Heating, ventilation and air conditioning systems are designed to create and maintain comfortable microclimate conditions for efficient and fruitful human life. The effective operation of HVAC systems largely depends on a well-executed design, high-quality installation and proper operation. It also follows that competent design, high-quality installation and proper operation of HVAC systems are only possible if the designer has the appropriate knowledge and skills.

This article is devoted to the issue of adjusting heating systems (HS).

The heating system is designed to maintain a comfortable (required) air temperature in the room. We can also say that the operation of the heating system is aimed at compensating for heat loss in the room. This is achieved by returning the required amount of heat to it. The latter is generated by a heat source (boiler, boiler room, heat pump, etc.) and transported by a coolant (water, air, steam, etc.) through heat pipes (pipelines, air ducts) to the consumer (heating device, heated floor, heat exchanger, heater, etc. .P.). In general, the heating system can be represented as follows - Fig. 1.

Based on the main task of the heating system - providing the consumer with the required amount of heat - we can talk about the efficiency of the heating system. Efficiency can be assessed by the temperature in the room, the temperature and pressure of the coolant, the presence of leaks, as well as the uniformity of heat distribution throughout the facility. At the same time, we are interested in the efficiency of the heating system both during commissioning and during use.

Forced circulation water heating systems must include the following elements:

- heat source (boiler);

- heating device;

- circulation pump;

- expansion tank;

- pipelines, fittings and pipeline fittings (valves, taps, air vents, safety valves, etc.);

- instrumentation and automation system.

The absence of any of these elements makes the system inoperable - completely or partially. There is no expansion tank - the thermal expansion of the coolant will not be compensated, but static pressure will appear. This, in turn, will lead to leaks in the system, its unstable operation, and failures in automation, if any. If there is no pump, the circulation of the coolant will almost completely stop, the required amount of heat will not reach the consumer, and it will freeze. No boiler - no heat. There is no heating device - there is little heat (the function of heating devices can be performed by the system pipelines).

Duration of commissioning work when starting heating in microdistricts

- adjustment tests under operating conditions, balance experiments (setting optimal modes, testing valve control in manual and automatic modes, checking automation settings, identifying deficiencies and developing proposals for eliminating them), the result is an individual test report;

- comprehensive testing (72 hours of continuous operation for all major equipment, 24 hours for heating networks), its beginning is considered to be the time when all systems are started at maximum load.

Some companies document all activities directly related to the preparation and testing of devices in a separate document - the Commissioning Methodology, which comes as an addition to the Program.

In the Program they include more general things of an organizational nature. That is, there is an actual division of the entire complex of work into organizational, legal and technical components.

According to the Decree of the Government of the Russian Federation dated May 23, 2006 No. 307 “On the procedure for providing utility services to citizens,” the requirement for utility heating services is uninterrupted round-the-clock heating during the heating season. The permissible duration of a heating break is a total of no more than 24 hours within one month.

In case of failure to provide utility services or provision of utility services of inadequate quality, the consumer notifies the contractor's emergency dispatch service or other service specified by the contractor. A notification about the failure to provide utility services or the provision of utility services of inadequate quality can be made by the consumer in writing or orally (including by telephone) and is subject to mandatory registration with the emergency dispatch service.

The technical report is usually issued by an involved specialized organization within one month. proektoved.com Commissioning of heating systems Before putting the heating system into operation, it is necessary to perform a number of preparatory work, conduct tests and establish the interaction of various units with each other. All this is included in the commissioning of the heating system, the purpose of which is to identify and eliminate shortcomings and errors made during installation, as well as to bring the entire system into compliance with the standards established for it.

As a result of this work, the client receives a reliable, productive and efficient system. The cost of heating commissioning is fully paid for by subsequent trouble-free operation and safety of the equipment. Composition of commissioning works

Commissioning work is carried out after installation.

As part of the commissioning and commissioning of refrigeration supply, the following types of test work are performed:

- checking the correct assembly of all components and components of refrigeration equipment;

- filling the cooling system with all necessary working media (freon, nitrogen and oil);

- checking the functioning of protection and control equipment;

- starting the system and bringing it to the required operating mode;

- briefing (and, if necessary, training) of service personnel.

Important! The last point can be included in the commissioning program only by agreement with the customer. The procedure for commissioning heating and heat supply systems The term “heat supply” is usually associated with the organization that supplies the coolant, while the concept of “heating” is associated with its consumption and is applicable to organizations involved in the operation heated rooms

Commissioning program

Many projects involve major construction or reconstruction of structures and buildings with the installation of new equipment or special processes. Such work includes the installation of fire extinguishing systems, electrical supply, air conditioning, ventilation, and fire alarm systems. They all ask for commissioning and commissioning work, and for this purpose a commissioning program is now very often drawn up.

What is PNR and why are they carried out?

According to SNiP, commissioning work is a set of activities that are carried out during the preparation of complex testing and individual testing of the supplied equipment. This includes testing, testing and adjusting equipment to achieve project performance.

In most cases, all these actions are carried out on a contractual basis by special organizations that have the necessary permits and a staff of professional craftsmen. The necessary conditions for their activities on the site (industrial sanitation, occupational safety) are organized by the customer, who also pays the commissioning work at the expense of the entire estimate for putting the facility into operation. All operations must be carried out by personnel of the commissioning organization, instructed and certified for any specific case, under the supervision of a responsible representative from the customer.

There are two main stages in commissioning activities:

- Individual checks are actions that are required to guarantee compliance with the requirements that are taken into account by technical specifications, standards and working documentation for checking units, machines and mechanisms. The purpose of individual tests is to prepare for comprehensive testing in the presence of a working commission.

- Comprehensive checks are actions carried out after the acceptance of mechanisms by the working commission, and specifically the system testing itself. At the same time, the interconnected joint operation of all supplied equipment is checked at idle, then under load, after which the technological mode envisaged by the project is reached.

Although this is not prescribed at the legislative level, in our time very often the customer requests that a commissioning program be drawn up for testing work. This gives confidence that not a single invisible moment will be missed, and the operation of all systems will comply with the approved standards and project documentation.

How is the commissioning program compiled and what does it include?

The commissioning and commissioning program is a document that clearly outlines a complete list of actions that will be carried out by an important organization. You can see debates online as to whether the commissioning methodology should be included in the Program or whether it should be drawn up as a separate document. There are no specific requirements regarding this, so everything depends on the agreements of the parties. A sample for each specific situation can easily be found on the Internet.

The program is drawn up and approved by a representative of the commissioning company and agreed upon by the customer; the signatures and seals of the parties are installed in the header of the document. Next come the following sections (for example, let’s take the preparation of a hotel heating system):

- General provisions that describe for which object the Program is approved, the availability of specialized permits for test participants, a list of regulatory documents on which the actions taken are based.

- The procedure for organizing and carrying out the main adjustment activities. The residual task is set - to provide conditions for an equal supply of coolant to the heating systems. Then all the actions that need to be performed and the list of necessary devices are briefly described.

