The stove can be called an integral heating structure of a Russian private home. After all, it allows you to heat the room and even cook dishes. Despite the emergence of a large number of different design options, the rocket stove still remains in demand among owners of dachas and full-fledged private residential buildings. Let's consider its design features, advantages, principle of operation, common metal models and the manufacturing process of 21 bricks, as well as designs with a stove bench.

A convenient version of the stove called “Rocket” Source chipmaker.ru

General information about the design

A distinctive feature of the design of the stove called “Rocket” is its simple device. It contains two main parts: a firebox and a smoke exhaust pipe. The fuel bunker can be vertical or at an angle relative to the horizon. It is even removed from the chimney. In addition, designs with two fuel bunkers are being created. The option is selected for a specific place of use and depending on the wishes of the person.

The rocket furnace can have one of the following designs:

- A vertical firebox, which is located some distance from the chimney. The length of the connecting section is not standardized. This part is used as a hob and to increase efficiency. Indeed, due to the elongated horizontal element of the stove, the heating surface increases. Therefore, it will take less time to warm up the room.

- The vertical fuel hopper is located next to the smoke exhaust pipe. This is a common option for an exclusively heating design.

- The firebox is located at an angle. The design allows for more convenient fuel loading.

Options for stoves called “Rocket” with corner fireboxes Source prom.st

The stove option, which is distinguished by the presence of two fuel bunkers, implies their location on the sides of the smoke exhaust pipe. In this case, the fireboxes have a vertical orientation. Moreover, they are created with a large cross-section. This design option is often used to heat water. Therefore, the stove design implies the presence of a special container on the chimney. It is usually installed on a special stand.

Types of products

The units differ in construction material:

- Metal - usually constructed from barrels, fire extinguishers, pipes, gas cylinders, sheet steel. The prevalence and availability of components makes it possible to manufacture a reliable and productive device.

- Clay-brick - Fireclay clay and brickwork have a high heat capacity, absorb heat well and warm up the room. When burning in such devices, the temperature increases to 1000 degrees. This material is also simple and easy to maintain.

- Based on improvised means - the simplest versions of rocket stoves are assembled from all sorts of available and cheap containers - steel buckets, cans. They are well suited for field use.

Advantages and disadvantages

The advantages of a rocket-type furnace include:

- high rate of heating of a room with an area of usually no more than 50 m2, if the structure is used in a house and is connected to a pre-created chimney;

- high efficiency of at least 85%;

- work on any type of solid fuel;

- absence of soot and soot, since the exhaust is a mixture of carbon and steam;

- low solid fuel consumption, almost 5 times less than what is required for the operation of a conventional furnace structure under the same operating conditions;

- long-term heat retention if the stove has been well preheated.

One of the options for a rocket-type stove for the home, which heats up quickly and retains heat for a long time Source pinimg.com

Despite a number of advantages, a long-burning rocket stove also has disadvantages. One of them is manual control. It is sometimes inconvenient to do this, because for the stove to function effectively you will have to constantly add solid fuel. In addition, many elements of the structure become very hot. Therefore, you have to use it carefully so as not to get burned.

The stove called “Rocket” is not used in baths. In addition, the design is not an attractive product. Therefore, it is not suitable for all interiors.

Features of using reactive furnaces

Being a long-burning system, the rocket stove requires preheating before use. As a rule, in mobile installations no one complies with this requirement - they consume little fuel, and the potbelly stove itself is most often used on the principle of “it works, oh well.” In stationary structures, warming up the furnace before starting is extremely important, since with a cold flame tube there can be no question of afterburning. The wood will burn without giving off heat, and the chimney will very quickly become covered with soot, tar and creosote.

The stove is heated using wood chips, paper or shavings, which are loaded into the firebox and set on fire. Reaching operating mode is judged by a humming sound in the heat channel. A loud sound indicates ineffective operation of the unit. As soon as the hum begins to subside, you need to start adding the main fuel. The vent should be completely open for the first 10–15 minutes. Then the air supply is reduced, focusing on the sound of the stove - it should “rustle” or “whisper”. After the wood burns out, the air duct of the firebox is covered to prevent heat from escaping from the room. Once every 2-3 days, ash is removed using a metal scoop and poker.

