Why do you need to insulate your house? Most likely, this question will cause confusion among many ordinary people.

A residential building must be insulated. If you reliably insulate a residential building, you will be able to create a stable internal microclimate at any time of the year. Thus, how comfortable the homeowner and all members of his family will live will not depend on temperature changes and the vagaries of nature. By also insulating the house, you will ensure reliability of all elements of the structure and increase their durability.

Before starting to build a private house, it is worthwhile to think through the issue regarding the insulation of not only the walls and ceiling, but also the entire structure. These activities can be carried out not only at the construction stage, but also during the operation of the building (this is best done in the warm season).

If a residential building has unsatisfactory thermal insulation performance, this will negatively affect not only the people living in the house, but also the building itself.

All members of your family will be susceptible to frequent colds. Life in cold rooms will not be comfortable. The walls of the house will be subject to freezing, and then the appearance of mold and mildew on them.

If all structural components of a building have increased thermal conductivity, this will cause self-destruction of building materials.

From the above, one conclusion suggests itself: a residential building needs to be insulated . And how this can be done must be decided by each homeowner individually.

You can insulate your house with one of these materials:

- mineral wool;

- Styrofoam;

- extruded polystyrene foam;

- penoplex;

- penofol;

- penoizol;

- polyurethane foam.

Foam for wall insulation: types and features

To insulate walls, modern craftsmen use various materials and technologies. They have significant differences among themselves, but they are all designed for the same purpose - to make the thermal insulation of the house as productive as possible.

IMPORTANT!

Polyurethane foam is considered one of the most effective materials used for insulation . This material will best protect against cold air entering the building.

Liquid foam for wall insulation is called polyurethane foam (PPU).

All the necessary ingredients are mixed at the factory and the composition required for polymerization is kept under high pressure in cylinders. In order for the foaming and hardening reaction to occur, contact of this composition with oxygen is necessary.

Insulation with polyurethane foam

Is it worth insulating walls with foam? Of course, it’s worth it for one simple reason - polyurethane foam is an ideal material for this purpose, and besides, it performs another very important function - sound insulation.

What is foam insulation? This is a special pliable mass that, when interacting with air, tends to foam. This composition has a fairly strong and elastic structure. To spray it, cylinders, pneumatic devices and other devices are used.

Today, when constructing frame-type houses, the areas between the “sandwich panels” are filled mainly with foam insulation.

Consumer properties

Like any insulating material, Polynor has a number of advantages:

- Features excellent heat conservation. These insulation indicators are higher compared to expanded polystyrene and mineral wool.

- Non-toxic. Consumer reviews about Polinor are quite good, since it is not poisonous and does not require protective equipment when using it.

- Ease of use. When using POLYNOR, a heat-insulating layer is created, which does not require a frame for fastening. Also, no tools or auxiliary materials are required.

- Excellent grip. The composition quickly adheres to any surface - brick, wood, plastic, stone, concrete, which significantly expands the scope of its application.

Polynor insulation is very popular due to the fact that it is applied by spraying. This affects better adhesion of different surfaces, even if they are not very smooth. Very often this insulation is used to finish hard-to-reach places, for example, where pipes or cables are laid.

Advantages and disadvantages of foam insulation

The main advantages of insulation:

- Possibility of processing even large areas in a short period of time.

- The coating has no seams.

- This material is not subject to rotting processes, and mold and mildew do not form on it.

- This is a highly flammable material that is not subject to combustion, it can only melt.

- By interacting with the metal coating, a dense anti-corrosion protection is created.

- The result is a smooth surface, which is characterized by excellent heat-saving properties.

- The foam does not deform the base on which it is applied.

- Light weight.

Regarding indicators such as environmental friendliness and durability, I would like to say the following: the material is absolutely safe for long-term use in residential premises.

Advantages of the material

Disadvantages inherent to this type of insulation:

- It is negatively affected by direct sunlight.

- The material may become unusable from continuous contact with water.

- The product is not cheap.

- To apply it, special conditions must be created.

- When working with foam insulation, you need to use a special tarpaulin suit, gloves, a respiratory mask and safety glasses.

- Since this material has a low level of vapor permeability, phenomena similar to those occurring in a thermos occur inside the building. Therefore, it is imperative to install a forced ventilation system for the premises.

Myths about the dangers of foamed plastics

Conspiracy theorists and unscrupulous advertisers of competing classes of insulation products often spread rumors about the terrible health risks caused by foamed plastics.

If you look at it without hysterics and exaggeration, polyurethane foam actually has one property that carries a potential threat.

When burned, it can form toxic volatile substances based on formaldehyde resins. During a fire, this may be an additional risk factor for those who did not have time to leave the burning premises.

During application of the foaming composition, some inert gas and other chemical compounds are also released.

