Home » Classification of gas boilers » Operating principles » Features of installing parapet gas boilers

Parapet gas boilers are installed in rooms where it is not possible to install a full-fledged gas unit. They have many advantages: they are compact, do not require the installation of a full chimney, do not depend on power supply, and are environmentally friendly. Parapet units are often installed for heating small cottages, apartments, country houses and even garages. Therefore, the question of how to install a parapet gas boiler is always in demand.

…

- 1 Types of parapet units

- 2 Selecting a location for installing parapet units

- 3 Preparing for installation

- 4 Installation process

- 5 Popular parapet gas boilers

Main types of parapet boilers

Both in an apartment and in a country house, devices can be used, which can be divided into:

- installation location;

- availability of automation;

- power;

- autonomy from electricity;

- method of removing gas combustion products;

- coolant type;

- functionality;

- type of burner;

- price and so on.

At the installation site, devices can be:

- wall-mounted;

- with installation on the floor.

The former are more popular, since their power often does not exceed 30 kilowatts. No, there are also more powerful devices that are hung on the walls, but these are rather mini-boiler rooms that combine several devices using a cascade principle.

Floor-standing equipment is often more powerful and can heat buildings with an area of several square kilometers.

By type of chimney

From this point of view, a parapet gas boiler comes with:

- forced draft;

- natural.

In option No. 1, the coaxial chimneys described above take place, and in the second, traditional ones, made in the form of a pipe and passing through the roof.

Attention! There are often references to turbocharged boilers. These are, in principle, the same wall-mounted parapet models, but the combustion products in them are removed through a coaxial chimney using special fans

If the draft is natural, then the burner in the boiler will be open, and the air will be supplied directly from the room. And if the pipe is coaxial, then it is supplied from the outside. And such boilers are usually used together with parapet devices, which is why the environmental conditions in the room are significantly improved, because the air is not burned, but comes from outside.

Attention! These chimneys can be horizontal or vertical, due to which the possibilities when choosing a place to install a heat generator are significantly expanded.

By functionality

As we have already said, parapet-type devices can have one or two circuits. In the first case, only the home is heated; in the second, it is possible to additionally provide all residents with hot water. They are equipped with flow-through heaters, mainly copper (this metal has the best thermal conductivity). Also, boilers can be connected to the system on the left, on the right, or on both sides at once, making heating wiring much simpler.

Attention! Despite the fact that the devices were originally intended to operate on natural gas, if necessary, you can replace the burner, and they will work very effectively on liquefied gas.

Rating of the best manufacturers

Gas double-circuit parapet boiler, which manufacturer is better, what to focus on. It is necessary to analyze the rating of parapet gas boilers and read reviews.

Imported parapet gas boilers. Among them, it is worth highlighting equipment with cast iron heat exchangers, their advantage is reliability, with a power of 12 to 60 W. They will be able to heat larger houses and apartments. A distinctive feature of this kind of heat exchangers is their resistance to temperature changes and mechanical deformation. Thus, the Electrolux company produces equipment that can withstand critical temperatures above 90 degrees.

It should be noted the high-quality products of such companies: Italian - Fondital, Beretta; Slovak – Alphatherm Beta, Attack; Hungarian - Alphatherm Delta.

Russian parapet gas boilers. Domestic manufacturers often use components from the CIS and EU countries to manufacture equipment. These are cast iron heat exchangers, sensors, controllers. Thus, while maintaining quality characteristics, the final cost is reduced to approximately 15%.

This type of product includes: “Titan N” boilers (Ryazan); Lemax Leader GGU-ch (Taganrog); Siberia KCHGO (ZAO Rostovgazoapparat). These models are distinguished by a wide range of equipment power. Manufacturers offer single-circuit and double-circuit boilers of various types.

It is worth noting the high-quality products of Russian companies Helios, Danko, Conord.

We can conclude that parapet gas boilers are universal equipment for heating a home, which combines high quality indicators (efficiency 93-95%) and optimal prices. They compare favorably with chimney models with an open gas chamber in that they do not require a separate room for a boiler room. At the same time, compared to turbocharged models, it is easier to operate. The advantageous aspect of this type of equipment is its independence from the power supply system. This makes it possible to install the boiler in areas where there is a risk of power outages.

Types of gas heating equipment

Heating boilers vary in size, efficiency volume, degree of heating, power, type of combustion chamber, and methods of removing combustion products.

