The Planar air heating device, produced in Samara, is widely popular. If there is not enough heat in the car, it is an indispensable assistant, even in the most severe winter weather. In the cabin of a small passenger car model or a spacious van, the driver and passengers become as comfortable as possible in a short period of time.

The operation of the device is based on a simple principle - drawing surrounding air masses into the heating chamber. When fuel burns, thermal energy is released. It is sent to heat the air, which then enters the cabin.

Operating principle and features of the device

One of the advantages that a planar heater has is the ability to regulate the heating power. For this purpose, the device has a special handle on the regulator, which can be easily turned and set to the desired position.

Having set the desired power value, there is no need to interfere with the further operation of the device. It will be controlled automatically:

- When the temperature drops to a critical minimum level, the Planar turns on

- A constant increase in heat inside the cabin will gradually reduce power, reducing the supply of warm air

Circulation pumping units - design and principle of operation

Closed heating systems require forced circulation of hot water. This function is performed by circulation pumps, which consist of a metal motor or rotor attached to a housing, most often made of stainless steel. The release of the coolant is ensured by the impeller. It is located on the rotor shaft. This entire system is driven by an electric motor.

Circulation pump

Also in the design of the described installations there are the following elements:

- shut-off and check valves;

- flow part (usually made of bronze alloy);

- thermostat (it protects the pump from overheating and ensures economical operation of the device);

- work timer;

- connector (male).

When installed in a heating system, the pump draws in water and then delivers it into the pipeline due to centrifugal force. This force is generated when the impeller produces rotational movements. The circulation pump will work effectively only if the pressure it creates can easily cope with the resistance (hydraulic) of various components of the heating system (radiator, pipeline itself).

Video of work

The Planar heater device includes not only a power regulator in the form of a rotary knob, but also a timer. The latter is necessary in order to turn off the installation after prolonged operation.

The device is designed in such a way as to make the work autonomous in all aspects. Automation also monitors the current state of each working element located inside. The ignition process begins only when the control element is convinced that all components are in working order. This ensures a very high level of safety during operation.

The workflow can be described in more detail as follows:

- First of all, the combustion chamber is purged

- The glow plugs are then heated to the desired temperature.

- The necessary portions of air and fuel are supplied inside the combustion chamber

- Direct combustion of fuel occurs

- The candle maintains it until the process stabilizes, after which it turns off

To ensure that the resulting flame remains within normal limits, it is controlled by an appropriate indicator. If the temperature limit is exceeded, the control unit will stop burning.

Despite the high level of automation, turning off the device is supported in manual mode. The combustion chamber begins to ventilate. The fuel supply stops completely.

Some features of the Planar heater device

As a rule, fuel enters the combustion chamber of the device directly from the fuel tank of the vehicle. However, this option is not the only one possible. Sometimes the device has its own container into which the fuel necessary for operation is poured.

Features of work in various situations

Of course, the Planar heating device is very useful and indispensable in cold winters. However, many car enthusiasts do not risk installing it because they are afraid of incorrect operation in emergency situations.

Engineers took into account all possible features of operating the device in various conditions. Let's look at some of them:

- The operation of the heater is constantly controlled automatically. If it is faulty, the warning LED (orange or red) lights up.

- The device will not allow the heat exchanger to overheat - in such a situation it will turn off

- There may be cases when combustion stops due to spontaneous reasons - in such situations the installation also automatically shuts down

- As a result of an unsuccessful start of the heating equipment, the automation will make several restarts. If each of them fails, a fault warning will be issued.

Constant power surges can be very dangerous. The control unit will ensure the operation of the device only in situations where it does not go beyond normal limits:

- Onboard voltage 12 V (device 4DM-12) – from 10.5 V to 16 V

- On-board voltage 24 V (device 4DM-24) – from 20.5 V to 30 V

Overheating is often caused by incorrect installation of equipment. It occurs in cases where the inlet and outlet openings of the heater were blocked.

Installing a circulation pump with your own hands: instructions, connection, photo of work

Autonomous heating of a country house with natural circulation is characterized by a common problem.

Uneven movement of the coolant through the system leads to uneven heating of heating devices, especially if the heating system is quite extensive.

Heating heat pumps solve the problem of uneven movement of the coolant, turning the heating into a forced circulation heating system.

Why install a circulation pump

If you are faced with problems of uneven heating of the heating system around the house, you can solve it in two ways:

- Replace all heating pipes by installing larger diameter pipes;

- Or install a circulation pump in the system.

Obviously, installing a circulation pump is much cheaper and more practical than replacing pipes. By installing a circulation pump into the system, you can solve several problems:

- The heating of heating devices will be more uniform;

- The heating system circuit will expand significantly;

- The pump will eliminate the problem of air locks.

It is worth noting that to install a circulation pump in a ready-made heating system, you do not have to do complex installation work. Tap-in technology is used

Selection (calculation) of a circulation pump

To select a circulation pump, you need to calculate its power. If you have a complex heating system, it is better to entrust the calculation of the pump to a specialist. In a simple heating system, the power of the required pump is calculated by the formula:

The calculation will allow you to select a pump according to the parameter: maximum water output or throughput.

