Home / Gas boilers

Back

Published: 06/07/2019

Reading time: 5 min

0

6281

Installation of heating in household plots, in the absence of central heating systems, is carried out taking into account the available natural fuel in the region of location and its price.

Based on these criteria, today the cheapest source is gas, which makes the AOGV gas boiler one of the most promising types of individual heating.

The advantages are enhanced by the fact that such devices are easy to operate due to the absence of the need to load coal fuel, while ensuring complete combustion and protecting the environment from harmful emissions.

- 1 Decoding of AOGV

- 2 Advantages of AOGV boilers

- 3 Design and technical characteristics

- 4 Operating principle

- 5 Boiler manufacturers AOGV

- 6 Brief overview of models

- 7 Maintenance

Decoding AOGV

The abbreviation boiler AOGV 11 6 stands for simply:

- A - apparatus;

- O - heating;

- G - gas;

- B - hot water.

- 11 6 - boiler power 11.6 kW.

AOGV boilers for individual heating of apartments and houses differ from conventional standard boilers because they are energy independent, since they are able to operate without a power source and are equipped with an automated control system - an automatic monitoring and control system that independently controls the operating modes of the equipment and combustion in the furnace.

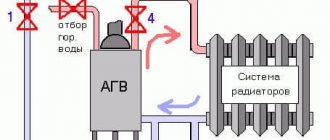

Operating principle of a standard closed loop installation:

- The coolant leaves the unit to heating devices with air vents.

- The circulation pump with the upcoming sump tank is placed on the return pipeline in front of the entrance to the boiler.

- The expansion tank is mounted at the highest point of the heating system.

- In systems operating with natural circulation, it is necessary to lay pipes with a slope.

About company

Before the Great Patriotic War, the Zhukovsky Machine-Building Plant produced a variety of metal structures, and in the post-war period, equipment for aviation maintenance. It still produces similar equipment for the domestic and foreign markets.

The company also produces heating equipment. Today, over 30 options are produced with a power from 11 to 68 kW. The most popular modification of the Zhukovsky MZ is the AOGV boiler. The remaining series - AKGV and KOV - are in demand among Russian consumers. The company has diplomas and distinctions for the high quality of its products.

Advantages of AOGV boilers

The main advantages of AOGV, which distinguish it from other gas analogues:

- Versatility is expressed in the ability to work both from a central gas pipeline and from imported bottled gas; for this you only need to change the type of burner device.

- Autonomy, in the absence of voltage in the house electrical network, the electronics in the automatic control of a floor-standing boiler are completely replaced by mechanics.

- Mobility is expressed in the fact that you can choose models for rooms of different sizes and heat loads or power, which is reflected in the name, for example, AOGV 23 boiler - maximum power 23 kW.

- Affordable prices for installation and commissioning; installation of AOGV costs approximately 1.5 times less than Western-assembled double-circuit boilers.

AGV modifications

Considering the variety of modifications of gas water heating devices on the market, it is worth understanding how the AOGV differs from a gas boiler. Looking ahead a little, there is no fundamental difference between the devices; all the differences lie in small nuances.

If we talk in detail, then everything that distinguishes an AOGV from a boiler comes down to the following points:

- Glass thermometers have been replaced with modern Italian components;

- Honeywell products began to be used as automation elements;

- The design is supplemented with a piezo ignition device;

- The last difference between the AOGV and the boiler is that the appearance of modern modifications has been slightly improved, for which a higher quality coating has been used.

Device and technical characteristics

In the Russian Federation, the main suppliers of AOGV are the Borinsky and Zhukovsky plants; for the same power, the technical characteristics of the units are almost the same.

The Borinsky plant produces a line of heaters with a power from 7 to 29 kW in two versions - single-circuit and combined, which makes it possible to economically heat houses with an area of up to 100 m2.

Design of Borino boilers AOGV 29:

- Open combustion chamber with air intake from the room.

- The installation scheme has the ability for natural and forced ventilation.

- In buildings where it is technically impossible to organize good air exchange, you can install an electric fan.

- In the upper part of the firebox above the burner there is a jacket with coolant.

- The device is equipped with separate heat exchangers for heating and hot water.

- A safety system that turns off the boiler with a sensor in the form of a copper thermocouple works in tandem with an electromagnetic valve that cuts off the gas if the torch goes out.

Installation features

To protect flammable surfaces, a sheet of metal is nailed to the walls and floor.

In order for the OGV units to work properly after installation, the following recommendations of specialists are followed:

- if possible, it is better to install the heating element in a separate room;

- for floor options you will have to build an additional reinforced foundation;

- the diameter of the chimney should not be less than 14-15 cm, and its height – 5 m;

- the smoke exhaust pipe must be additionally insulated to prevent condensation from appearing inside;

- if the design has an open combustion chamber, the room is equipped with forced ventilation;

- a sheet of metal measuring 1*1 m is nailed to the floor in front of the boiler;

- the minimum distance from the walls during installation is 20 cm, and all surfaces must be treated with non-flammable material.

AOGV is a floor or wall heating unit that works equally well both in a private house and in an apartment. However, the choice of equipment must be made correctly. It is better not to select high-power devices for small structures, as this will lead to unnecessary fuel consumption.