Boiler with chimney

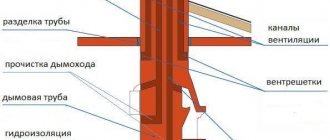

When installing a chimney, the pipe must be brought up in a strictly vertical position. During installation, safety requirements are observed. The height of the chimney depends on the type of boiler design.

Cold air enters the burner from inside the building through the ash pan and rises to the firebox, where combustion is maintained. The strength of the flame and the intensity of combustion are regulated by the width of the door opening.

Such boilers should only be placed inside separate rooms. There are a number of requirements for boiler houses. For example, space standards, the presence of doors, windows, good ventilation equipment.

Turbine system

The turbine device is characterized by a hermetically sealed combustion chamber, which does not draw air out of the room and prevents the risk of gas poisoning.

The turbine itself becomes a forced ventilation system that completely removes combustion products from the chamber.

Air exchange occurs through a coaxial chimney, which is discharged through a hole in the nearest wall. You can install it strictly horizontally or raise it up, but the first option is more effective.

The coaxial design consists of two pipes with a distance between them. Through this layer, fresh air is supplied through the bottom to the firebox, and gases escape through a smaller pipe.

The tip protects the pipe from debris, small animals or birds.

The equipment is ignited by an electric spark, so the boiler must be connected to the mains.

Parapet boiler

The difference between a parapet boiler and a turbine boiler is that air does not enter the apparatus forcibly.

Otherwise, the equipment has many similarities, for example, a closed combustion space, installation of coaxial chimneys.

Components of the strapping

Which components and elements will be included in the set of heating system components depends on the type of heating system:

- Heating with natural (gravitational) circulation of heated water (coolant) - popularly called “physics” heating;

- Forced circulation – with connection of an asynchronous circulation pump;

- Mixed scheme.

Set of strapping elements

In a scheme with natural water circulation, the set of piping elements will be as follows:

- Heating boiler - after it, the heated coolant rushes up and moves through the pipes, returning to the boiler slightly cooled;

- Heating piping pipes - most often for a “gravity” scheme, metal pipes are used that are larger than plastic pipes, with a diameter of up to 2 inches. The diameter is selected based on the need to minimize coolant resistance for its unhindered circulation;

- Expansion tank - installed at the highest point of the system, and can be open or closed in design;

- Heating devices – radiators, radiators or registers;

- Mayevsky tap - installed on the heating radiator to bleed air;

- Fittings - welded or threaded turns, doubles, tees made of cast iron, brass, bronze, copper or stainless steel, tees, drains and other types of connectors;

The advantage of the “physics” system: easy independent installation, simple circuit, common parts and assemblies, low cost of components.

Disadvantages: large size of components, inertness, insufficiently fast heating of wiring and heating devices.

Heating scheme with gravitational water circulation

Selecting a heating system

To determine which gas boiler is better, parapet or chimney, you need to understand the structure and operating principle of the equipment. When choosing equipment, you need to take into account the size of the room, the quality of ventilation, and interruptions in the power supply.

A gas boiler with a chimney is a reliable, inexpensive and efficient technique that heats water in the heating system. A chimney is used to remove exhaust gases from a device with an open combustion chamber. The temperature difference allows the exhaust gas to be discharged through the pipe to the street. Boilers with a closed combustion chamber are equipped with a short and wide exhaust pipe. Equipment with a chimney is suitable for private houses with a good ventilation system.

Parapet boilers are more versatile because they are equipped with a closed combustion chamber and do not require the installation of a pipe that removes exhaust gases. This equipment can be installed both in houses and in city apartments with poor ventilation systems. Only two pipes are mounted on the device, providing clean air supply and exhaust gas outlet. If you choose a model with suitable characteristics, you can heat the entire area of the apartment with just one boiler.

Attention: A parapet gas boiler is an alternative to a wall-mounted device. The floor-mounted unit must also be attached to the wall using special brackets.

Requirements for the chimney

Chimneys for gas boilers are necessary to remove the results of combustion and neutralize condensate.

Although boilers with an open chimney chamber do not have a chimney, combustion products are still released, so it is better to install it in a separate room.

In the closed type of devices there is forced draft. Since the flow of the air mass depends on the strength of the fan, the cross-section of the pipe does not have to be large; a coaxial pipe of small diameter will be sufficient, or you can install a damper on the chimney.

