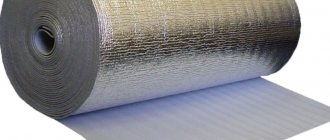

There are many different insulation materials. Foil insulating material reflects up to 97% of infrared radiation in the direction of its arrival.

It is made on the basis of expanded polystyrene, foamed polyethylene, mineral and basalt wool. Its effectiveness will depend on proper installation.

In this article, we will look at which side to lay insulation with foil on the floor, the types and characteristics of materials, and the rules for their installation.

What is foil insulation

Foil insulation is a combined material consisting of heat-insulating raw materials and a metallized layer. The reflective coating is installed on 1 or 2 sides at once.

Foil reflects thermal energy back into the room, which is why this insulation is thinner than other materials.

Aluminum film has increased reflectivity, and metallized film has good resistance to alkali.

Laying underlay under laminate with foil

Sometimes substrates for laminate with foil are made with an applied adhesive layer. If you don’t have it, you need to prepare foil tape to fasten the backing material to be laid together.

Video: how to lay foil underlay under laminate

Now you know why you need a backing for a laminate flooring, what kind of backing materials there are, what a foil backing is for a laminate flooring, and how to install it. We hope that this knowledge will be useful when choosing materials and designing a laminate floor in your home on your own.

Source

Characteristics and cost

The performance characteristics of thermal insulation with foil coating are significantly higher than materials without foil:

- better tolerates humidity and temperature changes;

- reflects up to 97% of heat into the room;

- reduces the vapor permeability index to 0.001 mg/m*K;

- extends the operational period of the foundation by 2 times;

- increases the noise insulation rate to 68%.

The cost of insulation depends on the material used and its size. For example, a set of 6 LOGICPIR slabs measuring 1190x590x40 mm (to cover an area of 4.16 m²) will cost from 1900 rubles.

Basic functions of the substrate

The laminate is laid on a pre-prepared, flat and dry base, on a layer of substrate spread under the laminate.

The quality of installation and the duration of use of the laminated coating largely depend on professional installation and correctly selected and laid underlay material. The importance of the lining under the laminate can hardly be overestimated; its choice and the quality of the material largely determines how long and faithfully the laminated coating will serve you, whether it will be cozy and comfortable for you in your apartment in the winter.

In some types of laminated panels, the backing layer is attached to the reverse side, most often these are coatings with strength class 33. Basically, the underlay is laid separately, before laying the laminate. It performs several necessary functions at once:

Today there are many varieties of substrate materials, both natural and synthetic.

The most common substrate materials:

Types of insulation

Products are made of different thicknesses, from different materials, with different heat-reflecting coatings.

Penofol

This is a universal material, which is also called ecofol or isolon. Thermal insulation is produced in rolls. One or both sides can be covered with foil.

There are insulators that have a foil coating on one side and a self-adhesive coating on the other. Some types of insulator are additionally equipped with reinforcing mesh.

Main characteristics:

- thermal conductivity - 0.038 W/(mK);

- vapor permeability - 0.001 mg/m*K;

- moisture absorption - 0.35-0.7%.

Most often, such products are used to insulate pipelines, floors and roofs.

Penofol with thermal conductivity - 0.038 W/(mK).

Expanded polystyrene

Sufficiently thick volumetric insulating coatings are made from expanded polystyrene, foil-coated on one side.

Advantages of the material:

- not afraid of mold and mildew;

- does not rot;

- withstands temperature changes -180…+180ºC.

Disadvantage: the possibility of using polystyrene foam only for insulating floor bases.

Expanded polystyrene does not rot.

Styrofoam

Polystyrene foam is made by fusing polystyrene granules. It is used in conjunction with the “warm floor” system.

Main characteristics:

- thermal conductivity - 0.035 W/m²;

- insulator thickness - 0.3-0.5 cm;

- density - no more than 45 kg/m³;

- possibility of using the material in the temperature range -180…+180ºC.

Foam plastic is used to cover areas with increased mechanical loads and humidity.

Foam plastic for underfloor heating systems.

Aluf

Alufom (bestizol) is cellular polyethylene covered with aluminum foil. The product absorbs shocks and sounds well. The main advantage is low thermal conductivity.

Alufom has a small thickness, so it is often used to insulate pipeline communications and ventilation systems. It does not lose its qualities in either heat or cold.

Alufom is a fairly thin material.

Mineral wool

Fiberglass is used to produce the product. The thickness of the finished rolls (mats) can be from 5 to 10 cm. Thanks to aluminum film, insulation is used for buildings with high humidity (baths, showers).

Basalt wool can withstand temperatures of -200…+300ºC. Its thermal conductivity is up to 0.07 W/(mK).

Mineral wool is not susceptible to mold and damage by rodents. The insulating coating is resistant to fire, so it is often used for finishing wooden buildings.