- Setup goals. The parameters that need to be achieved after completion of all work are described in detail (required temperature characteristics and boundary deviations, uniform distribution of the coolant, possible heat losses). Methods of achieving the goal are also indicated (vertical and horizontal adjustment, measurements at control points).

- Characteristics of the object. All inherent systems and their characteristics are described (presence of a heating point, heating systems, hot water supply and ventilation, parameters of the coolant for any of them, specialized pumps and batteries).

Preparation for testing systems. This includes checking all the necessary documentation, drawings and permits, visual inspection of the technical readiness of systems, control and accounting devices, designation of control points, training of employees, compiling a list of activities.

- Measures to ensure labor protection. The conditions under which certain activities can or cannot be done (for example, descending into a flooded thermal chamber or basement) are clearly outlined, as well as a list of required work clothes for the staff.

Further, the document describes specifically the commissioning, which includes:

- checking the correctness of the installation process, the readiness and serviceability of equipment in visual mode (control devices, shut-off valves, filling the system with water), based on the results, a defective list is compiled;

- adjustment checks under operating conditions, balance experiments (setting good modes, testing valve control in manual and automatic modes, checking automation settings, identifying disadvantages and working out proposals for eliminating them), the result is an individual test report;

- system testing (72 hours of continuous operation - for all key equipment, 24 hours - for heating mains), its very beginning is considered to be the time of startup of all systems at the heaviest load.

Certain companies document all activities related specifically to the preparation and testing of devices in a separate document - the Commissioning Methodology, which is included as an addendum to the Program. In the Program they include more general things of an organizational nature. In other words, there is a practical division of the entire complex of work into organizational, legal and technical components. But often the Methodology is considered an important part of the key body of the approved Program.

An important part of the Program may be the following additional documents:

- passports of ventilation systems, heat supply and hot water supply, as well as individual units for their connection;

- the procedure for the preparation and future conduct of commissioning operations with a list of all operations, their start and completion times;

- a list of fixed and portable measuring instruments (instruments for determining pressure, thermometers, etc.);

- list of control and shut-off valves, equipment (pumps, valves, heat exchangers, filters);

- a list of control points and measurement protocol for any of them;

- a list of indicators that require clarification and adjustment (ambient humidity and temperature, pressure in pipes, heat carrier costs);

- methodology for measuring heat loss by building structures (a specialized report is drawn up and a certificate is provided).

After completion of all commissioning work, comprehensive testing and operational testing, a commissioning report is drawn up with the relevant appendices (a list of mechanisms and equipment on which adjustment and testing were carried out).

The technical report is usually issued by the special organization involved within one month.

Heating adjustment work using shut-off valves

Throughout the entire process, the water entering the system must have a constant temperature. Adjustment is usually made according to temperature changes by changing the volume of supplied water, which depends on the type of heating system and thermal input.

Temperature changes depend on the volume of water consumed and this value is inversely proportional. Thus, in order to increase the difference to the required value, the coolant flow should be reduced. To do this, either close the valve located at the inlet or reduce the flow itself.

The more water passes through heating devices, the higher the speed of its movement and, accordingly, the coolant cools less. As a result, the average temperature in the radiator increases and the heat transfer of the device increases. After completing the adjustment in the heating unit, individual risers of the structure are subject to adjustment. If problems arise, repairs are carried out in such a way that it is possible to use control valves for the heating system on risers or balancing valves (more details: “Regulation valves for heating radiators, valve installation”).

One way to adjust the heating system is shown in the video:

When there are only taps on the heating risers, only preliminary adjustments are made. It should be taken into account that the closer the riser is to the inlet, the more the tap should be opened. This is necessary so that the heating shut-off valves on the closest riser allow a minimum volume of water to pass through.

At the same time, on the riser located farthest away, you need to open the tap, such as in the photo. First, they check the quality of heating of the furthest riser and finish with the one that is closest.

Typically, in two-pipe systems, due to pressure, devices on the upper floors overheat. If this deficiency is not present on the lower floor, then adjustment of the upper heating radiators is necessary. If there is a double adjustment valve, it is possible to reduce the flow area. In the absence of such taps, the heating radiators are adjusted by installing throttle washers.

In two-pipe heating systems, the uniformity of heating of radiators will increase with increasing water flow. The most important parameter for heating structures is operating pressure (read: “Losses and pressure drop in the heating system - solving the problem”). To lower it, use a pressure regulator in the heating system, and to increase it, use circulation pumps.

The temperature of the coolant when adjusting the device cannot exceed 50-60 °C. After completing the adjustment, the water temperature must be brought to 90 °C, and the heatability of the radiators must be checked again at this temperature. It is advisable to seek the services of specialists to adjust heating systems.

Proportional method

The method is based on the patterns of flow deviation in parallel sections of the system when regulating one of them. From the hydraulics course it is known that pipeline circuits can be connected in parallel, in series and in branches. Each section of the pipeline has a certain resistance characteristic S [Pa/(kg/h)2]. Depending on the method of connecting various pipelines, these characteristics are summarized in a certain way.

With a series connection, this dependence has the form: S = S1 + S2, G1 = G2. For parallel connection:

The pressure loss in the area is determined by the following equation:

Δр = SG2.

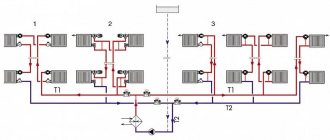

It is known that in parallel connected pipelines there will be equal pressure losses. Accordingly, for the system (Fig. 3) we obtain:

It is assumed that adjusting one of the valves in the circuit does not lead to a proportional change in the parameters in the remaining valves in the circuit.

There is a proportional relationship between water flow rates in the system circuits - a change in the resistance of one of the valves entails a redistribution of flow rates while maintaining the proportion between them (Fig. 3).

Algorithm for adjusting the heating system using the proportional method:

1. Define circulation rings.

2. Select the main circulation ring.

3. Open the valve of the main circulation ring (while slightly closing the remaining valves of the circuit). If you are not sure which circulation ring is the main one, we leave it open.

4. We determine the existing proportion between risers or the proportion between actual and design costs in risers (circuits).

5. We find the riser or circuit relative to which we will carry out regulation (usually this is the circuit with the smallest ratio G1ph/G1pr).

6. Then, using the method of successive approximations, the flow rate in circuit 2 is set by an adjustable valve G1ph/G1pr = n = G2ph/G2pr, etc.

7. At the final stage, we adjust the main valve, setting the ratio Gph/Gpr = 1 on it, and according to the law of proportionality in the remaining circuits of the system, the ratio G1ph/G1pr = G2ph/G2pr = 1 will also be established.

This control method is used in large branched systems.

Pros: it is possible to configure complex branched systems; possibility of quick adjustments when regulating by design method in case of changes in installed systems relative to the design. Disadvantages: the presence of a large number of balancing valves and, as a result, increased pressure losses in the system; multiple measurements of coolant flow rates in circuits; the need for measuring instruments and time.

Recalculation for heating when setting up a heating system

The purpose of individual tests is to prepare for complex testing in the presence of a working commission.