Paying attention

Important! When operating, circulation pumps produce a fairly strong “buzzing” sound. This parameter may be indicated in the pump descriptions and you need to pay attention to it; the smaller it is, the better.

Material for work

Materials you will need:

- The pump itself;

- Connecting fittings for tapping the pump;

- Check valve or bypass valve;

- Two shut-off valves (ball valves) for installation on both sides of the pump;

- Coarse filter;

- Connecting coupling with lock nut;

- Plumbing winding and paste.

For work, prepare the following tool:

- Adjustable wrenches and wrenches of the required size;

- Welding.

Selecting a pump installation location

A modern “wet” type circulation pump can be installed in both the return and direct heating branches. Traditionally, the circulation pump is placed in the “return” in front of the boiler in order to:

- Reduce wear and increase the service life of the pump rotor;

- Avoid boiler boiling due to air being drawn out of the boiler by the pump;

- Damage to the pump due to possible boiling of the boiler, especially solid fuel.

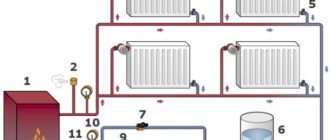

Instructions for connecting the circulation pump

Note: There are two options for pump tapping: installing a shut-off valve or installing a ball valve on the main tapping line.

- When installing the pump in an existing heating network, first drain all the coolant;

- If necessary, clean the heating pipes;

A bypass is installed at the pump installation site. The diameter of the bypass pipe must be made smaller than the diameter of the main pipe;

We install a dirty filter in front of the pump. The filter has an arrow for water movement. It will stop the system sludge;

- The pump shaft must be installed horizontally. An arrow for coolant movement is shown on the pump body;

- Shut-off valves (ball valves) are installed before and after the pump. They play a technical role in case of repairs.;

- A shut-off valve or ball valve is placed on the main coolant pipe;

When assembling, we adhere to the diagram;

After installation of the pump is completed, the system is filled with coolant. Next, the pump screw is opened to bleed air (water will appear in the screw hole).

Important! The installation of the circulation pump is complete. If the heating system is shorter than 80 meters, then one circulation pump is sufficient

Photo of vertical installation of a circulation pump with a ball valve

Photo of vertical installation of a pump with three valves

Electrical connection of the pump

Due to the fact that water flows through the pump, the electrical power supply circuit of the pump must be protected by an RCD (residual current device) with a cut-off current of 30 mA. You can connect the pump to power:

- Through a socket with a grounding contact and degree of protection IP44;

- Directly, without sockets, using the cable included with the pump or a PVS cable 3×1.5 mm.

Obotoplenii.ru

Planar heater: the main advantages of its use

Among car owners, especially truckers who spend most of their time on the road, the planar heater deservedly receives a lot of positive feedback. Domestic development, in comparison with imported analogues, is reliable, but less expensive.

A large number of positive characteristics include:

Planar heaters are widely used in vehicles used for transporting medicines, drinks, animals, process liquids, etc. They are actively used by drivers of cougars, cranes and other special equipment.

About the choice of equipment and the rules for its independent calculation

The key indicator that determines the efficiency of the circulation pump is its power. For a household heating system, there is no need to try to purchase the highest-power installation. It will only make a loud noise and waste electricity.

Mounted circulation pump

You need to correctly calculate the power of the unit based on the following data:

- hot water pressure indicator;

- pipe section;

- productivity and throughput of the heating boiler;

- coolant temperature.

Safety precautions

One of the main aspects of using a Planar heater is compliance with safety regulations. Let's look at the most significant rules:

- If the device has been turned off, it can be turned on again only after 10 seconds

- Do not turn off the power during the purge cycle.

- The heater must be disconnected from the network if the body is subjected to welding work

- It is recommended to turn off the device when refueling the car.

Anyone can install a planar heater on their own. However, for greater confidence in its subsequent reliability and performance, it is recommended to entrust this process to a professional. The cost of services is relatively low and significantly lower than the cost of possible restoration or repair.

The considered device for heating cars in winter or small, but always well-ventilated rooms (gatehouse, change house, etc.) is in demand. However, despite the many benefits, cost can be a bit of a barrier. On average, prices for various models start from 18 thousand rubles.

As mentioned earlier, you can install heating equipment yourself. In order to save time and for greater reliability, you should contact a specialist, whose service cost starts from 5-6 thousand rubles.

Since insulating the radiator grille (previous entry) had less effect than I thought, and in the cold in traffic jams the engine temperature needle went to the far left zone, I thought about installing a cabin heater. It didn't take me long to choose. I decided on the power almost immediately - 4 kW. I don’t see any point in putting less in the 110th Defender. I thought a little longer about the brand. At that time (autumn 2014), Webasto and Eberspacher cost about 50 thousand, and Planar 17 thousand. Since I planned to install it myself, I bought Planar 44D-12-GP. The cost of an error is less, and I didn’t want to overpay three times for a device that is a little quieter (in Defender, yeah) and has the ability, when purchasing additional options. block for 10-12 thousand can be launched remotely. In addition, the issue of spare parts and their cost for Webasto and Eberspacher is not entirely obvious.