides, it performs another very important function - sound insulation.

What is foam insulation? This is a special pliable mass that, when interacting with air, tends to foam. This composition has a fairly strong and elastic structure. To spray it, cylinders, pneumatic devices and other devices are used.

Today, when constructing frame-type houses, the areas between the “sandwich panels” are filled mainly with foam insulation.

Some important tips

Before you choose this material and start insulating walls with foam, you should take into account useful tips for choosing and working with insulation

Let's consider in what cases and how best to insulate walls.

For dealing with cracks on the exterior walls of a home, the polyurethane foam type is ideal. It can also be used to insulate the floor if it is an open veranda, and also for insulating the attic. But if you decide to make a room out of the attic where you plan to spend a lot of time, or the windows face the sunny side, then it is not recommended to use polyurethane foam there either.

If you plan to fill a large space with foam or fill it, then the use of penoizol will be indispensable. But don’t forget about purchasing a special spraying apparatus, because... a regular bottle won't be enough.

If you need to repair cracks and other defects in the wall or provide thermal insulation in small areas, then it is better to insulate the house with polyurethane foam in cylinders. This non-flammable insulation is environmentally friendly and becomes quite dense after final hardening.

There is one more tip about applying foam. If it is necessary to repair external defects, then the technology of applying foam is direct - using a balloon or a special apparatus. But if defects are found in the thickness, then it is necessary to use a long hose to push the foam. Just before doing this, you should drill a couple of holes in the wall.

Advantages and disadvantages of foam insulation

The main advantages of insulation:

- Possibility of processing even large areas in a short period of time.

- The coating has no seams.

- This material is not subject to rotting processes, and mold and mildew do not form on it.

- This is a highly flammable material that is not subject to combustion, it can only melt.

- By interacting with the metal coating, a dense anti-corrosion protection is created.

- The result is a smooth surface, which is characterized by excellent heat-saving properties.

- The foam does not deform the base on which it is applied.

- Light weight.

Regarding indicators such as environmental friendliness and durability, I would like to say the following: the material is absolutely safe for long-term use in residential premises.

Advantages of the material

Disadvantages inherent to this type of insulation:

- It is negatively affected by direct sunlight.

- The material may become unusable from continuous contact with water.

- The product is not cheap.

- To apply it, special conditions must be created.

- When working with foam insulation, you need to use a special tarpaulin suit, gloves, a respiratory mask and safety glasses.

- Since this material has a low level of vapor permeability, phenomena similar to those occurring in a thermos occur inside the building. Therefore, it is imperative to install a forced ventilation system for the premises.

Is it possible to increase sound insulation in this way?

The foam has sound insulation properties. This is affected by:

- The thickness of the applied insulation layer reflects the incoming noise.

- Elasticity absorbs vibration from sounds.

- The tightness of seams and cracks prevents noise from penetrating into the room.

But the foam in the cylinders does not have the same characteristics as the material sprayed through the equipment.

The only type of foam in cylinders that has good performance is MAXFORTE SoundFLEX.

Today, foam is widely used to insulate walls indoors and outdoors. It is used in attics and basements, attics and loggias. Insulation of pipelines and chimneys is carried out.

The material has many positive aspects and has good sound insulation properties. When using insulation, you should familiarize yourself with the application method and also think about the cladding.

What is the best way to insulate a building with foam - from the outside or from the inside?

It is difficult to give an unambiguous answer to this, but we will try to do so. One of the varieties of liquid foam, penoizol, is used for thermal insulation of frame buildings . This material fills the air gaps between:

- external and internal walls;

- wall and plastic panel;

- a wall and a sheet of drywall;

- subfloor and floor covering.

Insulation outside and inside

Using polyurethane foam, slabs made of solid thermal insulation materials are fixed, and the seams between them are also filled with foam.

Some homeowners use foam to insulate the facade of their building.

Polyurethane is used to eliminate minor defects on walls.

You will get an equally good result if you insulate the walls of frame-type houses, the roof, the attic, the facade of the house, as well as the basement and lower floor with polyurethane foam.

Briefly about the main thing

Insulating a house with foam has the following number of advantages:

- No load on structures.

- Seamless and hermetic filling of cavities.

- Biological resistance.

- Fire safety.

- Harmlessness.

- Creation of anti-corrosion protection for metal elements.

- Simple application procedure.

Disadvantages - high cost, low water resistance and sun protection, the need to use a protective kit during spraying. The most common types of foam insulation are penoizol, polyurethane foam, polyurethane foam and foam concrete.

The materials can be used both in liquid form and in the form of finished panels and blocks. The main purpose is to seal cracks and cavities, fill frame walls, insulate roofs, basements, floors, and facades. Thermal insulation can be done independently according to the instructions, but it is better to entrust the procedure to professionals.

Types of foam insulation: polyurethane foam and polyurethane foam

There are a large number of different types of foam materials on the market for construction needs; we will not consider them all in detail. For example, let's take just a few of them, which are considered the most popular and effective. We will talk about polyurethane foam and polyurethane foam.

NOTE!

Polyurethane foam is used to fill cracks and voids when installing windows and doors, as well as seams between floor slabs and joints of structural elements.

Polyurethane foam is used for:

- Achieve good sound insulation effect . To do this, fill the joints between pipes and holes in the wall with foam. Thus, it is possible to significantly reduce the noise level from the heating system, plumbing and operating air conditioners.