Mineral wool is recommended for wooden buildings.

Frame installation

If, before starting work on installing insulation, you did not have a frame ready for filling, then you should not be afraid of it. It is created using a fairly simple technology, which requires the use of wooden blocks, usually 50x50 mm in size. They are mounted vertically and at a distance of 580 mm from each other, so that mats or insulation boards fit perfectly here. The thickness of the insulation is 50 mm, and the width is 600 m

This is very important, if you make a mistake, you will have to cut off the edge of the insulation, do you really need additional work that could have been avoided without loss of quality? If you have mats whose width is 1200 mm, simply cut them into 2 parts, and there is no need to expand the frame - then the insulation will not be attached firmly enough. It is quite important to be demanding about the strength of the frame; usually people think specifically about insulation, forgetting that the frame will be one of the foundations on which the comfort of your home rests

Advantages and disadvantages

Advantages of foil thermal insulation:

- retains heat in the building, does not let in warm air from the street in summer and cold air in winter;

- characterized by increased wear resistance;

- in some cases it can be used as waterproofing;

- resistant to mold and mildew;

- has good soundproofing characteristics;

- does not release toxic components.

The only drawback: the insulation itself cannot be covered with finishing.

How to insulate a brick wall

When using polystyrene foam, the walls are pre-plastered; this is a mandatory procedure. After the surface has dried, it needs to be leveled; putty is used for this. Putty can be applied to brick walls in one layer, after which the waterproofing material is laid. Do not neglect waterproofing; foam plastic is susceptible to moisture and may rot due to condensation.

It is worth remembering that the glue is applied to the wall itself, after which sheets of foam plastic are applied to it

It is important to avoid gaps that do not contribute to heat retention. Lastly, a vapor barrier material is laid on the foam.

Mineral wool is mounted on brick walls in the same way as on concrete walls. Despite the high characteristics of the insulation materials used, it is worth considering that for concrete walls it is better to choose extruded polystyrene foam.

Other options are also suitable, but only if a vapor barrier material is attached. But for brick walls, foamed polystyrene foam is most preferable.

Before deciding on insulation, you need to know what characteristics this material should have:

If the selected insulation has all of the above qualities, then the result will really please you, of course, if the installation is carried out correctly.

Application area

Foil-coated thermal insulation products are often used for heating equipment (heaters, oil radiators, boilers).

In addition, wall surfaces and floor bases are covered with such insulation with foil towards the room. The reflective layer retains maximum heat in the room and does not let it out.

Since the product is small in thickness, it is often used to insulate small areas. It is used for thermal insulation of saunas, garage cooperatives, outbuildings, pipeline communications, wells and boreholes.

Penofol for floor insulation.

Carrying out calculations

To achieve optimal insulation of a residential building, it is necessary to ensure the thermal resistance of the structure is not lower than the normalized value established by the current building codes.

The total resistance consists of the values of individual layers of the structure that are not separated by a ventilated layer. For example, the heat transfer resistance of the floor base on a balcony is equal to the resistance of the reinforced concrete slab, insulation layers and floor covering.

The normalized thermal resistance is different in each region of Russia.

Source

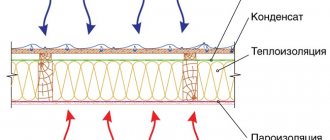

Which side should the vapor barrier be laid on?

Depending on the base to be insulated, insulation material can be laid in different ways.

For external walls

The rough side of the product is placed against the insulation, the smooth side towards the street. Insulation of rough floor subfloors is carried out in a similar way.

Correct installation of insulation.

For under-roof space

The dark side of the product is laid outwards, the light side is placed towards the insulation.

On the basement floor inside the house

The product is placed on a rough surface towards the heat insulator.

For ceilings, external walls and partitions

The smooth surface of the film is placed towards the insulator.

Rules for laying on floors, external walls and partitions.

Polyethylene foam mounting side with foil

Foamed polyethylene is applied to the wall, another heat insulator.

Let's sum it up

So, we found out that there are several types of foil insulation:

- polystyrene foam in sheets for flooring;

- mineral wool in sheets and rolls;

- penofol;

- shells for insulating pipes made of foam plastic and mineral wool.

All types of insulation, except shells, with a reflective layer are intended for internal insulation. The foil should be placed in the middle of the room. Such materials are suitable for external insulation, since the concept of reflecting IR radiation is reduced to nothing. Therefore, there is no point in paying for something that will not bring results.

Foam and mineral wool slabs must be glued using a special plaster-adhesive mixture from trusted manufacturers. The latter include the same Knauf or Ceresit. Laying on the walls is carried out from the bottom up, the sheets are additionally secured with dowels. And the most important thing is the presence of a ventilated gap in front of the reflective surface. If it is not there, then instead of reflecting heat you will get even more heat leakage and, in addition, mold on the finish.