Principle of operation

In order to ensure high-quality heating of the coolant with automatic regulation and safe operation of the equipment, the following structural elements are installed:

- A magnetic valve that shuts off gas to the burner when the torch breaks or the draft decreases below the minimum parameters established by the passport data.

- Two-position thermostat (on/off) for automatically maintaining the set temperature of hot water in a pipe heat exchanger, transmitting a signal to the gas burner, with temperature adjustment in the range from 50 to 90 C.

- Traction sensor with signal transmission to igniters and shut-off magnetic valve.

- Fittings for connecting coolant and two outlets for hot water supply and heating.

- A cylindrical tank is connected to an in-house pipe system with internal heat exchangers, which increases the efficiency of the installation.

The house system consists of: supply and return pipelines, heating radiators, expansion tank, shut-off and control valves. Under the influence of natural circulation, water enters the device from the return pipeline, where it is heated by fuel combustion products and passes into heat exchangers for heating and hot water supply, cools, transferring heat to the external circuit, and then returns through the return pipeline to the unit.

Automation of the new AGV

It completely controls the entire process of heating water. And the automation unit itself consists of:

- a temperature sensor that controls the water temperature;

- an electromagnet, which is responsible for controlling the main gas supply valve;

- thermocouple, which is mounted near the igniter. Heated by a constantly burning torch, it creates an electric current in the circuit;

- traction sensor. It is mounted in the chimney and controls the optimal draft of the pipe.

Boiler manufacturers AOGV

of the Zhukovsky Mechanical Plant is more popular among consumers ; similar boilers are produced in Belarus.

The most popular are atmospheric boilers equipped with:

- Steel heat exchanger, and for 2-circuit systems.

- The DHW boiler is made of copper.

- Fuel modulation, ability to work on natural and liquefied sources.

- The system constructively takes into account the realities of the gas transportation system of the Russian Federation - low parameters in the pipeline.

- Affordable prices compared to foreign analogues. For example, the fee for a steel AOGV is about 300 euros, which is 2 times lower than analogues in the EU.

New generation of AGV devices

Russian factories produce AOGV - 23.2 - 1. This is a household heating gas cylinder. It is intended for heating houses with an area of 140 - 200 square meters. meters. There is also a device with slightly less power for heating an area of 100 - 140 square meters. m. Otherwise, these two types of heaters are practically no different from each other.

Recently, a more modern model AKGV - 23.2 - 1 with a water circuit has appeared. It can also be used to heat a home and supply hot water. And instead of a pipe running inside the boiler, three steel sections are installed, which are made using a special stamping method and are hollow inside. The sections are mounted vertically and are connected into one chimney, through which gas combustion products flow into a separate chimney pipe.

How to choose gas heating boilers?

New generation of AGV devices

Water is heated using a special coil, which encircles the entire circuit inside the boiler and the water that is used for everyday life flows through it. And in the boiler the water for heating is also heated. That is, it turns out that this device is two in one.

The new model includes an injection burner, which ensures efficient combustion of gas without residue. This type of burner works perfectly even when the gas pressure in the pipeline is low.

Brief overview of models

Zhukovsky Machine Plant sells AOGV in the range from 11.6 to 29.0 kW in 3 versions: economy, station wagon and comfort. They differ in the level of automatic control, completeness and the country of origin of the auxiliary equipment. All devices with piezo ignition for autonomy of the unit.

The OGV gas burner is made of stainless steel ensuring durability. The inner jacket of the hot water supply is made of copper, and the body is protected by polymer materials. The automation is equipped with temperature sensors and regulators to ensure a constant indoor air environment and prevent emergency conditions.

Automation equipment:

- Thermocouple for monitoring gas flow.

- Stabilizer of supply air to the firebox, to compensate for air changes in windy weather, which can tear the torch away from the burner.

Burner

An important element of a heating device is the burner. Siberia gas boilers are equipped with open type burners with natural draft. There are 2 of them:

- ignition;

- atmospheric.

They are made of stainless, high-carbon steel, which does not deform at high temperatures. Produced in Italy.

Burners in AOGV Siberia provide environmentally friendly, clean combustion without the release of harmful substances. They are equipped with a built-in gas control system that stops the gas supply when the flame goes out.

It lights up due to the built-in piezo ignition. The spark ignites the functioning burner, and the igniter ignites the atmospheric burner.

In order for the equipment to work for a long time and properly, it is important to service it once a year, clean the gas filters, check the chimney draft, as well as the tightness of all connections.

Maintenance

The longevity of boiler equipment is ensured by proper operation, which is clearly described in the factory instructions.

Key points:

- Install a relief safety valve of 1.5 kgf/cm2 at an area of 150 mm from the supply valve of the heating system.

- An expansion tank is installed at the top point of the main riser of the system.

- Provide a slope of horizontal pipelines of 10 mm by 1 m towards the batteries when installing the boiler.

- Ensure the tightness of the indoor heating system.

- It is prohibited to drain water from the system after the heating period, due to an increase in the corrosion process and emergency failure of the boiler.

- Add water to the tank only as needed.

- Install a mud trap on the return pipeline.

- The boiler is kept clean and in working order.

- The owner is obliged to clean the chimney part of the boiler.

- Water for the boiler has restrictions on hardness and should not exceed 5 mmol eq/l.

AOGV belongs to objects of increased danger, therefore it is recommended to entrust the inspection, professional maintenance and repair of AOGV boilers to specialists authorized for such types of work.