The air from gas-generating boilers is ventilated directly to the street by a fan; large holes are also not required. Here there is no need for a chimney, but there is a need to regularly clean the entrance from possible debris from the street.

If power is often cut off in the area where the unit is installed, it is better to use a model with natural draft - non-volatile, which does not require a chimney, or install an uninterruptible power supply for a gas boiler.

Advantages and disadvantages

The advantages of parapet boilers include:

- no electricity consumption;

- no internal air is used, there is no additional load on the ventilation system;

- there is no need to connect to a common chimney;

- low fuel consumption;

- efficiency, practicality, resistance to external loads.

The disadvantages of the models are:

- installation requires making a hole in the wall from 25 to 31 cm in diameter;

- installation is only possible near an external wall;

- it is not possible to provide full-function control and protection of units and parts of the unit (for non-volatile models).

Despite the existing disadvantages, parapet boilers are highly rated by users. The demand for them is constantly growing.

The need to use parapet boilers

Parapet boilers are one of the best options. They can even be used to heat a city apartment. Initially, such equipment was developed as an alternative to wall-mounted ones, which have many advantages, but are very demanding in terms of operating conditions. For stable operation, they need constant pressure, soft water, high quality gas, as well as an uninterrupted power supply. For this reason, such devices often fail and require regular maintenance. Over time, they were replaced by parapet boilers. They do not require such stringent operational requirements and are able to ensure stable operation of the heating system. The described installations are energy-dependent heating units, which are intended for installation in apartments and private houses, combining all the positive characteristics of convectors and gas boilers.

Installation Summary

As you can see, there is nothing impossible or particularly difficult about installing a parapet boiler with your own hands. And if you approach this issue with due patience and accuracy, then a positive result will certainly be achieved.

Gas heating remains the best option for organizing heat supply to apartments and houses. To install equipment, you need to know the current regulations and obtain permission from the appropriate service. It is especially difficult to install a wall-mounted gas boiler in a wooden house with your own hands. The requirements for such buildings are much stricter than for reinforced concrete or brick buildings.

Features of installing a parapet type gas boiler

Boilers are purchased only in stores specializing in gas equipment. Upon first request, the seller must present a license, all documents for the equipment, and certificates.

Installation of a parapet boiler begins with obtaining permission from local authorities for the installation of gas equipment and its connection.

SNiP requirements and standards

Installation of gas equipment is carried out in a room whose walls and floor are finished with non-combustible materials. There should be a gap of at least 2 cm between the boiler and the wall.

When installing equipment in a wooden building, it is necessary to cover the walls with fire-resistant materials that prevent smoldering and burning. Mineral wool cardboard, ceramic tiles, a small layer of asbestos coated with a metal sheet are used. Plaster can be applied, but a layer of at least 3 cm will be required.

Example of a room according to SNiPs

The device may only be placed on a special substrate made of non-flammable material. High-temperature-resistant tiles or fire-resistant bricks are laid on wooden floors. Protrusions of at least 10 cm are made along the contour of the entire boiler.

Coordination of work, technical conditions

Installation of a geyser is permitted only after approval. Restrictions, failure to comply with which will result in refusal:

- Installation of the boiler is permitted only in non-residential premises that are separated from other rooms by a well-closing door. Restrictions on installing equipment in a bathroom or toilet have been lifted.

- The boiler room must be at least 4 m², equipped with ventilation.

If these requirements are met, you can begin processing documents.

Design

At the stage of preparing documents for permission, a technical plan for gasification of the house is prepared.

The project must take into account the brand of the meter, contain detailed information about the boiler used, a diagram of the system connection, boiler room equipment with all additional devices.

Sample Project

You can order a project only from companies that have a license for this type of activity, but it is best to do this from an organization that supplies gas to the population. The equipment installation plan will be carried out in strict compliance with all requirements. This reduces the risk of unforeseen situations in the future when the system is connected to the gas pipeline.

Obtaining permission from Gorgaz

Approval is issued after registration. Specifications for connection to the main line are drawn up, indicating the expected volume of fuel consumption, and a gasification project from an accredited company is attached. All that remains is to add documents with permission from Rostekhnadzor and the technical passport of the installed equipment.