Features of insulation technology

When using self-adhesive material for insulation work, lathing is not used. In this case, the base is thoroughly cleaned of old finishing material, and all recesses are sealed with putty. Then the surface is primed and insulation boards are applied, after removing the protective film.

Foil insulation without a self-adhesive coating is fixed between 2 layers of sheathing.

What tools and materials are needed for the job?

When performing installation work, you need to have the following tools and materials:

- reinforced tape;

- wood slats for making sheathing;

- insulating material;

- hammer drill (drill);

- stairs;

- screws for wood, concrete and dowels;

- tape measure, building level, pencil for taking measurements and marking the base;

- hacksaw;

- primer mixture;

- putty;

- roller;

- mounting stapler with staples;

- putty knife;

- container for preparing the solution;

- stationery knife for trimming excess insulation material.

The list of tools and materials may vary slightly depending on the area of insulation work and the method of fixing the insulation.

Indoor wall insulation stage

The sequence of performing insulation work indoors:

- Preparation of wall surfaces - removal of old coating, cleaning, puttying of the base.

- Fastening insulation boards to a self-adhesive coating or using lathing, additionally fixing them with staples.

- Sealing cracks with mounting tape.

- Fastening the slats to form ventilation between the insulation and the facing material.

If you plan to completely insulate the room, it is recommended to start installing the insulation from the ceiling. Next, the material needs to be mounted on the walls. Work on the floor is being completed.

Insulation of walls inside the house.

External wall insulation stage

For external insulation of buildings, it is recommended to use foil insulation made on the basis of fiberglass.

Isolation algorithm:

- Installation of metal sheathing on insulated bases. The structure is fixed to the walls with dowels.

- Fixing heat-insulating boards on the sheathing.

- Leveling and polishing the surface.

- Attaching windproof film.

- Laying waterproofing material, which is fixed with a stapler. You can use small nails with large heads, but be careful not to damage the insulation.

To install the finishing coating, additional sheathing is installed to form a ventilation space.

Insulation of the walls of the house from the outside.

Installation work on the ceiling

The sequence of insulating ceiling surfaces with foil penofol:

- Preparing the base: cleaning, removing old coating, sealing cracks and crevices.

- Surface priming.

- Laying a thin layer of insulation, fixing it with wooden slats in 0.5 m increments. The joints are taped with construction tape.

- Laying the main thermal insulation boards. They need to be attached to the slats using a mounting stapler and staples. The joints are sealed with tape.

- A sheathing of slats is also installed on the main insulation layer.

Next, you can perform the finishing cladding of the ceiling surface.

Attaching insulation to the ceiling.

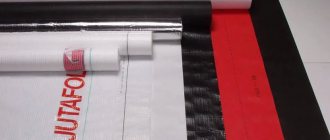

Installation of penofol for attic insulation

For thermal insulation of attic spaces, mineral wool, ecowool or penoizol are most often used.

Work order:

- A vapor barrier film is laid on the outside of the rafters. Fastening is carried out using a stapler. The joints are sealed with metallized tape.

- A lath for the finishing coating is installed above the vapor barrier.

- The roof is being installed.

- Next, the selected insulation material is laid between the rafters, leaving a gap of 10 mm between the vapor barrier film. Penofol must be laid with the foil down. To fix the canvases, you can use wooden planks or staples.

- All joints are taped with reinforced tape.

It is not recommended to insulate the floor in the attic, because... it will be heated from the premises of the building.

Insulation of the attic.

The stage of gluing the insulation to the gable

The sequence of attaching the insulation to the pediment:

- The loose coating is removed from the plastered base.

- Fungus and mold are removed. Then the problem areas are dried with a hair dryer and treated with an antiseptic.

- Use a solvent to remove all oil stains.

- All irregularities that could damage the insulation are smoothed out.

- Cracks and holes are sealed with concrete mortar. If the pediment is made of wood, the cracks are caulked, large potholes are sealed with tow and foam. The wood is additionally treated with fire retardants and antiseptics.

- Next, the pediment is primed and insulating material is laid, having previously covered the working side (without foil) with a solution. The insulation panels are laid end to end.

It is quite difficult to make high-quality attic insulation yourself. And if there are even small gaps, there will be significant heat loss. Therefore, it is better to entrust work in such a room to experienced craftsmen.

Covering the pediment with insulation.

Laying insulation on pipes

To insulate pipelines, a specially shaped “cocoon” coating is used. Most often this is moisture-resistant polystyrene foam or mineral wool that can withstand high temperatures.

There are also main insulation and special ones for chimneys. Materials may vary in diameter and temperature rating.

The installation technology is simple - an insulating cocoon is placed on the pipes, which does not require additional fastening.

Insulation of pipes.