Maintenance of the jet stove is carried out no more than once a season. To do this, open the ash pan door, through which the remaining soot is removed. If necessary, clean the smoke channel using the hatch of its trap. It must be said that proper operation of a jet heater never leads to smoke in the room. All that is required of the owner is to follow the recommendations for using the “rocket” and not neglect safety rules.

General operating principle

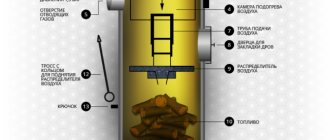

Any long-burning rocket works on the same principle. It is based on the thermal decomposition of the fuel used. Firewood is mainly used to kindle the structure. As a result of their combustion, gaseous substances are formed. They decompose, resulting in wood gas. It has high heat dissipation.

One of the options for the movement of combustion products in a furnace rocket structure Source etokirpichi.ru

If the stove has a horizontally located channel or it has an inclined design, then the combustion products move slowly. They do not go directly into the chimney. Due to this, the combustion products burn out in a horizontal or inclined channel. Therefore, more heat is generated as a result of the use of the structure.

The operating principle of reactive furnace devices is as follows:

- solid fuel is placed in the combustion chamber;

- ignition is carried out mainly with wood;

- during the combustion of solid fuel, gases are released;

- combustion products move through a vertical pipe.

The operating principle of a rocket furnace structure is very similar to the operation of a pyrolysis boiler. Thanks to a special device, the upper part of the product gets very hot. This allows you to cook different dishes, heat water in a metal container and even heat the room. However, for the latter option it is necessary to ensure the removal of smoke outside the building.

On a note! A rocket stove for a cauldron or other similar utensils must be equipped with a platform at the top of the vertical pipe.

Rocket stove design with a platform for preparing dishes Source rocket-pech.rf

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

What is the working principle?

The meaning of the functioning of a rocket stove is taken from other types of stoves and there are 2 options:

The design will work using the pyrolysis method.

- Natural gas and smoke circulation from within the system. A similar principle is used in a potbelly stove. Very often, such a stove design is suitable for people who plan to cook.

- Pyrolysis. The working principle of a rocket stove is based on the natural afterburning of unburned gas under conditions of limited oxygen supply to the combustion area. This option is not used for cooking, since it is impossible to create the necessary conditions, so it is considered an excellent option for home heating.

to come back to the beginning

Common models

In fact, there are different versions of the stove. One of the simplest products is a mobile model. This rocket stove is made from a profile pipe. Its operation saves time. At the same time, such a stove design consumes a small amount of fuel.

The mobile version of the stove is also compact in size. Specialists are able to produce such a structure in just a maximum of 3 hours.

Mobile versions of stoves called “Rocket” Source hitsad.ru

A distinctive feature of a simple unit is the movable lower part of the structure. It represents the bottom of the firebox. In other words, this is a grate. When it is mobile, it is easier to load fuel. The bottom of the combustion hopper, after being pulled out, can serve as a convenient stand for laying wood chips. In addition, such an element simplifies cleaning the stove. Thanks to its presence, it becomes more convenient to remove ash from the unit.

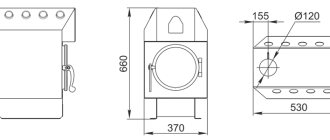

A metal rocket stove is made using a 150*150 mm profile pipe. Typically the wall thickness of this material is 3 mm. Additionally, craftsmen use a metal strip and a steel rod to make the grating.

On a note! A mobile oven made from a profile pipe is made to order or purchased ready-made from a specialized store.

Ready-made version of the stove Source prom.st

To create even the simplest stove, a drawing is always first developed. The work itself is being carried out in stages. During the manufacture of the structure, the master:

- Cuts the prepared pipe into blanks. Their length corresponds to the dimensions in the drawing.

- Makes markings on prepared workpieces. At the same time, a 45° cut is indicated on the edge of one of them.