The approval process takes about 90 days. If errors are identified, a refusal is sent with instructions to eliminate the deficiencies. After the amendment, the documents are submitted again.

Installation location: recommendations for installing equipment

A parapet boiler is installed in the kitchen, utility room, bathroom or toilet.

The smoke exhaust pipe must not be installed on a balcony, loggia, canopy, porch or other building. It is necessary to install the chimney so that it does not interfere with other people, and the combustion products discharged through it do not fall into the windows of other apartments.

Installation work, connection to the system

Heater installation steps:

- A hole is made in the wall for the chimney pipe. For this, a diamond drill with a diameter of 2.4-2.7 cm is used.

- Parts of the pipe that are not directly connected to the boiler are installed. The middle section is placed so that the joints or seams are outside the wall and not inside the cut-out space.

- The chimney is made with a slight slope outward and downward, so that condensate does not accumulate, but flows down from the walls of the pipe.

- If the boiler is of a mounted type, then fasteners are fixed under it. Markings are made for the floor model.

- When installing a double-circuit unit, a water supply system is assembled and a pipe is installed to remove exhaust gases.

- An internal pipe from the smoke exhaust pipe is installed, and the main boiler is mounted.

- Gas and water outlets, pipes, and circulation pump are connected.

Coaxial chimney

The final step is to test run the system and check for leaks.

Choosing a location for installing parapet units

Parapet gas boilers are installed in the same way as conventional ones in non-residential premises: kitchen, hall, corridor. They are placed only on the external wall of the house. If the walls are built from flammable material, then the distance from them to the pipe must be at least 20 cm. The surface on the side of the boiler and pipe must be protected with fireproof materials.

The coaxial chimney should not be located next to other facade elements or objects. The permissible distance to the chimney is about 30 cm. The chimney must not go out onto a balcony, loggia or under a canopy.

All about parapet gas boilers here

The pipe should not interfere with people passing by the wall or smoke out the window of neighbors.

For units with a power of up to 7 kW, it is allowed to place the pipe at a distance of 25 cm from the window. If the boiler is more powerful, then 50 cm.

When the gas boiler is located on the ground floor, the installation height of the pipe cannot be less than 0.5 m. And if there is a passage for people at the chimney outlet, the height of its placement should be from 2.2 m.

From balconies and other elements protruding more than 40 cm, it is allowed to place the pipe no closer than 2 m (for a unit power over 7 kW - 3 m).

The chimney should be placed so as to provide free access to it, which is necessary for the care and maintenance of the pipe.

There should be no flammable objects near the gas boiler indoors; the permissible distance to them is 30 cm.

Near the unit panel and its shut-off valves, free access of 1 m is required for control, operation and repair.

Types and prices

The advantage of such boilers is a large selection of models with different mountings: floor-mounted and wall-mounted. When choosing a boiler, real connection conditions are taken into account.

Boiler equipment from European factories, Russia, CIS countries and China is quite widely represented on the construction market. It is clear that the quality of equipment from the EU is higher than that of boilers from China, but the price is also much higher.

Popular parapet boilers:

- TERMOMAX-C are non-volatile compact boilers for individual heat supply of single-storey and multi-storey buildings, equipped with a flue gas exhaust system through a coaxial channel, horizontally built into the external wall. Structurally, they are carried out in both single and double-circuit versions with markings E and EB and thermal power from 7 to 16 kW. For heating systems with high hydraulic resistance, a circulation pump is provided. Control, protection and start-up are carried out through the gas valve EuroSit 630. The burner is started using piezo ignition. TermoMax C 16EB has an efficiency of 90% and is capable of heating rooms measuring 120 m2, the cost of the unit is 20,100 rubles.

- Another Russian model of a parapet boiler is Lemax Patriot 20 with a closed firebox. The steel heat exchanger is treated with an inhibitory compound and covered with an enamel coating to resist corrosion processes. Mounting type: wall-mounted. The range of thermal loads of Lemax boilers is from 6 to 20 kW. Gas burner equipment from the Italian concern “SIT” with an injection flare burner “POLIDORO”. There are special holes on the front panel to create a convection effect and increase heat transfer in the room. Features include: removable cladding elements, igniter, coaxial smoke removal system, non-volatile installation option. The cost of the unit is 25,820 rubles.

