Few people pay attention to the fact that some brands of thermal insulation, made by foaming polystyrene of almost the same chemical composition, can differ significantly in their characteristics. At first glance, polystyrene foam differs from expanded polystyrene only in its softer, more pliable texture, but in practice the differences turn out to be noticeably greater, so the choice of thermal insulation must be approached more carefully.

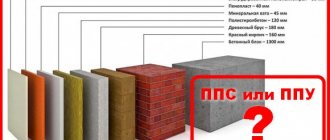

It is much easier to attach foam and polystyrene blocks to walls than mineral wool

Which material is better

What is the difference between polystyrene foam and polystyrene foam? This is a question many people ask. These products belong to the same type of insulation. In general, we can say that these are the same material with different production technologies. The composition of such insulation includes the following components:

- Polyurethane;

- Polystyrene;

- Urea;

- Formaldehyde.

Now the question of polystyrene and expanded polystyrene, what is the difference, can be resolved.

Important! When choosing insulation for your home, you need to pay attention to its components. There are a lot of fakes on the building materials market, which contain harmful chemicals that can harm human health.

1.4 Fire resistance

The flammability class of thermal insulation materials becomes of great importance when it is necessary to insulate objects whose structure has multiple wooden elements - attics or roofs

Also, building codes and regulations prohibit the internal thermal insulation of industrial premises with flammable materials, as this contradicts fire safety requirements.

In terms of flammability class, extruded polystyrene foam is no different from polystyrene foam. All polystyrene-based products belong to the flammability groups (depending on the impurities contained in the product):

To solve this issue, manufacturers add a fire retardant to both polystyrene foam and extruded polystyrene foam - a substance due to which the insulation acquires the ability to self-extinguish.

What is foam plastic

In fact, the two concepts of polystyrene foam and expanded polystyrene represent the same material, but produced using different technologies. As a result, both acquire differences in technical characteristics. The starting material for both polystyrene foam and expanded polystyrene are polymers based on:

- polyvinyl chloride;

- polyurethane;

- phenol formaldehyde;

- polystyrene;

- combinations of urea and formaldehyde.

In everyday life, the most common type of foam is called polystyrene, which is produced without such a technological step as pressing. This material was first produced at BASF factories in the middle of the last century, where it was first called “styrofoam” or PSB-1 foam.

Manufacturing technology

Granular styrofoam is produced using pentane, a substance that promotes the formation of tiny pores filled with gas.

Feedstock for foam production

At the same time, styrene itself in the total mass of the material contains no more than 2%, the rest is gas. During production, foam has a pure white color and is extremely light due to the fact that it consists practically of air. And it was precisely this circumstance that became the reason for using polystyrene foam as an insulating material, since there is no better insulation in nature than air.

The entire production process for producing polystyrene foam includes several operations:

- Primary foaming of granular styrene under the influence of hot steam.

Foaming polystyrene

- Place the foam material in the drying chamber.

- Aging of foamed cooled granules.

- Secondary foaming.

- Cooling the resulting mass.

- Cutting products according to specified parameters.

Foaming of granules can be done several times depending on the required density of the finished product.

How is Eps - extruded polystyrene foam - produced?

The technological process for the production of raw materials for polystyrene foam and extruded polystyrene is the same. The differences begin at the foaming stage, where special additives are introduced into the raw material mass.

The process occurs under the influence of high-temperature steam in a special device called an extruder, where the mass, under the influence of steam, acquires a homogeneous and smooth consistency that can take on any shape.

Production of extruded polystyrene foam (penoplex)

Through a special hole in the extruder, the liquid mass is squeezed out into prepared forms under high pressure. Finished products, after cooling, have the necessary density, rigidity and at the same time plasticity. On sale you can find insulation called penoplex, which is nothing more than extruded polystyrene foam.

The difference between such concepts as polystyrene foam and extruded polystyrene foam lies in the production technology, as a result of which the materials acquire different technical properties and characteristics.

Fighting noise

Using polystyrene foam or extruded polystyrene foam as a sound insulator will not justify the investment in this project. Due to the sufficiently high density, there is a slight decrease in the power of the sound wave within 50 dB. They cannot differ in this indicator due to almost the same density. Therefore, if, in addition to insulation, it is necessary to fully protect the house from external noise, it is recommended to opt for other materials.