- The cut pieces are welded to form a structure that looks like a boot.

When a stove is made from a profile pipe, the craftsman makes 20 mm long cuts on top of the chimney. They are needed to further secure the cross-shaped stand made of metal strips. It will be used to place the container. The master also uses steel strips to make a retractable frame.

A lattice of rods is fixed to the created frame. This element of the required size can also be purchased ready-made. If it is made by a master, then usually the distance between the rods is 10 mm. Then the specialist attaches a stand to the vertical pipe.

A stove called “Rocket” with a stand on a chimney pipe Source ebayimg.com

After manufacturing, the oven must be checked for functionality. To do this, firewood is loaded into the structure. Then it melts. If the structure is functioning normally, then wait for it to cool completely. After this, it is painted with heat-resistant paint.

On a note! Usually the combustion chamber is equipped with a door. To make it easy to use, a handle is welded.

Metal stove "Robinson"

One of the functional and convenient options is a design called Robinson. This type of baking product is popular in the country. It is also often used for outdoor recreation. This option is also made to order or purchased ready-made.

The combustion bunker of the Robinson stove is created from sheet steel or profiled pipe measuring 150*100 mm. Metal plates, fittings, and nuts are also used in production. A piece of round steel pipe is also being prepared.

A distinctive feature of the Robinson design is the presence of a rectangular firebox with a blower and a round chimney Source ad-cd.net

This rocket furnace is made from a profile pipe and is made with a blower. This compartment is separated from the firebox using an element that is created from reinforcement sections. This is a grate. Typically its cell size is 10 mm. It is welded to the walls of the combustion compartment.

Important! The grate is fixed at a distance of 300 mm from the bottom of the profile pipe.

At the next stage, the master attaches the nuts. They are used in the structure for screwing the legs. Their presence allows us to make the most stable product possible.

Next, a piece of round pipe is cut at one end at an angle of 30°. Then it is attached to the manufactured combustion bunker. Then the connection point of the parts is marked. This allows you to cut the exact hole through which flue gases will escape from the firebox. Finally, the master welds two parts. In this case, the smoke exhaust pipe is located strictly in a vertical plane.

Assembled Robinson stoves Source wp.com

A stand for a container, for example a pan, is made of five plates. They are pre-bent and connected. The result is a stand on which you can steadily place a large enough container for heating water or preparing food. Finally, the stove made of corrugated pipe is equipped with 3 legs.

FAQ

Can Rocket be used in a greenhouse?

Yes. A rocket stove is suitable for heating a greenhouse. The chimney pipe is buried in the ground. Other models are not capable of working in such conditions. For this stove, it is enough to have a small difference between the firebox (air inlet) and the end of the chimney. And there is no need for forced air supply at all.

How often should the rocket furnace firebox be cleaned of soot?

The main part of combustion products evaporates independently through the chimney pipe. You need to remove ashes from the firebox every 15–20 days.

A rocket stove is an opportunity to quickly heat a small room and cook food using a minimum amount of fuel

Improved variants of rocket stove design

The modernized design is a standard stove with a door on the combustion chamber. The presence of such a part with a handle allows you to conveniently regulate the heat generated. Usually the door is secured so that it opens upward.

Rocket stove structures with doors Source ct.yimg.com

A more advanced option is a design with a damper. It’s good if it moves in different directions - down, right, left. It is recommended to provide such an element when ordering a stove structure. Experts also advise making the firebox from metal 3-5 mm thick.

A square pipe stove is another design option. Basically, rolled products with a square cross-section are used for the manufacture of a vertical section. You can even place a hob on it, created from a wide metal plate. This design will allow you to prepare various dishes as conveniently as possible.

Stove "Antoshka"

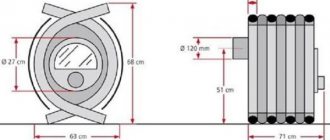

This type of rocket stove design has a more complex design. The product is also a mobile option. Its craftsmen also make it from profile pipes. It usually has a square cross-section. Steel plates, rods, scarves and corners are also used in the work.