- The double-circuit boiler “Slim 2.300 Fi” is produced by the Baxi brand with a heat load from 14.9 to 29.7 kW, capable of heating objects measuring 140 -160 m2. The boiler is made of high-quality materials, with a price from 120.0 to 140.0 thousand rubles.

- EcoCompact VSC D INT 306/4-5 190L, boiler of the German brand Vaillant - a highly efficient unit, can heat 160-180 m2, price 240.0 thousand rubles.

- The Danko parapet boiler, with a power from 7 to 18 kW, is equipped with a cast iron boiler with a wall thickness of 3 mm and a closed combustion chamber. The universal design allows for two-way connection of utility networks; the control unit is located on the operating panel of the boiler. The units are equipped with Honeywell gas automatics, piezoelectric ignition and a micro-torch burner, heating area up to 160 m2, price – 21 thousand rubles.

- Eurotherm KT TSY (P2) for individual heat supply in systems with natural and forced circulation of the heating circuit, with water heating temperature up to 90 C, thermal power 10 kW, gas consumption 1.13 m3/hour, efficiency 92%, weight 59 kg, warranty period 24 month, heating area 100 m2, price – 24 thousand. rub. Steel boilers are equipped with a copper recovery system with a bypass channel. A specially designed copper coil is placed in a water cavity to produce hot water. Design features: heat recovery system with a receiving tank, housing, control and protection unit, air duct, flue, wind protection cover. The design allows you to install the unit at floor level near the wall. The DHW circuit connecting pipelines are made on one side. The air intake duct passes through the outer wall with a thickness of 200 - 500 mm. Mounting on walls in a wooden house is not allowed without fire protection measures.

Installation diagrams

After preparing the premises and obtaining permits, you can begin installing the boiler. The equipment installation site is finished with fireproof materials. For wall-mounted models, the use of reliable fasteners is mandatory.

How to hang a gas boiler on a wooden wall, and what standards must be followed? To do this, you need to familiarize yourself with the general rules:

- Drawing up a diagram. The location of the pipes for connecting to the pipeline and the location of the gas main are taken into account. Before installing a gas boiler in a wooden house, the diagram indicates the location of auxiliary equipment - indirect heating tanks for domestic hot water, a circulation pump, an expansion tank and a protection group.

- The minimum permissible distance to the surface of the wall on which the equipment is installed is 4.5 cm. To the side ceilings this value is at least 20 cm. The distance to the floor is from 30 cm, to the ceiling 45 cm.

- The hole in the interfloor ceiling or wall for the chimney is protected by a special fire-resistant sleeve. Its function is to prevent direct contact of wood with the heated surface of the chimney.

- Use of plastic pipes in heating. To protect the surface of the main from overheating, it is recommended to install a steel pipe up to 0.5 m long at the hot water outlet from the boiler.

In practice, the same installation of a wood-burning boiler in a wooden house will be easier. But in the future, heating and maintenance costs will be higher than for gas heating.

Advantages and disadvantages

Advantages of parapet boilers:

- No need to connect to the mains. The autonomous system is powered by a battery, and the fuel is supplied from the gas pipeline, or cylinders are connected to the system.

- Such boilers are easier to install, connect, and do not require maintenance. To regulate the operation of the system, the necessary sensors and controllers are installed on them.

- The design of the device is simple, which simplifies the task of maintenance.

- Universal equipment can become a heat source for a heating system made of pipes and radiators, or an individual means of heating due to convection windows.

- The equipment is installed in small rooms (small apartment, small private house or cottage). You can place it where it is more convenient. There are floor-mounted and wall-mounted varieties. Such devices are compact.

Convection holes

Disadvantages:

- Weak internal pressure, which needs to be artificially increased by a circulation pump.

- Possibility of icing of the chimney during severe frosts.

A detailed overview of the parapet installation model can be seen in the following video:

Most common problems

A parapet floor-standing gas boiler, like a wall-mounted one, can sometimes go out.

The most common reasons:

- Icing of the external chimney unit. In this case, the access and removal of air is disrupted. It is recommended to try starting the boiler at minimum power and try to warm it up in this way. Or carefully knock off the ice.

- When using boilers of all types, it is advisable to install water purification filters. If it is hard enough, the heat exchanger system may clog. In this case, you need to disconnect it and clean it.

- When there is a strong gusty wind, sometimes its gusts enter the exhaust chimney (backdraft), which leads to the flame being blown out.

