Relatives bought a small two-story apartment with autonomous heating using a gas double-circuit boiler. An electric boiler was recently installed. Physically, I don’t understand why, a double-boiler boiler heats hot water. Please explain why an electric boiler is installed in the system.

An electric boiler is installed in addition to the existing gas heating device for:

1 Have an additional source of hot water supply (DHW) What is useful if you have to pay for gas according to consumption categories (to avoid gas consumption in the summer so that at the end of the year you will remain in a lower consumption category, with a lower cost per cubic meter of gas)

2 Have a reserve of hot water so that during peak water consumption there will be no “beating” of the hot water temperature

(a double-circuit boiler is capable of producing a limited amount of hot water per unit of time

maximum 12 liters per minute) That is, when someone takes a shower, and at this time in the kitchen they begin to wash the dishes, the person taking the shower receives less warm water on his back, but if there are several sanitary facilities, then everything can be more regular and more fun.

The boiler contains a supply of water heated to a given temperature and this allows you to smooth out temperature fluctuations.

3 The boiler also allows you to organize recirculation of hot water.

We used to heat ourselves with coal-stove heating, and heat the water with an electric boiler. When the gas was installed, I did not dismantle the boiler for reasons: “maybe it will do.” And it really came in handy when the sensor on the boiler failed and it stopped heating water. While they were repairing it, they used hot water from the boiler for a week.

For the same reasons, I did not dismantle the stove, you never know what will happen.

The boiler can be connected to the system, also as a guarantee that in the event of a boiler breakdown, the system will not defrost.

Or maybe it’s just that your relatives found it easier to hang a boiler than to pull a line of hot water up.

It also happens that not all boilers are equipped with pumps powerful enough to raise water to the 2nd floor.

There are many options.

Maybe they use the boiler as an expander? I know a case where people had scanty pressure in the water supply and the boiler did not perceive this pressure to the workers, so it did not start. An acquaintance bought an electric boiler and connected it to the system - the boiler turns on, the coolant expanding creates operating pressure and the boiler starts. (I would, of course, in this case, prefer an expander and a pump, but there are so many opinions among us.)

The lineup

Let's start with the fact that there are two models that work using the same technology, but the boiler itself is located differently:

- Models with a free-standing boiler.

- With built-in reservoir.

First option

For this, a separate gas boiler and a separate boiler are purchased. Here it is very important to accurately correlate the boiler power with the volume of the container. It may happen that the performance of a gas boiler is not enough to heat the water inside the boiler to a certain temperature (often up to +60°C) in a short period of time. This means you will not receive either hot water or an efficient heating system. Why?

It's all about the principle of operation of wall-mounted or floor-standing gas boilers with a boiler. It turns out that the coolant, heating up inside the boiler, is redistributed as needed. If the temperature of water for household needs inside the boiler corresponds to the programmed indicator, then the coolant works for the heating system. As soon as the temperature becomes lower, it is immediately redistributed to the DHW system. That is, the supply of coolant to the heating system is immediately turned off. This means the temperature in the house becomes lower.

Floor-standing with boiler

Attention! The larger the boiler volume you choose, the higher the likelihood that when the coolant is redistributed, the temperature in the house will always be lower than necessary. That is why we already said above that it is necessary to accurately correlate two indicators: the power of the heating unit and the volume of the boiler.

Currently, manufacturers offer two options for this type of boiler:

- Single-circuit with a separate hot water tank.

- Dual-circuit.

In the first case, these are floor-standing gas boilers with high power. In the second, these are wall structures. And here the question arises, which one to choose? It all depends on how much area you have to heat. If this is an apartment or a small country house (dacha), then the second option. If this is a large private house, then only the first one. But keep in mind that each type has its own advantages and disadvantages.

With built-in boiler

For example, a double-circuit gas boiler with a boiler has a heat exchanger with a small cross-section, that is, with a small cross-section. This is a minus. In addition, salt and mud deposits quickly settle in them, which means they will have to be washed and purged more often. In addition, maintenance of a single-circuit boiler and the boiler itself is simpler; in fact, the consumer receives a kind of central network through which the coolant flows, used for both heating and domestic hot water.

Connecting a water heater to a double-circuit boiler.