Comparison of polystyrene foam and expanded polystyrene

Expanded polystyrene is used for external work, as it is resistant to moisture.

To select the optimal insulation for specific purposes, the technical characteristics of the material should be taken into account.

Thermal conductivity

This is one of the most important indicators that you need to pay attention to when choosing a suitable thermal insulation material. It determines how high-quality and effective the insulation of a house or any other building will be.

Expanded polystyrene is the leader here. Its thermal conductivity is 0.028 W/m*K, while that of foam plastic is one and a half times higher - 0.039.

With high-quality insulation, the heat loss of a building when using polystyrene foam is significantly reduced.

Mechanical strength

PPS has high mechanical strength, therefore it is suitable for floor insulation.

An indicator in which two materials that are similar in appearance are very different. It becomes especially important if you plan to insulate the walls from the outside, since the insulation will have to withstand certain loads. At the same time, it should not break - any crack will turn into a cold bridge, significantly reducing the effectiveness of thermal insulation. It is necessary to take into account not only compression loads, but also bending loads.

Here, polystyrene foam also outperforms polystyrene foam. It can withstand pressure around 0.4-1 MPa and bending load around 0.25-0.5 MPa. Such a significant variation is explained by different brands of insulation, as well as the thickness of the sheets. Similar indicators for foam plastic are 0.05-0.2 and 0.07-0.2 MPa. Therefore, if you need insulation that can withstand fairly heavy loads, it is better to give preference to expanded polystyrene - it will last much longer.

High strength allows you to make various products from polystyrene foam - ceiling tiles, baseboards and much more.

Ability to absorb water

Polystyrene foam is covered with plaster, since the material absorbs more water than polystyrene foam.

In damp climates, this parameter must be taken into account. If the insulation becomes saturated with moisture, its thermal insulation properties will sharply decrease and its efficiency will drop significantly. Chemical insulation is not subject to rotting, it dries quite quickly and returns to its original characteristics, but it is better to choose a material that practically does not absorb water.

To determine hydrophobicity, the thermal insulation material is immersed in water for 24 hours and 30 days. Due to this, the foam absorbs quite a lot of water - 2% of the volume of insulation per day and 4% per month. The micropores between the granules are quickly filled with moisture. Because of this, it is recommended to use the material indoors or protect it with high-quality waterproofing to reduce contact with moisture to a minimum.

Expanded polystyrene absorbs water much worse - its indicators are 0.2 and 0.4%, respectively - it absorbs moisture ten times worse. The material can be used to insulate the external walls of a house.

Results

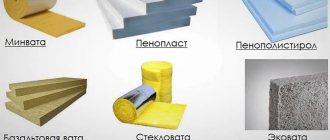

Today we reviewed the most commonly used home insulation materials. Based on the results of comparing different characteristics, we obtained data regarding thermal conductivity, vapor permeability, hygroscopicity and the degree of flammability of each of the insulation materials. All this data can be combined into one common table:

| Name of material | Thermal conductivity, W/m*K | Vapor permeability, mg/m*h*Pa | Moisture absorption,% | Flammability group |

| Minvata | 0,037-0,048 | 0,49-0,6 | 1,5 | NG |

| Styrofoam | 0,036-0,041 | 0,03 | 3 | G1-G4 |

| PPU | 0,023-0,035 | 0,02 | 2 | G2 |

| Penoizol | 0,028-0,034 | 0,21-0,24 | 18 | G1 |

| Ecowool | 0,032-0,041 | 0,3 | 1 | G2 |

In addition to these characteristics, we have determined that it is easiest to work with liquid insulation and ecowool. PPU, penoizol and ecowool (installation using the wet method) are simply sprayed onto the work surface. Dry ecowool is poured manually.

Scope of materials

Foam plastic is used in the following areas:

- Construction. The material is used as insulation for walls outside and inside, as well as for insulation of ceilings. Another use case is soundproofing in an apartment. In some cases, the balcony and loggia are also insulated. In places where there are no heavy loads on pipes and other utility networks, foam plastic is used as insulation. However, it is worth considering that for each individual type of insulation or sound insulation, different types of foam are provided. They are usually labeled so that the consumer can make their own choice.