- The fire may go out if there is insufficient gas pressure. The cause must be eliminated; there may be a leak.

- Failure of various sensors and controllers. Replacement or repair of boiler parts is required.

Features of the parapet boiler "Lemax Patriot 16"

This model of equipment costs consumers 21,000 rubles. The boiler can work in conjunction with forced or natural heating systems. No connection to the electrical network is required. The rectangular heat exchanger is based on high-quality 2 mm steel, which meets the European standard.

The heat exchanger is coated with anti-corrosion enamel and treated with an inhibitory compound, thanks to which the material is reliably protected from the effects of aggressive factors, namely mineral oils and salt solutions. The boiler can only be used in conjunction with a heating system that is equipped with original gas burner components. Heating can be connected from both sides.

The boiler power is 16 kW. The heated area reaches 160 m2. The front panel has holes that create a convection effect. You don’t have to worry that the boiler will overheat, because the manufacturer has equipped it with a special protection system. Servicing the boiler is quite simple, since the design has removable cladding elements and profile equipment. You can observe the combustion of the pilot and main burners through the viewing window.

Choosing a gas boiler

Reliability primarily depends on the thickness of the steel used in the design of the heat exchanger. Unfortunately, not all manufacturers indicate this parameter, so when choosing a boiler you need to clarify this point with the seller separately, as this can play a key role in the operation of the parapet boiler.

Steel with a thickness of around three millimeters is considered optimal. If the steel is thicker, the heat transfer process will slow down, which will negatively affect the overall efficiency of heating the room. In addition to the thickness of the steel, its quality also matters. The quality of the metal and the entire boiler as a whole can be determined by the maximum pressure level allowed by the manufacturer. The higher it is, the more reliable and better quality the selected parapet boiler is made.

The quality of metal during manufacturing can be determined by the maximum level of pressure

The efficiency of a parapet boiler is influenced by the design of the heat exchanger and its efficiency. In order to determine how economical the selected boiler will be in operation, you need to find out its efficiency (efficiency factor), this parameter will most accurately show the efficiency of the heat exchanger and the boiler device as a whole.

To date, almost all manufacturers have achieved an acceptable level of efficiency, which is 90-92%. But just in case, it’s worth checking the efficiency level when purchasing, since in some cases two or three percent can make a difference. This indicator is the only one that will objectively reflect the efficiency of the boiler, because different rooms differ from each other in the level of their own thermal insulation, so reviews from people who have already bought a boiler will always be subjective.

Significant technical parameters include the size, dimensions of the boiler, location of connection connectors and power. The size and dimensions are selected individually in each case and depend on the location and installation conditions. Also important for the boiler is the location of the connectors. The modern model range includes options with both right-hand and left-hand connections of the boiler to gas and water supply. There are also universal models that can be connected from any side.

Boilers come in different sizes, it all depends on the power

The power of a parapet boiler is no less important than its efficiency. The quality of room heating, as well as the efficiency of using the boiler, will depend on the choice of a model with optimal power, because if it is too powerful, gas and electricity will be wasted. The formula 1 kW per 10 m2 is often used, but in fact this is not correct, since this indicator is averaged so much that it almost never corresponds to reality

When calculating a power of 1 kW per 10 m2, the difference between an apartment and a house, the number of windows in the room, wall material, ceiling height and other parameters that make up the overall level of thermal insulation are not taken into account

The formula 1 kW per 10 m2 is often used, but in fact this is not correct, since this indicator is averaged so much that it almost never corresponds to reality. When calculating a power of 1 kW per 10 m2, the difference between an apartment and a house, the number of windows in the room, wall material, ceiling height and other parameters that make up the overall level of thermal insulation are not taken into account.

It is best to double this formula, that is, for 10 m2 take 2 kW of power, and not one. In this case, a margin is obtained that takes into account windows, possible drafts, thin walls or high ceilings of the room. But, of course, it is best to consult with specialists when purchasing and determine the optimal boiler power individually in order to achieve the most optimal price-quality ratio for heating.

A parapet boiler is economical, easy to use, has a low cost, can perform the functions of a water heater and does not require the creation of an additional heating network, since it is both a stove and a convector. The ease of installation allows you to connect the parapet boiler yourself, without the help of specialists.

To summarize, we can say that a parapet boiler is a convenient modern heating device that can be installed in any type of premises, in a private house, apartment, garage or any outbuilding.