Hello to you, my reader! I dedicate this post to an interesting question that different people periodically ask me. This question sounds like this: “I heard that you can connect a storage water heater to a double-circuit boiler and not buy an indirect heating boiler. Is it true?" I will say right away that such a scheme exists. Let's figure out together why all this is needed.

Why connect a water heater to a double-circuit boiler?

In summer, the double-circuit boiler does not work to maintain the required temperature in the rooms. It is switched to a special “summer” mode, in which only hot water supply works. When a flow appears through the heat exchanger, the burner turns on. Often, a characteristic pop is heard due to the ignition of gas in the combustion chamber. Listening to these claps all day is below average pleasure, and it’s unnecessary stress for the boiler. To solve this problem, a scheme for connecting a storage water heater to the hot water supply circuit of the boiler was invented. A storage water heater acts as a battery in which hot water is stored.

Schemes for connecting a water heater to a gas boiler.

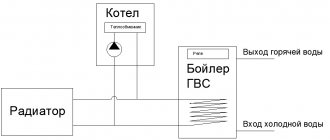

Now let's move on to considering the diagram for connecting the water heater to the DHW circuit of the boiler. So, look at the picture below:

The figure shows that the storage water heater is connected separately to the boiler and to consumers. The separation is done using two three-way valves with servo drives. Switching the servos and turning on the circulation pump is carried out by a device called a “power control circuit”. This device is connected to the water heater thermostat. There are no standard solutions here and you will have to invent this device from scratch.

For comparison, I will give you another diagram from the technical document:

There are no three-way valves and no power management circuitry in this circuit. The circulation pump is powered directly through the water heater thermostat. This is done according to the following scheme:

The upper diagram has one important feature - the water heater there has three connection pipes. This is a non-standard option for electric water heaters, but indirect heating boilers have a recirculation input and output, through which it is quite possible to organize a similar connection scheme. Well, for ordinary electric water heaters we will again have to invent something. Sometimes such a “collective farm” takes a lot of time, effort and money. Now let's understand how water circulates in the upper circuit. To do this, I will give two more pictures:

In the upper figures, arrows indicate the direction of water circulation in each operating mode. In this scheme, heating and water withdrawal can occur simultaneously.

Summary of the article.

Based on the results, I can say that such a scheme has a right to life, but is more suitable for lovers of non-standard solutions and technical creativity. The above schemes are not the only possible ones, and you can certainly find other, perhaps more elegant, solutions to this problem on the Internet. However, in my opinion, this scheme should only be used if you are critically short of money for an indirect heating boiler. That's all for now, I'm waiting for your comments and reposts on social networks! See you again!

znayteplo.ru

Other options

We talked above about storage-type structures. That is, the water in the tank has a certain volume, which heats up. But there are also flow-type models on the market. In them, water is heated to a certain temperature as it moves through a special heat exchanger.

Typically, the heat exchanger is made of a material with high thermal conductivity and good corrosion resistance. Therefore, this unit is most often made of copper, aluminum or stainless steel. But their shape is coiled, because you have to install a heat exchanger of quite a long length in a small volume. And the longer it is, the more efficiently it heats the water. By the way, water heating gas boilers, which were already mentioned above, operate using this system.

Simple connection diagram

Principle of operation

The operating principle of a gas heating boiler is quite simple. Through the return pipeline from the heating network inside the house, cooled water is supplied by a circulation pump to the input of the heating circuit heat exchanger.

At low coolant temperatures, an electromechanical valve opens, supplying fuel to the injector. The igniter ignites the gas and the combustion process begins. The boiler constantly operates on the heating circuit.

The DHW circuit begins to function when the tap on the mixer is opened. This thermal scheme of the boiler operation in the summer makes it similar to the operation of a conventional gas water heater.

How does a condensing boiler work?

The name “condensing” boiler units was acquired due to the fact that they implement a technology for obtaining additional thermal energy by modifying the aggregate state of condensate from steam located in the flue gases.

Operating principle of a condensing boiler

During the combustion of natural gas in a condensing gas boiler, water vapor is created, which in traditional units evaporates and is released into the atmosphere through a chimney.