Complex tests represent actions carried out after the acceptance of mechanisms by the working commission, and the complex testing itself. At the same time, the interconnected joint operation of all installed equipment is checked at idle, then under load, after which the technological mode envisaged by the project is reached.

Although this is not prescribed by law, in recent years the customer has increasingly required that a commissioning program be drawn up for testing work. This gives confidence that not a single nuance will be missed, and the operation of all systems will comply with approved standards and design documentation.

Why is crimping needed?

After completing the installation of the heating system, pressure testing is a mandatory stage of commissioning. By increasing the pressure inside the heating system, you can notice weaknesses and shortcomings even before starting, you can find sources of leaks that allow elements to pass through. The fact is that when the heating system operates, the water inside it heats up and expands, increasing the pressure, which means that there may be a breakthrough in weak spots. It is safer to identify such deficiencies at an early stage. To avoid major damage.

The same applies to the heating season. Over six months of inactivity, the elements of the system may weaken, and without checking and adjustment, an emergency may occur during the supply of hot water.

Methods for adjusting the heating system

It often happens that errors made during the installation of a heating system can only be detected after the equipment is put into operation. Among the reasons for failures in the heating supply of a house is incorrect determination of the required amount of coolant. When there is little liquid in the system, the room will be cold, and if there is a lot, the air overheats and does not pass to other rooms.

To adjust the operation, adjustment of the heating structure is required. If this is not done, then the service life of the equipment will be significantly reduced.

Adjustment of the heating system is carried out using one of two methods:

- in a qualitative way - by changing the temperature of the coolant;

- quantitative method - it changes the volume of liquid.

Qualitative adjustment is carried out at the heat source, and quantitative adjustment is carried out directly on the heating structure. Before starting to carry it out, determine the volume of liquid consumed and the temperature of the coolant, using special devices for this - a water meter and a flow meter.

When there are no such devices, then the actual flow rates are compared with the calculated data. Most often, two-pipe heating systems are installed, which can provide warmth and comfort in the house. You will also need shut-off and control valves for heating.

Methods for self-balancing water heating in a private house

Law of Hydraulics: Any flowing fluid chooses the path of least resistance. In the heating network of a private house, the rule works like this: the coolant pushed by the pump tends to pass through the first radiator or the shortest circuit of heated floors. As a result, remote rooms of the building warm up much less well. To ensure uniform distribution of flows, hydraulic balancing of the heating system is necessary. We'll tell you how to adjust radiators and underfloor heating hinges with your own hands.

When to balance the system

Theoretically, adjustment of heating radiators is necessary in any case. The design engineer, when developing and calculating the water system, sets the coolant flow rate for each battery and underfloor heating circuit. After installation, filling and pressure testing of the pipeline network, the contractor is obliged to adjust the heat supply, focusing on the design parameters in the project.

Important point. Calculation of the heat demand and the corresponding consumption of heated water is done for the most unfavorable conditions - the minimum street temperature. Therefore, at the beginning of the settings, all radiator and other control valves are fully opened, and the boiler is brought to maximum operating mode.

Since the average homeowner only cares about warmth and comfort inside the home, it is recommended to take on the balancing yourself in the following cases:

- The radiators closest to the boiler heat up noticeably more than the radiators further away, respectively, the rooms are hot or cool (the temperature difference is too large).

- One of the radiators makes a distinct noise - the murmur of flowing water.

- Pipes embedded in the screed heat the floors unevenly.

- In the process of setting up a new heating circuit, assembled with your own hands.

Note. It is assumed that the fittings, equipment and heating devices are selected correctly, the system is filled with coolant, there are no air pockets or other defects. Otherwise, it is pointless to engage in hydraulic balancing - you will get zero results.

When you should not regulate the distribution of coolant to batteries:

- If the radiator network and heated floors work flawlessly. It’s not worth turning the valves over and over again - due to inexperience, you can make things worse.

- When various problems are detected - air in the batteries, leakage, clogged radiator or balancing valves, rupture of the expansion tank membrane, etc. First, fix the problem and check the heating is working properly. No adjustment may be needed.

- It is strictly not recommended to interfere with the operation of the central heating of an apartment building, or to install additional taps and valves into common risers. The exception is multi-storey new buildings with individual thermal inputs to each apartment.

What types of heating systems are there for an apartment building?

Depending on the installation of the heat generator or the location of the boiler room:

- An autonomous system in an apartment where the heating boiler is installed in a separate room or in the kitchen. The costs of purchasing a boiler, radiators and corresponding materials for piping are returned quickly, since such an autonomous system can be adjusted based on your own considerations regarding the temperature regime in the house. In addition, an individual pipeline does not lose heat, but on the contrary, it helps to heat the premises, since it is laid throughout the apartment or house. An individual boiler does not need to be adapted for the reconstruction of central heating - once drawn up and implemented, the heating scheme will work for a lifetime. And finally, the already working circuit can be supplemented with parallel or sequentially connected circuits, for example, a “warm floor”;

- An individual heating option that is designed to serve an entire apartment building or an entire residential complex is a mini-boiler room. Examples include old boiler houses serving a neighborhood, or new complexes for one or more houses using different energy sources - from gas and electricity to solar panels and thermal springs;

A centralized heating scheme in a multi-storey building is still the most common working solution to the problem.

Heating schemes depending on the parameters of the working fluid:

- Heating using ordinary water, in the pipes of which the coolant does not heat above 65-70 0 C. This is a development from the field of low-potential systems, but most often old schemes work with the temperature of the working fluid reaching 80-105 0 C;

- Steam heating, where not hot water moves through the pipes, but steam under pressure. Such systems are becoming a thing of the past, and today they are practically not used in the delivery of heat and heating of any type of apartment buildings.

Based on the piping diagram:

- The most common is a single-pipe heating system for a multi-story building, where both supply and return pipes are one thread of the heating main. Such a scheme can still be found in “Khrushchev” and “Stalin” buildings, but in practice it has a big drawback: batteries or radiators connected in series to the circuit do not ensure uniform heat transfer - each subsequent heating device will be a little colder, and the last radiator will be a little colder. the pipeline will be the coldest. For at least approximately equal distribution of heat throughout the rooms, each subsequent radiator in the circuit must be equipped with a larger number of sections. In addition, in a single-pipe heating scheme in a five-story building, you cannot use radiators that do not meet the design parameters, and devices for regulating heat transfer - valves, etc. regulation;

- The Leningradka scheme is a more advanced solution, but according to the same single-pipe scheme. This scheme has a bypass (pipe jumper), which can connect or disconnect additional heating devices, thereby regulating the heat transfer in the room;

A more advanced two-pipe heating system in an apartment building began its existence with the construction of buildings according to the so-called “Brezhnevka” project - a panel house. The supply and return in such a scheme operate separately, so the temperature of the working fluid at the inlets and outlets of the apartments of a 9-story building is always the same, as in radiators or batteries. Another plus is the possibility of installing an automatic or manual control valve on each heating device; The radial (collector) scheme is the latest development for atypical housing. All heating devices are connected in parallel, and taking into account the fact that this is a closed OO system in an apartment building, the piping can be made hidden. When implementing a beam scheme, all control devices can limit or increase the heat supply in dosed quantities.