Operating principle of a parapet boiler

When purchasing a non-volatile boiler, you need to turn on the device using the piezo ignition button. If the device is volatile, then the automation automatically turns it on. Boilers of the first type are common in Russia.

So, the parapet boiler works as follows. First, the pilot light ignites the main burner, which heats the water circulating in the heat exchanger. As soon as the water temperature reaches the required level, the burner automatically stops working. After some time, the temperature of the coolant drops again, and the igniter once again ignites the burner.

User manual

In order not to lose the warranty for the maintenance of your unit in any case, you do not need to carry out work on installing the boiler and repairing it yourself. Connecting the product, its proper configuration, and the first start-up must be carried out by service specialists. They will make a separate entry about the work performed in the passport of the unit you purchased. It is necessary to carry out preventative maintenance of the entire boiler once a year - this is also noted in the technical data sheet of the device. Failure to maintain such records may void your warranty.

The Conord burner may sometimes not ignite. This may happen because:

- There is a lot of dirt on the burner. Before turning on the structure, you need to clean the nozzles with a soft brush or just a vacuum cleaner.

- There may not be enough oxygen to start the burner quickly. Again, it is necessary to clean the nozzles that supply air, thoroughly ventilate the room, and try to light the burner again.

- Perhaps the contacts in the thermostat have simply oxidized. This is where the cleanup takes place.

- Automation sensors are broken.

- It is necessary to blow out the igniter or clean it of any existing dust or dirt.

If your coolant cools down very quickly, you just need to switch the thermostat to maximum settings or increase the supply of fuel to the burner, if only the device instructions allow this kind of action.

In the summer, you will need to turn off the heating circuit altogether. You just need to turn off the tap at the coolant inlet. If the burner works alone, the water will heat up to 60 degrees in 1 hour. If the heated liquid is not all removed at once, it will retain heat for about another 2 hours.

Domestic has already earned an excellent reputation in the domestic heating equipment market thanks to the production of high-quality equipment. Among users, Conord units, reviews of which have mostly positive features, are always in fairly high demand.

To learn how Conord gas boilers are produced, see the following video.

DIY boiler installation

A protective cap is installed on the chimney to prevent the wind from blowing smoke back in.

Installation of the boiler must be carried out by gas industry specialists. The property owner can prepare a base or a place on the wall for it, drill a hole for the chimney and make connections for heating and hot water supply. Fixing the device and connecting communications is carried out by a specialist. Exceptions are cases when the boiler is connected to a gas cylinder.

To prevent the wind from blowing into the boiler, it is necessary to make a protective cap at the end of the chimney at the installation stage, which will dampen turbulence and strong air currents. Periodically, the inner pipe must be cleaned of soot, since internal deposits reduce draft.

What is a parapet boiler

The boiler body is made of 3 mm thick steel, painted with a special fire-resistant anti-corrosion coating, which ensures its resistance to mechanical and corrosive influences.

Main elements of the boiler:

- closed firebox;

- gas burner device with igniter;

- coaxial chimney;

- two heating circuits with independent boilers made of copper and steel.

Control unit: pressure and draft sensors, thermometers and thermocouples, they protect the boiler from overheating. When the draft in the firebox drops to 0 mm.w.st., the boiler instantly begins to overheat the water; when the temperature rises above 65C, a signal from the plate will be sent to the cut-off valve, it will shut off the gas, and combustion will stop.

The thermocouple, when exposed to heat from the gas flame, creates a small voltage that controls the gas valve. During the absence of combustion, the voltage in it drops to 0 V, the valve instantly cuts off the gas supply to the boiler.

Why does the boiler blow out in the wind and what to do in this case?

Blowing out may indicate a failure in the connection of the chimney and automation; more often it indicates a lack of wind protection on the head. However, in general, blowing out the burner flame by the wind is a significant and most well-known problem with parapets, which is why they never gained super popularity.

As a rule, the casing of a coaxial chimney, manufactured in a factory, already has a special insert that protects against gusts of wind. If it is not included in the kit, then you will have to look for a suitable deflector or make it yourself: give a sheet of galvanized steel the desired shape, and then attach it to the head with press washers or rivets.

Factory wind protection and an example of a homemade solution by the owners.

When the boiler still goes out after installing the protection, there is no point in doing anything further: you can, of course, continue to install new heads and deflectors, add bends to the coaxial pipe, or install a vertical chimney, but then the whole point of installing a parapet model will be lost.