The temperature at which the condensate is converted is called the dew point of +55 C, and the technological process is called condensation. This temperature corresponds to the parameters of the return network water entering the boiler from the heating system. If it is more than +60 C, then the condensing boiler will work like a traditional device with low efficiency.

In addition, condensate creates a very aggressive environment containing acids. Therefore, its collection and disposal will require a special neutralization system, which the liquid must undergo before it can be discharged into the city sewer.

Condensing boiler. Photo source: allbuildingtips.com

In general, a convection gas boiler is an expensive device, however, fuel savings of up to 20% allow it to pay for itself within five years.

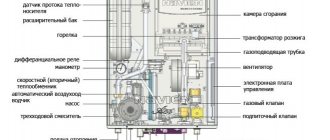

The principle of operation of a double-circuit gas boiler

The operating principle of a double-circuit boiler unit is designed for 2 thermal modes:

- heating;

- DHW.

In heating mode, the operation of the boiler is practically no different from a single-boiler boiler. Starting the burner involves a fairly long start-up period in order to increase the temperature in the heating circuit to operating levels. When the main mode is reached, the flow of fuel to the burner stops.

The internal air temperature sensor allows you to automatically regulate the temperature and sends a signal to open the gas when the permissible level decreases.

Modern double-circuit Baksi boilers, in addition to an internal temperature sensor, are equipped with a special weather-dependent automatic system that regulates the operation of the boiler based on the outside air temperature outside the building window. The burner increases the temperature of the heating water, the circulation of which through the pipelines of the heating system is ensured by a circulation pump. A three-way valve built into the system switches the movement of coolant through the heating circuit or into the DHW system.

Today's double-circuit heating boilers are equipped with automatic control and safety systems. In emergency situations, flame and draft sensors are capable of shutting off the gas supply to the boiler through an electromagnetic valve, thereby preventing the creation of an increased concentration of gas in the boiler room.

This mechanism not only shuts off the gas supply, but also informs others about the danger using sound and light alarms, and also starts exhaust ventilation to reduce the content of methane and carbon monoxide in the air.

Advantages of single-circuit boilers with a boiler

So, we have established that single-circuit gas boilers with a separate boiler are considered the most popular today. Therefore, there is a need to outline all its advantages:

- Large internal cross-section of the heat exchanger. This helps reduce scale formation. Unfortunately, the quality of water used in domestic water supply systems leaves much to be desired.

- High reliability indicator, which is determined by the simplicity of the design of the device itself.

- In this model, the consumption of thermal energy is more rational, and, therefore, this is the reason for the high efficiency and savings in fuel consumption.

- The water inside the boiler almost always has a certain temperature. It is not affected by pressure surges inside the gas line or temperature surges inside the heating system of the house.

- Ease of maintenance, where it is necessary to note a minimum of automation devices.

- The entire set (gas boiler plus boiler) consistently provides hot water to your home, regardless of the time of day. In addition, the heating also works stably.

- Simple built-in automation will help you set the necessary parameters for hot water in the DHW system and coolant in the heating system. She also controls these parameters.

Gas boiler with built-in boiler: pros and cons

Today on the market of autonomous heating systems there are models for all types of premises. Among the most popular options are single- and double-circuit gas boilers. Both devices are capable of heating and maintaining the optimal temperature of the coolant in the heating system. However, their approach to hot water supply is different. An indirect heating boiler (IBC) will have to be separately purchased and connected to a single-circuit boiler, while a double-circuit device already has a built-in water tank. Let's consider in which cases it is preferable to go with the first option, and in which the second will be indispensable.

Common installation mistakes

The manufacturer, referring to SNIP standards, requires during installation to insulate cold water/hot water supply pipes with a layer of 20 mm and a thermal conductivity of 0.030 W/m2. At the same time, both the pipe and all components are insulated.

They suffer without insulation and a cold water network, being a place where condensation accumulates en masse, creating unsanitary conditions. Another common mistake is installation without an expansion tank, especially for tanks with a volume of 200 liters or more.

List of other violations:

- The electrical cable is routed in a high-temperature area or on sharp metal surfaces.

- The procedure for connecting to the water supply system specified in the diagram by the manufacturer has been violated.

- The vertical/horizontal level of the installation is broken.

- There is no ground loop for the heater.