Balancing heating and heat supply of apartment and high-rise buildings in Perm

Services for hydraulic balancing of risers, central heating systems in apartment buildings, homeowners' associations in Perm and the Perm region.

Subsidies for overhaul of the heating system! The state provides subsidies of up to 80% for the reconstruction of heating and hot water supply. Find out more about reimbursement from our staff.

Comprehensive solution to issues in housing and communal services

Balancing heating system risers - hydraulic adjustment of pressure drop and control valves in order to ensure uniform heat distribution across heating devices.

If your apartment is cold, but your neighbor’s is hot, then the heating system in your home is not balanced. Insufficient coolant circulation through the batteries leads to a decrease in the temperature in the room, and too much water flow leads to excessive overheating and noise in the radiators.

Signs of an unbalanced heating system in a multi-storey building:

- The temperature in one part of the apartment building is too high, and in the other part it is too low.

- Apartments with high temperatures release excess heat onto the street.

- Apartments with low temperatures - turn on electric heaters.

- It's cold in the house

- Cold batteries

- Poor circulation in the heating system

- Stuffiness in the room

- Overpayment for heating

PNR heat supply

According to the importance of the procedure, the heat supply installation can be compared with the installation of equipment or design. At the moment of launch, all its components are monitored, as well as the readiness of the equipment, its effectiveness and productivity

Pressure testing as a fundamental stage in preparing a heating system

When the main phases of the installation process are completed, it is necessary to do commissioning work - check the efficiency of the heating, its serviceability, and also bring the equipment to operating parameters. Pressure testing is considered one of the initial stages of the heat supply system. This procedure ensures comfortable living in the room, in which the heating system functions correctly.

Crimping consists of the following sequential actions:

- Checking communications using extra pressure;

- Pump testing;

- Checking the reliability of pipelines is a fundamental stage of heat supply installations, which is considered mandatory;

- Monitoring the tightness of pipe coils;

- Hydraulic checks.

Pressurized communications are left under pressure for a day

It is necessary to pay attention that during a temperature change, the load in them will decrease slightly - you should not be afraid of this. This is a traditional physical process when, when a substance cools, it contracts

Even a person who does not have much knowledge in this area can handle the heating supply system - the procedure is simple and does not require specific abilities.

Test run for commissioning heating systems

The heating system is tested before the heating period begins. Before filling the pipes with water, they must be washed. The process removes very small particles of metal and polymer materials that become stuck during pipe processing.

The flow of liquid during heating supply is done according to the schedule for the start of heating work. The test is performed at a temperature of 60-70 degrees, depending on the period of the year: frozen pipes must be warmed up in advance.

The duration of the test is 7 hours, and the equipment test should show good results. All equipment must withstand the test load: this means that the pipes are ready for continuous operation.

Having launched test testing, the basement floors of the building are monitored. This is where problems may arise due to differences in pressure levels. To release air during heat supply, special opening devices are used, by means of which the remaining substances that appear are removed.

The final step is to check the boiler and adjust it, after which we proceed to use the heating completely.

Tools and devices for balancing

To independently adjust the heating radiators and heated floors of a private house, you will need a minimum of equipment:

- electronic contact thermometer;

- screwdriver;

- a thumb or wrench for rotating the balancing valve stem (a hexagon is usually used);

- sheet of paper, pencil.

Reference. Professional plumbers often use a thermal imager, which gives a clear picture of the heating of all heating devices. The device is expensive, so we’ll make do with simpler means.

To measure temperature, it is better to use a contact-type electronic device.

Instead of the indicated thermometer, it is allowed to use a remote (non-contact) pyrometer. Please note: the device measures the temperature of shiny surfaces with a small error. This note applies to radiators with new paintwork.

If you do not have a wiring diagram for a residential building, you should sketch it on paper before starting work. The sketch will help you understand the order in which the batteries are connected to the mains and the distance from the furnace room. Also, flush the mud trap at the entrance to the boiler and heat the system to a temperature of 70-80 ° C, regardless of the street weather.

A great help in setting up is the modern Grundfos Alpha 3 circulation pump, which accurately shows the depth of adjustment via a mobile application. The downside is the decent price of the unit (starts at 240 USD).

Commissioning of electrical equipment

Commissioning work that accompanies electrical installation work is a set of works that includes checking, adjusting and testing electrical equipment in order to ensure the electrical parameters and modes specified by the project. Qualified commissioning work carried out by electrical installation employees will not only be able to identify possible violations during electrical installation work and shortcomings in the operation of the equipment before it begins operation, but will also ensure its guaranteed operation for quite a long time.

What are the differences between different types of heating systems?

In one-pipe and two-pipe systems, each radiator is connected to two pipes. In a two-pipe system, the waste coolant is directly supplied to the boiler for heating. In a single-pipe system, the incoming pipe is connected to the outgoing pipe right next to the battery. As a result, warm and cold water is mixed.

Balancing valve for heating system Source iobogrev.ru

When using a collector connection, the pipes from each battery are connected separately to a common stand. Sometimes built-in measuring instruments are used to determine the supplied volume of coolant. This device is also used in cases where water heated floors are used.

The efficiency of operation depends on the material from which the radiators are made. If it is made using aluminum, steel or copper, it will quickly heat up and lose body. Cast iron batteries slowly gain temperature and retain it longer. If the owner plans to install a new model, then this must be done before the start of the heating season.

Heating of a private house Source innstroy.ru

In an apartment building, the possibilities for hydraulic balancing of the heating system are very limited. If vertical water supply is used in separate risers, then adjustment becomes impossible. In a private house the situation is completely different. Not only adjustments are available here, but also redevelopment of the heating system.

The need for heating

The need to heat your own home has always existed, but the ways to achieve this goal were very different. For hundreds of years, classic Russian stoves were used in Russia, and a little later fireplaces appeared. Traditional heating structures have been replaced by modern devices and heat supply systems, which are superior in quality and efficiency to their predecessors.

Currently, the heating system is a structure that usually consists of the following main elements:

- heating boiler;

- pipeline;

- heating appliances.

There is a coolant inside the heating system. In most cases, water is used to heat private households, since in case of leakage it does not pose a danger to people and the environment from an environmental point of view. Of all types of liquid coolants, it is water that accumulates heat best and, when cooled, releases it.

In addition, it flows well and moves almost instantly within the elements of the system. Water is always available in the water pipes and can be added to the heating structure at any time.

The functioning of the system consists of moving hot coolant through it using a circulation pump. The water is first heated in the boiler and then distributed through pipes from which it flows into the radiators.

Testing and warming up the heating system

Thermal testing of the heating system is carried out to check the heating of existing heating devices. Before filling the system with water, it must be flushed. Often, after processing, metal particles remain in the equipment, and substances that are used in the preservation of polymers remain inside the pipes. They can seriously damage heating equipment. In such cases, the manufacturer's warranty will not apply.