- Shipbuilding. Surprisingly, foam plastic literally saves lives in emergency situations. And all because light boats, swimming rings and belts are made from it.

- Used as a dielectric.

- Furniture is made from this material.

- Polystyrene foam is used as packaging for dishes, electrical appliances or other types of equipment.

- It is often used as a material from which blanks for full-fledged products are made.

Expanded polystyrene is mainly used in construction. It is used to insulate building facades, apartment walls, floors and roofs, as well as ceilings. Like polystyrene foam, it is used to insulate structures that are not subject to strong mechanical stress. This type of insulation is used especially well in rooms with high humidity. In addition, the insulation of foundations and other parts of the building is also under the control of polystyrene foam.

Foam plastic as insulation in a wet facade system

Let us immediately make a reservation that the use of polystyrene foam as insulation for the walls of a house is only possible in a wet facade system. The use of foam plastic in ventilated facades under any facade material is prohibited - this is contrary to fire regulations.

Any random spark from your or a neighboring area from a barbecue or from the chimney of a bathhouse or house can be carried into the ventilation gap by the air flow. There, this spark can hit the foam that is open or covered with a waterproofing film. A constant flow of air in the ventilation gap brings the oxygen required to create an open fire and fan the source of fire. This way, all the necessary conditions for a fire to occur inside the ventilation façade, under the façade cladding, are met. The house will burn “inside the walls”; fire crews arriving at the scene of the fire will not be able to help with such a spread of fire.

Polystyrene foam as insulation for exterior walls of a house - only in a wet façade system.

Thus, the place of polystyrene foam on the facade of a modern house is under a layer of plaster and decorative solid non-flammable coatings. When there is no access to open fire and oxygen, and there is no direct exposure to moisture, polystyrene foam as insulation exhibits its best properties - light weight, low thermal conductivity and reasonable cost.

Summary and selection criteria

After listing all the pros and cons, characteristics and applications of each material, we can draw a conclusion about each of them.

Styrofoam:

- Inexpensive;

- Applicable in many areas;

- Serves as a good insulator;

- Can be used as a sound insulator;

- Flammable But this problem can be dealt with. For example, coat the material with a specialized solution.

- Good to use in rooms where there is almost no humidity. For others, it is better to use polystyrene foam.

Expanded polystyrene:

- Expensive;

- Used as insulation and sound insulator;

- Has high strength;

- The density of the material is high enough not to collapse under mechanical stress;

- It has a tensile strength and compression strength higher than that of polystyrene foam.

- This material is often used in rooms with high humidity, as it has high water repellency.

Thus, it is clear that if the budget is limited and construction is not waiting, then it is worth buying polystyrene foam. However, it is worth remembering that the stingy pays twice. Because you will have to invest in ensuring that the foam performs its functions well as insulation. Be careful when transporting it. And also familiarize yourself with the rules for its installation and installation.

Now about the choice of polystyrene foam and polystyrene foam.

Expanded polystyrene has high strength

When choosing, you must be guided by the following rules:

- Decide for what work and insulation what insulation is needed. In accordance with this, the grade of material is selected. It should not be lower than 40.

- It is worth paying attention to how the material was produced in accordance with GOST or specifications. Depending on this, the characteristics of the materials may differ.

- Another point when choosing a material is a small check: you need to break off a piece of the material and check how much it crumbles.

- The last point when choosing is knowledge of quality manufacturers, most often these are European companies, but there are also Russian ones - Penoplex.

In this article, we figured out the difference between polystyrene foam and expanded polystyrene. Which material is better and in what area.

Let's summarize

Considering polystyrene foam or expanded polystyrene as a heat insulator, it is definitely impossible to say that it is better. It is necessary to make the choice consciously, based on the specific conditions of the availability of funds, transportation, installation and operating conditions.

If we abstract from the surrounding world, then the analysis carried out will help to draw certain conclusions.

Having awarded 1 point for a clear advantage in position, 0.5 points for equality of characteristics, we find that polystyrene foam scores 8 points, and polystyrene foam scores 6. Objectively, it turns out that an object insulated with polystyrene foam more fully satisfies the basic needs and requirements of the consumer .

During the comparison, the goal was to show as objectively as possible the disadvantages and advantages of common heat insulators. Help everyone make choices that will not make them regret them over time.

