In order for a house to be comfortable to live in, it must have high-quality insulation. A variety of materials can be used for it, but most often basalt or mineral wool is used for these purposes. They are similar in some properties. Therefore, in order to make an informed choice, it is necessary to understand: when basalt wool or mineral wool is used, which is better and why.

Mineral insulation in a roll Source tproekt.com

Basalt wool

To prepare it, the stone is crushed until small particles are obtained. They need to be heated to such a high temperature that they begin to melt. From this mass thin threads are made, on the basis of which cotton wool is created. The raw material for production is basalt, which is a volcanic rock.

Slag fiber in a roll Source tproekt.com

Video description

Mineral wool or stone wool?

Mineral wool is also produced from metallurgical slag. In particular, it differs from other varieties in its high tensile strength.

This material has gained popularity when used for various purposes. It is suitable not only for thermal protection of the walls or roof of a house, but also for the installation of high-temperature systems and pipelines. A layer of such material can be used to insulate cabins for insulation and noise protection.

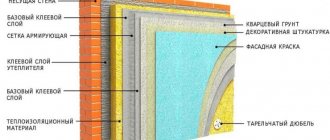

Installation of the insulating layer Source remontami.ru

Comparison of materials

Installation is carried out in the same way in both cases. However, it is necessary to take into account the difference between mineral wool and basalt wool.

It should be taken into account that basalt wool has a relatively dense consistency. This makes it more brittle and less elastic. Both materials can be used to insulate horizontal or vertical surfaces. Thermal insulation material may completely or partially lose its properties when exposed to moisture.

Basalt wool can withstand thirty percent wetness with virtually no loss. Since this material does not shrink, it can be used for laying in a screed or placed under plaster.

Mineral wool has less density and weight. It is soft and can absorb liquid well. When installing, it is important to provide this insulation with reliable moisture protection and vapor barrier.

Installation of basalt insulation Source pro-instrymenti.ru

Manufacturers of insulation

Buyers are provided with a wide range of thermal insulation materials. Leading enterprises, such as ROCKWOOL, Isover, IZOVOL, TechnoNIKOL and others, use high-quality raw materials, the latest equipment and unique manufacturing technologies, which ensure compliance with the highest standards. Features, advantages and disadvantages of products from large companies are presented separately.

Basalt insulation ISOVER Frame house. photo source here

Video description

Basalt wool or mineral wool: comparison of insulation.

Mineral wool is more convenient in this regard. Its fibers are relatively long, soft and durable. This material produces virtually no dust and is more environmentally friendly.

What these materials have in common is that they are both non-flammable. It is believed that these types of insulation are not susceptible to attacks by rodents or pests. If moisture penetrates inside, it will not lead to rotting or fungus formation. The thermal insulation properties of both materials are approximately the same.

Installation of roof insulation Source pulscen.ru

Usage

The main use is to provide thermal insulation. In this sense, the materials have approximately the same characteristics. There are differences, but they are minor.

These materials can also be used for sound insulation. This plays an important role, for example, where there is heavy traffic or in apartment buildings with good audibility.

Insulation of facades with slabs Source vitebsk.pulscen.by

Some designs use the load-bearing properties of the materials in question. An example is inversion roofs. In this case, the density and elasticity of the material play an important role.

Both basalt and mineral wool have a high degree of fire protection. If they get caught in a fire, the fibers will not burn, but will bake. Some other insulation materials are significantly inferior in such characteristics, being flammable materials. For example, this applies to polystyrene foam.

Product characteristics

*

Technical characteristics and consumer properties have made mineral wool popular among builders. Let's look at the critical indicators.

Thermal conductivity

Thermal conductivity is the main characteristic of mineral wool; it is precisely to preserve heat that products are needed.

The indicator characterizes the amount of energy that the material transmits per unit of time. You can find the value in manufacturer certificates and on product packaging. On average, according to GOST standards for production, it is in the range of 0.041-0.046 W/(m*S). The value depends on the thickness and length of the fibers, as well as the density of the material and is measured at a strictly defined temperature.