- The power supply parameters do not meet the requirements of the manufacturer specified in the passport data.

Before starting the device, you must carefully inspect the circuit; any, even the smallest mistake in the installation can become fatal during its operation, so every self-respecting owner should know how to connect the boiler correctly.

Materials and tools

Materials:

- Pipes, shut-off valves, check valves - there are no special requirements for them: use the same materials as for working with hot water supply or heating systems.

- Expansion tank - a separate one is required for the domestic water supply system; it serves to prevent sudden pressure changes when opening/closing taps.

Attention! The tank must be designed for use with hot water; usually such devices are marked with special markings. Circulation pump - as a rule, a separate pump is installed in the heat exchange circuit with the water heater. Circulation pump - as a rule, a separate pump is installed in the heat exchange circuit with the water heater

Circulation pump - as a rule, a separate pump is installed in the heat exchange circuit with the water heater.

In addition, in DHW systems with recirculation, a separate pump is required to circulate water in the DHW circuit.

This will eliminate the need to wait for hot water to arrive through long pipes from the installation site of the water heater: the water will immediately be hot.

- Wires and small electrical wiring - if you plan to connect the water heater thermostat to the boiler automation.

- Fasteners - especially in case of wall installation, also for securing pipes and pumps.

- Standard plumbing set of sealants, seals, gaskets.

Tool:

- gas key;

- wrenches of various diameters;

- Adjustable wrench;

- building level;

- hammer drill, screwdrivers, screwdriver;

- Minimum electrician's kit: knife, wire cutters, electrical tape, phase tester.

Installation process: how to connect

Ideally, the boiler should be located as close as possible to the heating boiler to minimize heat loss.

Cold water is always supplied to the bottom pipe of the boiler, and hot water is drawn from the top.

- Choose a location for the water heater so that it is not in the way and is easy to maintain. Mount brackets, stands, and secure it to them.

- Connect to the cold water network: make a tap, install a shut-off valve and a coarse filter.

- Through a tee, take the cold water line to consumers, connect the second output to the boiler through a safety valve.

- Connect the domestic hot water line to the boiler, not forgetting about the expansion tank on it. In addition, install bypass taps so that you can disconnect it from the circuit during maintenance.

- Now connect the boiler to the gas boiler according to one of the given diagrams. Don't forget to turn off the boiler and shut off the system before connecting!

- Connect electronics, sensors, pumps according to the instructions.

Startup and testing

After installation, the first thing you need to do is connect and fill the boiler with cold water. Make sure that all air pockets are removed from the system and that the boiler is completely filled to avoid overheating.

When the boiler is full, set the desired temperature using automation. Start the boiler, open the coolant supply from the heating system to the boiler.

When the system reaches operating mode, make sure that the safety valve (usually set to 8 bar) is not leaking, i.e. there is no excess pressure in the system. You should also check all connections, seals and taps for leaks.

Kinds

There are different design options for double-circuit boilers. They can be conditionally united according to specific characteristics.

By installation method:

- wall- mounted Gas boilers that are mounted in a hinged manner on strong, preferably load-bearing walls. The installation method implies the absence of massive and heavy parts. Because of this, the power of wall-mounted boilers does not exceed 35-40 kW;

- floor . They are installed directly on the floor (or on a stand). There are no restrictions on weight and dimensions, so the power of floor-standing boilers can be much greater - up to 100 kW and higher. Also, floor-standing units can be connected in a cascade (usually up to 4 pieces), which allows you to create a powerful heating unit.

By heat exchanger type:

- separate . The design of such boilers has two units - a primary (main) unit in which the coolant is heated, and a secondary unit (usually plate-type, for hot water supply);

- bithermic . This design resembles a coaxial pipe in which coolant flows through the outer cavity, and water for hot water flows through the inner cavity. This design significantly changed the specifics of water heating. The temperature has stabilized, there are no noticeable differences in the DHW supply . However, such a heat exchanger is susceptible to the formation of lime deposits. Flushing does not give noticeable results, and replacing a bithermic heat exchanger is too complicated and expensive.