One of the options for the Antoshka stove Source pinimg.com

This rocket camp stove can even have an additional heated surface. It is located horizontally from the inclined firebox to the vertical pipe. You can place some container on it where water will be heated or a dish will be prepared. Thanks to its presence, the surrounding space will warm up faster.

When making an Antoshka stove, the craftsman first marks a vertical pipe. He makes cuts on it at an angle of 30°. Then a combustion chamber and a smaller blower are cut out of a square pipe. Then holes are cut in the upper and lower planes of the firebox. They are necessary for smoke removal and air intake.

Next, all three parts are connected into a single structure. While welding the blower to the firebox, a grate is also installed. It is made of metal rod. In this case, the rear walls of the firebox and ash pan are covered with metal plates. The vertical pipe is fastened using metal corners. They will strengthen the structure.

One of the possible schemes of the Antoshka stove with a horizontally located ash pan, a side handle for carrying and a stand made of steel plates on a vertical pipe Source noyabrsk.teplozhar.ru

At the next stage, supporting elements from a metal corner are welded. After all, the product must be sustainable. After this, the so-called horizontal hob is attached, if provided for by the design. Finally, 4 bent rods are welded onto the vertical smoke exhaust pipe. You will get a kind of stand for placing, for example, a pan.

Brick rocket stove structure

Reactive stoves are made not only from metal. They are also made from bricks. Complex designs even have a number of internal channels. The combustion products first pass through them and only then rise to the upper part of the furnace. The hob is also usually located here.

When building such a structure, there is no need to create additional air supply. The movement of combustion products is provided by the chimney. As its length increases, thrust increases.

A brick rocket stove is made using special blocks. They are selected taking into account the calorific value of the fuel that will be used in the design. If you decide to heat the stove using coal, then choose refractory bricks. It must be used to construct all parts of the rocket stove product. The reason for this is the high calorie content of such fuel.

On a note! When laying bricks, the master uses an aqueous solution to which clay and sand are added.

For laying a brick oven, an aqueous solution with the addition of clay and sand is used Source designbuybuild.co.uk

The procedure for creating a rocket brick kiln

Work on laying a stove structure always begins with choosing the location for its construction. The customer must also explain to the craftsman what size he wants the stove to be. Taking this data into account, the specialist will first develop a design diagram.

On a note! The rocket brick stove does not have a complex design. It can even be folded using just 21 bricks. This design is suitable for cooking or heating various dishes outdoors.

Selection of installation location

The stove structure is often created in the house. Experts advise building it as close to the front door as possible. This arrangement will allow you to conveniently throw ash out of the structure. You don’t have to move it around the room or even several rooms. Therefore, the likelihood of contamination of the living space will be reduced.

Experts also advise installing the chimney pipe in a place where there are no rafters. They must be located at least 400 mm from the chimney. In addition, the stove is erected without adjacent to the outer wall. This arrangement will reduce heat loss.

The rocket brick kiln is not placed close to the outer wall Source pinimg.com

Preparation of the solution

When laying the furnace structure, no cement mortar is used. Craftsmen are well aware that it cracks when it is exposed to high temperatures. It is for this reason that specialists always use a mixture of clay and sand with the addition of water.

The amount of each component in the solution depends on the quality of the clay component. For kneading, one portion of clay and two or three parts of sand are often used.

Important! Less clay is added to the solution if it has a high fat content.

The master carries out the kneading, adhering to strictly proven technology. First the clay is soaked. Then it is filtered. Only after this sand is added. Then the viscosity of the solution must be checked.

Clay is combined with sand only after it has been pre-soaked and filtered Source 1nerudnyi.ru

For these purposes, the master can use a wooden stick. It is first placed in the solution, then pulled out of it and shaken well. After this, the mixture should remain on the wooden stick. If its thickness is less than 2 mm, then clay is added to the solution. When mixtures are more than 3 mm, sand is used as an additive.

Experienced specialists know well that the reliability of the entire structure depends on the quality of the solution. An incorrectly prepared mixture will not allow the bricks to be firmly fixed. Moreover, it has to smooth out all the unevenness. Therefore, it must have the required thickness and elasticity.