Important! You should not trust the manufacturer if the packaging indicates an indicator of 0.030-0.035 Vm*C. Such values indicate an attempt to mislead the buyer or an incorrect test method, which also indirectly indicates the integrity of production workers.

Density

The indicator depends on the number of fibers contained per unit volume. The indicator is measured in kg/m3. Products on the market fall in the range from 20 to 220 kg/m3.

Soundproofing properties

Noise absorption properties are important when insulating interfloor ceilings and walls of houses in populated areas with heavy traffic.

There are two approaches to achieving silence - sound insulation and sound absorption.

In the first case, vibrations and acoustic waves are reflected from the insulator, in the second they are absorbed.

The packages indicate a number from 0 to 1. A material with a coefficient close to zero reflects sounds, and one closer to one absorbs. It would be optimal to purchase mineral wool with an index of 0.4 to 0.6.

Vapor permeability

The indicator indicates the ability of the material to pass moisture through itself without accumulating it.

Attention is paid to the characteristic when walls made of porous material, for example, timber or logs, are insulated. In buildings made of monolithic concrete, the characteristic is not so important.

Geometric dimensions

Manufacturers adapt to the needs of construction organizations and produce products that are as close as possible to the standards of governing documents.

Mineral wool slabs are usually made 600x1000 mm, with a thickness of 50 to 200 mm. Width 60 cm - close to the pitch of the rafter system on the roofs of houses. This parameter is suitable for insulation using the dry ventilated facade method. A length of 1 meter is convenient when calculating the amount of material needed.

In rolls, the width varies from 60 to 120 cm, with a thickness of 50 – 150 mm. The length of the material may vary, but usually it is 9 - 10 m.

What to choose

At first glance, both materials are of equal quality. However, when choosing, you need to take into account the characteristics of a particular situation and how basalt wool differs from mineral wool. To determine which material is best, you need to pay attention to the following:

- You need to decide why exactly these materials are being purchased. They may be required not only to insulate a house, but also to protect pipelines, sewers, and underground tanks.

- If you need the material to provide protection from rodents, then glass wool is better suited in this regard. This feature will be useful, for example. When insulating basements or basements.

- If an insulator is required for noise protection, then a layer of glass wool is better suited.

- When insulating walls and roofs, the ability of basalt wool not to shrink is useful.

- Slag wool is the most vulnerable material among those presented to moisture. When working with it in conditions of high humidity, it is advisable to avoid direct contact with the metal. Otherwise, this may cause the development of corrosion processes.

- Basalt slabs have higher protection from moisture. They are practically not exposed to it and absorb it poorly.

The right material will allow you to create a comfortable and cozy home.

Insulation of facades with slabs Source vitebsk.pulscen.by

Features of installation of mineral slabs

To buy high-quality insulation suitable for specific purposes, you need to consider:

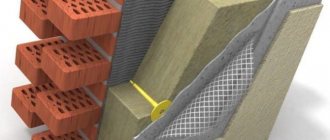

- for external wall insulation, it is advisable to choose a density of at least 80 kg/m3 and a thickness of 100 mm;

- for the roof, the density should be 30-40 kg/m3, and the thickness should be 150 mm;

- To soundproof partitions, the density must be at least 50 kg/m3, and the thicker it is, the better it will isolate the room from extraneous noise.

For fastening, special adhesive mixtures or umbrella dowels (with a large head) are used. The slab is cut with an ordinary, but sharply sharpened knife. If the density is over 100 kg/m3, you can use a wood saw.

Before insulating the ventilated facade, the walls are additionally protected with a vapor barrier material, which will release condensation to the outside and prevent cold air from penetrating into the premises. If the surface of the slabs must be as flat as possible (for example, under a “wet facade”), a lathing made of wooden beams or a metal profile may be needed.

When thermally insulating the roof, it is advisable to lay a windproof membrane on top of the basalt slabs.