The material for the heat exchanger can be:

- stainless steel . Used for units of budget units;

- copper . Used in expensive boilers from the most famous manufacturers. They have high performance capabilities and are lightweight, which is important in wall structures;

- ductile cast iron . Heat exchangers of this type are found in floor-standing boilers, where massive parts can be used. The qualities of cast iron make it possible to obtain a high heating effect and equalize temperature changes under harsh operating conditions.

By type of combustion chamber:

- open (atmospheric) . The burner operates on air that comes directly from the room. Smoke removal occurs naturally, using a stove-type draft. To do this, the boiler must be connected to the central chimney. This method is considered outdated and unstable, since it depends on external causes - gusts of wind, drafts, and other factors;

- closed (turbocharged) . The chamber does not communicate with the outside atmosphere, so air is supplied into it using a fan. In this case, excess pressure arises in the chamber, displacing smoke and other combustion gases out. In such designs, a coaxial type chimney is used, the outer pipe of which serves to supply air, and the inner pipe exhausts smoke.

By heat transfer method:

- convection _ Conventional heating of a coil with coolant in a burner flame;

- condensation _ A two-stage heating of the coolant is carried out, preliminary (with heat obtained from condensation of wet smoke) and main (in the usual way). It is necessary to take into account that full operation of such boilers is possible only in low-temperature heating systems - with heated floors, or in regions with high winter temperatures . The critical temperature difference between inside and outside the room at which the process stops is 20°. In Russia this is impossible even in the southern regions.

IMPORTANT!

When choosing a condensing boiler, you should know exactly the principle of its operation and be confident in the possibility of using it in the existing conditions. Otherwise, the money will be wasted.

Operating principle

The operation of a double-circuit boiler consists of two streams:

- The coolant enters the primary heat exchanger and receives the maximum possible temperature. It is then passed through a secondary heat exchanger, where it transfers some of the resulting energy to prepare hot water. After this, it passes into a three-way valve, receives the desired temperature by mixing some of the return flow, and is discharged into the heating circuit for a new circulation circle;

- cold water enters the boiler and is passed through a secondary heat exchanger. After that, it goes to the consumption devices. When the tap opens, water begins to pass through the plate device and heat up in flow mode. The more water is drawn, the lower the water temperature - at high flow rates it does not have time to heat up properly.

The coolant is prepared in the flame of a gas burner. For its operation, air is required, which is supplied by the turbocharger fan. Excess pressure arises, pushing the smoke out through a special coaxial chimney.

The operation of all system components is constantly monitored by self-diagnosis sensors.

They immediately signal the occurrence of failures or malfunctions, the control board places an alert on the display, and in some dangerous situations immediately turns off and locks the boiler.

NOTE!

Non-volatile models are equipped only with mechanical parts. They are much simpler and do not have fans, centrifugal pumps or control units. The functioning of the system occurs on the basis of natural processes of traction and lifting of warm layers of liquid upward.

Norms and rules for installing a boiler in an apartment

After the owner has made a decision and purchased an electric water heater, he must install it. Before installing a boiler in an apartment, you need to decide who will perform the installation work.

For this purpose, many owners invite specialists who have the necessary tools and experience, and are ready to install a water heating device efficiently and reliably in a couple of hours. The cost of installing a boiler will depend on the power and location.

Home craftsmen can easily handle this on their own. Before connecting the boiler, so that the installed equipment lasts a long time and does not become a source of dangerous situations, you will need to follow a number of rules:

- The wall for placing the device must be solid; installation of the water heater on partitions made of plasterboard or wood is prohibited.

- The location area is as close as possible to the intra-house distribution of utilities: water, sewerage and electricity.

- The electrical outlet for turning on the boiler must be located near the device and used only for it, with a direct connection without an extension cord.

- Free space is left in front of the water heater for maintenance and repair, and it is also placed as high as possible so that it does not obstruct the passage of people.

- For emergency drainage of water, the device must have access to a sewerage system.

- You will also need to first ground the boiler and install RCD protection on the power line.

- The boiler installation diagram must be carried out in accordance with the manufacturer's recommendations. To turn off the water heater for repair or maintenance, install shut-off valves and a safety relief valve, according to the standard sizes indicated in the documentation for the heater.

- If the boiler design does not provide a drainage line with a valve, it is installed on the cold water supply pipes at the lowest point in front of the storage tank.