- Needs thermal and waterproofing . Using polyurethane foam, you can thoroughly seal cracks in the roof, voids around pipes, as well as empty space created as a result of installing door and window frames. The main purpose of polyurethane foam is sealing.

- Bonding . With its help, you can firmly connect various elements made of different materials to each other.

Polyurethane foam

PPU is produced in cylinders and has the following features:

- Polyurethane foam has excellent thermal insulation properties . Therefore, it is widely used as insulation and sealing material in construction.

- The properties of this material directly depend on the additives used in its production.

- Using sprayed polyurethane foam, you can easily and without any problems insulate a structure of any shape . The material is not afraid of dampness, it withstands the effects of acids and alkalis. It is also too tough for rodents and various insects.

Polyurethane foam

Specifications

To obtain a qualitative assessment of the properties of this material, it is necessary to evaluate its technical indicators. These include:

- Operating temperature range – from -50 to +120 degrees;

- Material density – 5-75 kg/m3;

- Daily water absorption by mass – 10.5-20%;

- Thermal conductivity – 0.028 –0.047 (W/m) *°C;

- Humidity (mass fraction) – 5-20%;

- The standard service life is 50 years. According to recent studies, it is not limited.

Tensile strength:

- For bending deformations – 0.1-0.25 kg/cm. sq.;

- For compression (at 10% linear deformation) – 0.07-0.5 kg/cm. sq.;

- Tensile – 0.05-0.08 kg/sq.cm;

Slab penoizol

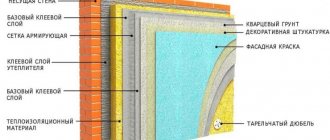

wall pie

Construction of a wall “pie” of a frame house:

- interior decoration;

- vapor barrier layer;

- insulation;

- frame stand;

- windproof layer;

- transverse lathing;

- vertical lathing;

- external finishing.

wall pie

If you plan to insulate the premises from the inside, you need to carry out all the work in stages. One of the main issues that you should pay special attention to is the correct placement of the vapor barrier film in the thermal insulation “pie”.

Vapor barrier can be made from:

- reflective film;

- diffusion membrane;

- steam condensate film.

When installing a vapor barrier material, you need to take into account one important point: it must be mounted on top of the insulation on the room side. If you plan to insulate the wall with polyurethane foam, then you will not need a vapor barrier.

Useful video

Before starting construction of a building, it is necessary to carefully consider the issue of its thermal insulation. In this case, not only the walls, but also the entire structure should be insulated.

Today, the construction market is represented by a huge selection of thermal insulation materials, but foam deserves special attention. It allows for high-quality insulation, protecting the building from temperature changes, and provides a constant indoor microclimate at any time of the year.

Installation of lathing and applying foam yourself

It is necessary to screw an aluminum profile to the ceiling and walls in vertical rows . Next, the sheathing is strengthened using horizontal jumpers ( steps of 0.5 meters ). Don't forget to screw the profile around the perimeter of the window doorway.

In order not to stain pipes and communications, they need to be covered with film .

Installing the sheathing

Rules for applying foam insulation in cylinders:

- First of all, you need to take care of safety precautions.

- Then you need to spray a small amount of automotive silicone grease onto the mounting gun.

- Next, you need to insert the can onto the gun and screw it tightly.

- Now you can apply the mounting foam to the desired location.

- The can must be removed from the gun and cleaned with a special compound.

- If the foam is not completely used up, you need to wash the valve located on the cylinder with a cleaner.

Applying foam to wall surfaces

Process nuances

Speaking about the process of insulating walls using foam, it is worth noting several main nuances.

First of all, this concerns safety.

Regardless of the type of foam insulation that will be used, it is necessary to wear a special protective suit. It should be made of polyethylene, since the solution will not stick to it.

Such a protective suit must have a hood, because if the solution gets on your hair, you won’t be able to clean it, you can only cut it. It is also necessary to have gloves, goggles and a special respirator that will protect the relevant areas of the body and organs.

One more point regarding the method of applying foam. There are several options.

The first involves the use of polyurethane foam from a can, and the second through an automatic material feeding machine.

When automation is used, the solution is evenly applied to the wall, and you need to move from bottom to top. This is due to the fact that it is easier to control the process of filling the space with solution. As a result, a kind of fur coat should form on the surface, made of foam and having a relief surface.

And the last, third nuance of application concerns the thickness of the layer itself. In cases where this figure exceeds 8 cm, the work must be carried out in stages. After each application, the foam must dry before applying the next layer.

Several layers are needed because after the material expands, strong pressure is exerted on the structure, which can break it. Therefore, when applying a large amount at a time, the wall frame may not withstand it and break.

Watch the video, which uses the example of a specific wall insulation to show the basic techniques for applying foam to a wall with your own hands:

Waterproofing

Polyurethane foam is also used for waterproofing. It increases in volume under the influence of moisture and hardens within 24 hours.

Polyurethane foam with waterproofing properties is sold in cans. It is endowed with high waterproofing and fixing properties. It is used for both external and internal work.

This universal material is not afraid of water and high humidity, so it is widely used in everyday life.

Conclusion

Foam insulation can be used for walls made of various materials, including aerated concrete, blocks and reinforced concrete panels. Therefore, they are used for insulation of private cottages and apartments. Before giving preference to any one type of foam, consult a specialist.

If you have decided to insulate your house with liquid foam, this is the right intention. Always try to buy raw materials from the best domestic and foreign manufacturers. This way you will be able to avoid premature wear of structures.