However, after the foam coating has completely hardened for the entire period of its operation, no harmful emissions occur. The complete film surrounding each microcell is chemically inert and impermeable.

To summarize, we can say that the foam coating is completely safe during operation.

During application, all precautions specified in the user manual should be observed:

- use only serviceable equipment;

- exclude the use of open fire and high-temperature heating devices during application;

- use personal protective equipment: respirator, gloves, protective overalls with a hood and thick shoes;

- When working indoors, ensure ventilation

- do not use the premises for people to stay in them until the composition has completely hardened (usually 24 hours.)

Of course, during the operation of foam coatings in the house, it is necessary to establish and strictly observe fire safety rules.

What is the best way to insulate a building with foam - from the outside or from the inside?

It is difficult to give an unambiguous answer to this, but we will try to do so. One of the varieties of liquid foam, penoizol, is used for thermal insulation of frame buildings . This material fills the air gaps between:

- external and internal walls;

- wall and plastic panel;

- a wall and a sheet of drywall;

- subfloor and floor covering.

Insulation outside and inside

Using polyurethane foam, slabs made of solid thermal insulation materials are fixed, and the seams between them are also filled with foam.

Some homeowners use foam to insulate the facade of their building.

Polyurethane is used to eliminate minor defects on walls.

You will get an equally good result if you insulate the walls of frame-type houses, the roof, the attic, the facade of the house, as well as the basement and lower floor with polyurethane foam.

Types of foam insulation: polyurethane foam and polyurethane foam

There are a large number of different types of foam materials on the market for construction needs; we will not consider them all in detail. For example, let's take just a few of them, which are considered the most popular and effective. We will talk about polyurethane foam and polyurethane foam.

NOTE!

Polyurethane foam is used to fill cracks and voids when installing windows and doors, as well as seams between floor slabs and joints of structural elements.

Polyurethane foam is used for:

- Achieve good sound insulation effect . To do this, fill the joints between pipes and holes in the wall with foam. Thus, it is possible to significantly reduce the noise level from the heating system, plumbing and operating air conditioners.

- Needs thermal and waterproofing . Using polyurethane foam, you can thoroughly seal cracks in the roof, voids around pipes, as well as empty space created as a result of installing door and window frames. The main purpose of polyurethane foam is sealing.

- Bonding . With its help, you can firmly connect various elements made of different materials to each other.

Polyurethane foam

PPU is produced in cylinders and has the following features:

- Polyurethane foam has excellent thermal insulation properties . Therefore, it is widely used as insulation and sealing material in construction.

- The properties of this material directly depend on the additives used in its production.

- Using sprayed polyurethane foam, you can easily and without any problems insulate a structure of any shape . The material is not afraid of dampness, it withstands the effects of acids and alkalis. It is also too tough for rodents and various insects.

Polyurethane foam

Application area

The scope of application of the sprayed material is quite wide:

- First of all, this is industrial construction. Insulation of industrial buildings is a rather long and labor-intensive process. The use of such insulation makes it possible to significantly reduce the construction period, and therefore its cost.

- Insulation of heating mains. All large main pipelines are buried in the ground. This means that the insulation does not have any problems with ultraviolet rays. And the use of material for installing pipes during repairs significantly reduces the period of localization and elimination of an accident on the heating main.

- Low-rise construction.

Due to its price, insulation is most widely used in low-rise construction. Only owners of private houses can afford to purchase and use this type of insulation. The main reason for the popularity of this method is the acceleration of work on insulating the perimeter of the building and the ability to use one material for any surface.

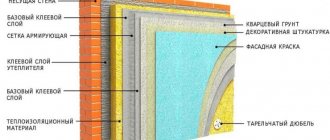

wall pie

Construction of a wall “pie” of a frame house:

- interior decoration;

- vapor barrier layer;

- insulation;

- frame stand;

- windproof layer;

- transverse lathing;

- vertical lathing;

- external finishing.

wall pie

If you plan to insulate the premises from the inside, you need to carry out all the work in stages. One of the main issues that you should pay special attention to is the correct placement of the vapor barrier film in the thermal insulation “pie”.

Vapor barrier can be made from:

- reflective film;

- diffusion membrane;

- steam condensate film.

When installing a vapor barrier material, you need to take into account one important point: it must be mounted on top of the insulation on the room side. If you plan to insulate the wall with polyurethane foam, then you will not need a vapor barrier.

Which variety to choose

In many ways, the choice will depend on the specific situation and what area needs to be treated. Using an example, we can consider the most common cases when a house needs foam insulation:

- If you need to seal cracks or eliminate any other defects on the surface, then polyurethane is suitable. But such material should not be exposed to sunlight.