At positive ambient temperatures, the thermal test of the heating system is carried out at a water temperature in the supply pipelines of more than 60 °C. Single-pipe systems are best tested at a water temperature of about 70 °C, and double-pipe systems at 65 °C.

If the thermal test is carried out in the cold season, then it is necessary to ensure the calculated coolant flow in the heating system, as well as compliance of the initial hot water temperature with the required value of the heating schedule.

The duration of the thermal test is about 7 hours. It is considered that the water heating system has passed the test in winter if all heating devices warm up to the required degree, the coolant temperatures in the collection and distribution lines correspond to the calculated indicators of the quality control schedule, and the air temperature in the room is as close as possible to the calculated values. The air temperature inside heated rooms is measured at a height of 1.5 m from the floor and at a distance of 1 m from the outer wall. The deviation of the temperature value from the calculated values should not exceed -1...+2 °C for residential buildings. If these indicators do not correspond to the heating system, installation adjustments are made.

After starting the heating system, you must carefully inspect it. Particular attention should be paid to the lower floors of the building, since here the hydrostatic water pressure reaches its highest level. After the inspection, you need to check again that there is no air in the system by opening the air outlets. In the future, this process must be performed every 2-3 hours until the air is completely removed from the system.

It is possible to restore the functioning of the heating system after freezing if the radiators, pipes, taps and fittings are not damaged. If there is damage, it is necessary to replace the failed elements and at least partially restore the integrity of the circuit. The easiest way to restore a heating system is to connect devices in parallel, since here each device creates its own heating circuit. When the operation of one of the circuits is restored, it is possible to obtain coolant circulation, which involves the radiator, riser pipe, expansion tank, boiler, parts of the direct pipe and return pipe. By maintaining the functioning of the heating circuit, the system can be warmed up in parts and its operation can be completely restored.

If the system is built on a series connection of radiators, it is a single circulation circuit. In this case, the entire system will have to be heated.

Before restoring the operation of the heating system, it is necessary to warm the house with other available means, be it a stove, oil radiators, heat guns, convectors, etc. Otherwise, when one part of the system is heated, the other will freeze. If this is not possible, then you will have to disassemble the circuit by fittings and heat the system in parts.

We recommend: Deflector for the chimney of a gas boiler - installation requirements and installation rules

As you know, a blowtorch is used to heat metal pipes, and a household or industrial hair dryer is used for plastic pipes. In hard-to-reach and inaccessible places, and for different types of pipes, it is recommended to use hot water.

There is no need to heat the pipes with electricity. Ice is a dielectric and cannot conduct electricity. Therefore, you will have to use traditional methods. The best option is to prevent such situations from occurring.

How to adjust the temperature

The temperature difference between the coolant inside the supply and return risers should be 15-20 degrees.

This indicator can be adjusted using special equipment - mixers, taps and servos. Mixers are a tap with two or three working positions. The inlet riser pipe is connected to one of the inputs, and the outlet pipe is connected to the second. The third is used to regulate the temperature in a separate section of the highway. Mixing units are equipped with a temperature sensor and a control unit. The sensor sends a signal about the temperature of the water inside the riser, and the control unit regulates the valve, thereby regulating the two-pipe heating system. You can adjust the heating of water in radiators with your own hands using taps. But servo drives will eliminate the need to do this, since with their help the heating of the risers will be adjusted automatically. The design of the servo drive includes a thermostat on which the desired temperature value is set. After this, the servo drive will begin to measure the incoming coolant flow and, if necessary, reduce or increase it. Important! It is impossible to regulate the pressure using thermostats, since they limit the flow of water only in one section of the system, without affecting its general condition and the heating of the remaining risers

Warm floors and radiant wiring

Since the underfloor heating circuits and radiator radiators are connected to a common comb, balancing is carried out directly on the collector. The setting method depends on the availability of rotameters - transparent flow meter flasks installed on the supply or return lines.

To correctly configure the coolant supply using rotameters, you should calculate the water flow through each loop using the formula:

- G – mass flow rate of heated water flowing through the circuit, kg/h;

- Q – the amount of heat that the circuit or radiator should release into the room, W;

- Δt – temperature difference at the inlet and outlet of the loop, the calculated value is taken to be 10 °C.

The power of one floor circuit Q is determined based on the heat demand of a separate room. The parameter is calculated according to the specific ratio of 100 W/m² of room area or according to the method of calculating the heating load. The flowmeter scales are marked in l/min, which means the result must be divided by 60.

Calculation example. Heating a room with an area of 10 square meters requires 1 kW of heat. Coolant consumption will be 0.86 x 1000 / 10 = 86 kg/h or 86 / 60 ≈ 1.43 l/min.

Clarification. If a large area is divided into 2 identical heating monoliths with separate water loops, we also divide the calculated flow rate in half.

Here the rotameters are installed on the supply line of the comb, but can also be installed on the return line.

Further balancing of the underfloor heating loops is carried out according to the instructions:

- With the system filled and pressurized, turn on the underfloor heating circulation pump. It is not necessary to start the boiler.

- Using the manual adjustment caps, close all thermostatic valves on the second part of the comb.

- Open the first valve completely and adjust the corresponding rotameter. The required flow volume is set by rotating the lower ring of the flow meter.

- After adjustment, close the valve again and move on to the next circuit. At the end, open all the regulators and check the water flow again using the rotameters.

Reference. On manifolds from different manufacturers, flow meters are installed on the supply or return manifold (they also differ in design). To adjust the maximum flow, the location of the rotameters does not matter.

Beam batteries are balanced in a similar way. To be sure, you can combine 2 options - according to the calculated flow rate and the temperature of the radiator surface (the method is described in the previous section).

Scheme of flow control with a rotameter. The flow rate through each circuit is shown by control washers in transparent flasks, the unit of measurement is liters per minute

If, in order to save money, you managed to buy a collector without rotameters, the setup will take several days. The goal is to achieve the same temperature in the return pipelines of all loops. That is, the initial installation is made approximately according to the power and length of the circuit, then the return temperature is measured and the flow rate is adjusted.

To check the balancing of the heated floor, you need to start the heating boiler. Negative point: after adjusting the flow rate, you will have to wait several hours until the thickness of the concrete warms up and the temperature of the return lines stabilizes.

Adjustment methods

The balancing procedure involves adjusting the shut-off valves. This is done in two ways:

- Adjustment of each valve and temperature measurements after each adjustment of their position;

- Dividing the system into modules and adjusting them separately. In this case, each area of the room receives its share of the total heat emitted by the system.

Before balancing, the heating system is diagnosed by opening all shut-off valves and test running; In this way, it will be determined in which part of the circuit the imbalance occurred.

- Coolant flow and pressure regulators;

- Balancing and bypass valves.

The necessary adjustment components are installed based on the type and complexity of the system. So, with a single-pipe circuit, ordinary taps will suffice. Balancing the heating system in this case is carried out by simply tightening them until the desired temperature is reached. Two-pipe circuits require balancing valves. They, firstly, provide more precise adjustment, and secondly, they allow you to connect a special device to measure the characteristics of the coolant supply - pressure, flow and temperature.