Combined models

In addition to traditional heating equipment, it produces 3 combined series of boilers:

- Electric gas heat generators KS-G-SN / KE with a heat output of 10-12 kW.

- Units "Zhytomyr-9" burning coal and natural gas. Designation - KS-G-SN / AOTV, power - 10, 12 and 15 kW.

- Heating and hot water installation “two in one” KS-G-SN, otherwise – “Zhitomir-10”. The range of models covers the range of 7…30 kW.

The line of gas-electric boilers is built on the basis of Zhytomyr-3 units and does not differ in appearance from conventional floor-standing units. The design is complemented by a control unit and an electric heater placed inside the water jacket. 2 types of heating elements are installed - with a power of 4.5 and 9 kW. Important feature: both heating methods can be turned on one by one or simultaneously.

The coal-gas heat generator “Zhytomyr-9” has the following parameters:

- on the left side of the body there is a firebox with a volume of 47 or 70 liters for storing anthracite or firewood;

- to the right of the solid fuel chamber there is a gas firebox with a Polidoro burner and an SIT 630 automation unit, a common heat exchanger, and separate smoke exhausts;

- efficiency on gas – 92%, solid fuel – 78%, operating water pressure – 1 Bar (Max 1.5 Bar);

- work in a closed system is allowed, condition - installation of a safety group with a 1.5 bar safety valve;

- duration of 1 coal combustion cycle – 6…8 hours;

- There are modifications with a DHW water circuit.

The operating algorithm is simple: while the coolant is heated by coal, the gas burner does not ignite. When the sensor detects a drop in temperature, the gas supply will open and the right side of the heat generator will start working. The main thing is that the pilot light is lit.

The gas installation “Zhytomyr-10” consists of two separate sections - a boiler furnace and an instantaneous water heater. Burners, safety devices and heat exchangers are completely separated. In fact, the gas water heater and the boiler are combined in one housing. The goal is to increase water consumption for hot water supply to a comfortable level without compromising heating efficiency.

Systems with two boilers

If it is necessary to organize heating of the coolant in a closed circuit from two heat generators, use the parallel connection principle. Let us explain the algorithm for the joint operation of two boilers - electric and solid fuel (the piping is shown in the figure):

- The main heat source is a TT boiler, connected in the standard way through a three-way valve. To prevent flows from looping in the other direction, a check valve is installed on each branch.

- When a stack of firewood burns out, the air in the house begins to cool. The temperature drop is detected by the room thermostat and starts the electric boiler with a pump.

- A decrease in the temperature in the supply line of the TT boiler to 50-55 °C causes the overhead thermostat to turn off the circulation pump of the solid fuel circuit.

- After the next loading of firewood, the supply pipe heats up, the temperature sensor starts the pump and heating priority returns to the solid fuel unit. The room thermostat no longer turns on the electric boiler because the air temperature does not drop.

It is also necessary to install a safety group at the output of the electric boiler; it is not shown in the figure.

An important point. The above-described piping option can be used for any pair of boilers. When installing a wall heater, a second pump is not installed.

Two heat generators, for example, gas and electric, are easily connected through a heat accumulator. The turning on and stopping of both boilers can be organized in various ways - by the temperature of the water in the tank, by time using a timer. Check valves are not needed here.

If it is necessary to connect 2-3 units of thermal power equipment with several heating circuits, it is better to assemble a diagram of primary / secondary rings. The principle is as follows: all heat sources and consumers with their pumps are connected to a common ring made of a pipe of increased diameter Ø26...40 mm (depending on the number of branches). Circulation inside the ring is provided by a separate pump.

The order of equipment installation matters: the water heater receives the hottest coolant, followed by the batteries, and finally the TP (along the water flow)

In a system with natural coolant movement, two boilers are also combined in parallel. Here it is important to withstand slopes of pipes Ø40...50 mm, and also to avoid sharp turns, using bends at an angle of 45° or bends with a large bend radius.

The water diverges along two parallel branches with boilers. But the unit that is currently turned on will make it move by gravity; the pump starts at the request of the owner

Advice. A series connection of 2 units has a right to life, but it is better not to use such a connection. Water heated in the first boiler will pass through the cold heat exchanger of the second and will certainly lose some of the heat.