- If you need to fill a large volume, then penoizol is suitable. But an ordinary cylinder will not be enough; you will need to purchase a special device with high pressure. You don’t have to buy it at all - you can rent it or borrow it from friends, because no one will use it often.

- If you need to seal small cracks and carry out thermal insulation in small areas, you can buy a cylinder with regular polyurethane foam. It does not support combustion, after hardening it is particularly hard, and it has an ecological composition.

- If defects are found on the outside of the wall, then you need to apply a composition based on polyurethane. It is applied directly using a special cylinder or apparatus.

It is worth remembering that foam insulation creates errors inside the layer that need to be eliminated.

To do this, you will need a long hose to push the material inside. If it is necessary to fill air gaps inside the insulation, then holes are made in the wall with something sharp. Polyurethane foam is not suitable for insulating the entire external facade - it does not have the appropriate characteristics necessary for this. Therefore, you should not choose it for these purposes, even despite its more economical cost.

Installation of lathing and applying foam yourself

It is necessary to screw an aluminum profile to the ceiling and walls in vertical rows . Next, the sheathing is strengthened using horizontal jumpers ( steps of 0.5 meters ). Don't forget to screw the profile around the perimeter of the window doorway.

In order not to stain pipes and communications, they need to be covered with film .

Installing the sheathing

Rules for applying foam insulation in cylinders:

- First of all, you need to take care of safety precautions.

- Then you need to spray a small amount of automotive silicone grease onto the mounting gun.

- Next, you need to insert the can onto the gun and screw it tightly.

- Now you can apply the mounting foam to the desired location.

- The can must be removed from the gun and cleaned with a special compound.

- If the foam is not completely used up, you need to wash the valve located on the cylinder with a cleaner.

Applying foam to wall surfaces

Price

Construction foam can be purchased in large quantities or at retail. Foam in cylinders for insulation will cost about 400 rubles. But few people actually use small quantities of the material. Usually large volumes are required, the cost of which the construction company tries to include in the cost of the work. In this case, they ask for about 100 rubles per linear meter. Penoizol can cost from 600 to 2500 rubles per cubic meter. The cost of polyurethane for a similar volume is usually not less than 3,000 rubles.

Builders recommend not saving on insulation, since a low-quality mixture has a short lifespan and quickly ceases to fulfill its main function. But high-quality material can last for many years, providing comfortable indoor conditions.

Wall insulation in the form of foam seems to be the most successful solution, since you can carry out the procedure yourself. Compliance with all the rules and a responsible approach to business will allow you to insulate the surface and save on the services of the construction team.

Temperature changes outside should have minimal effect on the temperature inside the house. Additional foam walls can isolate the room from influences, performing the function of vapor barrier and waterproofing. Modern materials help achieve results in a short time without using complex methods.

Waterproofing

Polyurethane foam is also used for waterproofing. It increases in volume under the influence of moisture and hardens within 24 hours.

Polyurethane foam with waterproofing properties is sold in cans. It is endowed with high waterproofing and fixing properties. It is used for both external and internal work.

This universal material is not afraid of water and high humidity, so it is widely used in everyday life.

Thermal insulation of PPU roofing: your benefits, our efforts

For construction organizations - thermal insulation of PPU roofs and waterproofing of roofs of newly constructed or reconstructed facilities according to your or our turnkey project. You are getting:

- reduction of construction time;

- The guarantee covers the period of liability of the developer (performer of the work).

Owners of industrial buildings - insulation of the roof of an industrial building. You are getting:

- thermal insulation of roofs in any condition, the ability to postpone the replacement of the existing roof covering;

- carrying out work without disrupting the operation of the enterprise.

Management companies, housing and communal services organizations and municipalities - insulation of roofs of apartment buildings, public and administrative buildings. You are getting:

- guaranteed compliance with the requirements of Federal Law N 261-FZ “On energy saving and increasing energy efficiency...”;

- “minimal presence effect” during work - no disturbance for residents, employees of organizations, customers, etc.

Conclusion

Foam insulation can be used for walls made of various materials, including aerated concrete, blocks and reinforced concrete panels. Therefore, they are used for insulation of private cottages and apartments. Before giving preference to any one type of foam, consult a specialist.

If you have decided to insulate your house with liquid foam, this is the right intention. Always try to buy raw materials from the best domestic and foreign manufacturers. This way you will be able to avoid premature wear of structures.

Service life of foam insulation

Foam insulation does not have a clearly limited service life. The following factors can accelerate its destruction:

- exposure to direct sunlight;

- ultraviolet radiation;

- quartzization.

For this reason, after thermal insulation with foam, finishing is required. In this way, not only the aesthetic appearance of the house is formed, but also an additional protective factor is created. If the cladding is not damaged, the foam can last almost forever.