Temperature adjustment method

The temperature adjustment method is similar to the trial and error method, they can even be called analogues. However, there are a number of “buts”. This method is based on the law of conservation of energy and on instrumental measurements of the temperature of the coolant at the inlet and outlet of the heating device. The method is based on the law of conservation of energy, the equation for determining the amount of heat:

When heat Q is transferred from the coolant through a heating device to the room, the temperature of the coolant t2 decreases. We change the flow rate G - heat transfer is regulated.

This method is used in fairly simple systems where balancing valves without fittings are used.

Pros: accessibility. This method can be used in situations where other methods are not available. This method is used when the master is limited in resources (instruments, modern balancing and automatic valves, “intelligence”, etc.).

Disadvantages: this method is inaccurate, especially in situations where the coolant temperature difference is insignificant. That is, the accuracy of the method increases with increasing outdoor temperature. An overestimated area of heating devices also leads to incorrect results.

We set up the heating system of a country house ourselves

In my previous article, I wrote that one of the effective ways to modernize heating systems in private buildings is to switch from an open heating system to a closed one. The heating system of a residential building improved in this way has many advantages, which together ensure its simple operation; you just need to turn on the boiler at the beginning of the heating season and turn it off at the end. All!

However, in order for the heating system of a country house to work in this mode (turned on, “forgot” for six months, turned off), you need to correctly configure and adjust its operating parameters. This is what my article will discuss. I will make the main calculations, conclusions and calculations using the example of my heating system, but the reader can always use this information by drawing an analogy with his own specific case.

When is a heating system pressure tested?

Pressure testing is carried out in the following cases:

- preparation for the heating season;

- replacement or repair of shut-off valves, pipelines and other system elements operating under pressure;

- commissioning of the heating system after installation work.

Depending on when the heating system is pressure tested, air or water is used. If the installation is carried out in winter, then a compressor is connected to the system, pumping air, and the pressure is measured using a pressure gauge. It is recommended to apply pressure 2-3 times higher than the working one. For example, at an operating pressure of 2 atm. you need to pump 5 atm into the system. air.

We recommend: Cooling towers of open and closed types: their design, operating modes, photos

In this case, you can connect to the tap that is used to drain the heating system, or to the radiator, after first unscrewing the Mayevsky tap and putting in its place an adapter for connecting the hose from the compressor. At the next stage, all leaks are eliminated. To do this, you need to look at detachable or soldered connections if the system is made of propylene pipes. When pressure testing the heating system of a private house is done with air, all connections must be treated with a soap solution. If it is water, the leaks will be clearly visible.

Pnr heating system

PRP of the company you have chosen;

- whether they have relevant experience;

- terms of service and warranty.

In this case, the following requirements must be met:

- Activities related to the commissioning of engineering systems (including commissioning and commissioning of air conditioning systems) must be carried out within the time limits established by the regulations.

- The equipment is put into operation under strict control by specialists from the contractor company.

- Upon completion of the entire complex of commissioning works, you must receive a documented guarantee of their high-quality implementation.

- The guarantee for them is provided from the moment of final commissioning of the facility.

Commissioning tests mean work performed on already installed (assembled) equipment, ready for launch and commissioning.

Attention

Home » Heating » Commissioning of heating systems Program for carrying out commissioning During the implementation of many projects, capital construction or reconstruction of buildings and structures is carried out with the installation of new equipment or specialized processes. Such work includes the installation of fire extinguishing systems, electrical supply, air conditioning, ventilation, fire alarm systems

Commissioning of Engineering Systems

Any work on the scale of industrial enterprises involves the installation of a complex network of engineering systems that require such a mandatory procedure as preparation for start-up and operational commissioning. Today, in the market for the necessary services, there are many companies ready to carry out commissioning work (including commissioning work on a residential building) at prices agreed with the customer.

When selecting a specific performer, great attention should be paid to the following main nuances:

- the level of professionalism of the employees and commissioning engineers of the company you have chosen;

- whether they have relevant experience;

- terms of service under warranty and guarantee.

In this case, first of all, the following requirements are met:

- Activities related to the commissioning of engineering systems (including commissioning and commissioning of air conditioning systems) must be carried out within the time limits established by the standards.

- The commissioning of equipment is carried out under constant supervision by the professionals of the contractor company.

- Upon completion of the entire complex of commissioning works, you are required to receive a documented guarantee of their good completion.

- The guarantee for them is given from the moment of final commissioning of the facility.

Commissioning tests mean work carried out on already installed (assembled) equipment, ready for start-up and operational commissioning. In some cases, they are considered as part of the construction work, after which they move on to the stage of very fine and detailed configuration of certain systems (commissioning of equipment that runs on gas, for example).

According to the provisions of the current standards, standard commissioning work includes two components:

- pre-launch or individual checks;

- full (system) testing.

Scope of work using ventilation as an example

Pre-startup or, in other words, individual checks as part of the commissioning and commissioning of ventilation, for example, require the following mandatory operations:

- preparatory testing of assembled ventilation systems;

- checking their technical condition;

- sampling and testing of individual components of equipment over the time period established in the manufacturer’s instructions.

Please note: In the case where the duration of the check is not indicated in the accompanying documentation, the checks are carried out in idle mode for one hour of continuous operation.

Upon completion of individual tests, they proceed to a comprehensive check of the equipment’s performance, carried out over a period of 72 hours.

In the process of such testing, the joint functioning of all components of the equipment is examined specifically “under load”. At the same time, the ventilation system is tested for the absence of very different types of breakdowns that are associated with a violation of its tightness.

At the end of this stage of commissioning and commissioning work, first of all, drawing up and submitting a certificate of acceptance of equipment into operation, signed by two interested parties.

When constructing large industrial facilities, professionals from a variety of contractor organizations are generally invited to perform installation, commissioning and commissioning work.

Additional information: At small construction sites with a relatively small volume of engineering equipment, installation and startup operations are often carried out by representatives of the same company. An example of such work would be the commissioning and commissioning of cleaning facilities carried out on a suburban private farm or at any other non-industrial facility.

Standard commissioning tests, in addition to ventilation systems that are mandatory for many enterprises of the PNR industry, include a control check of the operability of the following utility networks:

- provision of water and electrical supply (as a particular case - lighting in Poland);

- fire alarm and air conditioning;

- gas supply and heating networks;

- sewerage treatment facilities, etc.

In addition, one should not lose sight of such a mandatory component of test work as commissioning of alarm systems with security elements.

The entire test procedure (program)

Upon completion of the installation process of utility networks, a general commissioning and performance check of the assembled installations is carried out according to a schedule drawn up in advance and agreed with the customer. Let's consider the procedure for carrying out these works for the case of implementing a water supply program, for example.

First, the professionals of the contracting company simultaneously turn on all the installed installations, after which they monitor their operation. During the observation process, the following points are monitored:

- First of all, the compliance of the performance indicators of water supply systems with the planned design indicators is determined.

- In the event that the indicators do not coincide with the design data, a thorough analysis of the discrepancy that has arisen is carried out and its causes are determined.