Comparative characteristics

Based on the above information, it is possible to make a complete comparison of these insulation materials, as a result of which it will be possible to answer the question: is polystyrene foam or not? Thus, expanded polystyrene has low thermal conductivity, which ensures heat retention inside indoor buildings. For polystyrene foam this figure is significantly lower. This circumstance affects the cost of products.

Important! Expanded polystyrene is a fairly durable material. It can withstand extreme loads over long periods of time. The moisture resistance of the material is also at the highest level, which cannot be said about polystyrene foam.

However, the weak link in the characteristics of insulation materials is their flammability. Both products will not be able to provide reliable safety during a fire without additional processing.

Shrinkage of materials is of no small importance when choosing. The higher this parameter, the worse the performance of the insulation. In this comparison, foam loses again. It is easily deformed under external loads. It also does not tolerate exposure to sunlight.

Expanded polystyrene has all the qualities of a suitable insulation material. This circumstance is influenced by the manufacturing methods of the product. Thus, this material is somewhat similar to foam, but it does not crumble.

What is extruded polystyrene foam?

What is extruded polystyrene foam? This is also called extruded polystyrene foam; the peculiarity of this material is its production method, for example, ordinary polystyrene foam is foamed, which adds air to its structure and makes the foam cells filled with air. And extruded foam is produced by pressing raw materials and pushing them through extruders. This technology makes the foam more dense.

Its strength and moisture resistance depend on the strength of the foam; of course, the denser the foam, the higher these indicators will be. EPS practically does not allow moisture, gases, or water vapor to pass through, unlike mineral wool, which simply absorbs them. Even taking into account the high porosity of the material, water in EPS will not be able to rise by capillary action; it will simply remain in the voids. Extruded polystyrene foam materials do not allow steam and heat to pass through.

The material is resistant to temperature changes and does not change its properties during any temperature changes. EPPS is easy to install and is practically not subject to destruction. Manufacturers of EPS claim that when using the material as thermal insulation, you do not need to install a waterproofing layer, but a turnkey membrane roof installed by professional roofers will guarantee its long service life.

Serious disadvantages of the material will be its fire hazard; at temperatures above +70 degrees it can emit vapors harmful to human health, and this material is also afraid of contact with direct sunlight. Does not tolerate contact with solvents well.

Tips and tricks

When choosing insulation for your home, it is important to take into account its features, as well as follow certain rules and requirements:

- Determine the tasks that the insulation must accomplish during use. Once you make a decision, you need to choose the appropriate brand of insulation. Its indicator should not fall below 40.

- Consider the manufacturing methods of the product. The production of insulation materials must meet the requirements specified in GOST (e). Specifications for materials manufactured using different methods may vary.

- It doesn't hurt to do some research before purchasing. Its essence is as follows: Cut off a small piece of the product and make sure that it does not crumble too much. This circumstance indicates high-quality insulation.

- Don't forget about the manufacturers. It is better to give preference to a trusted company. This approach to business will help avoid unpleasant consequences in the future.

Thus, today's article looked at the differences between polystyrene foam and expanded polystyrene. Each material has its own individual characteristics, positive and negative sides. It is also important to follow the instructions for using the products. Based on the above data, it is easy to make the right choice. A responsible approach to business is the key to the best result.

Historical reference

The discovery of expanded polystyrene occurred about 50 years ago in Germany, where it almost immediately began to be used in construction. During the time that has passed since this discovery, research into its qualities, properties and advantages has not stopped. In particular, the Germans tested expanded polystyrene, which was extracted from houses built 40 years ago.

The studies carried out made it possible to determine that expanded polystyrene retained its properties by almost 90%, and this once again confirms the durability of this material.

How to choose polystyrene foam correctly

Expanded polystyrene is one of the most popular building materials. It is light, warm and cheap, and very easy to work with. Since the demand is great, there are more and more offers from manufacturers. And each of them assures that their polystyrene foam is the best, and its quality is beyond praise.

1. Lost by countless offers, do not rush to buy material. First, carefully study its parameters. If you need to insulate a facade, take polystyrene foam PSB-S, which is positioned as self-extinguishing. Its brand must be no lower than forty. And if the brand has a number of 25 or less, then don’t look in the direction of such material - it is only suitable for packaging, but not for construction work.