Jet stove - what is it?

The home heat that comes from a jet stove cannot be provided by any modern heater.

A jet stove, or, as it is also called, a rocket stove, actually has nothing in common with modern technologies. The only thing that makes this heating unit look like a space vehicle is the intense flow of flame and the humming associated with improper operation. Nevertheless, it cannot be said that the rocket stove is a completely backward device in technical terms. Despite its simple design, it uses the most advanced methods of burning solid fuels:

- pyrolytic combustion of gases released during dry distillation of solid fuel;

- movement of gaseous products through the furnace channels, which does not require forced ejection due to draft.

This is what a simple jet-powered stove looks like

The simplest “rocket” is a curved piece of large diameter pipe. Firewood or other fuel is placed in a short horizontal section and set on fire. At first, the heating device works like an ordinary potbelly stove, but this is only until the temperature of the longer vertical part, which acts as a chimney, rises. The red-hot metal promotes the re-ignition of flammable substances and the appearance of a vacuum at the top point of the chimney. Due to increased draft, the air flow to the firewood increases, which significantly increases the burning intensity. In order to achieve even greater efficiency from this original device, the firebox opening is equipped with a door. When the cross-section of the air channel decreases, the supply of oxygen to the firewood stops and its pyrolytic decomposition into gaseous hydrocarbons begins. But in such a simple installation they will not burn completely - for this you will need to set up a separate area for afterburning the flue gases. By the way, it is this, as well as the thermal insulation of the chimney, that allows more complex “rockets” to successfully compete with other solid fuel units. As for the simplest design we are considering, it is often used for cooking or heating food. All that is required for this is to equip a convenient platform for a pot or kettle on the vertical section of the stove.

Geography of application of rocket heating units

Being a simple and convenient heating and cooking unit, the rocket stove is widely used in both mobile and stationary versions. Most often it is used:

- for heating residential premises;

- as equipment for drying fruits;

- for heating greenhouses;

- to ensure normal working conditions in workshops or garages;

- to maintain above-zero temperatures in warehouses, utility buildings, etc.

Thanks to its simplicity, unpretentiousness and reliability, the jet heater enjoys well-deserved respect among fishermen and hunters, car rally enthusiasts and survivalists. There is even a special version, the purpose of which is indicated by the name - “Robinson”.

Advantages and disadvantages of the rocket stove

Despite its simple design, the rocket stove has many advantages:

- efficiency level at the level of the best examples of modern heating equipment operating on solid fuel;

- efficiency - to achieve the required temperature, the jet unit will consume four times less firewood than a traditional stove;

- heating temperature above 1000 °C;

- the ability to use any type of solid fuel, including dry plant waste, cones, pine needles and shavings;

- complete combustion and environmental friendliness - during operation, the flame temperature increases so much that the soot ignites. Rocket stove smoke consists primarily of water vapor and carbon dioxide;

- possibility of additional fuel loading for continuous operation of the heating device;

- simplicity and reliability;

- the presence of portable structures intended for mobile use.

The heating unit is not without its drawbacks. Operation of the device is associated with the risk of carbon monoxide entering the home. The stove cannot be used to heat a large house, and attempts to install a water heat exchanger in the combustion zone lead to a decrease in thermal power and disruption of normal operation. The disadvantages include the low aesthetic value of the design, which, however, is a very ambiguous statement, since for lovers of ethno-style, the design of the stove is a real find.

Video description

How to lay a rocket stove structure made of 21 bricks is shown in the following video:

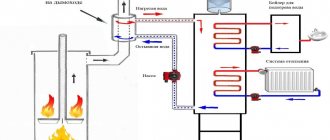

Installation of a rocket stove structure with a stove bench

A brick rocket stove, which is complemented by a heated bench, is one of the practical design options. Although it takes more time to create. After all, it is a massive structure, which is actually a combined option.

On a note! The bed of the stove design can be made in the form of a sofa or bed. They often place a mattress on a heated place and rest during the day or at night.