- After their detection, they begin to eliminate all observed violations in the water supply.

Please note: In addition to checking the operability of the networks themselves, first of all, the control devices that serve them, protection and automation devices, etc. are tested.

v At the last step of the tests, the level of operating pressure of the carrier is measured at control points of the water main.

Likewise, properly organized and well-conducted commissioning work can help you identify all the inherent shortcomings and remove them in a timely manner. In the following sections we will consider certain types of very important commissioning activities.

Specifics of startup and adjustment of refrigeration systems

As part of the commissioning and commissioning of refrigeration supply, the following test options are carried out:

- checking the correct assembly of all components and parts of refrigeration equipment;

- filling the cooling system with all the necessary working media (freon, nitrogen and oil);

- checking the functioning of protection and control equipment;

- starting the system and bringing it to the required operating mode;

- briefing (and, if necessary, training) of personnel.

Main! The last point can be included in the commissioning program only by agreement with the customer

The procedure for commissioning heating systems and heating

The term “heating” in most cases is associated with the organization that supplies the heat carrier, while the concept of “heat supply” is associated with its consumption and is applicable to organizations involved in the operation of heated premises.

Accordingly, with this division, the specifics of commissioning and commissioning of heating systems and heating should be considered, which must be carried out with the necessary compliance with the following requirements:

- at the beginning of the control and start-up tests, both at the thermal substation and on the consumer side, work on the installation process and testing of power supply systems must be completed, and the commissioning of the fire alarm must be completed;

- it is mandatory to check to what extent the operating capabilities of the entire complex of equipment involved in the heat carrier supply and exchange lines comply with the design requirements;

- in addition, commissioning of heating systems involves a forced study of the tightness of network sections hidden behind individual structures (for this, the contractor must have a specialized tool base);

- At the last stage of testing, heat supply and heating lines are tested to ensure they work together with additional equipment (drives, dampers, valves, etc.).

During the commissioning process, all permissible deviations in the operation of networks must be identified, and only after their timely elimination can the heating network and heat supply be accepted by the customer.

Similar products:

Responsibilities of the customer

Implementation of general, operational and technical management of the quality of construction, installation, adjustment and testing of equipment; carrying out pre-start and start-up operations on equipment, components and units; work of acceptance committees; elimination of equipment defects, construction and installation.

Ensuring the organization and conduct of pre-installation inspection of equipment and equipment.

Providing commissioning work at all stages:

— financing of work;

— qualified operating personnel (starting with unit testing);

— working tools and materials in the required quantities;

- standard instruments, design and factory technical documentation.

Ensuring the safety of equipment and installations, experimental control systems, as well as documentation, equipment and apparatus of organizations involved in commissioning work at the power unit and a regime that excludes access by unauthorized persons.

Providing personnel of commissioning and research organizations with office and laboratory premises, housing and other household services.

Development, together with the general contractor, of measures to ensure safe working conditions, and the adoption of general measures for industrial safety and fire safety at the power unit.

Price list for one-time work

| Type of work | price, rub. | price, rub. |

| Departure of a specialist to carry out repair and diagnostic work (including 1 hour of work and transportation costs) under a service agreement | 3 000 | 3 500 |

| Departure of a specialist to carry out repair and diagnostic work (including 1 hour of work and transportation costs) without a service agreement | 5 000 | 5 500 |

| 1 standard hour of repair and diagnostic work under the contract (starting from the 2nd hour) | 1 500 | 1 500 |

| 1 standard hour of repair and diagnostic work without a contract (starting from the 2nd hour) | 2 000 | 2 000 |

| Cost of automation installation work | ||

| Installation and configuration of the heating controller | 5 000 | 5 000 |

| Installation and configuration of the Vexve controller | 1 000 | 1 000 |

| Installation and configuration of the KromSchroeder controller | 4 000 | 4 000 |

| Temperature sensor connection | 500 | 500 |

| Pump connection | 500 | 500 |

| Connecting and setting up a 3-way valve servomotor | 1 500 | 1 500 |

| Connecting an outdoor temperature sensor | 3 000 | 3 000 |

| Connecting a room thermostat | 3 000 | 3 000 |

| Connecting a room radio thermostat | 500 | 500 |

| Installation of an electrical panel (up to 10 power supply units) | 3 000 | 3 000 |

| Installation of an electrical panel (up to 20 power supply units) | 5 000 | 5 000 |

| Installation is carried out in plastic boxes or in a flexible corrugated pipe. | ||

Duration of commissioning work when starting heating in mkd

Important

Flushing of heat consumption systems is carried out annually after the end of the heating period, as well as installation, major repairs, routine repairs with replacement of pipes (in open systems, the systems must also be disinfected before commissioning). The systems are washed with water in quantities exceeding the calculated coolant flow rate by 3-5 times, and complete clarification of the water must be achieved

When carrying out hydropneumatic flushing, the flow rate of the air mixture should not exceed 3-5 times the calculated coolant flow rate. Tap or process water is used for washing.

Connecting systems that have not been flushed, and in open systems, flushed and disinfected, is not allowed. Diaphragms and nozzles of hydraulic elevators must be removed when flushing the heating system.

After flushing, the system must be immediately filled with coolant.

Design (calculation) method

The valve presetting method is based on adjustment based on the results of hydraulic calculations when designing heating systems.

Actually, it is primarily carried out during the design process. In this case, the designer coordinates the circulation rings during the calculation of throughput and adjustment of control valves.

Advantages: the installer just needs to set the required setting, check the coolant flow and, if necessary, adjust these settings.

Disadvantages: changes made during the installation of heating systems are not taken into account, and there may be plenty of them. Installation is an insidious thing, and very often the “views” of the designer and the installer differ for a number of objective and biased reasons.

Commissioning of heating systems

Before putting the heating system into operation, you need to do a number of preparatory works, carry out checks and establish the mutual action of a variety of units with each other. All this is included in the commissioning of the heating system, the purpose of which is to detect and remove disadvantages and errors made during installation work, as well as to bring the entire system in accordance with the standards established for it. As a result of these works, the customer receives a good, productive and effective system. The cost of work on setting up and starting up the heat supply is fully reimbursed by the subsequent trouble-free operation and safety of the equipment.

Scope of commissioning and commissioning work

- Commissioning work is done after installation work has been completed. These include:

- Connecting the boiler to the gas main (if a gas boiler is used);

- Setting up security systems;

- Installing an electrical voltage stabilizer and connecting the boiler to it;

- Coordination of the operation of the boiler and indirect (if used);

- Connection of thermal converters and their adjustment;

- Testing and pressure testing of heating systems;

- Filling the system with coolant;

- Bleeding air from the system and balancing it;

- putting the system into operation;

Upon completion, a report on the commissioning work of the heating system is drawn up, which lists the scope of work performed and draws conclusions regarding subsequent operation and improvement of the operation of the equipment.