2. When purchasing material, check to what standards it is made. If a manufacturer manufactures products not according to GOST, but according to its own specifications, then the characteristics of the material may differ. For example, expanded polystyrene PBS-S-40 (grade forty) can have different densities - from 28 to 40 kilograms per cubic meter.

It is beneficial for the manufacturer to mislead the buyer in this way - less money is spent on the production of polystyrene foam of lower density. Therefore, you cannot rely only on the number in the brand name, but you must ask to see documents confirming the technical characteristics of expanded polystyrene.

3. Before purchasing, try breaking off a piece of material from the very edge. If it turns out to be low-grade packaging foam, it will break with a jagged edge with small round balls visible on the sides. The material obtained by extrusion has regular polyhedra at the site of a neat break. The fault line will run through some of them.

4. As for expanded polystyrene manufacturers, the best of them are European ones, Nova Chemicals, Styrochem, BASF. Russian manufacturing companies, such as Penoplex and TechnoNIKOL, are not far behind them. They have a production capacity that is quite enough to produce polystyrene foam of very high quality.

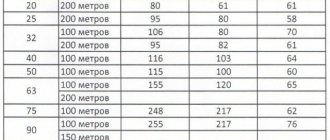

Price

Expanded polystyrene can be bought from 1300 rubles per 1m3. The cost may vary depending on the raw materials used in production. This also affects the brand of material, which is the difference between Penoplex in terms of density and operating temperature range.

The cost of 1 m3 of Penoplex is 3.5–4.5 thousand rubles. It may vary depending on your region and the season of purchase of the material. Often, when purchasing in bulk, material can be purchased cheaper; often the size of the discount is affected by the total purchase volume.

When purchasing, you need to take into account the need to cut the material and adjust individual elements; for this reason, it is necessary to increase the volume of the purchased batch of insulation by 10% of the calculated one.

How to lay polystyrene foam on the roof?

How to lay polystyrene foam on the roof? Of course, polystyrene foam is significantly inferior to insulation materials such as mineral wool. Due to the fact that it is impossible to lay polystyrene foam boards very tightly, unfilled voids will form cold bridges. These bridges will accumulate condensation, which will lead to stagnation of moisture and subsequent mold formation. Of course, expanded polystyrene is used to insulate roofs, but not so often.

So, for example, when insulating a pitched roof with a closed rafter system, a roofing pie with polystyrene foam will look like this:

- vapor barrier;

- insulation;

- waterproofing;

- sheathing;

- counter-lattice.

Before starting work, the surface must be cleaned and degreased. Next, we lay the foam between the beams of the rafter system. The foam sheets must be laid as tightly as possible, the seams between the sheets must be sealed, for this we use foam sealant.

For additional fastening of polystyrene foam sheets, you can use dowels. The next layer is a vapor barrier; to form this layer, it is best to use membrane sheets or foil materials; when calculating the cost of a membrane roof with polystyrene foam, you need to take into account the need to study the fire safety of materials. In addition, do not forget that PVC membranes and polystyrene foam cannot come into contact with bitumen.

The vapor barrier membrane film is stapled to the rafters, and there is no need to stretch the material much. It is better to glue the seams between the sheets with a special tape in order to maintain the high waterproofing properties of the material. Then a finishing layer of lining, plasterboard, etc. is mounted on the sheathing. If a membrane roof is installed professionally, the price may include the cost of professional soldering of the sheets. For such work, special welding machines are used, which allows the seams to be made airtight.

Expanded polystyrene in the door, what is it?

Expanded polystyrene in the door, what is it? Due to the fact that polystyrene foam has high vapor and sound resistance, noise insulation and sound insulation: we already know what the difference is. The difference is that one absorbs sound and the other reflects it.

It is convenient to use for filling doors. Doors that have such a filler inside will hold well indoors. Also, such doors can isolate from noise.

The main requirement for such fillers is safety, environmental friendliness, and moisture resistance. Of course, given the fact that polystyrene foam releases toxic substances at high temperatures, its use in residential areas is not advisable. In addition, the material does not allow moisture and air to pass through. Which can lead to the formation of condensation inside the doors, which, unlike roofs, do not have waterproofing and vapor barrier layers.