Concrete floor insulation stage

The thermal insulation coating is placed on the concrete base of the floor with the foil down. Often a roll insulator is used for this. To fix it to concrete, glue made from rubber is used.

The procedure for performing thermal insulation work:

- Preparing the subfloor. All cracks in the concrete slab are sealed with mortar. If the surface has significant differences in height, it is leveled.

- After the base has dried, a roll of insulation is spread on it with the foil facing up and cut to the required size. The floor is smeared with glue, the prepared piece of insulation is placed on it with the foil down and pressed well. The remaining strips are glued similarly and pressed tightly against each other.

- After the installation of thermal insulation is completed, all joints are sealed with special foil tape.

If the floors are cold enough, you can additionally lay wood logs in 2 layers on top of the insulation layer, and heat-insulating boards between them.

Floor insulation.

Wooden floor insulation stage

To insulate wooden bases, it is better to use foil materials with a self-adhesive surface. Other insulators are attached to the floor surface using 2-sided tape or staples using a mounting stapler.

Sequence of work:

- All skirting boards in the room are removed, and the floor base is thoroughly cleaned of various contaminants.

- If there are irregularities on the wooden surface, they need to be sanded (scraping is performed if necessary).

- The cracks and cracks are filled with putty.

- Next, the base is primed with special antiseptics.

- Then you need to spread a roll of thermal insulation on the floor, cut the pieces to size and leave them to straighten for a day.

- The next day, the material must be glued to a wooden surface with a self-adhesive coating or glue (2-sided tape).

- The joints are sealed with foil tape.

Afterwards you can lay the finishing coating on the floor.

We insulate a wooden floor.

Foil insulator for heated floors

When installing a “warm floor” system, the heat insulator must be mounted with the foil facing up. The base must be level, without any defects or deviations in height.

Installation order:

- The insulator is placed on the base of the floor with prepared strips end-to-end, the joints are sealed with mounting tape.

- A “warm floor” system is laid on top of the insulation.

- Next, a layer of hydro- and vapor barrier is installed.

- A floor screed 3-5 cm thick is poured.

You can connect the electric heating system after about a month, when the solution is completely dry.

Installation of heated floors.

Insulator for floating screed

It is recommended to use 2-layer insulation under a floating screed.

Work order:

- Dirt is removed from the floor base and defects are eliminated.

- The lower part of the wall surfaces is being plastered.

- A damper tape is glued along the perimeter of the walls, the height of which must correspond to the thickness of the floor.

- The base is coated with a primer in 2 layers.

- The product is placed with the foil facing up, the seams are sealed with construction tape.

- Next, the screed is poured.

Due to its high performance characteristics, foil-coated thermal insulation material is very popular among both consumers and professional builders.

The seams are sealed with construction tape.

Preparatory work

Before we consider the technology for preparing walls for insulation, we note that we will only consider internal work, since foil thermal insulation for external walls is essentially money thrown away in the cold, as mentioned above.

The presence of a layer of foil on the insulation eliminates the “wet” method of insulation for several reasons:

- additional fastening of the slabs with dowels is necessary, which destroys the integrity of the metallized layer, reducing the effectiveness of thermal protection;

- decorative plaster will not adhere to foil;

- when the outer layer of the reflector is in close contact with any other materials, the effect of reflecting infrared rays disappears: the material in contact with the foil will heat up, in turn heating the aluminum, and it, along the chain, will transfer heat out into its substrate, and not into the room. That is why the instructions for using foil materials for insulation provide for the installation of a ventilation gap. In this case, the reflected heat rays will heat the skin. In this case, the foil itself does not heat up much.

Since there is no “wet” method of thermal insulation, then there will be lathing. This is where all the preparatory work is geared towards. Necessary:

- remove from the wall everything unnecessary that interferes with work: switches, sockets, lamps, various fasteners, etc.;

- remove old finishes and, if necessary, plaster;

- clean the surface from dust, dirt, soot and grease stains;

- repair small and large cracks;

- prime the wall in two passes.

There is no need to carefully level the surface - the insulation will hide everything.

In more detail, the process of performing the above operations can be found in the article “How to prepare walls for wallpapering.”

After the primer has dried, you can begin installing the sheathing. Detailed instructions for this stage of work are presented in the material “Wall insulation with stone wool”.

Attention: window and door openings are covered with battens under mineral wool. This is not done under foam plastic. However, in the case of foil foam, the openings will also have to be padded, because... Great difficulties arise when strengthening the ends and outer corners of polystyrene foam.

Let us briefly list the main stages of the sheathing installation:

- vertical trim posts are adjusted to the height of the ceiling and attached to the wall;

- horizontal strapping is screwed to the fixed racks using metal corners;

- Vertical internal slats are installed. The pitch is equal to the width of the insulation sheets;

- horizontal slats are installed. They are only needed under drywall. Vertical posts are sufficient for OSB boards.