To ensure ventilation under the future roof, a counter-lattice is created on top of the insulation - for this, bars 10-15 mm thick will be enough. Date: September 25, 2022

Carrying out work

Creating a thermal insulation layer requires following general rules. Regardless of the characteristics of a particular material, it is necessary to create conditions for its most effective use. The following must be taken into account:

- Although different types have different resistance to moisture, it is necessary to provide adequate protection for them. It is important to understand that, for example, if rain wets the thermal insulation layer of the roof, it will cease to perform its functions. A similar situation arose when groundwater entered the layer protecting the basement.

- If moisture has already gotten inside, you need to create the opportunity for ventilation and vapor barrier. Under such conditions, the liquid will gradually evaporate, ensuring the normal functionality of the protective layer.

- Although the material is often considered to be well protected from rodents and insects, it is nevertheless better to take additional measures to ensure this.

- In the production of basalt or mineral wool, special chemical compounds are used. During production, safety measures are observed to ensure the harmlessness of the material. However, you need to understand that there are different technological processes and in some cases you cannot be sure of 100% environmental friendliness. Therefore, when installing a layer, you need to ensure that it is well closed.

- During operation, dust may be generated to varying degrees, which can be harmful to health. This is due to the fragility of the fibers. Therefore, it is important to ensure that the wool layer is sealed tightly.

- In conditions of high humidity and for outdoor work, it is beneficial to use basalt wool. It will be more effective due to good mechanical strength and relatively high moisture resistance. To secure it, you can use a lathing or use special dowels with a wide head instead.

- If you need a material that will have to be used in conditions of strong heating, then it is more profitable to use basalt wool. This is due to increased resistance to temperature effects and the fact that no harmful substances are released when heated.

- If the materials in question are used to insulate areas of complex configuration and high-quality insulation cannot be counted on, it is necessary to ensure that the safest material in this regard is used.

Advantages and disadvantages

The raw materials used, production technology, equipment used are parameters that affect the positive and negative parameters of each material. Basalt wool has the following advantages:

- resistance to open fire, chemicals, clumping and caking,

- low level of water absorption,

- long service life,

- low thermal conductivity coefficient,

- ease of installation,

- light weight,

- ease of transportation,

- environmental cleanliness,

- versatility.

The disadvantages of stone insulation include high cost and the need to be careful when installing, since particles released during cutting and installation, getting on the skin and mucous membranes, can cause allergies and irritation, the use of protective equipment is necessary; connection seams formed during installation, after some time, contribute to a decrease in thermal insulation properties; Rodents can make their home in the insulation.

Basalt insulation ISOBOX ExtraLight-31 100Х600Х1200 mm/4.32m2/0.432m3/6pcs. Stroylandia Photos

The main advantages of glass wool include:

- excellent thermal insulation properties,

- environmental friendliness,

- versatility,

- low water absorption coefficient,

- non-toxic,

- non-flammability,

- ease of transportation and installation,

- resistance to fungus and mold,

- low specific gravity,

- safe for human health.

Glass wool has more disadvantages than its basalt-based counterpart : high hygroscopicity, short service life (no more than 10 years, after which the material ceases to provide thermal insulation properties due to shrinkage), installation must be carried out using protective equipment, low resistance to impact chemical components, attractive to rodents.

Slag wool, actively used in the Soviet Union, is now used quite rarely. The unpopularity is due to a number of disadvantages:

- high percentage of residual acidity of the slag,

- low resistance to temperature changes,

- good moisture absorption,

- coarseness and fragility of fibers,

- limited scope of application, it is not recommended for use in rooms and buildings with high levels of humidity, in wooden buildings, since when wet the material undergoes rotting.

As a result, slag materials are now being used in temporary buildings.

Thermal insulation Ursa Geo M-11F 12500x1200x50mm foil based on fiberglass. Photo by Maxidom

But slag wool also has positive properties:

- low cost,

- high sound absorption coefficient,

- ensuring good thermal insulation,

- ease of installation,

- long service life, but provided there is no exposure to moisture and high temperatures.

Thus, fibrous materials have both similar and different characteristics. Some parameters should be considered in detail, indicating specific values, which is done below.