The process of manufacturing a rocket stove structure with a stove bench is performed as follows:

- Create a 100 mm recess so that the firebox can be installed. In the process of this work, fireclay bricks are used. The base is laid out of it.

- The formwork is installed strictly along the perimeter of the furnace structure. At the same stage, reinforcement or mesh is laid on the brick base.

- Fill the structure with solution.

- Wait until the concrete base dries. It cures within 24 hours.

- Lay out a brick base.

Concrete stove base with a recess for the fuel compartment Source kuhnidizayn.ru

- The walls are formed by installing several rows of bricks.

- A lower missile channel is created.

- Lay bricks across the lower channel. In this case, the firebox compartment and the smoke exhaust hole are left unblocked. Only the combustion chamber is covered with bricks.

- They take the body from an old cylindrical boiler, which is cut off on both sides. This allows you to get a large diameter pipe.

- Attach the flange to the bottom of the old housing. It is needed for installing a pipe of a horizontally located heat exchanger. All connections are made by welding.

- The outlet pipe is welded to the boiler body.

- The cylindrical structure is treated with a primer, and then several layers of heat-resistant paint are applied to it.

- Weld a branch on the side of a horizontal chimney. It will be used to create the ash pit.

- Lay out the brick flame tube strictly vertically. Its size is 180*180 mm.

Lined vertical smoke exhaust duct Source stroyfora.ru

- Place the casing on the lined brick pipe.

- Perlite balls are placed in the space between the flame tube and the casing.

- Cover the lower part of the flame tube with a clay solution to prevent the heat-insulating material from spilling out.

- The firebox cover is made from the cut-off boiler part.

- A solution is prepared from a clay mixture and sawdust, the amount of which can reach 50%.

- Coat the previously created structure with the resulting mixture.

- The outer contour of the stove is formed from bricks.

On a note! When giving the stove structure the desired shape, you can use bags of crushed stone. They are laid out in the required sequence, then coated with adobe mixture. This is a clay solution with the addition of sawdust.

- Place a 200-liter barrel on the prepared base, the lower pipe of which should be directed towards the bench. This will be the outer casing of the furnace.

- A corrugated channel is formed. Street air will be supplied through it. The channel is laid to the firebox. Thanks to its presence, the stove will use air from the street, and not from the room, to burn wood.

Corrugated pipe to form a channel through which street air will be supplied to the firebox Source sod-98.ru

- The functionality of the stove structure is checked by lighting it.

- Connect the pipe on the brick base to the heat exchanger pipelines in the stove bench.

- The bed is shaped in the same way as when shaping the appearance of the main body.

Formed stove rocket structure with a stove bench Source pinimg.com

How to heat?

Taking into account the long path of the smoke removal system in a stationary structure, it is necessary to start the operating mode after preheating. When working with rocket stoves, this rule does not need to be followed. But a large oven is first heated with dry shavings, paper, and other suitable consumables. For loading, use a blower with the door open.

The degree of readiness is assessed by noise reduction. At this stage, the usual loading of fuel into the appropriate part of the furnace is carried out.

What kind of rocket stove would you install in your dacha?

PurchasedHomemade

To adjust the operating mode, use the displacement of the main hopper cover and the adjustment of the blower door. If there is a lot of oxygen, combustion is activated while simultaneously blocking the pyrolysis process. Under such conditions, fuel consumption indicators deteriorate and carbon deposits form in the riser.

It should be emphasized that it is difficult to clean a closed central channel. In the worst situation, its throughput is reduced to critically low values.

Briefly about the main thing

The rocket furnace structure is made of metal or bricks. The device consists of a vertical, inclined or horizontal firebox and a smoke exhaust duct. The design is characterized by high efficiency, fast heating, absence of soot, and the ability to retain heat for a long time.

A rocket-type furnace operates by burning solid fuel. The structure is heated by combustion products, which move slowly due to the presence of a vertical, inclined or horizontal channel.

They purchase ready-made or custom-made stoves “Robinson” and “Antoshka”. The design has a platform for installing a cauldron or other similar utensils. There are also models with a hob. A brick structure can be laid out quickly using 21 bricks. It is also created with a heated bed.