The essence of the system check processes and its start-up

As you can see, commissioning work consists of a huge number of operations, the most important of which are related to testing the heating system. Let's take a closer look at one of the main stages of commissioning - pressure testing of the system. It should be performed to detect all suspected areas of leakage. The essence of the procedure is to pump water or air into the system under pressure a couple of times higher than the working pressure. During crimping, all connections must be checked very carefully. If air is used during testing, the pipe connections must be coated with a soap-based solution.

Another stage of verification is thermal testing of the system. Its goal is to warm up all radiators with water at a temperature of 60-70 0C for 7 hours. At the same time, monitoring is carried out to monitor the degree of heating of the radiators, the temperature of the coolant at the outlet and inlet to the boiler, and the air temperature. If all indicators are as close as possible to the design ones, the system has successfully passed thermal testing. If not, then further adjustment is made. Before filling the system with water for testing, it should be flushed to remove equipment preservatives and other debris from the pipes.

To start the system, you need to fill it with a coolant, bleed the air and put the boiler into operation. To fill the system with coolant, the make-up tap is opened, the location of which can be found in the documentation for the boiler room equipment. When the system pressure can reach the required value, the valve is closed and the boiler is started for the first time. After turning on the circulation pump, you should bleed the air from it by slightly unscrewing the screw in the very center. When water flows from under the screw, it must be turned all the way. Then the electronics will put all boiler systems into operation, and for some time air will be removed from the system, which will be indicated by gurgling sounds. When the system is working properly, you need to check the pressure, and if necessary, bring it up to normal by replenishing the amount of coolant.

After the first start-up of the heat supply, you can adjust the system using taps for adjusting heating devices. It is necessary to ensure that the energy of the coolant is sufficient to warm up the last heating device in the chain. Such adjustment may take a couple of days and is carried out during operation. There is no need to worry about this, because in general the system is already debugged and does not stop working in normal mode.

Pressure testing of the heating system of a private house

Reliable operation of the heating system in a country house ensures comfortable living conditions. To improve the quality of work, crimping is used.

Pressure testing of a heating system is a test of communications and heating equipment using excess pressure. During the tests, the reliability and tightness of pumps, heat exchangers, radiators, pipelines, etc. are checked. Pressure testing should be carried out for preventive purposes, for example, before the heating season. A mandatory stage of commissioning work is hydraulic testing. They are also carried out after repair, installation and emergency restoration work before putting heating systems into operation.

After pressure testing, the system must be left under pressure for a day. It should be noted that during the day, due to temperature changes, the pressure in the system will decrease slightly. This is a normal process, since when water or air cools, it contracts. Thus, the crimping process is quite simple, and even a non-specialist can handle it if desired.

Responsibilities of the head commissioning organization

3.2.1. Ensuring that the scope of commissioning work on equipment is completed in accordance with the agreed distribution of volumes between the involved commissioning organizations.

3.2.2. In addition to performing your scope of commissioning work:

— distribution of volumes of adjustment work (when drawing up a coordination plan);

— coordination of the actions of all participants in commissioning work: development of engineering support for commissioning work, participation in the development and coordination of a combined schedule of construction, installation and commissioning work, development or coordination of work and technical programs for commissioning work in accordance with the instructions of Appendix 3, participation in the formation of consolidated commissioning unit teams, including separating a number of unit foremen from its composition;

— monitoring the results of commissioning work by all participants, participation in the work of acceptance committees;

— ensuring round-the-clock duty of leading specialists to provide operational technical assistance during the period of startup operations on the equipment;

— submitting for consideration by the launch headquarters questions and proposals regarding the organization and progress of construction, installation and commissioning work;

— generalization, together with co-executing organizations, of the results of commissioning work and, on their basis, prompt issuance to the customer, design organizations and manufacturing plants (in a copy - to the relevant departments) of proposals for improving technology, circuits, modes and designs of equipment and monitoring their implementation;

— summarizing operating experience of similar equipment and issuing proposals for implementation to the customer;

— development, together with the customer, of instructional and technical documentation.

The main commissioning organization, together with the customer, bears the main responsibility for the timing and quality of commissioning and commissioning of equipment.

3.2.3. The instructions of the head commissioning organization regarding the technology and timing of commissioning work are mandatory for all organizations involved in the supply of equipment.

3.2.4. The main form of activity of the head commissioning organization is the conclusion of a single contract agreement for the implementation of the entire complex of commissioning works with the involvement of other commissioning organizations on a subcontract basis.

3.2.5. Additional performance by the commissioning organization of the “head” functions is paid in accordance with the “Regulations on the relationship of general contractor organizations with subcontractors”, approved by the Decree of the USSR State Construction Committee and the USSR State Planning Committee dated 07/03/87, No. 132/109 and an agreement with the customer.

3.2.6. In the absence of a head commissioning organization, its functions in terms of distribution, control and coordination of work are performed by the customer or, when the project is delivered on a turnkey basis, by the general contractor.

How the balancing procedure is performed

It is important to note that when carrying out it, it is necessary to take into account what kind of heating system is used - it can be single-pipe, two-pipe, with a collector or using heated floors.

Two-pipe heating system

To balance a two-pipe system, you must perform the following steps:

- When the coolant is well heated, all existing valves must be fully opened.

- At the outlet of the heating boiler, the liquid temperature should be maximum. To do this, a contact thermometer is applied to the pipe that leads from the boiler to the first radiator.

- Next, move on to the nearest radiator. It is necessary to measure the temperature of the coolant at the inlet and outlet. If the equipment is working properly, this difference should not exceed 10 degrees. In the case when the specified requirement is met, it is considered that this radiator does not require adjustment.

- A similar procedure is carried out in relation to each radiator installed in the house. At each step, the obtained data must be recorded.

- It is necessary to compare the temperature at the input valves of the first and last radiators. If it is less than 2 degrees, you need to tighten the input valves of the first two batteries by 0.5 or 1 turn. After this, the measurements must be repeated. The temperature difference is expected to increase slightly.

- If the value under consideration is in the range of 3-7 degrees, the inlet control valves of the first two radiators are tightened by 50%-70%, the next two by 30%-40%, and the rest are left unchanged.

- Before taking the temperature again, you need to wait 20-30 minutes. This is required so that the heating equipment warms up in accordance with the new settings. You need to make sure that the difference does not exceed 2 degrees at the inlet taps of the first and last radiator. If the heating main is of considerable length, the difference is allowed to be 3 degrees.

- These procedures must be repeated, tightening the input valves until the goal is achieved. These steps may need to be repeated several more times.

When hydraulic balancing is performed, it is necessary to control the temperature difference between the inlet and outlet valves. If it is more than 10 degrees. The inlet valve will need to be unscrewed slightly. It must be taken into account that precise adjustment occurs individually for each heating system.

Balancing valve for radiator Source termopaneli59.ru

Single pipe heating system

When adjusting a one-pipe system, they usually try to tighten only the valve on the first radiator. Usually after this it is possible to immediately achieve the desired indicators.

Manifold system

This section discusses balancing a system in which pipes are connected to a single node. Such balancing can also be carried out for heating systems that additionally use heated floors. These methods are also used to regulate the operation of heated floors. In this situation, there are two configuration methods.

Balancing valve for radiator Source termopaneli59.ru